FCS PCorr+ User manual

1

User Guide: PCorr+ and Permalog+

(Device description and uses).

Permalog+ PCorr+

MAN-031-0003-A

2

TABLE OF CONTENTS

1Introduction, Background and Support of Product........................................................3

1.1 Safety ..........................................................................................................................3

1.2 Background ................................................................................................................3

1.3 Support of Product ....................................................................................................3

2Overview: ...........................................................................................................................4

2.1 Logger Device - Overview..........................................................................................4

2.2 System Overview........................................................................................................5

2.3 Logger Device –Radio-Link .......................................................................................6

2.4 Logger Device –Serial Interface................................................................................6

2.5 Logger Device –(Reset) - Activating Logger & Radio Comms.................................7

2.6 Logger Device - LEDs .................................................................................................7

2.7 Logger Device - Leak-State Evaluation .....................................................................8

2.8 Logger Device - Noise Histograms Measurement History .....................................8

2.9 Logger Device –Leak Evaluation Measurement History ........................................8

2.10 Logger Device - Scheduled Aqualog Measurement ................................................8

2.11 Logger Device - Sound Recordings (PCorr+ only)....................................................8

2.12 Logger Device - Scheduled Sound Recording (PCorr+ only)...................................9

2.13 Logger Device - Model Variations .............................................................................9

3Logger Installation and Removal ...................................................................................10

4Examples of Product Use................................................................................................11

4.1 Loggers used for Investigations..............................................................................11

4.2 Loggers used for Sound Recordings for Correlation ............................................11

4.2.1 Setup for Correlation Recordings –Method 1 ...............................................12

4.2.2 Setup for Correlation Recordings –Method 2 ...............................................12

4.3 Mobile (Lift and Shift) Loggers ................................................................................13

4.4 Permanently Installed Loggers ...............................................................................13

5User-serviceable parts ....................................................................................................13

6Troubleshooting ..............................................................................................................14

6.1 Logger Device - Firmware Upgrade........................................................................14

3

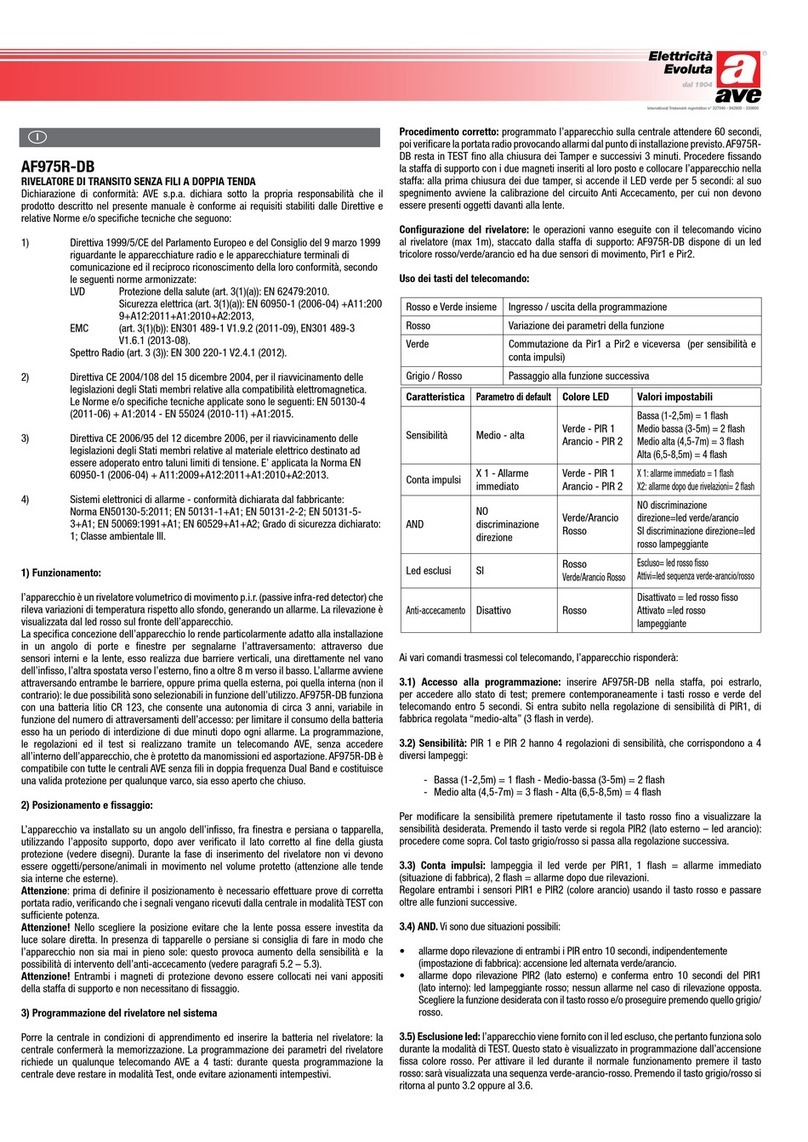

1INTRODUCTION,BACKGROUND AND SUPPORT OF PRODUCT

Thank you for choosing an HWM data device. We trust it will provide you with many

years of service.

1.1 SAFETY

Before continuing, please read the “Safety Warnings and Approvals Information”

document supplied with the product (MAN-130-0013).

1.2 BACKGROUND

Pipeline leaks are a constant burden to the water industry, which can affect the

efficiency of the individual company’s performance. Leakage loss reduces the amount of

fluid actually being delivered, thus affecting the financial side of the business. The

longer the leak is left, the larger the economic, and potentially environmental,

consequences. It is therefore more beneficial and safer to detect a leak early and make

repairs to the pipes before significant damage to the business is caused. At HWM, we

pride ourselves in designing the best leak detection equipment at an affordable price

for the benefit of the water companies.

1.3 SUPPORT OF PRODUCT

This user-guide covers the following product families of leak detection equipment:

PCorr+ (PR5*)

Permalog+ (PR4*)

Permalog+ Lift & Shift

Permalog+ AMR (PR4AMR*)

Various software applications (PC and Mobile-phone based apps) are available for the

setup and operation of the PCorr+ and Permalog+ devices.

Note: Each software application has different capabilities and features, and may not

use or support all of the features available within the logger devices themselves.

Please refer to the user-guide of the software application that is being used.

HWM also provides support of the product by means of web-pages:

https://www.hwmglobal.com/pcorr-support/

https://www.hwmglobal.com/permalog-support/

Should you have any questions that are not covered by a manual, or Frequently Asked

Questions (FAQs) provided online, please contact the HWM Technical Support team on

+44 (0) 1633 489479, or email cservice@hwm-water.com

4

2OVERVIEW:

2.1 LOGGER DEVICE -OVERVIEW

Note: PermaLog+ and PCorr+ will both sometimes be referred to as “device”,

“logger” or “logger device” within this document.

The Permalog+ product family and PCorr+ product family are Leak Noise detectors built

by HWM. The equipment’s primary and repetitive function is to detect the presence of a

leak in a pipe network. The devices accomplish this by means of a specialised

microphone that can detect the sounds emitted from a leak. A micro-controller, built

into the unit, measures the noise level once per day and performs a statistical analysis

to generate a noise “histogram”. The results are saved in memory for collection by the

user.

The saved data could be in the form of:

•A “leak / no leak” status.

This gives a simple indication of whether the histogram indicates a

probable leak.

•A Level / Spread indication.

This is a numeric summary of the noise histogram.

•A “noise histogram”.

This provides a detailed indication of how consistent the noise measurement

is, and can be used for more advanced analysis.

•An “Aqualog”.

This is a set of up to 28 histograms, made at regular intervals and used to

analyse the consistency of noise measurements over a longer period.

The name originally referred to a separate type of logger manufactured by

HWM, but this function has now been integrated into Permalog+ / PCorr+

The logger devices are powered by non-rechargeable Lithium batteries. The software

within the logger is designed to take steps to minimise the battery use and thus

increase the life expectancy of the unit (e.g. the loggers are only active when needed;

most of the time they are asleep). The battery life is also affected by the user-

programable settings.

The stored data can be read from the loggers by means of communication over a

proprietary radio-link to a nearby device (the patrol equipment).

A version of Permalog+ (referred to as AMR models) also have a built-in serial interface

for connection to certain types of meter-reading equipment; these can then wake the

logger and read its leak-state data using the wired connection.

PCorr+ products are an enhanced version of the Permalog+ product. Most of the

functions are identical, but PCorr+ additionally allows a sound recording to be made.

5

The sound recording can be up to 20 seconds in duration. It can be made automatically

when the logger encounters a new suspected leak. The sound file can be downloaded

from the device and used to confirm whether the sound from within the pipe does

resemble the sound produced by a leak.

PCorr+ products can, when several units are used together, be used to approximately

locate the position of a leak. This is an advanced use of the product. Always use a

ground microphone to confirm the leak location prior to commencing repair works.

Note: Many of the logger’s activities occur at specific times, according to the

configuration programmed into them.

The logger itself makes no automatic annual adjustments to its clock-time

(e.g. for daylight saving).

If it is required to change the time within the logger to match any local time

changes, this must be done by reprogramming the devices with the changed

clock-time.

2.2 SYSTEM OVERVIEW

The logger devices form only a part of a functioning system; other items are required.

A typical system will comprise of:

•A set of loggers (PCorr+ or Permalog+).

These typically are set to evaluate the sounds within a pipe overnight, when

water use is minimal, and determine if a leak could be present nearby.

•A Patroller unit.

This is required to communicate with the logger devices via a radio-link.

Examples of Patroller models are “Patroller 4” and “USB Radio Transceiver”.

These act as an interface, relaying messages between the logger devices and

either a laptop PC or mobile phone.

•The Laptop PC or mobile phone (with HWM software installed).

This device will provide a Graphical User Interface to the user.

The chosen platform will have a HWM application (an “app”) installed, used both

to set-up the devices for use and also to read measurement data from them.

•HWM application software.

Personal Computers require the “PermaNetPlus” software, and

Mobile phones require the “WebCorr” software

The software packages have different graphical user-interfaces and also differing

capabilities.

The PC version keeps a local database of logger details, locations, and

measurement results.

The mobile phone version is integrated with HWM’s cloud-based

database of logger information.

(Refer to each application manual for a description of its capabilities and how to

use the software).

6

•Required for mobile phone app:

oAn internet connection (via the mobile network),

oAn account and password for the HWM DataGate system.

2.3 LOGGER DEVICE –RADIO-LINK

The loggers are designed to conserve energy use wherever possible in order to prolong

the life of the battery, which is not rechargeable. The radio-link is one function affected

by this. The loggers do not continuously send data over the radio-link, but only do so for

part of the day; This period is known as the “patrol window”. Typically, this will be up to

8 hours per day, during a time when data is planned to be collected by the user. The

rest of the day (and at times when measurements are being made) the radio interface is

turned off. During the patrol window, the logger transmits data typically every

2 seconds in order to ensure a patroller that is installed in a passing vehicle has

opportunity to detect the signal (usually several times) as it passes within the range of

the radio. Each message is very short and is sometimes referred to as a “chirp”.

The loggers can sometimes be factory set into another radio mode, where the radio-link

has a “patrol window” of 24 hours. To compensate for power use, the loggers transmit

chirps less frequently. Loggers with these settings can transmit to a fixed receiver

installed near-by. This is sometimes referred to as “Fixed Network Mode”.

Some loggers can be factory set (or set by the user) to have no patrol window at all,

conserving energy even more. This setting is often used for a logger being used as a “lift

and shift” device by the user.

Any time the logger device is not within its patrol window, it can have the radio-link

temporarily re-activated by resetting the logger (see section 2.5). This awakens the

logger’s radio-link for a period of approximately 2 minutes.

The logger devices have to establish a 2-way conversation in order to download certain

types of data. To save power, the logger does not continuously listen for the Patroller

signal. It may therefore take typically up to 40 seconds for a device to begin the 2-way

conversation to allow data downloads to begin.

2.4 LOGGER DEVICE –SERIAL INTERFACE

In addition to the radio-link, some loggers (Permalog+ AMR models only) have a wired

interface for connection to 3rd-party Automatic Meter Reading equipment. This allows

the AMR equipment to use the logger as an external leak noise sensor, collecting the

latest leak state result over the cable.

7

2.5 LOGGER DEVICE –(RESET)-ACTIVATING LOGGER &RADIO COMMS

The loggers are shipped from the factory to the user in a “deep-sleep” mode (also called

shipping mode) to conserve battery life. They need to be activated before use (i.e. They

do not operate until the user has reset them by swiping them). Once activated, they

operate normally. They should be put back into “sleep mode” if stored unused for a long

period in order to maximise the battery life of the unit.

The logger device can be reset by swiping a magnet over the side of the plastic case (the

base of another logger is a good way to do this). This will activate a magnetic switch

inside the logger which causes it to reset and consequently to “wake up”from shipping

mode. This is the only way to reset the unit.

A successful reset / start operation is

confirmed by observing the two LEDs

(positioned next to the antenna connector)

alternately flash after swiping.

Reset of the logger does not erase

any measurement history.

Reset of the logger does temporarily re-activate the radio-link (for approx. 2 minutes).

(The radio link may otherwise be in standby, depending on the logger settings).

Loggers used for sound correlation purposes should not be reset until the sound file

has been produced and downloaded. Caution is therefore needed. Keep loggers

separated to ensure they are not accidentally reset during handling when using them

for correlation.

2.6 LOGGER DEVICE -LEDS

The loggers have two LEDs positioned below a thinned-out area of the top of the plastic

body.

The LEDs function as follows:

After Reset:

Micro-controller OK: 3 flashes of outer LED, then

3 alternating LED flashes.

Leak state: Outer LED: 2 flashes every 8 seconds.

No-Leak state: Inner LED: 1 flash every 5 seconds.

The LED activity times are set within the factory and cannot be changed. They can be

active constantly, only active during patrol times, or only after a logger reset.

Reset swipe area.

8

2.7 LOGGER DEVICE -LEAK-STATE EVALUATION

The Leak-state evaluation program takes place between 2-4am (although it can be

changed). Typically, it is made during a time of low water use to reduce the possibility of

water use by consumers being judged as a leak. During this time if the logger

determines a change of leak state the logger carries out a secondary confirmation

evaluation.

2.8 LOGGER DEVICE -NOISE HISTOGRAMS MEASUREMENT HISTORY

Whenever a leak-noise evaluation is made, the data for noise histogram is also

produced. The logger device saves the last 28 leak evaluation histograms. These are not

time-stamped. Support of download of the histograms is application dependant –refer

to the manual of the application.

2.9 LOGGER DEVICE –LEAK EVALUATION MEASUREMENT HISTORY

The logger device saves the last 28 results of its leak-noise evaluations (Noise level,

Noise-spread summary). These are not time-stamped. Support of download of historic

measurement data is application dependant –refer to the manual of the application.

2.10 LOGGER DEVICE -SCHEDULED AQUALOG MEASUREMENT

The logger device can accept one-off instructions to make an Aqualog (noise histogram)

measurement (or multiple measurements) of a site. No judgement of leak / no-leak is

made by the logger following the measurement. The measurement borrows some of

the memory that the logger uses for storing its regular histogram data. The data in this

memory is protected from being over-written until the Aqualog results are downloaded,

then the memory is released for use once more. (i.e. The capacity to store 28 regular

histograms is temporarily reduced until the Aqualog data has been downloaded).

Whilst a scheduled measurement is pending, the regular logger activities (over-night

measurement) is suspended. It will resume once the scheduled measurement is

finished.

Refer to your application guide to see if it supports using this feature of the logger.

2.11LOGGER DEVICE -SOUND RECORDINGS (PCORR+ONLY)

PCorr+ logger devices are able to store one sound recording only, 10 seconds in

duration as standard but can be extended to 20 seconds for more challenging leaks. An

automatic new recording is normally made only after a change from a no-leak state to a

leak-state. To save battery use, the logger only does this once (unless otherwise set),

and keeps this recording until it is downloaded via the Patroller. Once downloaded, the

9

logger will permit the sound recording to be over-written the next time a no-leak to leak

transition occurs.

The situation of a logger requiring a “no-leak to leak transition” to initiate an automatic

recording would be problematic to a mobile logger, also known as a “lift-and-shift”

device, since these regularly change location. The logger has no way of knowing where it

is located, nor that it has been moved to a new site.

The problem is overcome by swiping the logger (to reset it) prior to each new

deployment. Resetting the logger also sets it to always make a new recording if the next

evaluation indicates a leak (irrespective of what the previous leak-state was).

If a logger is removed from one site, swiped to reset it (and activate the radio-link so

that its data can be downloaded), and then it is deployed to a new site … There will be

no issue if a leak was present at both the old and new sites; the automatic sound

recording is still made.

All sound recordings have a timestamp of when the recording was made built into the

file. It is possible for the user to download the sound file and determine when it was

made.

To enable the automatic sound recording feature, the loggers must have the “Record

automatically on new leak” control set.

2.12 LOGGER DEVICE -SCHEDULED SOUND RECORDING (PCORR+ONLY)

The logger device can accept instructions to make a one-off sound recording of a site.

The measurement borrows the same memory as the logger uses for saving an

automatic sound recording.

Whilst a scheduled audio recording is pending, the regular logger activities (over-night

measurement) continue, but making any automatic recording is temporarily suspended.

Automatic recordings will resume 24 hours after the scheduled recording is finished.

This gives a time-limited protection of the scheduled sound recording to allow for it to

be collected (supported from s/w version 2.30).

Refer to your application guide to see if it supports using this feature of the logger.

2.13 LOGGER DEVICE -MODEL VARIATIONS

Several versions of the devices exist. They are similar appearance, but vary as follows:

•Permalog+ were originally yellow in colour, with red and green LEDs.

The label may have “P4”, next to the serial number.

The logger will have a Permalog+ label on it.

•PCorr+ is blue and has blue LEDs.

The label may have “P5”, next to the serial number.

The logger does not have a Permalog+ label on it.

10

•The loggers are available as a standard unit (with an antenna), or versions

without an antenna connector (known as Lift and Shift models). Lift and Shift

models have an internal antenna and therefore less radio range.

(Regular models can also be programmed for “lift and shift”style of use).

•PCorr+ can make a sound recording. Permalog+ does not have this feature.

•The radio-link is a single-frequency channel, time-shared between the loggers.

Due to radio regulations varying (dependant on country of use), several different

models exist to comply with the various radio standards. The antenna supplied

with each logger is similarly matched to the frequency and power required by

the radio regulations, and should not be swapped for an alternative type.

Note: The loggers require a Patroller (radio transceiver) with a matching

frequency.

3LOGGER INSTALLATION AND REMOVAL

The loggers are of a water-proof plastic and metal construction. They include a

magnetic base, which is the attachment point of the logger onto the pipe network.

Most models are shipped with an antenna. Ensure the screw thread for the antenna is

clean, before hand-tightening the antenna to the logger. If optional lifting hooks have

been purchased, ensure these are fitted tightly.

The loggers are shipped from the factory in an “off” state (in a deep-sleep mode), where

they are almost totally inactive (to preserve the life of the battery). Before first use they

have to be started, or “woken up”. This is accomplished by resetting the logger.

Once reset, the logger will operate continuously for the life of the battery. The battery

life depends on the factory settings (and any subsequent changes).

Installation consists of attaching the logger to a metal pipe fitting (typically a valve inside

a chamber) using the magnet on the logger base. Always ensure the metal contact point

is free from dirt or oxidization so that the magnet makes a good contact. The

microphone is positioned just behind the magnet, so good contact is important. HWM

recommends the use of a wire brush to clean the pipe/valve/hydrant fitting prior to

attaching the logger. An alternative method must be used for non-magnetic pipes.

For best performance, it is recommended that the logger is deployed in a

vertical / upright position as this gives the most effective radio range.

When fitting or removing a logger from the installation location, please grasp the main

body of the logger or use the optional lifting hooks. Removal of the logger by grasping

the antenna can cause permanent damage and is not covered by warranty. Store

unused loggers safely –Refer to the supplied safety instructions.

The loggers can optionally be pre-configured with the desired program settings prior to

being shipped from the factory.

11

4EXAMPLES OF PRODUCT USE.

The logger devices have at least 3 different modes of use:

•Logger devices used for investigations.

•Temporarily installed (mobile) devices.

(also known as “Lift and Shift” logger devices).

•Permanently installed devices.

4.1 LOGGERS USED FOR INVESTIGATIONS

These loggers can be deployed to (or indeed may already be installed on) sites that have

a suspected leak near them which is now under investigation. The logger supports

collection of some measurement history or the making of several new measurements,

including:

•Obtaining logger leak-state history: Last 28 leak-noise measurements.

•Obtaining logger leak profile history: Last 28 noise histograms.

•Make several new pipe noise histograms (known as “Aqualogs”) during the day or

over several days (up to a maximum of 28 measurements).

•Make a sound recording at a pre-set time of the week (only a single recording

can be made). (Available on PCorr+ only).

•Obtain synchronised sound recordings from several devices for correlation

purposes (one per PCorr+ logger).

The available options from the above list depend on whether they are supported by the

app you are using. They involve 2-way communication with the logger to download the

data or setup the new measurement requirement. This takes a few minutes to

complete.

Investigations can include making sound recordings for correlation purposes. This has

more demanding requirements of the loggers, discussed below.

4.2 LOGGERS USED FOR SOUND RECORDINGS FOR CORRELATION

Many of the measurements made by the logger do not require much accuracy for the

time of measurement. The making of sound recordings, within PCorr+ devices, for

correlation purposes is an entirely different situation, being very sensitive to time.

Production of sound files for correlation is an advanced use of the PCorr+ product. For

correlation, each logger is required to have its clock precisely aligned with the others in

the set. For successful correlation results, always follow the requirements

specified in the user-guide of the app for your system.

12

Correlation requires that the loggers simultaneously record the sound from various

points along the pipeline. Since the correlation process is very sensitive to time

differences between the devices, the recording and the collection of the sound file must

occur within a day (before the clock of each device has drifted far from its original

accuracy).

For the greatest positional accuracy, use of specialist correlation equipment that

evaluates live audio is recommended, such as HWM’s MicroCorr Touch Pro Correlator.

With PCorr+, results are improved when the recording is made and collected as soon as

possible after the scheduled recording is programmed. Always use a ground

microphone to confirm the leak location prior to commencing repair works, such as

HWM’s DXMic ground microphone.

A scheduled sound recording needs to be programmed into each logger in the set. The

procedure required to ensure the logger clocks are aligned will vary according to the

application being used and also the model of patroller being used.

Note: The logger devices must have a patrol window available in order to be able to

collect the sound files. The files must be collected without a reset of the logger

(which disrupts the internal timekeeping of the device).

4.2.1 Setup for Correlation Recordings –Method 1

The USB Transceiver type of Patroller requires all loggers to be brought together (within

radio range) and programmed as a set. Similarly, the loggers need to be brought back

together as a set to download the audio. The time accuracy of each logger is checked by

the app following file download to confirm it is OK for correlation use. This includes

whether any of the devices have been reset since they were set up.

Whilst the sound recording is pending, some normal logger operations are suspended,

but will resume when the recording is completed. (See section 2.12.)

4.2.2 Setup for Correlation Recordings –Method 2

When the patroller being used to program the loggers has a high-accuracy time

reference within it (e.g. Patroller 4, when GPS sync is OK), the possibility exists to set the

clock within each of the loggers accurately, one at a time.

(i.e. There is no need to gather them together; dependant on software support of this).

13

4.3 MOBILE (LIFT AND SHIFT)LOGGERS

Devices used in this way are typically deployed at a site, left over-night for the leak

evaluation to occur, and then collected from the sites on the following day. Radio range

is not an issue, as the loggers are removed from their installation sites; this allows the

data to be collected at a short-range. After downloading Leak-status data and any other

required data, the loggers are then deployed on new sites and the cycle re-starts.

4.4 PERMANENTLY INSTALLED LOGGERS

These loggers are permanently installed at a site, typically by attaching to a metal valve

or hydrant, etc. A further consideration in their location is that the data from the logger

has to be collected over a radio-link with a limited range. Usually the loggers are located

so that they are able to be readily detected whilst passing by them at a modest speed.

(This can be tested by doing a trial-run after installing). The data can also be collected by

passing close to the installation site on foot.

Once a day (the user may set the time) the logger makes measurements of the pipe

noise and evaluates if a potential leak exists. The logger device is also set (prior to

installation) to have a patrol window that matches the possible data collection times.

When within the patrol window, the logger enables the radio-link and sends periodic

broadcasts of information. This identifies the logger and also includes the following:

•The leak status (i.e. Leak/No-Leak),

•Noise level maximum,

•Noise spread.

Any further data (e.g. a sound recording) must be specifically requested by establishing

a 2-way conversation with the logger, and takes longer to download.

Any drift in the clock accuracy is insignificant for the task of confirming whether the

sound from within the pipe does resemble the sound produced by a leak; the precise

time the recording was made is not important. Any sound files collected will not be

suitable for correlation purposes as the clocks of each device will be free-running, and

will not be sufficiently aligned after several days. To produce files for correlation

purposes, setup and use a scheduled sound recording - see section 4.2.

5USER-SERVICEABLE PARTS

No user-serviceable parts exist except those listed below:

•Antenna.

oOnly use antenna recommended and provided by HWM.

oRefer to Safety and Approvals Information document.

14

6TROUBLESHOOTING

6.1 LOGGER DEVICE -FIRMWARE UPGRADE

The logger devices can have the internal program (firmware) upgraded over the

radio-link. The process should only be undertaken if advised by HWM. The facility to do

this may not be implemented on all apps. Firmware changes require a special cable

fixture to minimise problems due to radio interference, etc.

15

Fluid Conservation Systems

1960 Old Gatesburg Road Ste 150

State College, PA 6803

(800)531-5465

©HWM-Water Limited. This document is the property of HWM-Water Ltd. and must not be copied or

disclosed to a third party without the permission of the company. Copyright reserved.

MAN-031-0003-A September 2019.

This manual suits for next models

1

Table of contents

Other FCS Security Sensor manuals

Popular Security Sensor manuals by other brands

Honeywell

Honeywell Peha D MLS2001AF Installation and commissioning instructions

Niko

Niko 351-25458 quick start guide

ECOTEST

ECOTEST Gamma Sapiens operating manual

Scott

Scott Alpride Series quick start guide

Emerson

Emerson Net Safety Millennium Reference manual

Renkforce

Renkforce 1362922 operating instructions