CST/BERGER Magna-Trak 102 User manual

INSTRUCTION MANUAL

Magna-Trak 102®

Magnetic Locator

2

Introduction

The Magna-Trak 102 magnetic locator is a flux-gate type of mag-

netometer which incorporates a unique patented technology that enables

the factory to balance the magnetic sensing coils to a finite condition. This

patented method of magnetic balancing is more advanced in the state-of-

the-art technology.

The Magna-Trak 102 implements “peak response” over

ferromagnetic objects by yielding on increasing audio signal as the object

is approached and passed over.

This instrument is the product of many years of experience and ser-

vice provided by Chicago Steel Tape to the industry.

Table of Contents

Introduction ..............................................................................2

Theory of Operation ..................................................................3

Features....................................................................................4

Pictorial Description .................................................................5

Basic Operation and Description .......................................... 6-9

Field Operation .......................................................................10

Signal Responses ............................................................. 11-13

Locating Near a Steel Fence...................................................14

Specifications, Warranty & Service.........................................15

3

Theory of Operation

The Magna-Trak 102 locator finds ferromagnetic objects by sensing

the magnetic field radiated by the object. The locator contains two sen-

sor coil assemblies that are precisely spaced and electronically balanced

to achieve a near magnetic balanced operating condition. In a uniform

magnetic field, such as the earth’s field, the two sensor coils maintain

a magnetic balanced status, because both of the coils experience the

same magnetic lines of force. However, when a ferromagnetic object is

approached the field strength and angle of the magnetic lines upon each

sensor is different. This difference, although minute, is enough to offset the

critical balance and produce an audible indicating signal.

When no ferromagnetic objects are present, the speaker emits a steady

low frequency tone. As the object is approached, the audio frequency in-

creases until the center of the object is directly beneath the locator’s lower

tip. The frequency peaks and then decreases as the object is passed. The

peak indicates the exact location of the object.

Nonferrous objects do not effect the locator. Objects made of brass,

aluminum, copper, etc. are ignored.

Sensor coils unbalanced by iron stake’s magnetic field.

4

Features

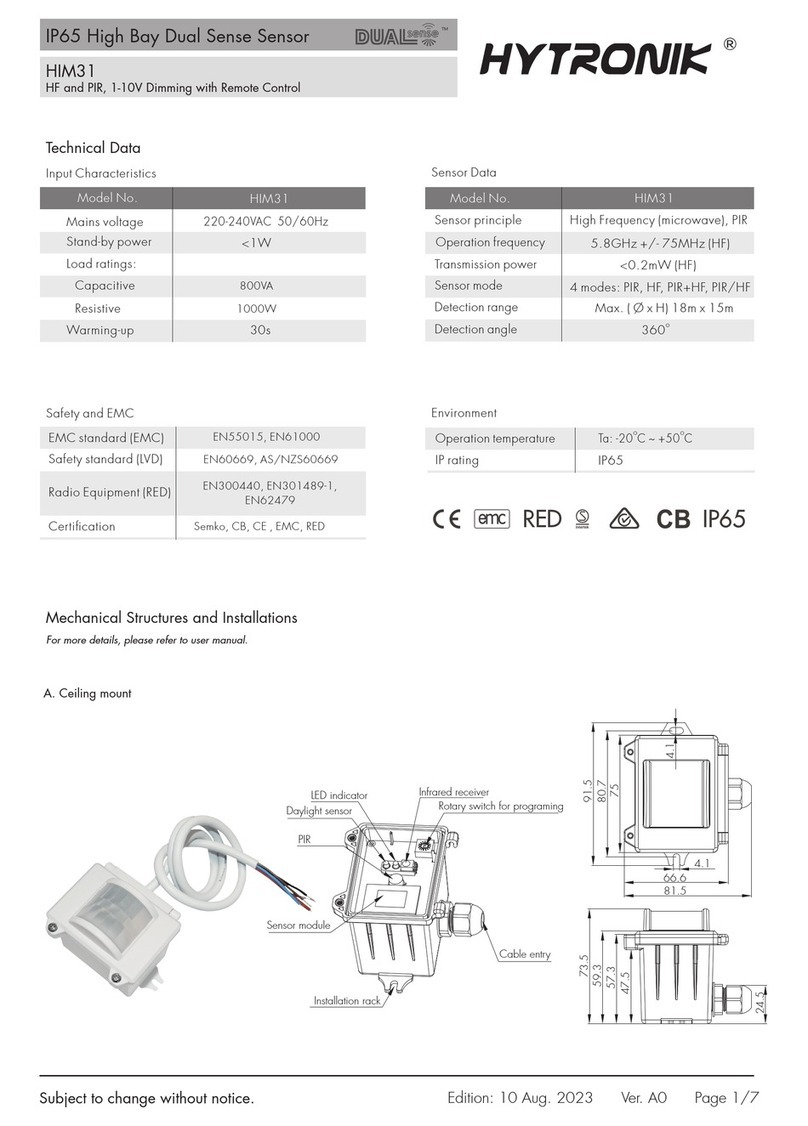

1. Instrument Control Panel

a) LCD Visual Display

b) Water-repellant push button switch operation

2. LCD Visual Display

a) Two digit numeric signal indicator

b) Expanding analog bar graph signal indicator

c) “Low Battery” alert flashing indicator

d) Displays “ferrous” model operation

e) “Caution: Power Line” alert flashing indicator

3. Water-repellant push button operation, single action

a) “ON” – power ON

b) “OFF” – power OFF

c) “ERASE” – Interferences such as a nearby fence are virtually

erased allowing the signal to return to the normal audio tone.

4. Rugged high impact plastic enclosure with aluminum sensor pole.

5. Powerful magnetic speaker constructed with waterproof Mylar cone.

6. Six AA 1-1/2 volt battery operation.

7. Approximately 25 hours battery life under typical conditions.

8. Sensitivity control, single turn, continuously variable wide range

depth adjustment.

9. Volume control, single turn continuously variable adjustment for

selection of audio intensity.

10. Ergonomically designed for light weight, comfortable balance for

easy handling.

11. Flip out battery compartment cover for easy battery access.

12.Signal “peaks” over magnetic objects.

13.Excellent depth capability.

14.Includes padded carrying case with shoulder strap or hard case.

15.Deep tone audio under search conditions.

16.Water-resistant construction.

5

6

Basic Operation and Descriptions

Power On Button: Press once to activate the locator

circuitry. Simultaneously, the circuitry is automatically set to the proper

audio tone.

Power Off Button: Press once to turn the battery

power off.

Volume Control: Rotate the knob to the desired audio sound level. Full

volume is achieved when the knob is turned

full clockwise.

Sensitivity Control: The sensitivity or depth range can be varied with

the rotation of the sensitivity knob. Maximum range is provided at full

clockwise rotation. The optimum setting is determined by each particular

application. Areas crowded with various undesired ferrous metal may

require a reduced sensitivity level. Deeply buried objects being searched

will require the higher sensitivities.

Control Knob Decal: The markings for both the sensitivity and volume

control knobs are provided as a reference for future settings

or comparisons.

Speaker: When no magnetic metal is present the audio sound heard will

be a low frequency tone. As ferrous metals are approached the audio tone

will increase.

LCD Visual Display: Several visual display functions are

provided for ease of operation as defined below.

Ferrous–Defines the basic function of the locator as a “ferrous

locator” (fixed indicator).

Digital Signal Indicator–A two digit numeric display shows the

relative signal level related to the audio signal response being

heard from the speaker. At the lowest signal level when no mag-

netic metal is present a small number will be viewed between

“0” and “5”. As metal is approached, the numbers will increase

until “95-99” is viewed. Deeply buried objects or lower sensitivity

levels will yield a lower peak number to aid in pinpointing.

Analog Bar-Graph Signal Indicator–the bar graph corresponds di-

rectly to audio frequency by expanding outward from the center

7

“diamond” as the signal increases due to magnetic metals.

Low Battery Indicator–Although not visible under normal conditions

the LCD will display a flashing “Low Battery” warning when the bat-

teries fall below a predetermined voltage. This alerts you to replace

the batteries soon. Several hours of battery life remains. However,

in cold temperatures this usable time may be shorter.

Power Line Indicator Feature–The electromagnetic fields

radiated from buried or overhead power lines are picked up by the

new sensitive electronic circuitry and internally transformed into

a visually flashing indicator in the display window as shown:

The distance or detection

range from the cables where

the locator responds depends

on the energy being carried

by the electrical conductors.

The higher the energy, the

greater the distance the lo-

cator will respond to it. If the

cables are dead (no electrical

connection or energy trans-

fer), then no visual indication

will appear.

When the locator is

turned ON, this feature is

activated immediately. This feature only responds to 50 or 60Hz

power line frequencies and not to telephone or TV cables. This

feature is intended as an aid only and not to be used

for locating or pinpointing electrical cables.

The magnetic detection operation and performance of the

magnetic locator are completely independent from the power line

indicator feature.

Erase Button: This is an optional button that is primarily used in locations

where large metal objects normally interfere with the desired operation of

magnetic locators. Cyclone fences, metal buildings, vehicles and other large

magnetic objects can be electronically erased with this button.

The operation of this feature is best defined by explaining the typical

locator without this feature. For example, typical magnetic locators will

normally yield a screaming audio tone when they are being operated in close

8

proximity to a metal fence. The magnetic field from this fence will usually

override the signal being sought from the buried object in search of. The only

option is to reduce the the sensitivity until the interference from the fence

is minimized. However, the locator’s sensitivity to the buried object is also

minimized and usually undetectable.

The new Magna-Trak 102 and its “Erase” feature solves this problem

by providing an Erase button; simply press this button when the interference

is annoying and the metal structure is electronically erased. The audio tone

returns to the “no metal” tone; the search continues and the buried object

is located.

This erasing action is functional within a reasonable circular area around

the position of the locator in which the erase button was pressed. This circular

area, referred to as the erase zone, may be affected by the magnitude of the

magnetic field of the fence and the distance from the fence when the button

was pressed. In extreme cases, there may be a point where you may have to

press the Erase button again as you approach the fence.

If you inadvertantly erase the object you are directly over, simply move

the locator to one side and activate the Erase button and return to a normal

search procedure.

Battery Replacement: Turn the power off. Unscrew the thumb screw on

the battery cover between 2-5 turns. Lift the cover off until the tab at the rear

of cover clears the slot it is located in. Remove the batteries by raising the

ERASE ZONE

9

batteries at the junction or contact point of each set of two batteries. This is

the point where the two batteries contact each other. You may prefer other

methods of your choosing. Dispose of the weak batteries properly. Insert the

new batteries observing the polarity markings located inside the battery wells.

Install the cover in the reverse manner. Do not over tighten the thumb screw.

Do not replace the batteries under raining conditions, whereby allowing water

to enter the battery compartment.

Dead Batteries should be removed immediately-especially before stor-

age of the locator. Dead batteries are prone to leakage and may potentially

damage the locator.

Replace all six batteries at once. Never selectively replace batteries.

In the event the “Low Battery” indicator is not displayed, no visual indi-

cations appear on the LCD window and no sound is heard after pressing the

power ON Switch–the batteries may be completely dead. Check the battery

compartment immediately.

Personal Items: Your magnetic locator is not only sensitive to buried magnetic

objects–it will also respond to items in your possession. Ferrous objects such

as steel tipped shoes, a pocket knife, some wrist watches, key chains and

other magnetic objects will cause false signals during your search.

10

Field Operation

The recommended search position is a 45 degree angle from the earth’s

surface. Scan the locator pole from side-to-side in a slow sweeping motion

while walking in a uniform direction. Once the object being searched is lo-

cated, pinpointing the objects location can be accomplished by holding the

locator vertical and sweeping it in an “X” pattern until the absolute peak is

found. Maintain a consistent height above the ground during the side-to-side

sweeping motion. The audio sound and visual LCD display will provide the

pinpointing results shown.

Physical “X” Motion Shown

Locator’s Electrical

response

representation

11

Signal Response

Below is an example of audio and LCD visual signal responses to (1) no ob-

ject, (2) one small deeper metal target and (3) a second larger and shallower

metal object. The LCD display indicates both the numeric digital and analog

bar-graph response as the locator passes over the ground.

(1) (2) (3)

12

Typical Signal Responses

The metal handles on the septic tank cover will provide a usable signal to

determine the location of the actual cover.

Signal Response

The metal handles on a septic tank cover

Large metal objects may cause double signals as indicated.

The center of the cover is found by sweeping the locator back and forth to cre-

ate a ring pattern response. The center null will designate the cover’s center.

Sewer cover

Signal Response

13

Typical Signal Responses

Water Locations:

The locator can be submerged into water with the pole section to just under

the plastic case.

Hold the locator in a vertical position while searching to produce the best

results.

The joints, elbows and ends will create the strongest signals.

Cast iron pipe, joints, elbows, etc.

14

Locating Near a Steel Fence

Approach the fence and stop at the distance at which you wish to begin your

search. While holding the locator in a vertical position, press and release the

“erase” button on the membrane panel. Begin sweeping the locator side to

side parallel to the fence. As you move toward or away from the fence during

the sweeping motion, at some point you may have to press the “erase” button

again.

Continue this process throughout the search. The need to reactivate the

“erase” circuitry depends on the proximity from the fence and the magnetism

of the fence itself.

Searching Under an Unattended Vehicle

In the event you must search under an parked vehicle that is unattended, you

can simply slide the sensor pole under the vehicle and activate the “erase”

feature. Slide the sensor pole side to side until you locate the target.

15

Specifications

Power: Six AA 1 1/2 volt batteries

Battery life: Approximately 25 hours of intermittent operation (alkaline batteries)

Output: Powerful magnetic speaker with water proof Mylar cone.

LCD Display: Numeric digital, analog Bar-graph and low battery indicator feature.

Weight: Approximately 3 lbs. (1.3kg) with batteries.

Operating temperature: 0°F to 120°F (-18°C to 49°C).

Length: 40 inches (101.6 cm.).

Construction: High impact plastic, water resistant, light weight and epoxy painted. Aluminum

sensor tube waterproof to just under the plastic case (see page 13).

Patent: United States #4,439,732.

Nominal sensor 20 inches (50.8 cm.).

Warranty

CST/berger, Robert Bosch Tool Corporation, warrants the Magna-Trak 102 against defects

in material and workmanship for a period of five years from the date of purchase. Deficient

products will be repaired or replaced at CST/berger’s discretion. For warranty and repair

information, contact you local distributor.

Before returning the instrument to CST/berger, please call (815) 432-9200 for a Return

Authorization Number from our Customer Service Department.

CST/berger’s liability under this warranty is limited to repair or replacement of the unit.

Any attempt to repair the product by other thanfactory authorized personnel will void this

warranty. Calibration, batteries and maintenance are the responsibility of the user. Where

permitted by law, CST/berger is not responsible for incidental or consequential damages.

Agents of CST/berger cannot change this warranty. CST/berger is not responsible for

damage resulting from wear, abuse, or alteration of this product. The user is expected to

follow ALL operating instructions.

This warranty may provide you with additional rights that vary by state, province or nation.

Magna-Trak 102 is a registered trademark of CST/berger.

IMPORTANT NOTE: The customer is responsible for the correct use and care of the instru-

ment. Moreover he is completely responsible for checking the job along its prosecution,

and therefore for the calibration of the instrument. Calibration and care are not covered

by warranty.

Subject to change without notice

16

04/14 Rev. 5 2610A04629

© Robert Bosch Tool Corporation, 1800 W. Central Road Mt. Prospect, IL 60056-2230

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056-2230, E.U.A.

Importado en México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405, Zona Industrial,

Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

Robert Bosch GmbH

Power Tools Division, 70745 Leinfelden-Echterdingen, Germany

www.bosch-pt.com <http://www.bosch-pt.com>

www.cstberger.com

Insert Barcode

Table of contents

Other CST/BERGER Security Sensor manuals