FDC Orion-M User manual

Orion-M Honeywell UDC2500/3200 Series Controller System Guide Rev C

Fe ruary 7, 2011

Supersedes: Rev B (March 25, 2010)

Orion-M

Honeywell UDC2500/3200

Controller System Guide

Orion-M

FDC Orion-M PREFACE

Safety Information in this Manual

Notes, cautions and warnings appear throughout this ook to draw your attention to important operational and

safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and

performance.

A “WARNING” safety alert appears with information that is important for protecting you, others and equipment

from damage. Pay very close attention to all warnings that apply to your application.

This sym ol (an exclamation point in a triangle) precedes a general CAUTION or WARNING

statement.

This sym ol (a lightning olt in a lightning olt in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a pro lem with your Orion-M controller, review all of your configuration information to verify

that your selections are consistent with your application: inputs; outputs; alarms; limits; etc. If the pro lem

persists after checking the a ove, you can get technical assistance y dialing +1 (866) 342-5332 or y faxing

your request to +1 (866) 332-8014, Monday thru Friday, 8:00 a.m. to 5:00 p.m. Eastern Standard Time. You

can also email your request to support@futuredesigncontrols.com.

An applications engineer will discuss your application with you.

Please ha e the following information a ailable:

• Complete Model #’s and/or Serial #’s for Component(s) in Question

• Complete Software Version #’s

• All Configuration Information

• All User Manuals

Warranty and return information is on the back co er of this manual.

Your Comments

Your comments or suggestions on this manual are welcome. Please send them to:

Future Design Controls, P.O. Box 1196, Bridgeview, Illinois, 60455

Telephone: +1 (888) 751-5444; fax: +1 (888) 307-8014

csr@futuredesigncontrols.com

The Orion-M Honeywell UDC2500/3200 Controller System Guide is copyrighted y Future Design Controls,

Inc., © 2009, all rights reserved (http://www.futuredesigncontrols.com/Orion-M.htm).

.

Orion-M

TABLE OF CONTENTS FDC Orion-M i

1 What is the Orion-M? ............................................................................................... 1.1

1.1 Features............................................................................................................................................... 1.1

2 Getting Started.......................................................................................................... 2.1

2.1 Installing the UDC2500/3200 Controller.............................................................................................. 2.1

2.1.1 Communications Wiring ................................................................................................................ 2.1

3 Configuring the Honeywell UDC2500/3200 Controller .......................................... 3.1

3.1 Assigning the Proper Communications Settings ................................................................................. 3.1

3.2 Input Type Assignments ...................................................................................................................... 3.2

3.2.1 Input 1 Operation .......................................................................................................................... 3.2

3.2.2 Input 2 Operation .......................................................................................................................... 3.3

3.3 Control Output Assignments ............................................................................................................... 3.3

3.3.1 Auto-Tune and Auto/Manual Operation ........................................................................................ 3.3

Appendix

Software Usage Note

Warranty

Returns

Orion-M

WHAT IS THE ORION-M? FDC Orion-M 1.1

1 What is the Orion-M?

The Orion-M is a multi-loop process control system com ined with an em edded SCADA color touch

interface. The Orion-M provides a configura le control platform for a variety of OEM applications requiring up

to 15 separate loops of control. In addition to 15 loops of control, the Orion-M can also provide up to an

additional 15 inputs for process monitoring, for a total of 30 process inputs.

The system is provided with eight 24Vdc digital inputs, two 24Vdc outputs and 6 relay outputs standard. The

Orion-M can e expanded to a total of 16 digital inputs and 32 digital outputs. The Orion-M also provides the

capa ility of accepting analog inputs for remote set point control and analog outputs capa le of retransmitting

system varia les (PV, SP or %Out) to other devices such as a chart recorder. The 0-10Vdc or 4-20mA user

selecta le signals are provided through the addition of optional analog expander cards.

The Orion-M complements its versatile hardware platform y providing a host of standard features and

configuration capa ilities, all through its visual, touch interface. The touch screen interface is an em edded,

industrial PC with all software included. No external PC software is required for setup or configuration of the

Orion-M. All of the setup and configuration data is saved to the Orion-M’s internal memory.

Individual process controllers, one for each loop in the system, provide relia le, consistent and accurate

control y distri uting the process control requirements of the system among multiple processors. Each loop

controller provides full auto tune functionality with high resolution, universal process inputs. When coupled

with the uilt in ramping profiler of the Orion-M, it allows for automatic, timed control of all processes and

outputs of the system. No other control system on the market provides the flexi ility, functionality and

configura ility of the Orion-M.

1.1 Features

The digital inputs of the Orion-M can e configured as alarm inputs with adjusta le delay timers, as control

inputs for controlling profile operation or for direct control of the system’s digital outputs.

The digital outputs of the Orion-M can e used as direct outputs for controlling external equipment related to

the application through software switches, called events, or e programmed to act as system alarm or status

outputs. All outputs have adjusta le delay times for on, off and cycle times.

The Orion-M can e operated in single set point or automatic profile control mode. Profile entry is made easy

through the use of copy, paste and delete menu selections. Profiles can e copied to the external ‘USB’

memory stick and then imported to another Orion-M controller which eliminates the need to enter duplicate

profiles into multiple Orion-M systems. When running in automatic profile mode, the operator can place the

system into hold and change any control parameter without modifying the saved profile. This gives the

operator maximum flexi ility over the controlled process.

Data file analysis tools (auto-trend) make looking at historical data a simple task. Any control varia le saved

to the Orion-M flash memory can e plotted on the historical data trend, for any time frame within the data

file’s total time range. Full ‘USB’ print capa ilities from the Orion-M interface to a standard HP inkjet printer

Model 6540, 6940, 6980 (or compati le printer), eliminates the need for a PC, strip or circular chart-recording

device. Graphics trends, historical and report print functions are standard.

The uilt in Ethernet functionality includes a ‘We Server’ to provides access to all Orion-M data (view only), a

VNC interface for remote control and monitoring and an NTS clock, all availa le via a local Intranet

connection (wired or wireless), or the World Wide We using standard software like Microsoft’s Internet

Explorer.

Orion-M

1.2 FDC Orion-M WHAT IS THE ORION-M?

The Orion-M provides a rich set of tools for control interaction and data analysis. Views include system

overviews, trends, alarms, profiles as well as historical data, alarm history and audit trail views. The menu

driven interface eliminates screen ‘clutter’ y providing an easy to use ‘Windows’ interface for interaction

etween the user and the Orion-M system.

The Orion-M can store more than one year of data on its internal compact flash card. Data logging can e

ena led manually or automatically during automatic profile run. Data ackup is provided with the ‘USB I-

Stick’ for plug and play transfer of files to any PC running Microsoft Windows XP operating systems.

The Orion-M security module provides full system security with three levels of access. Each of the three

access levels allow for independent user rights. Up to 30 users can e entered into the system while the

audit trail tracks all operator actions and records them.

The Orion-M control system includes the ollowing inter ace eatures:

• Overview screen that displays all “runtime” information.

• Profile run and monitor views.

• Profile entry, open, save and download interface screens.

• Current alarm and alarm history views (alarm history for up to 1 year).

• Real time trends (with adjusta le X,Y limits) for all inputs.

• System and application setup (control loops, monitors, inputs/outputs, alarms, etc.).

• Data logging interface screens include log point selection and historical viewing.

• ‘Plug and Play’ memory stick functionality for data transfer/ ackup.

• Full USB print capa ilities and on-line help screens

• We server for intranet/internet access (view only).

• VNC server for intranet/internet access (control/view).

• FTP data ack-up for automatic data file transfer over intranet/internet.

• Integrated email server for alarm notification and file transfer.

• NTS clock with daylight savings time insures that the system is up to date.

• Full security with audit trail for tracking user actions.

• Maintenance counters for output cycles and on times.

• Helps screens are availa le for most screen views; configura le in English, Spanish and French

• Voice assisted help in English, Spanish and French (external speakers required – not included).

Orion-M

GETTING STARTED FDC Orion-M 2.1

2 Getting Started

The Orion-M requires one Honeywell UDC2500 or UDC3200 for each control loop required in the system.

Since the Orion-M is capa le of interfacing to more than one rand of controller, refer to the Orion-M part

num er matrix for the operating system to e sure that the HWSL, CM application software has een

provided. The Orion-M will not operate correctly if any other version of CM application software is used with a

Honeywell UDC2500 or UDC3200 controller.

2.1 Installing the UDC2500/3200 Controller

For applications requiring several loops of control or more, proper planning and arrangement of the Honeywell

UDC controllers prior to mounting is critical for optimum routing of the controller wiring. For applications

requiring frequent access to the controllers, panel mounting provides direct access. For applications where

operator access to the controllers is not required, or is desired to e kept at a minimum, the controllers can e

mounted directly inside of an enclosure. This also reduces wiring concerns y eliminating the need to run the

sensor, communication and control wiring for each controller to and from an enclosure door.

Refer to the Honeywell UDC2500 or UDC3200 Controller Product Manual for dimensions, appropriate

mounting and operating conditions, including proper electrical connections. Connect sensor and control

wiring as required, paying close attention to all wiring precautions and guidelines as noted in the controller

manual. It is recommended that all sensor and communication wiring, to and form the UDC controllers, e

routed away from all high voltage and/or output control wiring. This will minimize the chances of electrical

transients or spikes in the power/control wiring from causing communications or sensor reading errors.

2.1.1 Communications Wiring

Each UDC2500/3200 control used in the Orion-M system is its own independent loop control. However, in

order for the controllers to work as part of the system, they must communicate with the Orion-M control

module using RS485 serial communications. Therefore, each UDC2500/3200 used must e equipped with

the RS485 Mod us RTU communications option or they will not operate as part of the Orion-M system:

DC250X-XX-2XXX-XXX-XX000-XX-0

DC320X-XX-2XXX-XXX-XX000-XX-0

Order code 2 designates RS-485 Mod us serial communications

(see Honeywell UDC Product Manual for model num er interpretation)

Communications wiring must e run using a minimum of 24 AWG twisted-pair, copper conductors. For short

runs (< 50 feet total), non-shielded wiring can e used as long as proper separation from power/control

conductors is maintained. For communications wiring where the total length will exceed 50 feet, up to the

maximum allowed length of 650 feet, shielded twisted-pair must e used.

NOTE: FDC recommends the use o shielded wire or all installations regardless o the total length in order

to maintain optimum per ormance and minimize the possibility o communications errors.

When using shielded twisted-pair, e sure to ground the shield at only one end, prefera ly at the Orion-M

control module. Allowing any other portion of the ca le shield to come in contact with ground, or grounding

oth ends, will allow ground loop currents to flow in that section of the ca le shield which can disrupt

communications.

Orion-M

2.2 FDC Orion-M GETTING STARTED

NOTE: Re er to the Honeywell UDC2500 or UDC3200 Product Manual or all other connections including

power, sensor and control wiring. Since no two applications are the same, it is up to the system

designer to insure that the controllers are properly installed and wired to meet design speci ications.

Orion-M

CONFIGURING THE UDC2500/3200 CONTROLLER FDC Orion-M 3.1

3 Configuring the Honeywell UDC2500/3200 Controller

The unique and inherently flexi le design of the Orion-M system allows the OEM to tailor each component of

the system to the application. By using independent loop controls, each one can e configured for various

input and output types, control algorithms, etc., ased on the requirements of the application. It also allows

control loops to e added or replaced on the system at any time, simply y connecting the controller to the

Orion-M’s control module, RS-485 communication link.

If the application requirements change and a different input or output type is required, or if the controller were

to fail, it can e replaced quickly, and at a lower cost as compared to having to repair or replace larger,

integrated multi-loop controllers. The Orion-M only requires that the communications settings for each loop

control e properly assigned, and that the input type of the controller is set in the Orion-M Configurator, so

that the control loop input and set point can e displayed and set properly through the Orion-M interface.

3.1 Assigning the Proper Communications Settings

The Orion-M can support up to 15 UDC2500 and/or UDC3200 controls. They can e mixed and matched as

required, ut each one must have its own communication address. The allowa le address range is 1 – 15

corresponding to Loop Input #1 – 15 in the Orion-M Configurator. Communication addresses must e

assigned to all controllers on the communications link eginning with 1, up to the total num er of controllers.

As control loops are ena led in the Orion-M Configurator, the Orion-M will automatically use the Loop Input #

as the corresponding controller address. If more than one UDC controller has the same address, or a loop

input is ena led ut a controller is not assigned to that address, the Orion-M will report a communications

alarm for that loop input when the runtime application is started.

NOTE: The order o the loop controls on the communication link is not important. The communications

address or a controller can be assigned regardless o its position on the link.

In addition to the communications address, the aud rate, floating point format, shed ena le and computer set

point options must also e set to match the control module of the Orion-M. The Orion-M uses a default

communication rate of 9600 aud, 8 data its, 1 stop it and no parity, which are typical settings for Mod us

RTU communications and compati le with the UDC2500/3200 controller.

*Required UDC2500/3200 Communications Group Settings:

• Communications station address (ComADR): 1-15 (based on system design)

• Communications selection (COMSTA): MODBUS

• Infrared communications (IRENAB): DIS (recommended but not required)

• Baud rate (BAUD): 9600

• Transmit delay (TX DLY): 1

• Floating point data format (WS FLT): FP B

• Shed enale (SDENAB): ENAB

• Shed time (SHDTIM) : 60 (recommended – minimum o 30 seconds)

• Shed mode (SDMODE): LAST

• Shed set point (SHD SP): CSP

• UNITS: EGR

• Computer set point ratio (CSP RATIO): 1

• Computer set point ias (CSP BIAS); 0

*See section 3 Configuration, in the Honeywell UDC2500/3200 Product Manual for instructions on

accessing the control’s configuration menus and setting the abo e parameters as required.

Orion-M

3.2 FDC Orion-M CONFIGURING THE UDC2500/3200 CONTROLLER

3.2 Input Type Assignments

The Honeywell UDC2500/3200 controls provide universal input types for input 1. An optional analog input

(voltage/current) for input 2 is availa le on the UDC2500 while the UDC3200 can provide an optional

universal input for input 2. The Loop Input # for the corresponding control in the Orion-M Configurator is set

to match the selected input type for input 1 of the UDC control while the second input can e configured as a

monitor point in the Orion-M.

IMPORTANT: The Orion-M is unable to detect sensor break or input ailure conditions on the Honeywell

UDC2500 or UDC3200 controller. There ore, a problem may exist with a controller input, but

the Orion-M will be unable to report the alarm condition.

I the ailure o an input is a critical alarm condition that requires monitoring, the orion-M

provides 30 alarms that can be con igured to any loop or monitor input. A process alarm can

be con igured with alarm set points outside o the normal operating range or the input. A

ailure o the input on the UDC2500/3200 would result in a high scale or low scale break,

which could then be detected and reported by the alarm set in the Orion-M.

3.2.1 Input 1 Operation

When input 1 of the UDC2500/3200 is a temperature input, i.e., RTD or thermocouple, the temperature units

of the input on the UDC2500/3200 must e set to match the selection in the Orion-M on the Degrees C/F

screen. The Orion-M can not change the temperature units on the UDC controller. Thus, when you set up

the UDC controller, its temperature units must match that of the selection in the Orion-M. If the selections do

not match, the Orion-M may show units of degrees Centigrade while the actual value from the UDC control is

in degrees Fahrenheit.

In addition, if %RH (wet ul ) is selected for a Loop Input in the Orion-M Configurator, the temperature units in

the Orion-M must match the UDC controllers for the dry ul /wet ul calculation to e performed correctly. If

the temperature units do not match, the relative humidity reading on the Orion-M will not e correct.

NOTE: It is recommended that the Degrees C/F selection screen be disabled in the Orion-M Con igurator

once the proper temperature units selection has been made to prevent it rom being accessed. This

will prevent the temperature units rom being accidentally changed and causing operator con usion

when the units do not match between the UDC control and the Orion-M. See section 3.6 Orion

Functions/Startup View, in the Orion-M Con iguration Manual or in ormation on enabling and

disabling this item.

For either temperature or process (voltage/current/car on) input types, the Orion-M will set the lower and

upper set point limits for the input to match the settings in the Orion-M Configurator. The decimal point

selection for the Loop Input in the Orion-M and the UDC controller do not have to e set to match; however, if

the loop controls are visi le to the operator, it is recommended that the decimal point resolution of the Orion-

M and UDC controller match.

Loop Inputs set as temperature in the Orion-M Configurator allow a decimal point selection of 0 or 1. Process

type loop inputs can e displayed on the Orion-M with a resolution of 0 to 3 decimal points. The Orion-M has

a display range of -32768 to 32767, -3276.8 to 3276.7, -327.68 to 327.67 or -32.768 to 32.767 depending

upon decimal point selection. When selecting the decimal point resolution for the Loop Input in the Orion-M

Configurator, make sure that range of the UDC2500/3200 does not exceed the range selected in the Orion-M

or the value may not e displayed correctly.

IMPORTANT: The lower and upper set point limits are set once, each time the Orion-M enters the runtime

application. Do not alter the values in the UDC2500/3200 control once they have been set or

the Orion-M may not be able to set the correct set point to the controller.

Orion-M

CONFIGURING THE UDC2500/3200 CONTROLLER FDC Orion-M 3.3

3.2.2 Input 2 Operation

Input 2 of the UDC2500/3200 can e used as monitor inputs to the Orion-M. When Loop 2 Input is selected

as the monitor input type in the Orion-M Configurator, the Orion-M will display the second input of selected

loop controls as monitor inputs.

The Loop Input 2 monitor point selection allows inputs to e displayed on the Orion-M with a resolution of 0 to

3 decimal points. The Orion-M has a display range of -32768 to 32767, -3276.8 to 3276.7, -327.68 to 327.67

or -32.768 to 32.767 depending upon decimal point selection. When selecting the decimal point resolution for

the monitor point input in the Orion-M Configurator, make sure that range of the UDC2500/3200 does not

exceed the range selected in the Orion-M or the value may not e displayed correctly.

If input 2 of the UDC controller is a temperature value, its temperature units must match that of the selection

in the Orion-M. If the selections do not match, the Orion-M may show units of degrees Centigrade while the

actual value from the UDC control is in degrees Fahrenheit. Be sure that all temperature inputs to all UDC

controllers match the temperature units selection on the Degrees C/F screen on the Orion-M.

When using the second input of control loops for monitor points, it is important to note that the controller itself,

provides range, cali ration and input ias settings for the input. The ‘Monitor Input Offset’ screen in the

Orion-M runtime application allows an offset to e applied to the monitor points when input 2 of the loop

controls are used. However, the input offset of the Orion-M only corrects the value shown on the Orion-M and

does not offset the reading in the loop control.

If the loop control is visi le to the operator, it is recommended that the ‘Monitor Input Offset’ screen e hidden

(see Section 3.6 Orion Functions/Startup View in the Orion-M Configuration Manual) or even password

protected in the runtime application to prevent an offset from eing applied to the monitor point in the Orion-

M. Rather, use the input ias setting of the loop control so that oth the reading on the loop control and the

Orion-m will match to avoid operator confusion.

3.3 Control Output Assignments

The Orion-M uses a default resolution of 1 decimal point to display the percentage of output of all UDC

controllers attached to the system. Therefore, regardless of the display resolution set on the UDC2500/3200,

the Orion-M will display a percentage of output of 0.0 – 100.0% for the output.

If the UDC controller is set for imodal operation (heat/cool), a display value of 50.0% indicates that oth heat

and cool outputs are off. Values from 50.0 to 100.0% represent the percentage of heat output from off to full

on and values from 50.0 to 0.0% represent the percentage of cool output from off to full on.

3.3.1 Auto-Tune and Auto/Manual Operation

The Orion-M provides the a ility to switch each UDC2500/3200 in the system etween auto and manual

output operation. This function is accessed from the Orion-M runtime, Single Loop View screen via the ‘AM’

control utton.

The Orion-M cannot initiate the tune functions on the UDC2500 or UDC3200 controller. Pressing the ‘AT’

utton on the Single Loop View screen in the Orion-M runtime will provide the appearance that it will activate

the auto-tune on the control, ut once initiated, it will immediately turn off. Attempting to activate the auto-

tune function will not cause any malfunction or system error; however, it should e noted that the function is

inoperative when using the UDC2500/3200 control. Auto-tune must e manually initiated at the UDC

controller itself if the function is required.

Orion-M

3.4 FDC Orion-M CONFIGURING THE UDC2500/3200 CONTROLLER

3.4 Loop Permissions

The Orion-M iSeries configuration provides permissions which can e set to allow the control loop set point,

auto/manual and auto tune operations to e performed at the loop control itself as well as through the Orion-

M. These can allow an operator to make changes at the loop control in cases where the Orion-M interface is

located in a remote location.

3.4.1 Set Point Permission Exception

If the control loop is configured to operate under cascade control or is configured as an RH wet ul loop

type, the set point for the loop is generated y logic within the Orion-M. The loop will not function as

configured unless the se point is constantly set y the Orion-M. Thus, any change made at the loop control

will e overridden y the Orion-M. If local adjustment at the loop control may e required for any reason, loop

set point communications must e interrupted via a digital input to the Orion-M configured as ‘loop SP comms

disa le’.

In addition, the Honeywell controls will enter the computer set point mode (CSP) once they receive any set

point command from the Orion-M. This will lock out adjustments from the keypad at the controller. The

Orion-M is designed to send the ‘shed timer reset’ command to the UDC controller to take it out of computer

set point control when the set point permission is ena led. This allows control via the keypad of the

controller. However, during profile operation and after the profile completes, the UDC will remain under

computer set point control. In order to deactivate CSP, a single set point must e sent from the Orion-M in

order to unlock it. Triggering a digital input configured as ‘loop SP comms disa le’ will also take the UDC

controls out of computer set point control.

3.4.2 Auto/Manual Permission Requirement

The Honeywell controller provides the a ility to initiate manual mode or ‘failure transfer mode’ through a

digital input on the controller. If this function is used, the loop permission for auto/manual operation must e

ena led. If this permission is not ena led, a communication error will occur at the Orion-M. This is due to the

fact that without the permission ena led, the Orion-M will try and force the controller ack to auto mode if it

goes into manual operation via the digital input.

Since the digital input on the UDC controller is an override condition, it will deny the auto mode command

from the Orion-M. The Orion-M then has to respond with a communication error, since the controller did not

follow the command given. By ena ling the auto/manual permission, the Orion-M will accept the manual

mode force at the UDC controller.

Orion-M

APPENDIX FDC Orion-M A.1

Appendix

Orion-M

A.2 FDC Orion-M APPENDIX

Software Usage Note:

The selection, application or use of Future Design Control products or software is the purchaser or

user's responsibility. No claims will be allowed for any damages or losses, whether direct, indirect,

incidental, special or consequential.

In addition, Future Design reser es the right to make changes without notification to purchaser or

user to materials or processing that do not affect compliance with any applicable specification.

Future Design makes no warranties when using the Orion-M system.

Warranty:

Future Design Controls products descri ed in this ook are warranted to e free from functional defects in

material and workmanship at the time the products shipped from Future Design Controls facilities and to

conform at that time to the specifications set forth in the relevant Future Design Controls manual, sheet or

sheets for a period of one year after delivery to the first purchaser.

Future Design Controls products are warranted to e free from functional defects in materials and

workmanship at the time the products shipped from Future Design Controls facilities and to conform at that

time to the specifications set forth in the relevant Future Design Controls manual, sheet or sheets for a period

of one year after delivery to the first purchaser for use.

There are no expressed or implied Warranties extending eyond the Warranties herein and a ove set forth.

Limitations: Future Design Controls provides no warranty or representations of any sort regarding the fitness

of use or application of its products y the purchaser. Users are responsi le for the selection, suita ility of the

products for their application or use of Future Design Controls products.

Future Design Controls shall not e lia le for any damages or losses, whether direct, indirect, incidental,

special, consequential or any other damages, costs or expenses excepting only the cost or expense of repair

or replacement of Future Design Control products as descri ed elow.

Future Design Controls sole responsi ility under the warranty, at Future Design Controls option, is limited to

replacement or repair, free of charge, or refund of purchase price within the warranty period specified. This

warranty does not apply to damage resulting from transportation, alteration, misuse or a use.

Future Design Controls reserves the right to make changes without notification to purchaser to materials or

processing that do not affect compliance with any applica le specifications.

Return Material Authorization:

Contact Future Design Controls for Return Material Authorization Num er prior to returning any product to our

facility:

7524 West 98th Place – Bridge iew, IL 60455 – Phone 888.751.5444 – Fax 888.307.8014

http://www.futuredesigncontrols.com

Table of contents

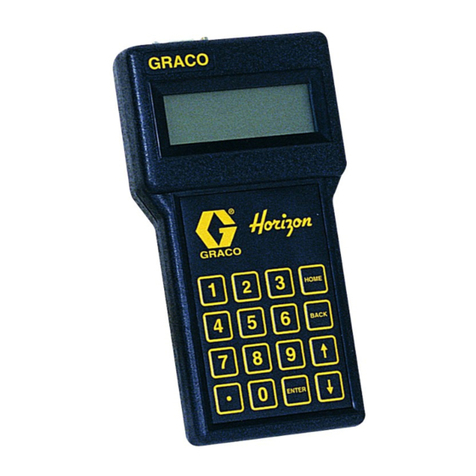

Popular Control System manuals by other brands

Vaillant

Vaillant sensoNET VR 921 installation instructions

ViscoTec

ViscoTec Preeflow eco-CONTROL EC200-B Operation and maintenance instructions

BriskHeat

BriskHeat PTBS-GET instruction manual

Icom

Icom rs-ba1 installation guide

NovaStar

NovaStar ET2000 user manual

smart home

smart home Securelinc Programming guide