FEDERAL PACIFIC PSE User manual

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 1

TYPE PSE

DEADFRONT PAD-MOUNT SWITCHGEAR

15kV • 25kV • 35kV

INSTRUCTIONS

For Installation and Operation

QUALIFIED PERSONS.................................................................................................... 2

SAFETY INFORMATION ................................................................................................ 2

INTRODUCTION.............................................................................................................. 3

Receiving.................................................................................................................... 3

Handling ..................................................................................................................... 3

Storage ....................................................................................................................... 3

GENERAL DESCRIPTION .............................................................................................. 3

SECURITY FEATURES.................................................................................................... 3

AUTO-LATCH DOOR ...................................................................................................... 4

Features...................................................................................................................... 4

Operation.................................................................................................................... 4

INSTALLATION ............................................................................................................... 5

Placement of unit...................................................................................................... 5

Customer cable connections.................................................................................. 5

SWITCH DESCRIPTION................................................................................................. 5

Switch operating sequence.................................................................................... 6

Switch ratings ........................................................................................................... 7

Operating the Auto-jet®II switch.............................................................................................................................7-8

FUSE DESCRIPTION....................................................................................................... 9

Fuse removal ........................................................................................................9-12

Fuse ratings ............................................................................................................. 13

MAINTENANCE............................................................................................................ 14

OPTIONAL FEATURES ................................................................................................. 14

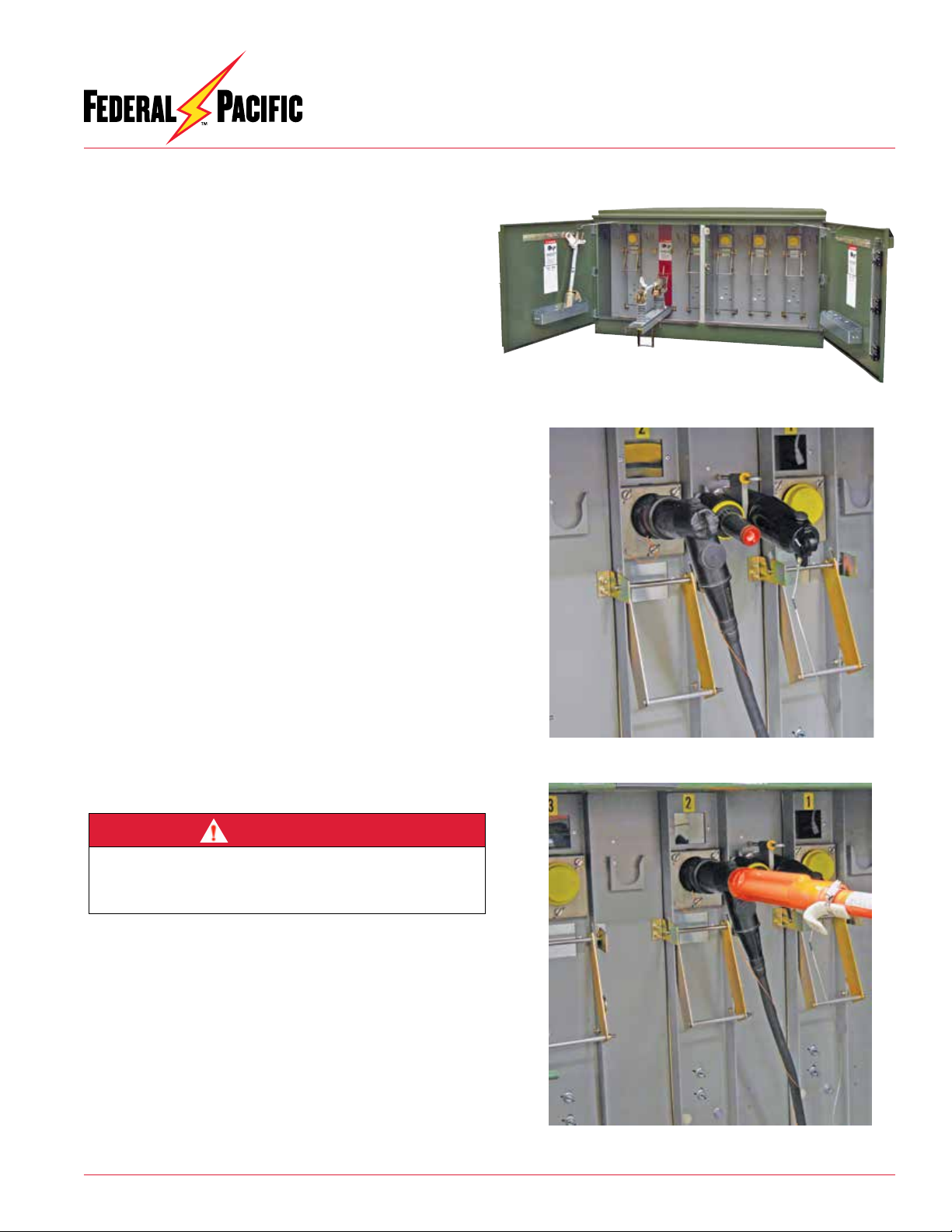

Figure 2. Switch compartment of Federal Pacific PSE pad-

mounted switchgear. Storage for fuse assemblies is on fuse

side, better facilitating fuse changing procedures. Wide-view

windows and broad blades provide improved visibility to make

it easier to verify switch position, even behind cables and

elbows, while the open/closed labels serve to further enhance

this user-friendly design.

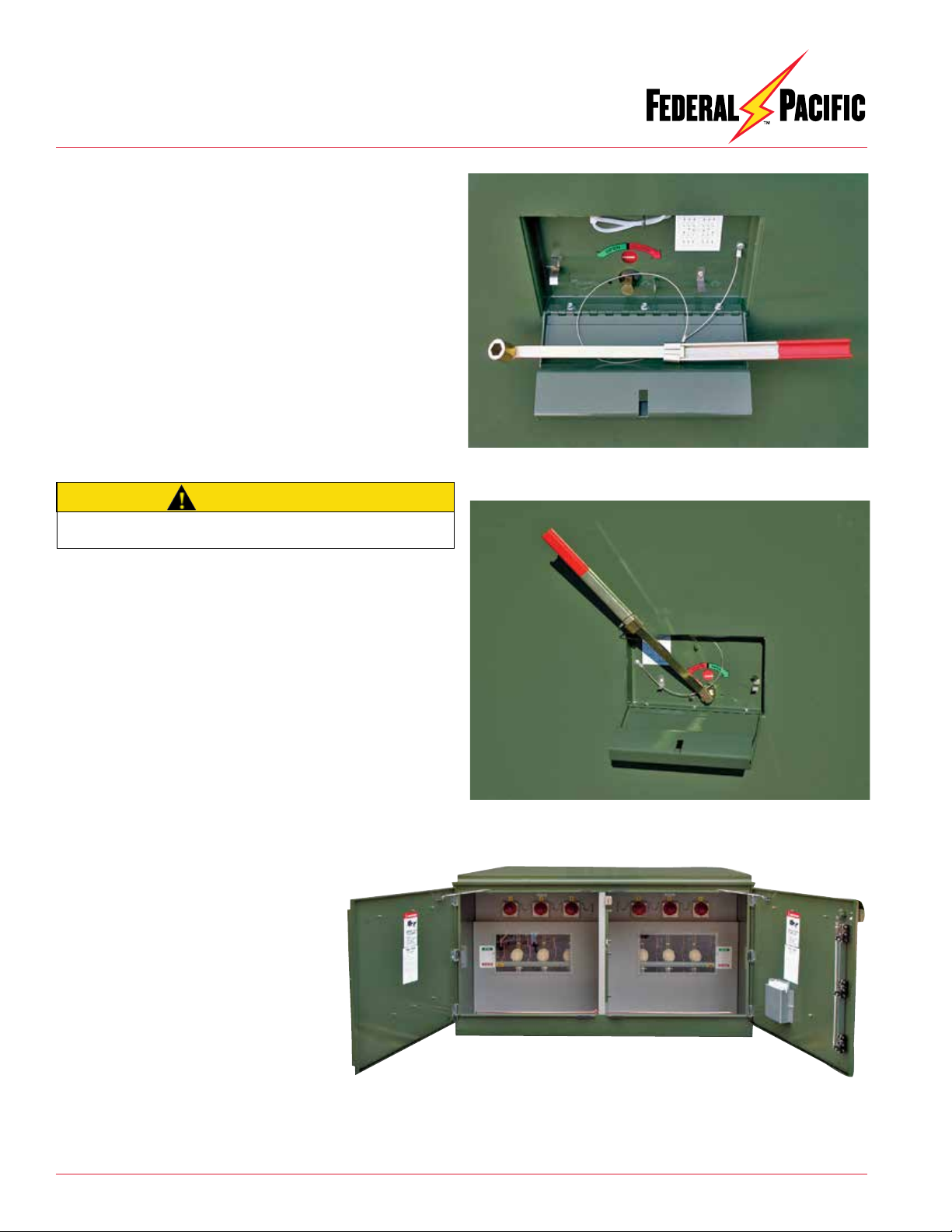

Figure 1. Fuse compartment of Federal Pacific PSE pad-

mounted switchgear. Spacing between fuse panels is

adequate to accommodate a horizontal feed-thru standoff

bushing - and there is a viewing window directly in front of

each fuse, making blown-fuse targets fully visible. Doors

feature three-point automatic, self-latching door latches. The

captive security bolt rotates 60° in either direction (clockwise

or counter-clockwise) to open. Do not use power tools. See

page 4 for additional information

Qualified Persons

© 2014 Electro-Mechanical Corporation

These training requirements would include, but are not limited, to the

following key points:

• The skills and techniques necessary to distinguish exposed energized

parts from other parts of electrical equipment.

• The skills and techniques necessary to determine the proper approach

distances corresponding to the voltages to which the qualified person

will be exposed.

• The proper use of the special precautionary techniques, personal pro-

tectiveequipment, insulatingand shieldingmaterials, andinsulated tools

for working on or near exposed energized parts of electrical equipment.

• Tasks performed less often than once per year have additional training

requirements.

These instructions are intended only for such qualified persons. They

are not intended to be a substitute for adequate training and experience

in safety procedures for this type of equipment. Additionally, the recom-

mendations in this instruction bulletin are not intended to supersede or

to take the place of established utility safety guidelines and established

practices. If there is any question, consult with your foreman or supervi-

sor, as appropriate.

Please refer to OSHA 29 CFR 1910.399 and NFPA 70E Articles 100 and 110.

The equipment covered by this publication must be selected for a spe-

cific application and it must be operated and maintained by Qualified

Persons who are thoroughly trained and knowledgeable in the instal-

lation, operation, and maintenance of underground power distribution

equipment along with the associated hazards that may be involved. This

publication is written only for such qualified persons and is not intended

to be a substitute for adequate training and experience in safety proce-

dures for this type of equipment. Proper installation is the responsibility

of the operating and construction personnel and the utility performing

and authorizing the work. Completion of these instructions implies no

further warranty by the manufacturer.

A Qualified Person is defined in the National Electrical Code (NEC/

NFPA-70) as:

One who has skills and knowledge related to the construction and op-

eration of the electrical equipment and installations and has received

safety training to recognize and avoid the hazards involved.

The specific electrical safety training requirements to be considered a

qualified person are detailed in NFPA-70E, Article 110.1(D), Employee

Training. Some of the requirements from the 2012 edition are shown

below. For the specific detailed training requirements for a Qualified

Person make certain to refer to the most recent applicable edition.

WARNING

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 2

SAFETY INFORMATION

Understanding Safety-Alert Messages

There are several types of safety-alert messages which may

appear throughout this instruction bulletin as well as on labels

attached to the pad-mounted switchgear. Familiarize yourself

with these types of messages and the importance of the various

signal words, as explained below.

If you do not understand any portion of this instruction bulletin

and need assistance, contact Federal Pacific at 276-669-4084.

Replacement Instructions & Labels

If you need additional copies of this instruction bulletin, contact

Federal Pacific at 276-669-4084.

It is important that any missing, damaged, or faded labels on the

equipment be replaced immediately. Replacement labels are

available by contacting Federal Pacific.

SAFETY PRECAUTION

FOLLOWING SAFETY INSTRUCTIONS

NOTICE

NOTICE is used to address practices not related to physical

injury.

SAFETY

INSTRUCTIONS

SafetyInstructions (orequivalent)signs indicatespecific safety-

related instructions or procedures.

DANGERindicates ahazardous situationwhich, ifnot avoided,

will result in death or serious injury.

DANGER

WARNING

WARNINGindicatesahazardoussituationwhich,ifnotavoided,

could result in death or serous injury.

CAUTION

CAUTIONindicatesahazardoussituationwhich,ifnotavoided,

could result in minor or moderate injury.

DANGER

Federal Pacific Fuse Mountings in conjunction with appropri-

ate fuses are designed to protect equipment and to disconnect

faulted equipment from the system. The fuses cannot protect

personnel from injury or electrocution if contact is made with

energized circuits or hardware.

NOTICE

Thoroughlyandcarefullyreadthisinstructionbulletin

before installation of the pad-mounted switchgear,

before switching or operating the switches or fuse

mountings in this equipment, and before performing

any maintenance on the equipment.

......

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 3

Introduction

TypePSEpad-mounted switchgear isdesigned toprovide depend-

able on-the-line service and to make installation, operation and

maintenance as simple as possible.

High quality materials and careful workmanship have been com-

binedto providethe bestswitchgear available.The switchgearhas

been thoroughly inspected and adjusted at the factory. However,

successful operation depends on proper installation and care.

This manual has been written to assist you in obtaining long and

economical service from your switchgear.

Readthis manualbeforeinstallingandoperating yourswitchgear.

Receiving

Upon receipt of the switchgear, check each item received for ship-

ping damage. Each item should be checked against the shipping

manifest to assure that the proper number of items were received.

Shouldanyshortage ordamageexist,noteitontheshippingpapers.

A claim should be filed at once with the carrier and the Federal

Pacific agent or sales office should be notified.

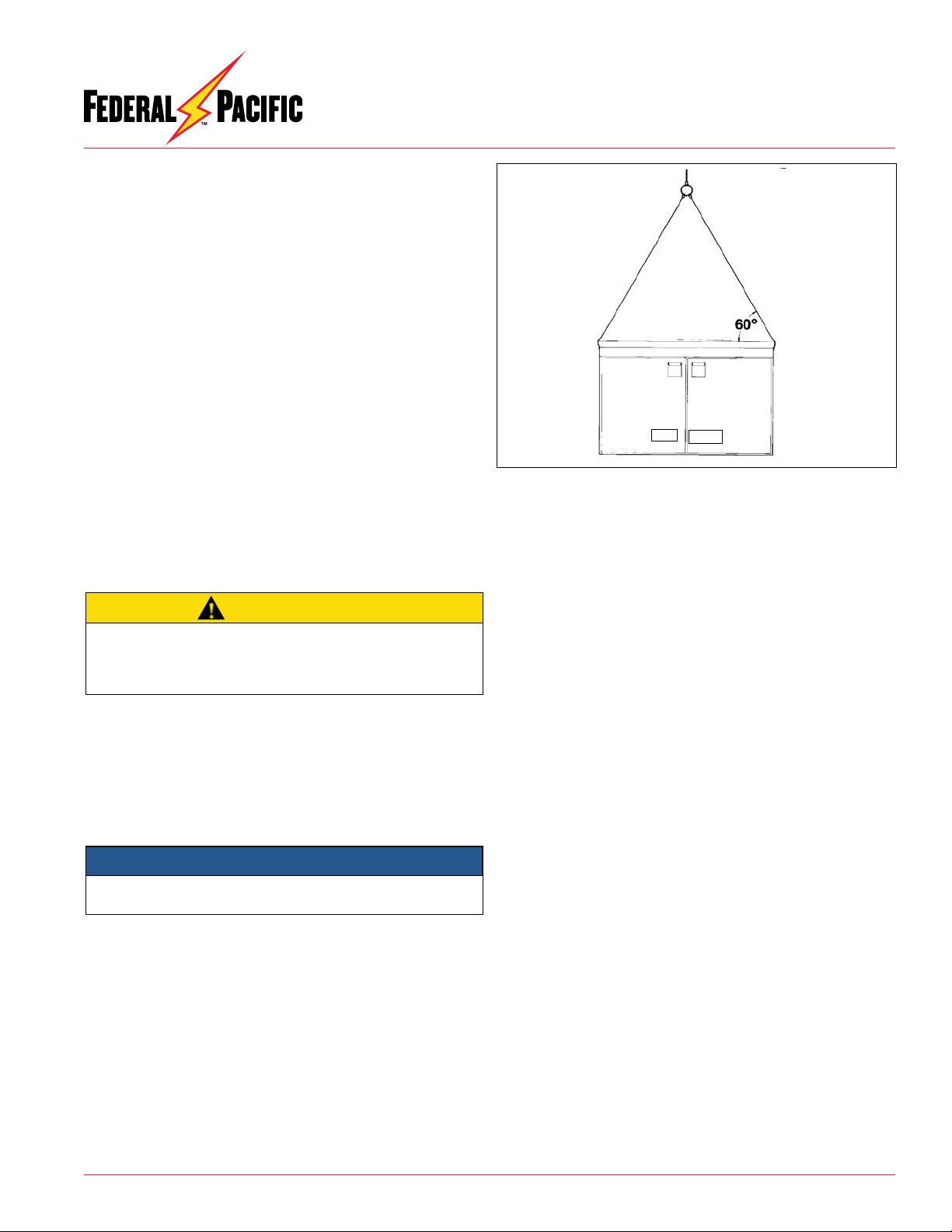

Handling

Removable lifting plates are provided to allow the use of hooks to

lift the complete enclosure. The lifting device should be arranged

to evenly distribute the lifting force between the lifting plates.

Do not lift at an angle less than 60° from the horizontal. See

Figure 3. A spreader bar may be required to maintain proper

angles. Failure to comply with this requirement may result in

damage to the equipment.

The switchgear is securely mounted to a sturdy shipping pallet

with provisions for forklift use. The use of a forklift truck is not

recommended, but if this method is used the forks must extend

completely through the skid to avoid damaging the equipment.

Storage

The switchgear as received may be wrapped in a protective

plastic film.

To avoid damage to the enclosure finish, the protective film must

be removed for outdoor storage of unit.

Export or special packing is available as an option based on cus-

tomer’srequirementsandspecial conditions.Separateinstructions

are available for these situations.

Figure 3. Lifting Method

General Description

Type PSE deadfront pad-mounted switchgear consists of one or

morethree-pole, single-throw, gang-operated,quick-make, quick-

break, load interrupter switches that may be used in combination

with one or more three-phase sets of single-pole fuse mountings.

Switches are typically equipped with 600-ampere bushings to

accommodate 600-ampere elbow connectors. Fuse mountings

are equipped with 200-ampere bushing wells to accommodate

200-ampere loadbreak (or non-loadbreak) inserts and elbows.

When used in conjunction with power fuses, expulsion or current-

limiting type, and other protective devices, the PSE switchgear

provides a secure and efficient means of 3-pole switching on

main feeders and circuit protection with single-pole switching of

elbows on load feeders.

Security Features

Type PSE pad-mounted switchgear incorporates a number of

security features to minimize hazards to operating personnel.

1. Rugged11-gauge steel,braced byall weldedconstructionof the

enclosure, roof, and doors assures a tamper-resistant design.

2. Padlockable switch operating pocket handles and doors with

security bolts provide customer-controlled access.

3.

Switch position indicators verify positive switch position.

4. Provisions to padlock switch in open or closed position provide

user controlled switch operation (optional).

5. Key interlocks to ensure a pre-determined sequence of me-

chanical operations (optional).

6. Hazard-alert signs and labels, both external and internal, which

indicate potential hazards to personnel.

NOTICE

CAUTION

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 4

Auto-Latch Door

Active Door (“Auto-Latch Door”)

The type PSE pad-mounted switchgear incorporates an active

door, which includes an automatic three-point latching system for

enclosure security. The features and operation of the auto-latch

active door are discussed below. See Figure 4a.

Passive Door

The passive door is overlapped by the active door, ensuring that

the auto-latch mechanism must first be released before accessing

the passive door. Once so accessed, the passive door is released

by raising the latch bracket from its engaged (latched) position.

See Figure 4b.

Features of the Auto-Jet Mechanism on the Active Door

The automatic door latching feature furnished on the active doors

provides ease in opening and closing of the doors. Features of the

Auto-latch system are:

• Automatic 3-point latching upon door closure (see Figure 4a).

• After opening, the door is automatically set for latching upon

door closure.

• Unlatching is only accomplished by an unrestrained rotation

(approximately60°in eitherdirection)ofthecaptivepentahead

or hexhead actuator bolt.

• The door padlocking provision prevents unlatching the

mechanism until the padlock has been removed. Padlocking

secures the door to the cabinet enclosure.

• A stainless steel protective cover guards the padlock from

tampering. Also, access to and visibility of, the actuator bolt

is only possible after the padlock has been removed.

Auto-Latch Door Operation

Opening:

1. Remove padlock and raise protective cover exposing security

bolt. See Figure 5.

2. If equipped with the standard pentahead security bolt, use the

standard pentahead socket (or if equipped with an optional

hexhead bolt, use a 3/4” hexhead socket) to rotate the captive

actuator bolt head approximately 60° in either direction until the

latching mechanism has tripped, releasing the door. Do not use

power tools to operate the security bolt. See Figure 6.

3. Open the active door. Open the passive door by simultaneously

pushing on it and pulling up on the latch bracket. See Figure 4b.

Secure the doors with the doorkeepers.

Closing:

1. Replaceorreleasedoorkeeperandcloseandsecurelatchbracket

onto passive door. Then, release and replace door keeper and

secure the active door by firmly and briskly pushing it closed.

Mechanism will automatically latch.

2. Install padlock through protective cover tab and enclosure tab.

Figure 5. Raise cover to access security bolt. Review and understand

the “CAUTION” label on the underside of the cover.

Figure 6. Use a manual wrench with pentahead or hexhead socket as

applicable. As explained on the caution label, DO NOT USE POWER

TOOLS. Rotate the security bolt clockwise or counter-clockwise to

release three-point latch and charge for subsequent door closing. Do

not use power tools to operate the security bolt.

Figure 4a. Auto-latch mechanism with

3-point latching on door closure.

Figure 4b. Release passive

door by simultaneously

pushing on it and raising the

latch bracket.

CAUTION

Do not use power tools to operate the security bolt.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 5

Customer Cable Connections

1. Make up the primary cable connections per user’s standard URD

operating procedures,cable manufacturerinstructions, andelbow

terminator manufacturer instructions.

Installation

Each unit is shipped with this instruction bulletin, which is located

inside the switch compartment door. These instructions should be

reviewed prior to placing unit on pad.

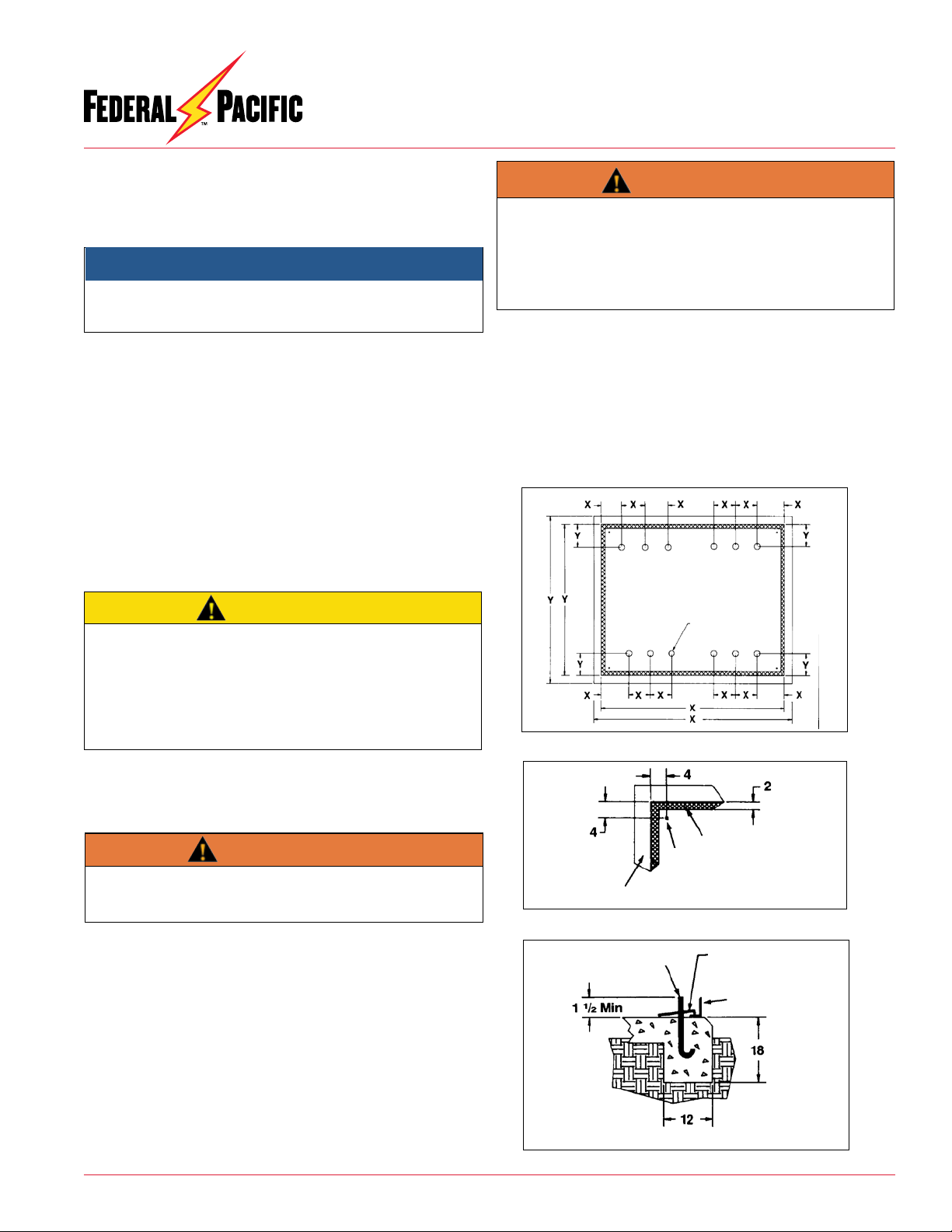

Placement of Unit

Remove unit from shipping pallet per handling procedures on Page

2 (see Figure 3). When unit has been correctly oriented and placed

on pad (see Figure 7), verify that unit is level and shim if necessary

betweenunitbaseandpad. Secureunittopadusingfour (4)tie-down

clips as furnished (see Figures 8 and 9). Check compartment door

operation for any binding due to enclosure distortion and re-shim

if necessary. A recessed grouting should then be applied between

unit base and pad to prevent entry of foreign objects and moisture.

Figure 7. Typical Pad Layout

PSE-X

Recommended Pad Layout

Approximate Cable

Locations

Figure 8. Typical Anchor Bolt Location

Base of Cabinet

Customers Pad Corner Detail

Anchor Bolt

Figure 9. Bolting Units to Pad

Cabinet

5/8-11 Anchor

Bolts (by others)

4 Tie Down

Plates Provided w/Unit

Recommended Pad Section

Before energizing the switchgear, remove all yellow and red

shipping caps on bushings and bushing wells, and replace

them with a suitable system of insulated separable connectors

(elbows), insulating protective covers, or plugs, as appropriate.

Failure to replace the shipping caps may result in flashover,

equipment damage, serious personal injury, or death.

WARNING

2. Connect the concentric neutral wires to the enclosure ground

pads inside enclosure to facilitate ground system conforming to

user’s grounding procedures.

NOTICE

Installer shall provide appropriate clear working space, as re-

quiredby applicablecodes and/orworkpractices, toallow instal-

lation,operation, inspection,and maintenanceof theswitchgear.

CAUTION

When terminating cables in dead-front switchgear, ensure that

eachcableterminationconnectorlaysflatagainstthe correspond-

ing flat copper contact surface of the associated bushing, prior

to making up the elbow, so that no additional strain is put on the

bushing.Theconnectinghardwareandcomponentsofdead-break

T-body elbows are not to be used to pull the cable terminations

into alignment with the bushings.

3. Install fault indicators, if applicable.

4. Fuse Compartment Cable Positioning

a) Cableconnectionstotheloadbreakfusemountingterminalsmust

be fed through the cable guides, which are located under the

parking stands. This is required to permit the proper operation

of the pivoting fuse mountings.

b) Each cable guide may be rotated or temporarily removed to

facilitate cable installation, so long as it is returned to its original

orientation, under its corresponding parking stand, after the

cables are installed.

Switch Description

The Auto-jet®II switch provides a unique method of load interruption,

producing a laminated jet of air which extinguishes the arc.

Auto-jet®II switches have a heavy gauge steel, all welded base

frame that assures proper alignment and eliminates any problem

with switch-to-enclosure alignment. A quick-make, quick-break

stored energy mechanism with heavy duty, long life die springs

provides high speed opening and closing independent of the op-

erating handle speed.

WARNING

The maximum momentary rating of the switchgear must be

considered when selecting cable size for connecting switch-

gear to system ground. Refer to unit rating plate.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 6

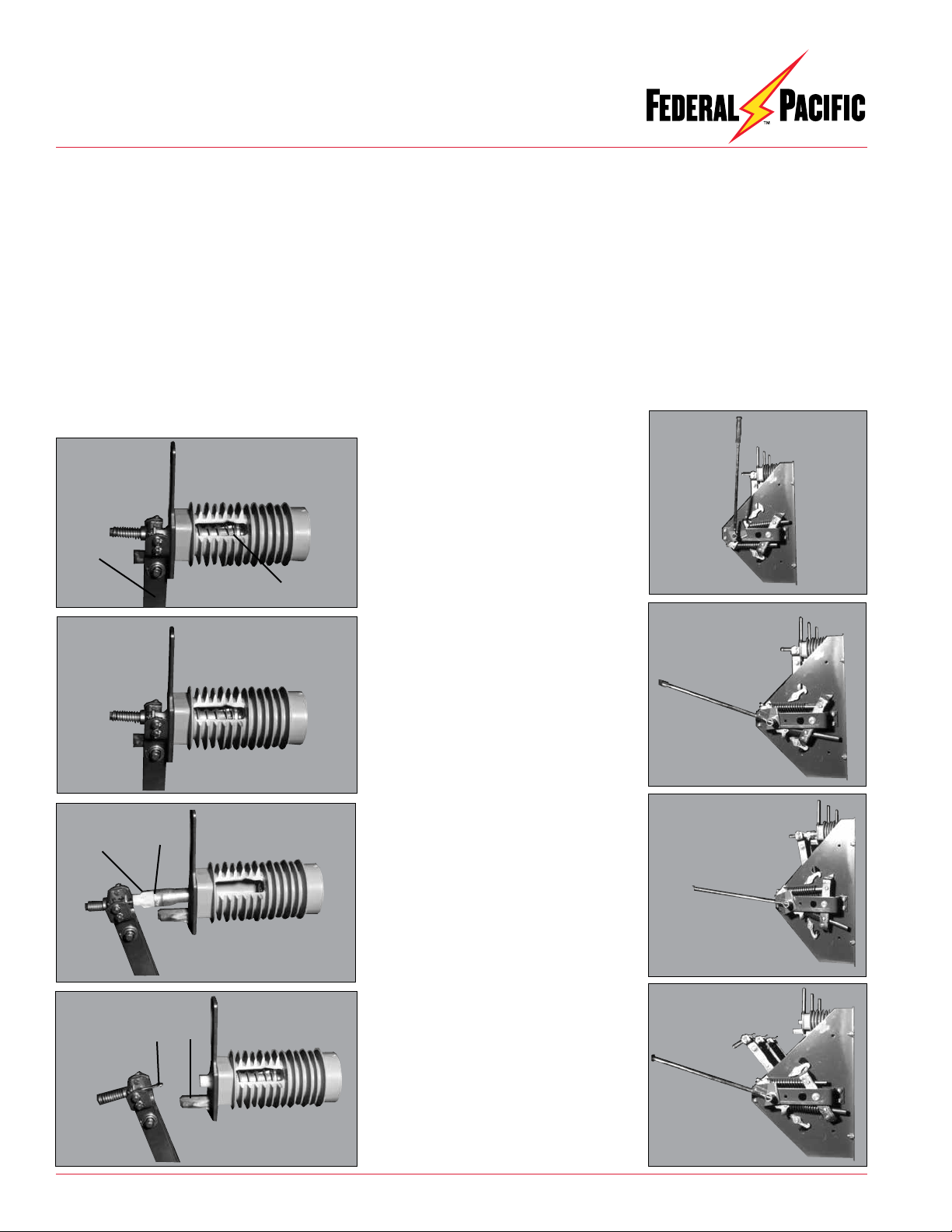

The operating sequence of the Auto-jet®interrupter is pictured

in the left-hand column in Figures 10(a) through 10(d) and the

corresponding positions of the switch and its mechanism are

pictured in the right-hand column. The Auto-jet®interrupter con-

sists of a piston (A) mounted in the cavity of the upper insulator.

The movable arcing probe (B) engages a tulip contact (C) inside

the piston. As the switch blade (D) is pulled open by the stored

energy mechanism, the blade separates from the main-contact

stab (E). The piston is pulled forward by means of the movable

arcing probe, which compresses a heavy gauge spring encircling

the piston and a spring encircling the arcing probe. At the end of

its travel, the piston is released from the arcing probe and, under

the action of the heavy spring, is rapidly pushed backward into

the cavity. This travel produces a jet of laminated compressed air

up through the center of the piston, which extinguishes the arc.

The spring encircling the movable arcing probe rapidly retracts

the probe and increases the speed of separation, which prevents

restrike. Allofthisactionisin addition to the spring energy transmitted

to the switch blades by the quick-make quick-break mechanism

of the switch.

Switch Operating Sequence

Figure 10(d)

Switch open with latch

engaged to hold switch in

position.

Figure 10(c)

Main contacts parted, puffer

and arcing springs charged.

(Simulated condition for

illustrative purposes, actual

duration of event is approx.

1/2 cycle.)

Figure 10(b)

Switch closed with opening

spring charged by manual

operating handle.

Figure 10(a)

Switch closed with opening

spring relaxed.

Cutaway Views of Interrupter

Views of Switch

DA

BE

CA

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 7

Figure 12. Remove padlock.

Figure 13. Open switch lockbox access cover. Handle is connected to

enclosure by a cable.

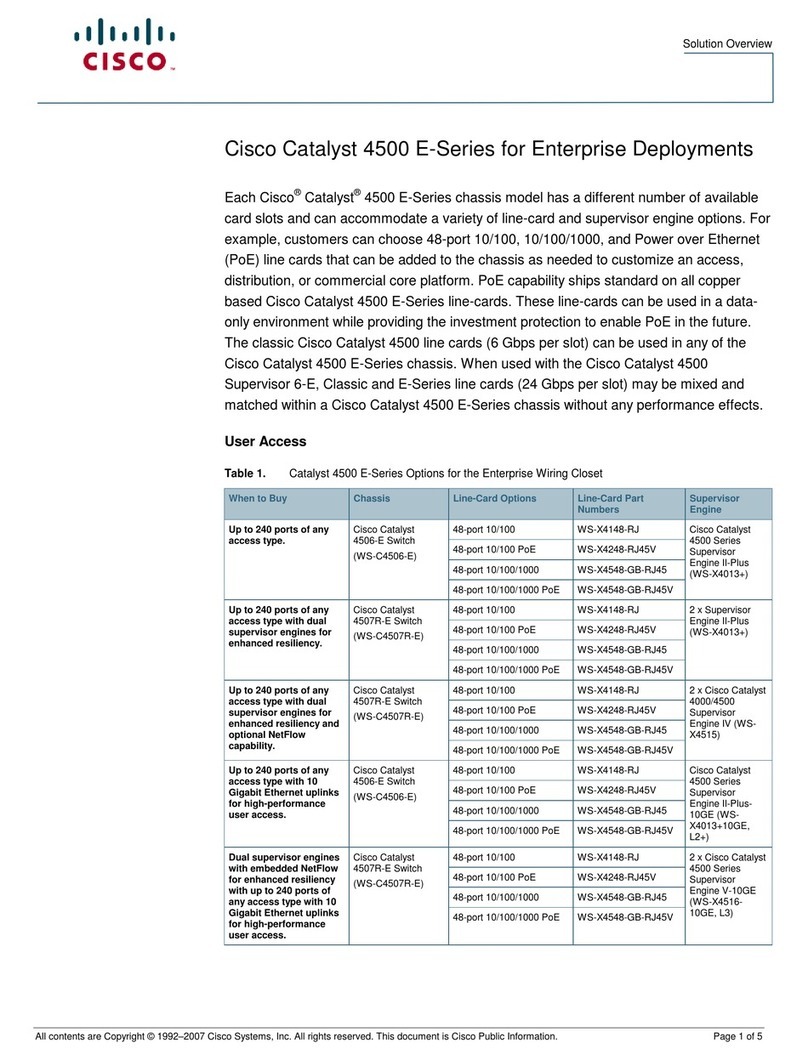

Ratings of the pad-mounted switchgear assembly are based on

the lowest ratings of the components furnished. Refer to ratings

labels on the interior of the compartment doors.

Figure 11. 15-kV Auto-jet®II Switch

*The three-time duty-cycle fault-closing rating means that the switch

can be closed three times into rated fault amperes and remain

operable and able to carry and interrupt its rated load current.

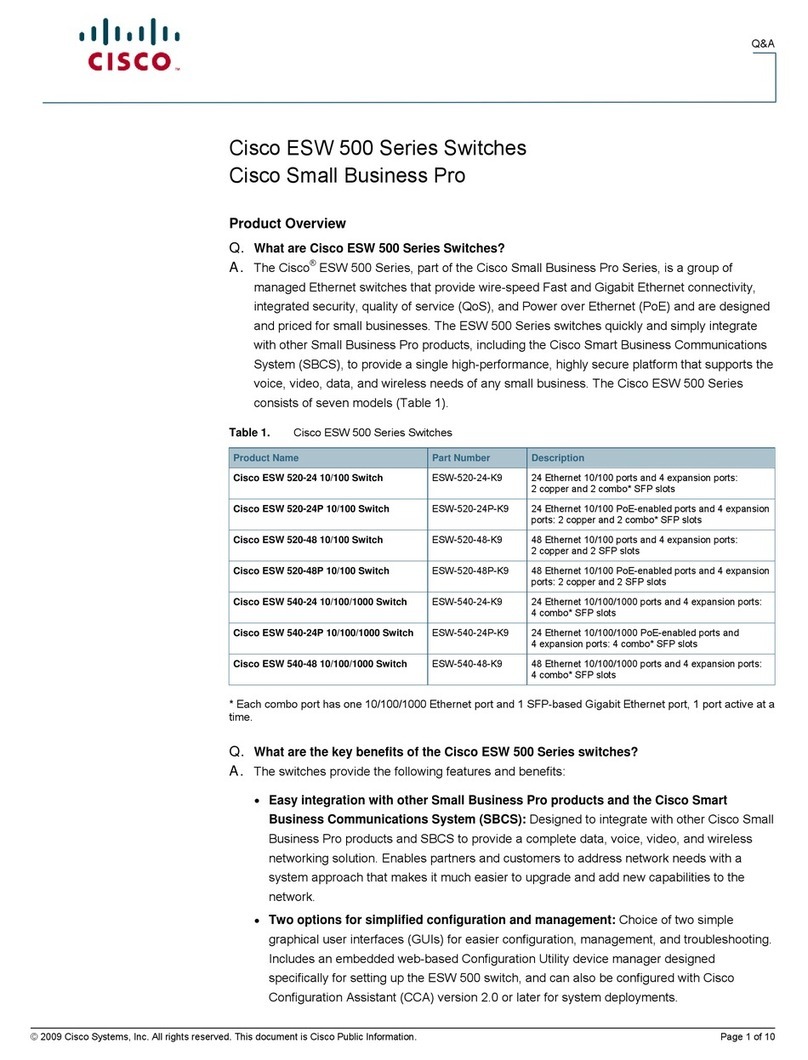

Switch Ratings

kV Amperes, RMS Fault-

Close

Duty

Cycle*

Nom. Max.

Des. BIL Cont.

Interrupting Nom. &

Fault-Close

(ASYM KA)

Load Cap. Mag.

15 17.5 95 600 600 10 21 40 3

15 17 95 1200 1200 10 21 40 3

25 27 125 600 600 15 21 40 3

35 38 150 600 600 20 21 40 3

Operating the Auto-Jet®II Switch

1. Remove padlock and open the switch lockbox access cover.

(See Figures 12 and 13.)

WARNING

Toavoidexposure to potentialarcingconditionsand eventhough

the switch is behind a grounded panel, it is recommended that

allswitchingoperations with theAuto-jet®switchbeperformed

with all enclosure doors closed and latched.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 8

Figure 14. Remove and unfold handle. Secure handle in the extended

position by sliding clip over joint of handle sections.

Figure 15. Place operating handle on hex shaft of switch. Rotate handle

in desired direction as shown by switch position indicator.

2. Remove switch operating handle from storage clips. Unfold the

handle and secure in the extended position by sliding the clamp

over the hinged section (see Figure 14). Place the handle on the

hexswitch-operatingshaft (seeFigure15). Ifprovisionto padlock

switch in open or closed position is provided (K2 option), the

additional padlock (if installed) must be removed before access

to hex switch-operating shaft can be accomplished.

If key interlock(s) are provided (K1, K3 or K4 options), switch

may be locked in the open position.

3. Rotate handle in the direction as indicated on the label to open

or close switch. Verify switch position by observing the switch

position indicator in the handle pocket and by inspecting the

switch through the viewing window provided in each switch

compartment. (See Figure 16.)

4. Remove handle from hex shaft, fold it for storage and place in

the correct orientation on the clips for storage.

5. Close switch lockbox access cover and padlock.

Access cover should be padlocked whenever switchgear is

left unattended.

6. Switch position should be visually verified by opening access

door of switch compartment and checking actual switch posi-

tion through viewing window. See Figure 16.

CAUTION

Figure 16. Visually verify switch position through switch viewing window.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 9

Fuse Description

The PSE pivoting fuse mounting provides a convenient means

to install fuses during initial energization as well as during fuse

replacement.The fusemounting includesaninterlocking latchthat

prevents access to fuses unless the elbow connector is removed,

while also providing a convenient means to unlatch and lower the

fuse mounting.

The PSE fuse mountings include a heavy gauge formed channel

base with viewing windows to observe the blown fuse indicator.

A GPO-3 fiberglass barrier blocks access to the interior of the PSE

unit, precluding exposure to high voltage, while the fuse mounting

is lowered. When the fuse mounting is in the lowered position, the

fuse is completely de-energized and isolated from high voltage.

A locking bracket secures the fuse mounting to the door stile,

facilitating fuse removal.

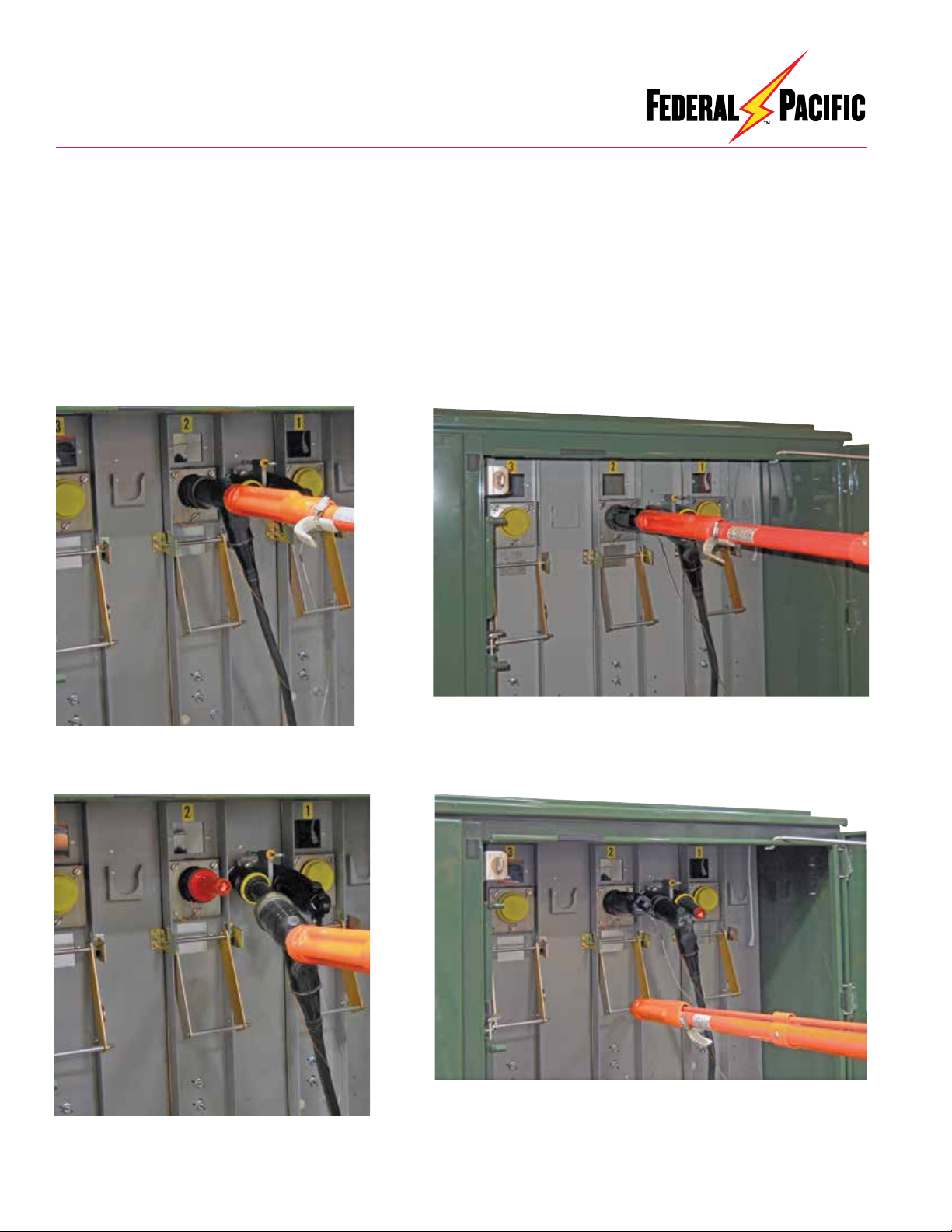

Fuse Removal

1. Open appropriate fuse compartment door and secure with

the wind stop. See Figure 17.

2. Install the grappler tool on the universal head of the shotgun

clamp stick.

3. Using theshotgunclamp stick,installthefeed-through standoff

bushing on the parking stand. See Figure 18.

4. If appropriate for operating circumstances of the system,

test the elbow to be moved for voltage. After verifying that

voltage is not present, use the shotgun clamp stick to remove

the elbow connector from the appropriate bushing well, fol-

lowing standard system operating procedures and the elbow

manufacturer’s instructions. Move the elbow connector onto

a standard feed-thru standoff bushing that is placed in the

parking stand. See Figures 19, 20, and 21.

5.

Installan insulatingprotective coveron theexposed 200-amp

bushing well insert. See Figure 22.

6 If appropriate for operating circumstances of the system,

test the remaining feed-through standoff bushing for voltage

and, after confirming that voltage is not present, then install

a grounding elbow on the remaining bushing.

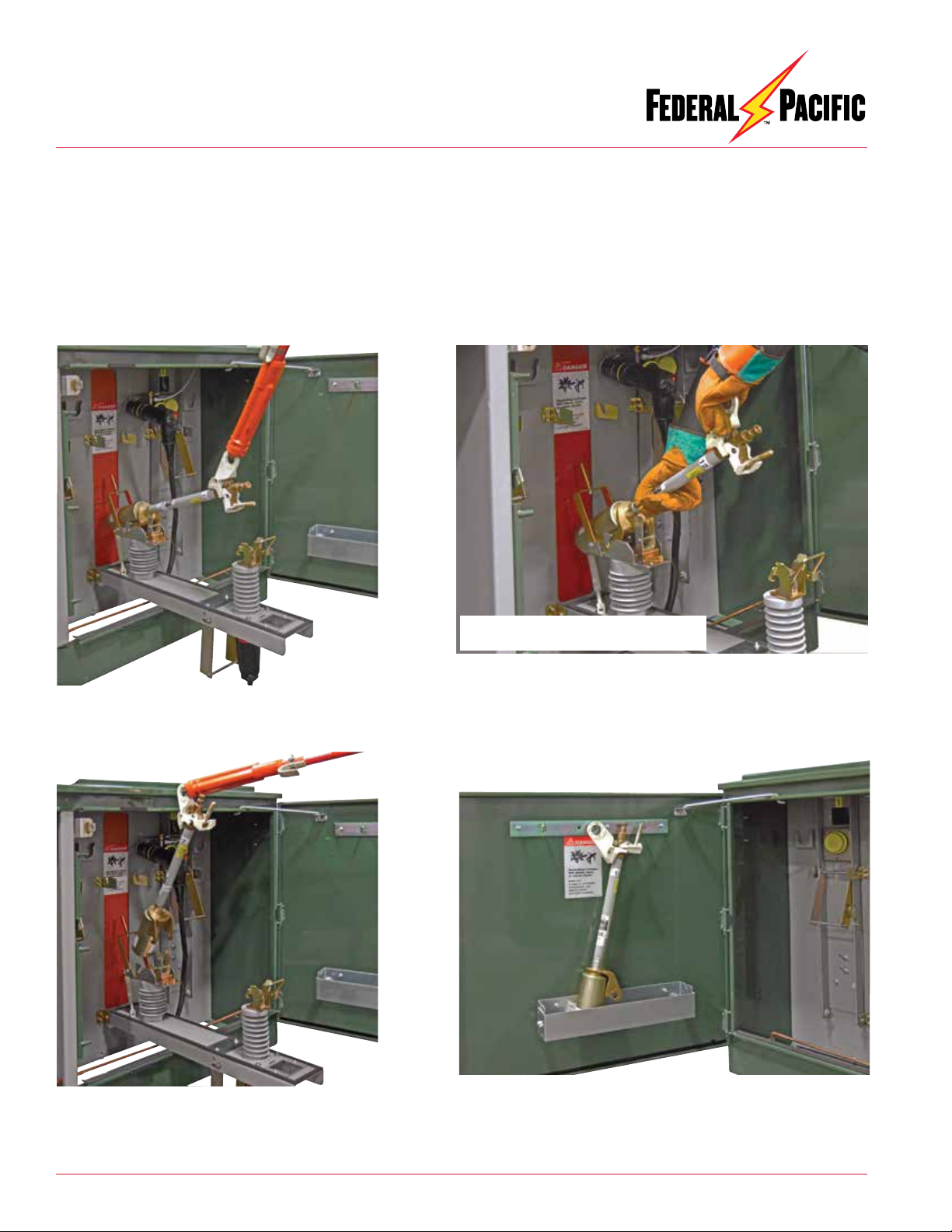

7. The fuse-panel latch interlock prevents access to fuses un-

less the elbow connector is removed to allow release of the

interlock. Secure the shotgun clamp stick to the interlock

lever and raise the interlock. See Figures 23 and 24.

8. With the shotgun clamp stick still secured on the interlock

lever, pull on the fuse panel; lower it to a horizontal position

and release the shotgun clamp stick. See Figure 25.

Figure 18. Feed through standoff bushing installed on

parking stand.

Figure 19. Shotgun clamp stick secured to elbow for

removal/connection.

Figure 17. Fuse compartments with doors secured open.

DANGER

Before installing grounding elbows, test for voltage. Failure to

properly test for voltage to establish that circuit is de-energized

beforeinstallinggrounding elbow mayresult in equipmentdam-

age, personal injury or death.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 10

Figure 23. Shotgun-clamp stick secured to interlock lever.

9. Rotate the locking bracket to secure the fuse access plate

down against the lower door stile. The locking bracket is

located on the side of the fuse access plate. There is no

need to remove the shotgun clamp stick from the interlock

unit until the opening process is complete. See Figure 26.

10. Make certain that the fuse retainer bail, located at the pull-

ring end of the fuse assembly, has been pivoted off the end

fitting. See Figure

27.

11. Secure the hook of the shotgun clamp stick to the fuse pull

ring. Pull and lift the fuse assembly from the fuse mounting.

See Figures 25, 28 and 27. Alternately, if user’s standard

operating procedures permit, the fuse assembly may be

removed fromthefusemounting usinganinsulating-gloved

hand because in the lowered position the fuse mounting is

isolated at both ends from high voltage. See Figure 30. If

optional fuse storage hooks (suffix -E3 or -E4) are provided,

the complete fuse assembly can be stored on the hooks,

which are mounted on the fuse-compartment door. See

Figure 31.

12. Re-fuse using the procedures included with the fuse

manufacturer’s replacement fuse (or refill) unit.

Figure 20. Shotgun clamp stick secured to elbow

with elbow in process of being removed/connected

to bushing insert.

Figure 21. Shotgun clamp stick secured to elbow

with elbow moved to feed through standoff bushing on

parking stand.

Figure 22. Insulating protective cover installed on bushing-well insert.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 11

14. Before removing hook from fuse pull ring, push firmly to assure

that the fuse assembly is completely seated in the hinge, closed

and latched.

15. Release the locking bracket that holds the fuse mounting down

against the lower door stile. See Figure 26.

16. Secure the shotgun clamp stick to the fuse mounting interlock

lever. Then raise the fuse panel and latch it closed.

13. Re-install the hook of the shotgun clamp stick onto the pull

ring of the fuse assembly. Then lift and place fuse assembly

into fuse mounting in the horizontal position, in the reverse of

Figures27, 28,and 29.Alternately,if user’sstandard operating

procedures permit, the fuse assembly may be placed in the

fuse mounting using an insulating-gloved hand because in

the lowered position the fuse mounting is isolated at both

ends from high voltage. See Figure 31.

Figure 26. Locking bracket being set in

place to secure fuse mounting against door

rail.

Figure 24. Interlock lever being raised to unlocked

position (or lowered to locked position).

Figure 25. Fuse mounting being lowered to access

fuse (or raised to reinstall fuse).

Figure 27. To release fuse latch, lower fuse-retainer bail. Secure shotgun clamp

stick on fuse pull ring. Pull up on the fuse pull ring to release the fuse. Remove

shotgun stick from fuse pull ring.

Fuse-retainer bail

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 12

Figure 28. By pulling shotgun clamp stick upward, fuse

will unlatch.

Figure 29. Shotgun clamp stick secured to fuse pull ring

and fuse assembly being lifted from the latched position

and being removed from fuse hinge.

17. Lower the interlock lever.

18. If applicable, remove the insulating protective cover from the

bushing-well insert.

19. Move the elbow connector from the feed-through standoff

bushing onto the 200-ampere bushing well insert.

20. Ifapplicable,removethe groundingelbowfrom thefeed-through

standoff bushing.

21. Remove the feed-through standoff bushing.

22. Close and padlock the main door before leaving gear.

Figure 31. Fuse fully removed from fuse mounting and stored on optional

fuse storage hooks on door.

Figure 30. Alternate method using insulating-gloved hand, if user’s

standard operating procedures permit, to remove or install fuse assembly

of fuse mounting.

Internal contact and bushing well are

visible, fuse is totally isolated at both ends.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 13

14.4kV Nominal

SM-4 fused units require three S&C Cat. No. 86632R2 SM-4Z

fuseholders and three S&C SM-4 fuse refills per fuse compart-

ment. ††

SMU-20 fused units require three S&C Cat. No. 3097 SM-20

fuse end fittings and three S&C SMU-20 fuse units per fuse

compartment. ††

DBU fused units require three FP Cat. No. EFA-42 DBU end fit-

tings and three Eaton DBU fuse units per fuse compartment.

††

NX fuses units: PSE fuse mountings will accommodate one

100 ampere Cooper (M-E) type NX current limiting fuse rated

8.3kV, one 100 ampere fuse rated 13.5kV, or one 80 ampere fuse

rated 15kV. ††

† The fuse must be replaced after each interruption. Refer to S&C

instruction manual for SM-4Z or SML-4Z holder and SML-20 end fitting

maintenance required after each fault-close or fault interruption.

Fuse Ratings

25kV Nominal

SM-4 fused units require three S&C Cat. No. 86633R2 SM-4Z

fuseholders and three S&C SM-4 fuse refills per fuse compart-

ment. ††

SMU-20 fused units require three S&C Cat. No. 3097 SM-20

fuse end fittings and three S&C SMU-20 fuse units per fuse

compartments. ††

DBU fused units require three FP Cat. No. EFA-42 DBU end fit-

tings and three Eaton DBU fuse units per fuse compartment.

††

NX fused units: PSE fuse mountings will accommodate one

100 ampere Cooper (McGraw-Edison) type NX current limiting

fuse rated 13.5kV, one 80 ampere fuse rated 15kV, or one 40

ampere fuse rated 23kV. ††

†† For fuse application and ordering information refer to the

current issue of:

• S&C Bulletin 252-31

• Cooper (McGraw-Edison) Cat. Sect. 240-60

• Eaton (formerly Cutler-Hammer) Medium Voltage

Expulsion Fuses Catalog - CA01303001E.

Fuse

Manufacturer

Type†

Amperes, RMS 3-Phase

MVA

Sym

Max.

Cont.

Interrupting

Sym.

At 14.4 kV Nominal Voltage - 95kV BIL

S&C SM-4 200 12,500 310

S&C SM-20 200 14,000 350

Eaton DBU 200 14,000 350

Cooper (M-E) NX 50,000 620

At 25kV Nominal Voltage - 125kV BIL

S&C SM-4 200 12,500 540

S&C SM-20 200 12,500 540

Eaton DBU 200 12,500 540

Cooper (M-E) NX 50,000 1,080

At 35kV Nominal Voltage - 150kV BIL

S&C SM-20 200 8.45ka 505

Eaton (Cutler Hammer) DBU 200 8.45ka 505

35kV Nominal

SMU-20 fused units require three S&C Cat. No. 3097 SM-20

fuse end fittings and three S&C SMU-20 fuse units per fuse

compartments. ††

DBUfusedunits requirethreeFPCat. No.EFA-42DBUend fittings

and three Eaton DBU fuse units per fuse compartment. ††

Applicable to All Voltages:

Ratings expressed in RMS amperes asymmetrical are 1.6 times

the symmetrical values listed.

Unit overall ratings are limited to the lowest component rating.

SM-5 fuses cannot be used in PSE Pad-mounted Switchgear.

Consult Factory.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 14

Maintenance

FederalPacificPad-mountedSwitchgeardoesnotnormallyrequire routine

mechanical or electrical maintenance. However, the following are some

recommendations for enhancing continued service of the equipment.

1. Yearly mechanical exercising of the switch is recommended.

The switchgear must be completely de-energized from all sources

before any attempt is made to enter switchgear.

2. Check for cleanliness generally, but particularly for accumulation of

any foreign material on insulators.

Do not put grease on switch probe or puffer.

3. If the switch is closed into a short circuit within the making capacity

rating and the short circuit is cleared by circuit breakers or fuses,

the switch should not sustain damage that will require major repairs.

However, the switch should be inspected before returning to service

to determine switch condition.

Optional Features

Standard options may have been supplied that best serve the customer’s

needs and operating practices. These are listed below and, if included

will be identified by corresponding suffixes to the catalog number.

Base Spacer (option suffixes A2 through A9; AS for stainless steel base

spacers) Non-compartmented or compartmented.

• Fuse Storage Hooks (option suffix E1 through E5)

• Finish color (option suffix F3)

• Stainless steel enclosure exterior (option suffix F4)

• Hex-head security bolts (option suffix H)

• Key interlocks (option suffixes K1 through K4)

• Cable supports (option suffixes T3 and T4)

• Fault indicators (option suffixes T6 and T7)

• Copper bus (option suffix C)

WARNING

CAUTION

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 15

This Page Intentionally Left Blank

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 16

Every effort is made to ensure that customers receive an up-to-date instruction manual on the use of Federal Pacific products; however, from time to

time, modifications to our products may without notice make the information contained herein subject to alteration.

© 2014 Electro-Mechanical Corporation

Other manuals for PSE

3

Table of contents

Other FEDERAL PACIFIC Switch manuals

Popular Switch manuals by other brands

NETGEAR

NETGEAR ProSafe GSM7252PS Software administration manual

Opencockpits

Opencockpits A320 Sidestick PRO Installation & user manual

LINK-MI

LINK-MI LM-SW41-ARC Operation manual

BEAMEX

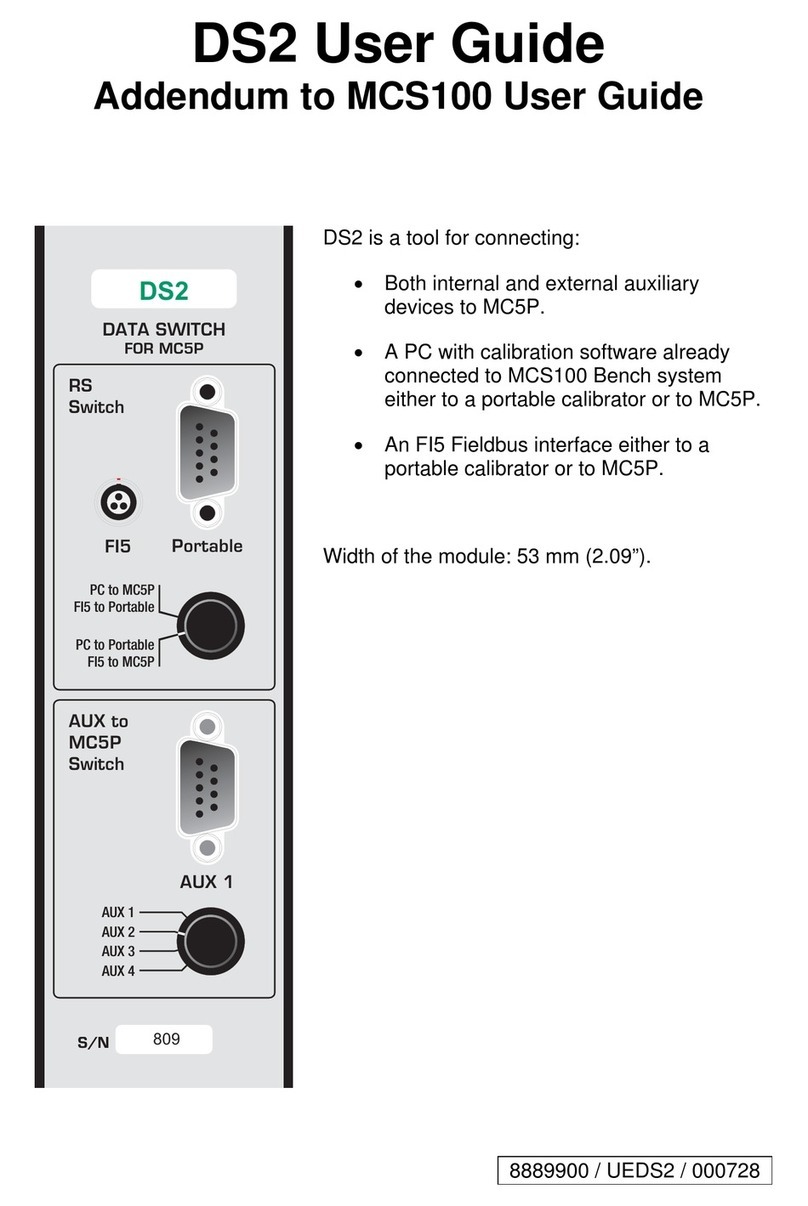

BEAMEX DS2 User guide addendum

Elnur Gabarron

Elnur Gabarron G CONTROL HUB Installation instructions and user guide

FRÄNKISCHE

FRÄNKISCHE DATALIGHT instruction manual