2562244A

REV. A 606

Printed in U.S.A.

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

FOR

VISIBEAM® II WIRELESS, REMOTE CONTROLLED SPOTLIGHT

SAFETY MESSAGE TO INSTALLERS AND USERS

People’s lives depend on your safe instal-

lation of our products. It is important to

read, understand and follow all instruc-

tions shipped with the products. In addi-

tion, listed below are some other important

safety instructions and precautions you

should follow:

• To properly install this kit: you must

have a good understanding of automo-

tive electrical procedures and systems,

along with proficiency in the installa-

tion and use of safety warning equip-

ment.

• DO NOT install equipment or route

wiring or cord in the deployment path

of an air bag.

• When drilling into a vehicle structure,

be sure that both sides of the surface

are clear of anything that could be

damaged.

• In order for the light to function prop-

erly, a separate ground connection

must be made. If practical, it should

be connected to the negative battery

terminal. At a minimum, it may be at-

tached to a solid metal body or chas-

sis part that will provide an effective

ground path as long as the light system

is to be used.

• Locate light control so the VEHICLE

and CONTROL can be operated safely

under all driving conditions.

• Do not attempt to activate or deacti-

vate light control while driving in a

hazardous situation.

• You should frequently inspect the light

to ensure that it is operating properly

and that it is securely attached to the

vehicle.

• File these instructions in a safe place

and refer to them when maintaining

and/or reinstalling the product.

Failure to follow all safety precautions and

instructions may result in property damage,

serious injury, or death to you or others.

Changes not expressly approved by the party

responsible for compliance could void the user’s

authority to operate the equipment.

Note: This equipment has been tested and found

to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference in a res-

idential installation. This equipment generates,

uses and can radiate radio frequency energy

and, if not installed and used in accordance with

the instructions, may cause harmful interfer-

ence to radio communications. However, there is

no guarantee that interference will not occur in

a particular installation. If this equipment does

cause harmful interference to radio or television

reception, which can be determined by turning

the equipment off and on, the user is encouraged

to try to correct the interference by one or more

of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equip-

ment and receiver.

- Connect the equipment into an output on a

circuit different from that to which the receiver

is connected.

- Consult the dealer or an experienced radio/TV

technician for help.

This product complies with FCC radiation expo-

sure limits set forth for an uncontrolled environ-

ment.

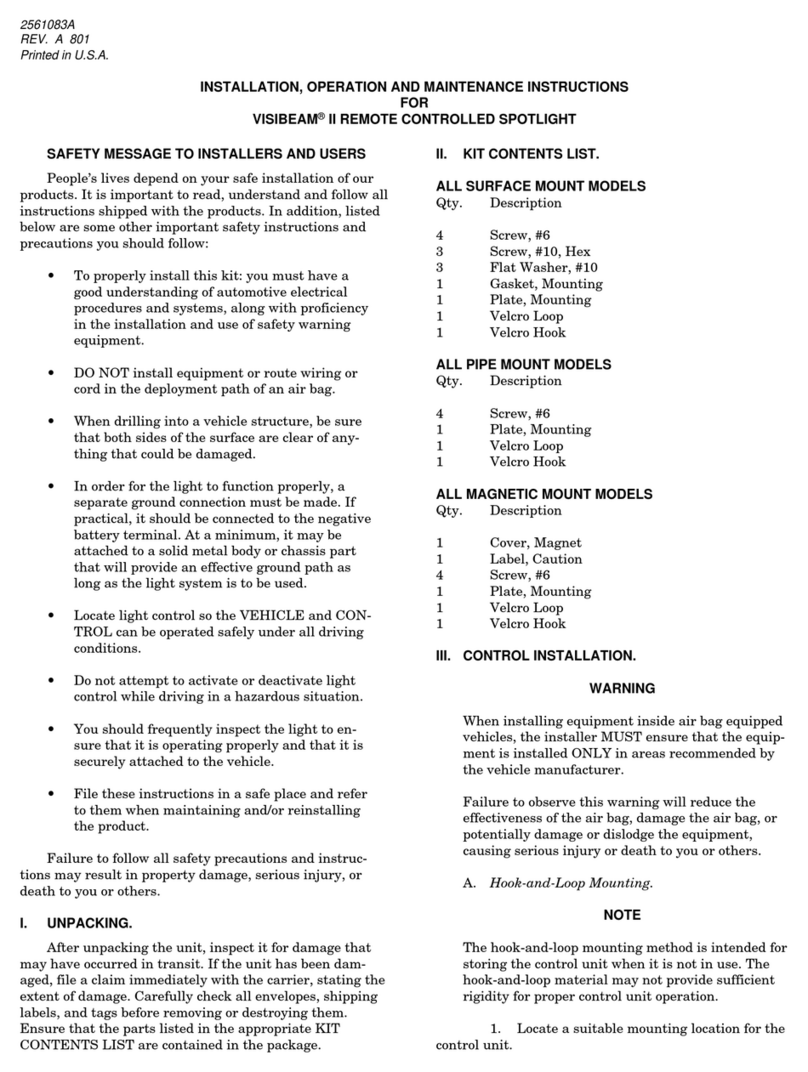

I. UNPACKING.

After unpacking the unit, inspect it for damage

that may have occurred in transit. If the unit has been

damaged, file a claim immediately with the carrier,

stating the extent of damage. Carefully check all

envelopes, shipping labels, and tags before removing

or destroying them. Ensure that the parts listed in the

appropriate KIT CONTENTS LIST are contained in the

package.