Mode 2 (Tow Mode)

1 - Alternate Double Flash D1, D4, D6, D8, P1, P4, P6,

P8 with D2, D3, D5, D7, P2, P3, P5, P7 with A

Center Out SignalMaster.

2 - Alternate Double Flash D1, D4, D6, D8, P1, P4, P6,

P8 with a Single Flash Of D2, D3, D5, D7, P2,

P3, P5, P7 with A Signalmaster Pattern Of S1, S2,

S7, S8 Alternating with S3, S4, S5, S6.

3 - The Lightbar is split into 4 Quadrants: A, B, C, &

D and are flashed as follows: A, C, B, D, A, C, B,

D…...Each block is Single Flashed at 50ms per

Flash.

4 - Double Quadrant Flash, followed by a full lightbar

Quad Flash, followed by a single Quadrant Flash.

5 - Quad Flash – Wrap-Around Inside to Outside

– Followed by a full lightbar Quad Flash.

6 – Wrap-Around Inside to Outside – 30ms Per Head.

7 - Alternate Full Flash followed by Tow Mode Pattern

2.

8 - Quad Flash – Alternate Quad Flash Each side of

bar.

9 – Wrap-Around Inside to Outside to Inside followed

by a Wig/Wag Alternate Flash followed by a Full

Quad Flash.

10 –Wrap-Around Inside to Outside followed by a Quad

Flash.

Mode 3 (On Scene Mode)

1 - Alternate Double Flash outside pairs with Quad

Flash inside pairs and End Caps.

2 - Quadrant Flash, followed by a Wrap-Around Inside

to Outside, followed by a full lightbar Triple Flash.

3 - Increasing Rate Alternating Flash, followed by a

full lightbar Triple Flash.

4 - Alternate Triple Flash entire bar.

5 – Alternate Double Flash S1, S2, S3, S4, D1, D4, D6,

D8, P1, P4, P6, P8 with S5, S6, S7, S8, D2, D3, D5,

D7, P2, P3, P5, P7.

6 – Alternate Double Flash S1, S3, S5, S7, D1, D4, D6,

D8, P1, P4, P6, P8 with S2, S4, S6, S8, D2, D3, D5,

D7, P2, P3, P5, P7, followed by a Wrap-Around

Inside to Outside.

7 – Double Flash S1, S3, S5, S7, D1, D4, D6, D8, P1,

P4, P6, P8, followed by a Wrap-Around Inside to

Outside, followed by a Double Flash of S2, S4, S6,

S8, D2, D3, D5, D7, P2, P3, P5, P7, followed by a

Wrap-Around Outside to Inside.

8 – Wrap-Around Inside to Outside, followed by an

Alternate Double Flash, followed by a Wrap-

Around Inside to Outside, followed by a full

lightbar Double Flash.

9 - Full Lightbar Quad Flash, followed by a Wrap-

Around Inside to Outside, followed by an Alternate

Double Flash, followed by a Wrap-Around Inside to

Outside.

10 –Alternate Triple Flash entire bar twice, followed

by a Wrap-Around Inside to Outside, followed by

an Alternate Double Flash, followed by a Wrap-

Around Inside to Outside.

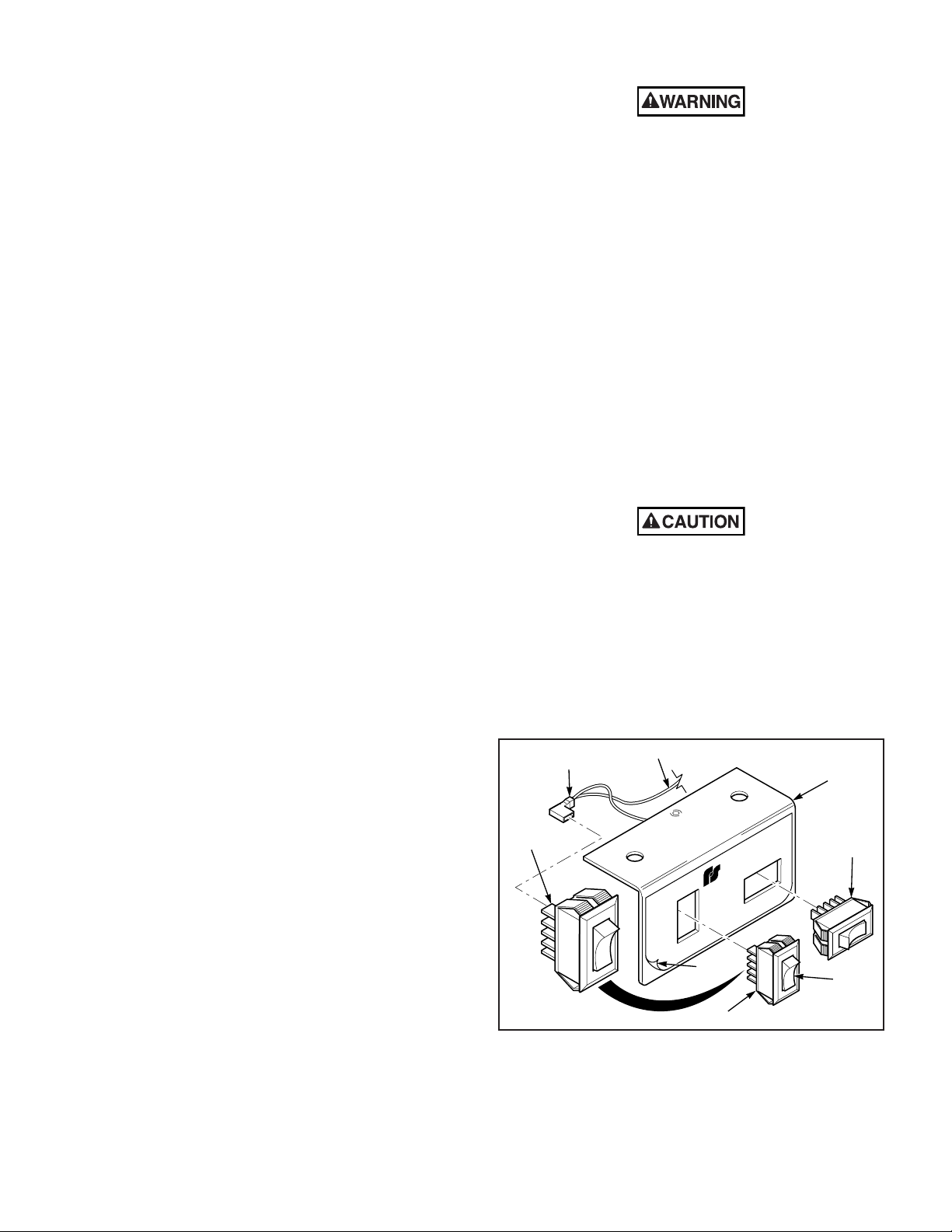

Programming is accomplished as follows:

a. Apply 12VDC to the mode input to be

programmed. The bar will flash the current pattern.

b. Momentarily apply 12VDC to the

Program (PINK) wire. The lightbar will stop briefly, then

the entire lightbar LEDs will flash the number of the new

flash pattern. The lightbar will then begin to flash the

newly selected pattern.

c. Repeat step b until the desired pattern is

selected.

d. To program the other modes, apply

12VDC to the desire mode input and repeat steps b and c.

C. Function Activiation – SignalMaster.

1. SignalMaster Center-Out (Warn)

Applying 12VDC to the SignalMaster Center-

out (BLACK) wire will cause the SignalMaster lights to

illuminate from the Center-out.

2. SignalMaster Left to Right

Applying 12VDC to the SignalMaster Right

(BIEGE) wire will cause the SignalMaster lights to

illuminate from the Left to the Right.

3. SignalMaster Right to Left

Applying 12VDC to the SignalMaster Left

(WHITE) wire will cause the SignalMaster lights to

illuminate from the Right to the Left.

4. SignalMaster Mode Programming

Each of the SignalMaster modes can be

programmed to operate with one of three available flash

patterns. These patterns include: single light chase arrow,

double light chase arrow, and single light solid arrow. Each

of these patterns is available in four speeds for a total of

twelve selectable flash patterns per SignalMaster Function.

Patterns are listed below:

LEFT ARROW: (Default Left Arrow Pattern is 1)

1- Solid Left Arrow – 250mS between flashes

2- Double Left Arrow – 250mS between flashes

– Double Flash at end

3 - Single Left Arrow – 250mS between flashes

– Double Flash at end

4 - Solid Left Arrow – 200mS between flashes

5 - Double Left Arrow – 200mS between flashes

– Double Flash at end

6 - Single Left Arrow – 200mS between flashes

– Double Flash at end

7 - Solid Left Arrow – 150mS between flashes

8 - Double Left Arrow – 150mS between flashes

– Double Flash at end

9 - Single Left Arrow – 150mS between flashes

– Double Flash at end

10 -Solid Left Arrow – 100mS between flashes

11 -Double Left Arrow – 100mS between flashes

– Double Flash at end

12 -Single Left Arrow – 100mS between flashes

– Double Flash at end

-3-