Feed Mill FME-WBHP-2300 User manual

USER MANUAL

WORKBENCH WITH HYDRAULIC PRESS

FME-WBHP-2300

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 2 -

TABLE OF CONTENTS

1. GENERAL INFORMATION 3

1.1 Machinery Information 3

1.2 IIB-Marking 4

2. INTRODUCTION 5

2.1 Staff 5

2.2 Individual Means Of Protection 6

2.3 Workplace 6

2.4 General Safety Instructions 6

2.5 Operational Restrictions 7

2.6 Protection Of The Environment 7

2.7 Calamities 7

2.8 Marking 8

2.9 Transport 9

3. INSTALLATION AND COMMISSIONING 10

3.1 General 10

3.2 Commissioning 10

4. SPECIFICATIONS 11

4.1 Machine Specifications 11

4.2 Conditions Of Use 12

4.3 Machine-Overview 12

5. MAINTENANCE AND REPAIR 13

5.1 Introduction 13

5.2 Security During Maintenance 13

5.3 Maintenance Instructions 14

5.4 Repairs 15

5.5 Storage 15

6. CONTROL 16

7. ELECTRICAL DIAGRAM 17

8. EC-DECLARATION OF CONFORMITY 18

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 3 -

1. GENERAL INFORMATION

This user manual.

-----------------------------------------------------------------------------------------------------------------------------

This user manual has been compiled in English by:

FEED MILL SERVICES & EQUIPMENT BV

Version: V2018

Version date: October 2018

Copyright: Feed Mill Services & Equipment BV, Deurne, 2018

Nothing in this user manual may be reproduced in any form whatsoever without the permission

of the manufacturer.

1.1 Machinery Information

This user manual belongs to the machine of the type as indicated on the cover page.

-----------------------------------------------------------------------------------------------------------------------------

This Workbench with Hydraulic Press, FME-WBHP-2300, is produced by:

FEED MILL SERVICES & EQUIPMENT BV

Dr. H. van Doorneweg 38

5753 PM Deurne

The Netherlands

Tel: +31 (0)493 310 059

-----------------------------------------------------------------------------------------------------------------------------

Date of issue at Feed Mill Services & Equipment BV: October 2018

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 4 -

1.2 IIB-Marking

The workbench with hydraulic press has been constructed and implemented by Feed Mill

Services & Equipment BV according to the relevant European directives on safety and health.

This means that the machine complies with the IIB-marking. The Declaration of Conformity

(included in this manual) indicates the guidelines applicable to this machine.

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 5 -

2. INTRODUCTION

This user manual is a support to allow you to handle your workbench with hydraulic press. You

should read this documentation completely. For additional information we ask you to contact the

Feed Mill Services & Equipment BV.

This user manual is part of the delivery and must remain in good hands while using the

workbench with hydraulic press. There must be a copy available for those working with this

press. When the workbench is surrendered, it is intended that this user manual is also

transferred.

Treat this instruction carefully. It is not allowed to change or delete pages. Feed Mill Services &

Equipment BV reserves the right to replace parts of this manual, in the context of the

improvement of the product, at any time without directly providing a new edition.

2.1 Staff

Certain operations can only be operated or made by qualified or trained staff. For the description

of the qualification level the following standard features are used:

- The qualified staff must have sufficiently technical knowledge and/or work experience to be

able to recognize and prevent potential danger (engineers and technicians).

- The staff must be adequately trained and/or controlled by the qualified staff to identify and

prevent the potential danger (the operated and maintenance staff). They should have the

following qualifications:

1. They must be trained to operate the product safely. They must be capable to

operate the equipment according to standard safety regulations.

2. They must maintain the product and use the safety devices as described in this

manual.

The customer and/or user is/are required to ensure, in particular, that the press uses:

- that the staff has read and understood this manual.

- that the staff follows the instructions as given in this manual.

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 6 -

2.2 Individual Means Of Protection

The staff, mentioned in the previous paragraph, must wear protective clothing which is

necessary for the employment of the press.

Safety shoes are required. The need for wearing hearing protection, eye protection and a helmet

can be defined by the user.

It isn’t allowed to wear clothing that can get caught in moving machine parts.

2.3 Workplace

If workplace is intended and requires a space of at least 1 metre around the entire workbench.

From here, all operations can be performed.

2.4 General Safety Instructions

The following provisions and recommendations are primarily based on observing the rules of

the safety regulations mentioned in this manual.

Feed Mill Services & Equipment BV isn’t responsible for possible damage to persons or goods

related to ignoring of the safety regulations and instructions in this manual.

Transportation, installation, operation and maintenance of the workbench with hydraulic press

can only be performed by the staff which meets the conditions described in the previous section.

The workbench with hydraulic press is designed and constructed so that it can be safely used

and maintained. This applies to the application, the circumstances and the rules as described

in this manual. Reading this manual and following the instructions is therefore necessary for

anyone working with or to this machine.

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 7 -

Additional safety measures may be prescribed by the company or country in which the

machine is in use. This concerns in particular working conditions. This manual describes not

how to comply, however, the necessary information about the machine is given.

A distinction is made in this manual between normal use and other work on the machine. The

reason for this is that, especially regarding safety, the service personnel are subject to

different requirements than to operators.

2.5 Operational Restrictions

Attention is hereby drawn to the following applications, for which the machine not

suitable:

- Processing of products other than those prescribed

- For functions other than those defined

Consequences regarding the use of the countersink machine in any application is not the

responsibility of Feed Mill Services & Equipment BV in any form whatsoever.

All claims for damage caused by unintended use are not permitted. Here the owner/responsible

is responsible for itself.

2.6 Protection Of The Environment

No special hazards are associated with the use, maintenance and demolition of this

workbench with hydraulic press, taking into account the prescribed (safety) measures.

The machine itself does not contain any substances that may pose a danger to individuals.

2.7 Calamities

By calamities is meant: fire, flood and the like.

Measures must be taken in an emergency situation that don’t endanger persons or goods. The

usual extinguishing agents can be used.

In the event of fire, care must be taken to ensure that the galvanizing machine isn’t connected

to the electrical circuit when taking measures.

The machine must be de-energized when there is damage to the equipment. Keep moisture

away from live parts. Moisture can lead to short circuit.

Repairs and work on electrical installations may only be carried out by a qualified electrician.

Ensure that hot surfaces can’t be touched. Touching hot surfaces can lead to severe burns.

Improper use of environmentally-friendly and hazardous substances can cause serious

damage to the environment.

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 8 -

2.8 Marking

The workbench is equipped with a type plate with a manufacturer-known and unique type

number. The type plate gives various information for example about the year of construction

and the manufacturer's details.

If the following warning sticker is indicated, attention must be paid to electrical danger during

repair or maintenance.

For indications on the standard parts see their own specifications.

Warnings:

- Read the user manual carefully before turning on the hydraulic press.

- When products fall during import, they must be removed as soon as possible. Products

that remain can be an obstacle to a subsequent import cycle.

Unreadable labels, symbols, etc. can lead to danger. They can become dirty or unreadable

over time. Therefore:

- Labels, symbols, etc. must be clearly legible.

- Damaged labels, symbols, etc. must be replaced. For this we advise you to contact Feed Mill

Services & Equipment BV.

Figure 2.8.1

Example of a type plate

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 9 -

2.9 Transport

Before shipment each machine has been examined and checked thoroughly. Check at reception

of the goods the integrity and the contents of the package to ensure that nothing has been

damaged during the transport. Check also if the delivery correspondents to the order.

When unloading should carefully be made to the equipment.

Report any defects or damage immediately to Feed Mill Services & Equipment BV and to the

carrier responsible for the damage during the transport.

An objection to any defects or damages must be made within 10 days after receipt of the goods.

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 10 -

3. INSTALLATION AND COMMISSIONING

3.1 General

Requirements for installation are:

- a stable surface that is a burden of at least ± 3000 kg can carry

- the machine must be set up in such a way that there is sufficient space to carry out control

and/or repair work

- the machine can be picked up by a forklift, which is certainly a burden of ± can carry 1500 kg.

3.2 Commissioning

For the first use after a major overhaul, repair or long-term storage, machine should be

recommissioned.

Check:

- Whether all parts and accessories are present

- Whether all moving parts can run freely

- Correct direction of rotation and connection of the motors

- Damage, especially external electrical wiring

- The correct operation of all mechanical control devices

- The correct settings corresponding to the type of product to be processed

- Whether all hydraulic connections still be in tact

Warning!

The risks of improper functioning are greater than normal during business counting. Take

additional safety measures where necessary.

Afbeelding 3.1.1

Heftruckbeugels

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 11 -

4. SPECIFICATIONS

4.1 Machine Specifications

Machine dimensions

Length: ± 2000 mm

Width: ± 1700 mm

Height: ± 2500 mm

Machine weight: ± 1250 kg

Motor power: 1.5 kW

Voltage: 230 V

Tank capacity: 8 L

Max. hydraulic pressure: 210 bar

Speed: <10 mm/sec

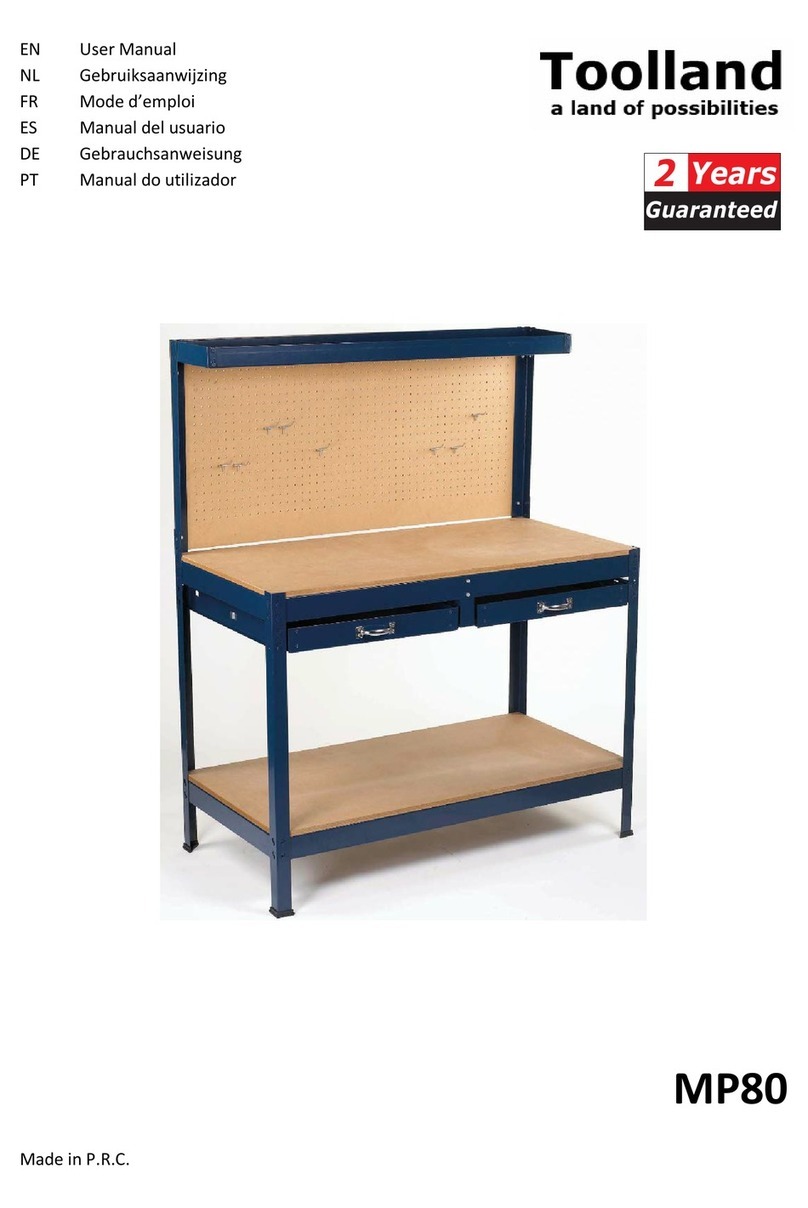

Figure 4.1.1

Workbench with hydraulic press

FME-WBHP-2300

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 12 -

4.3 Conditions Of Use

- Ambient temperature: +5 till +40 Degrees Celsius

- During transport: 0 till +45 Degrees Celsius

- Storage temperature: +10 till +60 Degrees Celsius

The machine is not intended for use in the open air.

The machine is not suitable for an explosive atmosphere.

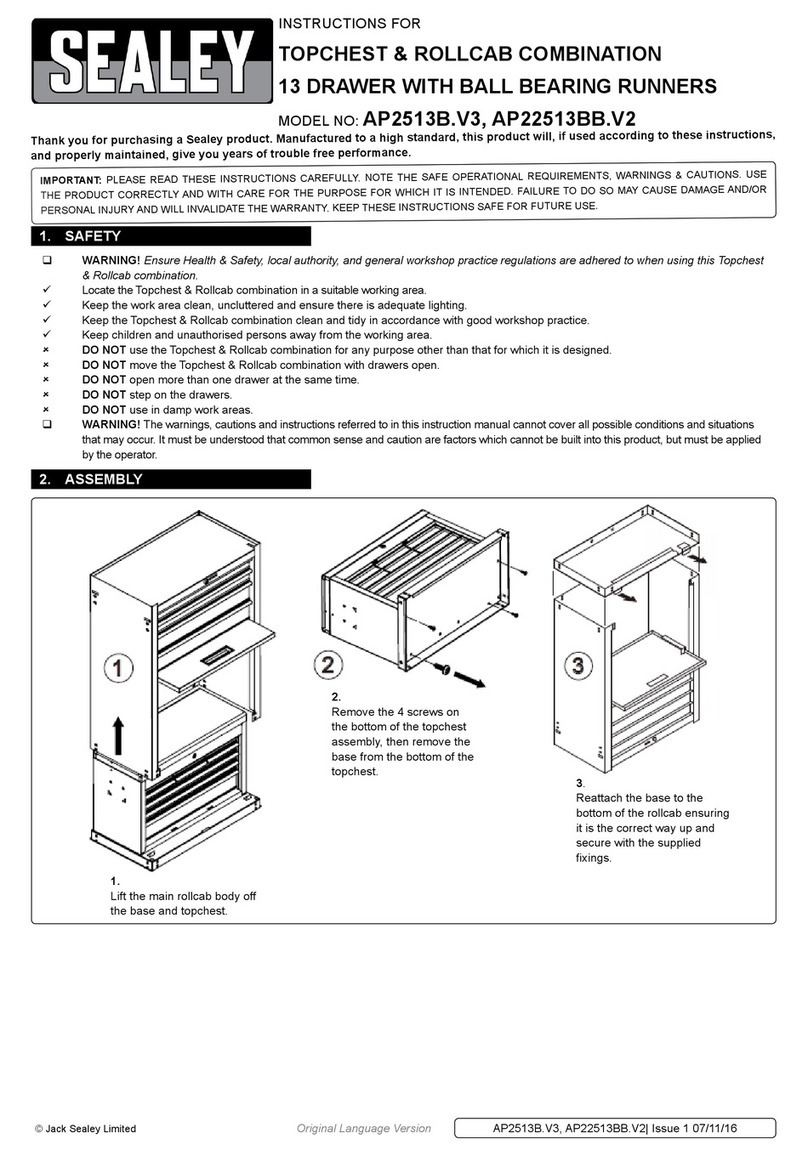

4.4 Machine-Overview

1. Manometer 5. Vise

2. Hydraulic Cylinder 6. Drawer Unit

3. Handle 7. Aggregate

4. Terminal box incl. 8. Control panel incl. Emergency stop

on/off switch (rear side)

1

2

3

4

8

5

6

7

Figure 4.3.1

Workbench overview

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 13 -

5. MAINTENANCE AND REPAIR

5.1 Introduction

The appropriate maintenance is important for a long life of the hydraulic press and its

components, under good and functional conditions. It also guarantees the necessary long-term

reliability.

5.2 Safety During Maintenance

The maintenance work of the countersink machine requires a few rules of conduct, namely:

- All maintenance work must be carried out by qualified personnel (see section 2.1).

- Maintenance work must be performed when the equipment is energized. The whole of

the operational and maintenance staff must adhere strictly to the rules for the prevention

of accidents of the equipment.

- Allow to cool hot surfaces

- Always wear safety shoes, protective clothing and other necessary equipment. During

maintenance work do not wear jewellery or loose clothing.

- Use only original parts for proper operation of the equipment.

- Do not use abrasive or corrosive materials or solvents when cleaning the hydraulic

press. Do not use any cleaning agents that affect the parts and/or cause corrosion.

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 14 -

5.3 Maintenance Instructions

Daily maintenance:

- Check the machine's business situation completely, especially the conduction rails

lubrication system

- Keep the workbench clean. A clean workplace is safer and more pleasant.

Weekly maintenance:

- Check on traces of wear, which can be visually identifiable by product/machine

damage

Other maintenance:

- Filling the reservoir. Fill the tank with clean oil (Viscosity oil: VG 46) to the maximum

level. This can be done by unscrewing the steel sheet and removing it from the frame.

- The first service must be carried out 100 operating hours after commissioning, in which

case the filters must be replaced and the oil checked. Furthermore, the entire installation

must be carefully checked. Follow the following points for attention:

- After the first service, major maintenance must be carried out after 300 operating hours

and then every 500 running hours, or sooner after the load and the operating conditions,

but in any case annually.

- The filters and the oil must be replaced with great maintenance.

Figure 5.3.1

Aggregate at the bottom of the workbench

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 15 -

5.4 Repairs

During the warranty period, repairs can only be carried out under the manufacturer's direction.

Each repair must be kept in a machine log. All parts that are replaced must meet the

specifications of the original components at least.

5.5 Storage

There are no special requirements for storage, a cool and dry space is most suitable. After a

long storage, the machine must be inspected by a technician for commissioning.

If the machine is brought from a cold in a warm space, it can occur during condensation (also

internally in electrical components).

Direct switching can cause damage to the machine and danger to the operator. Let the

machine first acclimatize.

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 16 -

6. CONTROL

•Switch On

- Plug the power plug into the socket

- Press the 'On/Off' button on the back of the machine to switch on the machine (see figure

6.1)

•Control

- Press and hold the black button (bottom) on figure 6.2 to send the cylinder 'downwards’

('press-position')

- Press and hold the white button (bottom) on figure 6.2 to send the cylinder 'up’ ('rest-

position')

•Switch Off

- Press the 'On/Off' button on the back of the machine to switch off the machine (see figure

6.1)

•Emergency

- In an emergency situation, press the 'Emergency Stop' (red button) shown in figure 6.2

Figure 6.1

‘On/Off’ button

Figure 6.2

Control panel

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 17 -

7. ELECTRICAL DIAGRAM

TECHNICAL CHANGES RESERVED

Feed Mill Services & Equipment BV –Tel. +31 (0)493 310 059 –www.feedmillservices.eu - 18 -

8. EC-DECLARATION OF CONFORMITY

This Declaration of conformity and the CE marking on the type plate are valid for the workbench with

hydraulic press which is part of the Feed Mill Services & Equipment BV delivery. When this workbench

is built into a larger system, the manufacturer of this system (this can also be the operator) must carry

out the conformity review process for this large system according to machinery Directive 2006/42/EC,

the Declaration of Conformity and provide the system with the CE marking.

We

Feed Mill Services & Equipment BV

Dr. Van Doorneweg 38

5753 PM DEURNE

The Netherlands

Declaring that workbench with hydraulic press FME-WBHP-2300,

In accordance with the EU Directives:

- “Machines” 2006/42/EC

- “Low voltage directive” 2006/95/EC

- “EMC directive” 2004/108/EC

Is designed and manufactured to the following standards:

- NEN-EN-ISO 12100-1/-2 Safety of Machinery –General Design Principles, Part 1 and 2

- NEN-EN-ISO 13857 Safety of Machinery –Safety distances to prevent hazard zones being

reached by upper and lower limbs

- NEN-EN 349+A1 Safety of Machinery –Minimum gaps to avoid crushing of parts of the

human body

- NEN-EN 982 Safety requirements for fluid power systems and their components -

Hydraulics

- NEN-EN 13849-1 Safety of machinery –Safety-related parts of control systems

- NEN-EN 14121 Safety of machinery –Risk assessment

- NEN-EN 60204-1 Safety of machinery –Electrical equipment of machines –Part 1

General requirements

Manufacturer

Mr. Frank Voss

Managing Director

Table of contents

Popular Tools Storage manuals by other brands

Wolfcraft

Wolfcraft 6156 owner's manual

Harbor Freight Tools

Harbor Freight Tools U.S. GENERAL 64166 Owner's manual & safety instructions

Forest-Master

Forest-Master UWWS manual

Seville Classics

Seville Classics UltraHD 20594 Assembly instructions

Costway

Costway HW67581 user manual

Office Star Products

Office Star Products AVE SIX EMERY EMEB quick start guide