Forest-Master UWWS User manual

Model: UWWS

IMPORTANT: Read this manual fully before assembly and

use and observe all safety rules and operating instruc-

tions

Forest Master Universal

Woodworking Station

Forest Master Model: UWWS2

Your Product

Thank you for purchasing the Forest Master Universal Woodworking Station. We

hope you are 100% satised with your product but if you have any questions or

queries, please don’t hesitate to contact us:

Forest Master Ltd Tel: +44 (0)191 265 5000

Heaton Website: www.forest-master.com

Newcastle Upon Tyne

NE6 5XB

About Your Product

The Forest Master Universal Woodworking Station is used for milling logs into all

kinds of lumber. A chainsaw is mounted to the chainsaw frame that comprises of

two C-shaped runners and an adjustable support bar. The runners slot onto the

two guide rails of the chainsaw mill, allowing the chainsaw to glide freely along the

horizontal plane, with no movement in the vertical plane, to give the smoothest

and most accurate cut possible. The chainsaw mill can be used in a variety of ways

outlined below:

• Milling slabs of wood from a large log.

• Milling multiple boards by clamping a number of slabs together, turning them

onto the side and milling o the bark on both sides.

• Creating fence posts in a quick and ecient way by drilling bolts into both

ends of the log resting the bolts into the V shaped slots. This allows the log to

be milled, unsecured, rotated 90° re secured and the milled again for all four

sides.

• Clamping a log in the vertical position to mill log coins.

• Used as a sawhorse by placing a log into the four, toothed V shaped sections

and cutting vertically with a chainsaw.

• Attaching the Forest Master Router Bed to the two guide bars to the surfaces

and edges of the wood can be routed (requires extra parts you can purchase

from Forest Master).

• It can also be used as a mitre saw stand by attaching the mounting clamps to

the frame and bolting a mitre saw to the clamps with the M6 coach bolts and

fastenings. Details of this can be found in the mitre saw stand manual.

No matter how you use your workbench, please read the safety instructions and

guidelines before use.

Forest Master Model: UWWS 3

Contents

Title Page

Specications 4

Safety 5

Parts List 6

Assembly 9

Adjustments 14

Operation 18

Warranty 28

Contents

Forest Master Model: UWWS4

Specications

Specications

Maximum Guide Bar Width 680mm

Minimum Guide Bar Width 400mm

Maximum Log Length (Up to 12ft with extension sold

separately)

1450mm

Minimum Log Length 200mm

Maximum Log Width 250mm - 520mm

Maximum Cutting Depth 400mm

Minimum Cutting Depth 15mm

Forest Master Recommendations for Chainsaw Milling

After thorough testing with this product, Forest Master can condently give the fol-

lowing recommendations to achieve the best results when chainsaw milling.

• A ripping chain is required for the best nish due to the acute angle of the cut-

ting blades.

• A low-prole bar can make the cutting process faster, but may have eects on

the nish of the cut.. A low-prole bar has an approximate cut thickness of

6mm whereas a standard 3/8 or .404 bar has a cut thickness of 8mm.

• The slower the cut the better the nish - be patient when milling timber, it

can be a slow process. Forcing the chainsaw can lead to a poor nish or bend-

ing within the bar which leads to the saw becoming stuck or being overworked.

• A chainsaw as little as 52cc can be used for milling but be aware, the more

powerful the chainsaw, the quicker and easier the milling process.

• Ensure the chain blades are always sharp before cutting. They must be sharp in

order to provide an ecient cut.

• The width of the guidebars and chainsaw clamps should be as small as possi-

ble and as close to the wood on each side to produce the best nish. By hav-

ing a lot of free space between the wood and where the chainsaw is clamped,

this gives the chainsaw bar space to ex, causing problems during the cut and

adversely eecting the nish.

Forest Master Model: UWWS 5

Safety

Safety Instructions

These instructions are intended for your safety. Please read them carefully before

using the workbench and retain for future reference.

Before You Start

• Check the box and make sure all the listed parts are included. If not, contact

the retailer for assistance.

• Remove all plastic bags and packaging and dispose of them safely.

• Retain the instruction manual for future reference.

Important Safety Information

• Always check the tightness of nuts and bolts prior to use.

• Make sure the chainsaw mill is positioned on a rm and stable surface before

operating. It is best to position the frame so you are cutting downhill.

• Make sure all the adjustment thumbscrews are tight before cutting.

• Always wear appropriate safety gear; gauntlets, safety glasses, ear protection,

chainsaw trousers, safety boots and a dust mask should always be worn when

operating the chainsaw mill.

• Always start the chainsaw on the ground and then lift onto the guide bars with

your hands away from the throttle trigger - use the support bar above the

chainsaw to lift.

• Never assemble, dismantle or readjust any parts of the chainsaw mill while the

chainsaw is still running.

• Be extremely careful of the chainsaw cutting chain while in use.

• Any bystanders or pets must be a distance of at least 10 metres from the

chainsaw mill when in operation.

• Do not operate under the inuence of drugs, alcohol, medication or if you feel

tired or drowsy.

• Never operate the chainsaw mill in an enclosed area - fumes from the exhaust

contain carbon monoxide which is a toxic, odourless and potentially fatal gas.

• Always turn the chainsaw o before dismounting from the guide bars.

• Always operate with one hand on the support bar and one hand on the

chainsaw.

• Never leave the chainsaw running unattended.

• You must be over the age of 18 to operate the chainsaw mill.

• Don’t overreach when milling - only operate the chainsaw from a comfortable

position.

• Don’t force the chainsaw through the cut - apply some force but ease the

blade through the wood. Over forcing the blade can cause injury and damage

the chainsaw.

The warnings, cautions and instructions referred to in this manual cannot cover

all possible conditions and situations that may occur. It must be understood

that common sense and caution must be applied by the operator when using the

chainsaw mill.

Forest Master Model: UWWS6

Parts List

Part

No.

Name Picture Qty.

1. Base Frame 1

2. Crossbeam 2

3. Guide Bars (1490mm) 2

4. Vertical Guide Bar Support 4

5. Left Chainsaw Clamp 1

6. Right Chainsaw Clamp 1

7. Chainsaw Frame Handle 1

Forest Master Model: UWWS 7

Parts List

Part

No.

Name Picture Qty.

8. Gripping Plates 4

9. Perpendicular Telescopic Slot

(PTS)

2

10. Vertical V-Slot 2

11. Horizontal V Slot 2

12. Vertical Sawhorse 2

13. Horizontal Sawhorse 2

14. Step Gauge 1

Forest Master Model: UWWS8

Part No. Name Qty.

15. M8 Hex Bolt 8

16. M8 Cap Head Bolt 8

17. M8 Washer 24

18. M8 Nyloc Nut 16

19. M8 Thumbscrew 16

20. Mounting Clamps (Use with Mitre Saw) 2

21. M6 Coach Bolt (Use with Mitre Saw) 4

22. M6 Washer (Use with Mitre Saw) 4

23. M6 Spring Washer (Use with Mitre Saw) 4

24. M6 Nut (Use with Mitre Saw) 4

Parts List

Forest Master Model: UWWS 9

Assembly

Assembly of the Frame

1. Open the legs of the frame (1) by pressing the pin

on the side of the frame and folding out the legs un-

til the locking pins click into place in the corresponding holes.

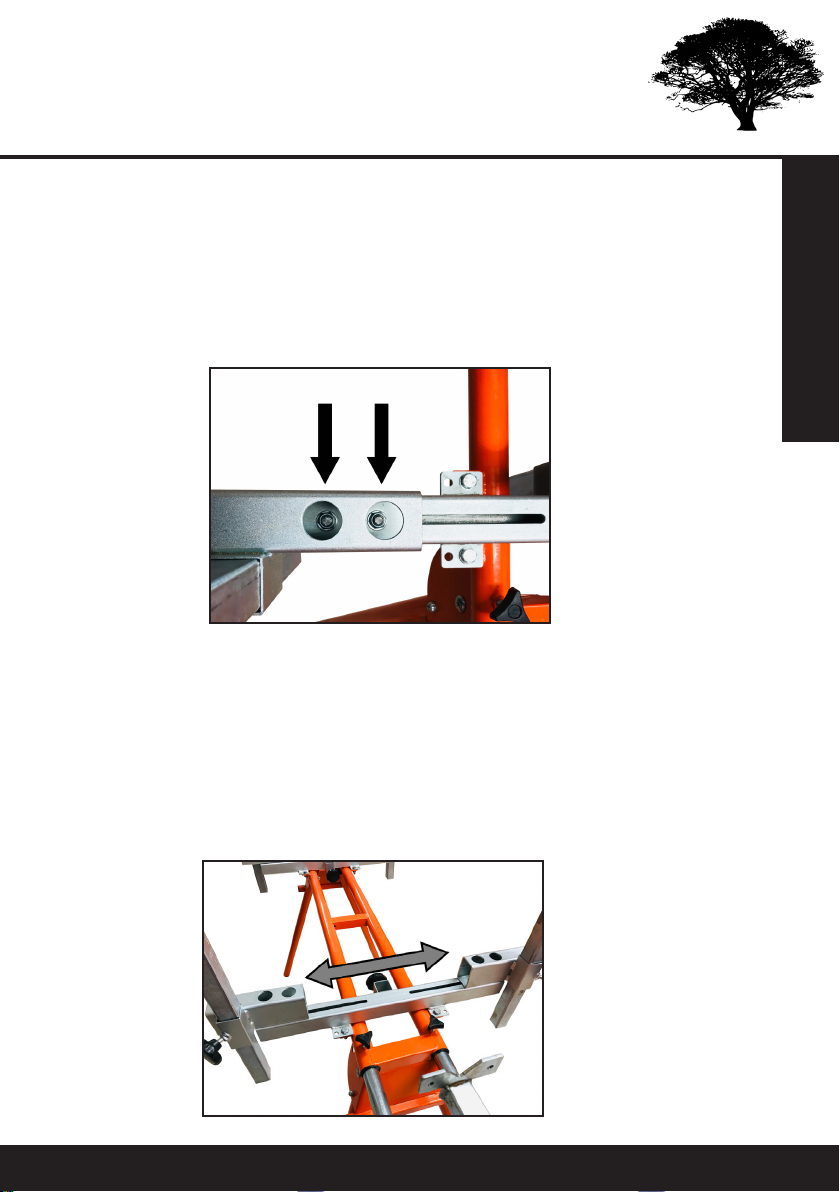

NOTE: For the next two steps it is essential that the bolts are loosely fastened

to allow for movement between the materials. This is so that the guide bars can

be calibrated and then tightened later to allow for smooth telescopic adjust-

ment in use.

2. Bolt the two crossbeams (2) to the base frame (1) with the middle telescopic

slots inwards, using the M8 hex bolts (14), M8 washers (16) and M8 nyloc nuts

(17). Two washers should be used for each bolt, one in between the crossbeam

and the frame and one in between the frame and the nut.

REMEMBER: bolts should be loosely fastened.

Forest Master Model: UWWS10

Assembly

3. Bolt the vertical guide bar supports (4) to the guide bars (3) by threading the

M8 cap head bolts (15) through the large holes of the guide bars to fasten into

the small holes and the plate of the vertical guide bars. The M8 cap head bolts

should situate inside the guide bars and be fastened on the outside with the M8

washers (16) and M8 nyloc nuts (17).

REMEMBER: bolts should be loosely fastened.

Forest Master Model: UWWS 11

Assembly

4. Slide the assembled guide bars (3, 4) into the telescopic slots on the outside of

both cross beams (2), making sure the large holes on the guide bars are facing

outwards and the nuts are facing inwards. Drop both guide bars half way down,

using the full height of the smaller side of the step gauge (19) (pg. 14) and

tighten all four thumbscrews on the slots to lock in place.

Forest Master Model: UWWS12

Assembly

5. Make sure the guide bars are the exact same height from the cross beams at all

four supports and then tighten all the loose bolts, starting with the crossbeams

and then the vertical guide bar supports. This should calibrate the guide bars to

allow for smooth vertical adjustment.

6. All the attachments are available to be mounted as desired in the telescopic

slots found in the middle of the crossbeams and at the end of the dual rails

(see adjustments and setup section).

Forest Master Model: UWWS 13

Assembly of the Chainsaw Frame

1. Loosen the thumbscrews on both the left chainsaw clamp (5) and the right

chainsaw clamp (6) and slide them onto the chainsaw frame handle (7) so that

they are facing the same way.

2. Loosen the two M8 nuts on both chainsaw clamps so that you can slide your

chainsaw bar in between the two serrated plates inside the clamps so that the

chainsaw frame handle is situated behind the chainsaw. Make sure the serrated

plates rest only on the bar of the chainsaw and not the chain nor the sprocket

on the nose of the bar.

3. Slide the clamps along both the chainsaw frame handle and the chainsaw bar

itself to the desired position and then tighten the thumbscrews and the M8

bolts on both clamps.

4. Check the chain can move freely through both clamps by manually turning the

chain.

Assembly

Forest Master Model: UWWS14

Adjustments

Setup and Adjustments

Setting the Height of the Guide Bars

For the height to be set correctly, the guide bars need to be of equal distance from

the crossbeams at all four vertical guide bar supports. This can be done one guide

bar at a time.

• To do this, loosen the thumbscrews on the crossbeams for the two vertical

supports of the guide bar, so that it can move freely up and down the in slots.

• Place the step gauge in between the upper section of the crossbeam and the

guide bar and make sure the at edge of the step gauge is ush with the cross-

beam.

• Drop the guide bar down onto the step gauge at the step that is the desired

height and tighten the thumbscrew. Repeat for the other vertical support of the

same guide bar. Then do the same process for the second guide bar and make

sure the height is the same at all four vertical supports.

• You can make your own gauges for specic heights you may require by cutting

blocks of wood down to size and using them in the same manner.

• The lowest the guide bars can be set is the smallest step on the gauge. If thin-

ner cuts are required then move the gripping plates underneath the wood up to

suit.

Forest Master Model: UWWS 15

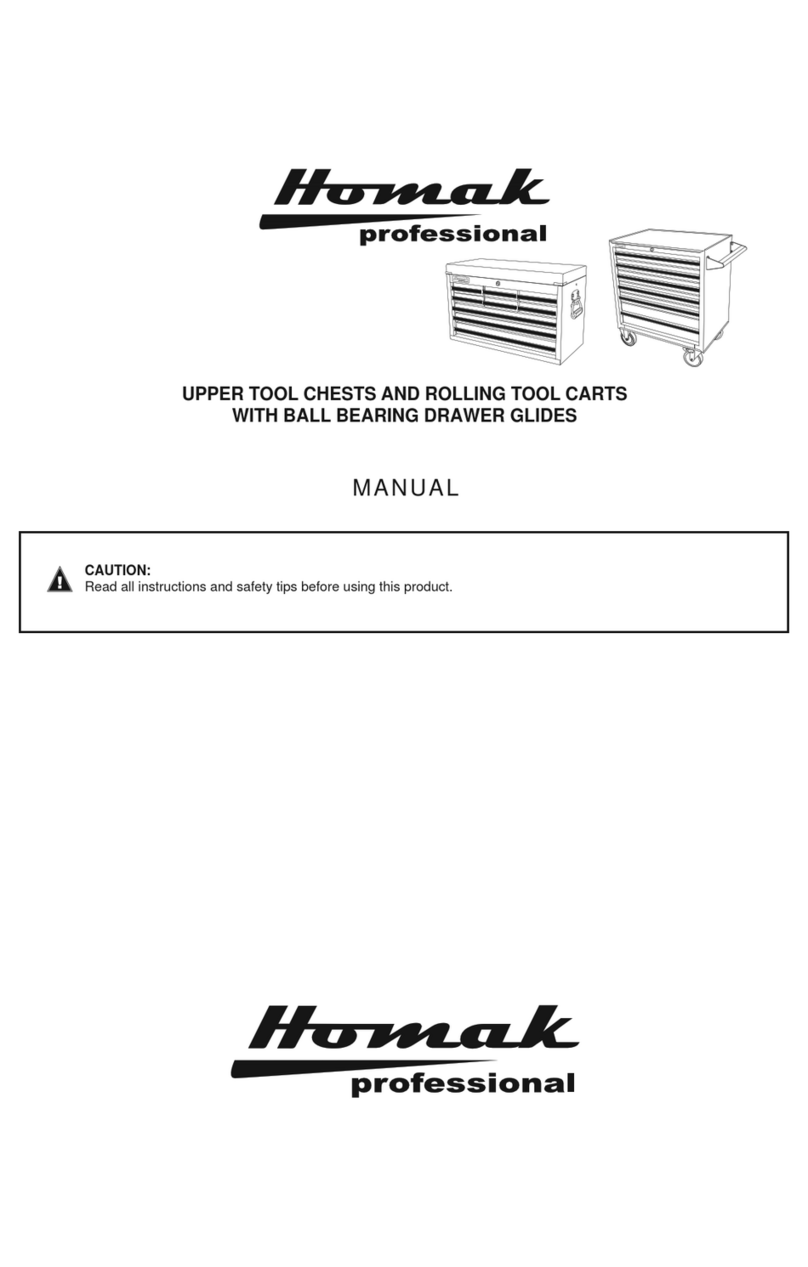

Width Adjustment

The width of the guide bars is adjustable by sliding the upper sections of the cross-

beams inward and outward to the desired position. This requires a 13mm socket

with a depth of at least 60mm.

• Loosen the two M8 nuts on the inside of each upper section by threading the

socket through the holes. NOTE: they only need to be loosened by a couple of

turns so that the section can move - do not fully take the nut o the bolt.

Adjustments

• Measure the width the guide bars need to be in order to t your specic chain-

saw bar. You must allow the space for both clamps and the nose sprocket to

be on the outside of the guide bars. It is easier to measure of you have already

assembled the chainsaw frame.

• Make sure the distance from the middle is the same for both upper sections

and crossbeams and retighten the M8 nuts to secure in place.

• Small adjustments can be made on the chainsaw clamps themselves by read-

justing the position on the chainsaw bar so that the C-Sections t perfectly on

the guide bars.

Forest Master Model: UWWS16

Adjustments

Clamp Setup

The height of the C-Section underneath the left and right chainsaw clamps needs to

be set in accordance with the size of the guide bars.

• To do this, loosen the two M6 nuts found on the side of both chainsaw clamps,

so that the lower plate can move up and down freely in the grooves.

• Slot the C-Sections onto the guide bars and position the chainsaw frame so that

it is perpendicular to the guide bars.

• Move the lower plate of the C-Section up so that it lightly clamps the guide bar

and then tighten the two M6 nuts on the side to secure. It needs to be tight

enough to the guide bars so that it cannot tilt or jump, but not so tight that it

is dicult to move the chainsaw along the guide bars. Move the chainsaw along

the guide bars to test the ease of movement before performing any cuts.

Forest Master Model: UWWS 17

Gripping Plates and Attachments

The gripping plates and attachments t into the telescopic slots in the middle of

the crossbeams and at the end of the dual rails. You can also add the perpendicular

telescopic slot (PTS) so that the gripping plates and attachments can be used in a

horizontal plane.

• The gripping plates have four holes for screws to pass through and grip into

the log to secure it in place. They can be used to grip the underside of he log

or used with the PTS to grip the ends of the wood. We recommend using M6

anged head coach bolts to screw into the wood. This is because normal Phil-

lips wood screws will be rounded after constant use. The screws also do not

need to be particularly long, 50mm is enough as they are only there to hold the

wood in place.

• The V-Slots and sawhorse attachments are used in the same manner and the

specics of which can be found in the operation section. The horizontal ver-

sions of the attachments are to be used with the PTS.

Adjustments

Forest Master Model: UWWS18

Operation

Operation

This section explains how to operate the chainsaw mill and the dierent processes

which can be performed on the frame for all types of work.

Mounting the Log

There are a few techniques that can be used to mount the log to the frame depend-

ing on the size and weight of the log.

• For manageable logs and timber, they can be simply lifted and placed so that

it rests on the two crossbeams. It is easier to have the guide bars as low as

possible or removed, so you don’t need to lift over them.

• For heavier logs, you can lift one end at a time and place each end on the

crossbeam. You will need to remove the guide bars for this method. To help

even further, you can position some trestles next to the frame to act as a step

so that you only lift half the height at a time for each end of the log.

• For very large or heavy logs, fold the legs in, turn the frame upside down and

place on top of the log. Then secure the frame to the log by screwing into it

through the gripping plates. The log can now be rolled over by hand or with

a log peavey so that the frame sits upright. It is usually best to perform the

rst few cuts on the oor to take some weight o the log before extending the

frame.

Securing the Log

The log can be secured to the frame through the four gripping plates enabling the

user to grip from underneath and the ends of the log by screwing wood bolts into

it - We recommend using M6 anged head coach bolts.

• When using the PTS, it is better to have the dual rails extended as little as pos-

sible for stronger securing.

• We suggest using two bolts for each gripping plated used. This is because the

more secure the log, the less it can move during the cut and therefore the bet-

ter the nish.

• The logs can also be secured through the two holes either side of the V on the

V-Slot when cutting fence posts.

Forest Master Model: UWWS 19

Operation

Performing Cuts with the Chainsaw

Before performing any cuts make sure all adjustable components of the chainsaw

mill and frame are tight and secure and the guide bars are the same distance from

the crossbeams at all four vertical supports.

• Cuts can be performed with the legs folded out and the stand at full height or

the legs folded in and the stand at a lower height, resting on the bottom of the

frame.

• It is best to perform cuts with the frame on a downhill angle so that gravity aids

the force of the cut.

• Start your chainsaw on the oor rst and then lift by the frame handle to slot

the C-Sections into the two guide rails. DO NOT lift with a hand on the throttle,

this could be very dangerous.

• Once the chainsaw is in position, you can start the cut. Run the chainsaw before

contact with the wood and then gently push the chainsaw by the frame handle

and the throttle handle through the wood.

• Push with enough force to ease through the cut but not so much that you

overwork the chainsaw. Patience is required when milling as it can be a slow

process. You cannot force the chainsaw too hard as it can jam in a downward

motion and get stuck, ruining the nish of the cut.

• The C-Sections have two spacers inside them to allow the chainsaw to tilt in the

horizontal plane. This allows the chainsaw to tilt in a ‘see-saw’ action as you

work your way through the cut, which is especially useful when encountering

knots.

• When you reach the end of the cut, turn o your chainsaw whilst the frame is

still mounted to the guide bars and then dismount the chainsaw frame from the

guides.

• Make sure all wood that has been cut is removed from the log before starting

the next cut.

Forest Master Model: UWWS20

Operation

Milling Slabs

To cut your wood into slabs, it is important that the wood is always resting on the

crossbeams and secured using all four gripping plates. We advise to use the two

vertical gripping plates in the crossbeam slots and the PTS with the other two grip-

ping plates to secure both ends from the dual rails.

• Set the guide bars to a height that can take the top of the bark o the full log,

making sure that the width of the second slab (beneath the cut) is as desired.

• Perform the rst cut following the cutting instructions.

• Once the cut has been completed, the guide bars need to be dropped to the

next position. The distance the guide bars are moved down will equate to the

thickness of the next slab. Therefore, you can do this with the step gauge or

measure it yourself for your own desired thickness.

• Then perform the next cut to complete the slab. The last two steps can be re-

peated until the log has been completely cut down.

Remember: Slabbing takes a long time for each cut due to the volume of wood be-

ing cut. Therefore, you must be patient with the cutting process and ensure you do

not force the chainsaw too hard into the wood. This can cause the bar to bow, get

stuck in the wood and overwork the chainsaw.

Table of contents

Popular Tools Storage manuals by other brands

Homak

Homak Pro BK04072601 manual

Harbor Freight Tools

Harbor Freight Tools 6843 Assembly and operating instructions

DIVERSIFIED WOODCRAFTS

DIVERSIFIED WOODCRAFTS WW31-0V SERIES Assembly guide

Clas Ohlson

Clas Ohlson TW40002 manual

Black & Decker

Black & Decker Workmate 79-041 instruction manual

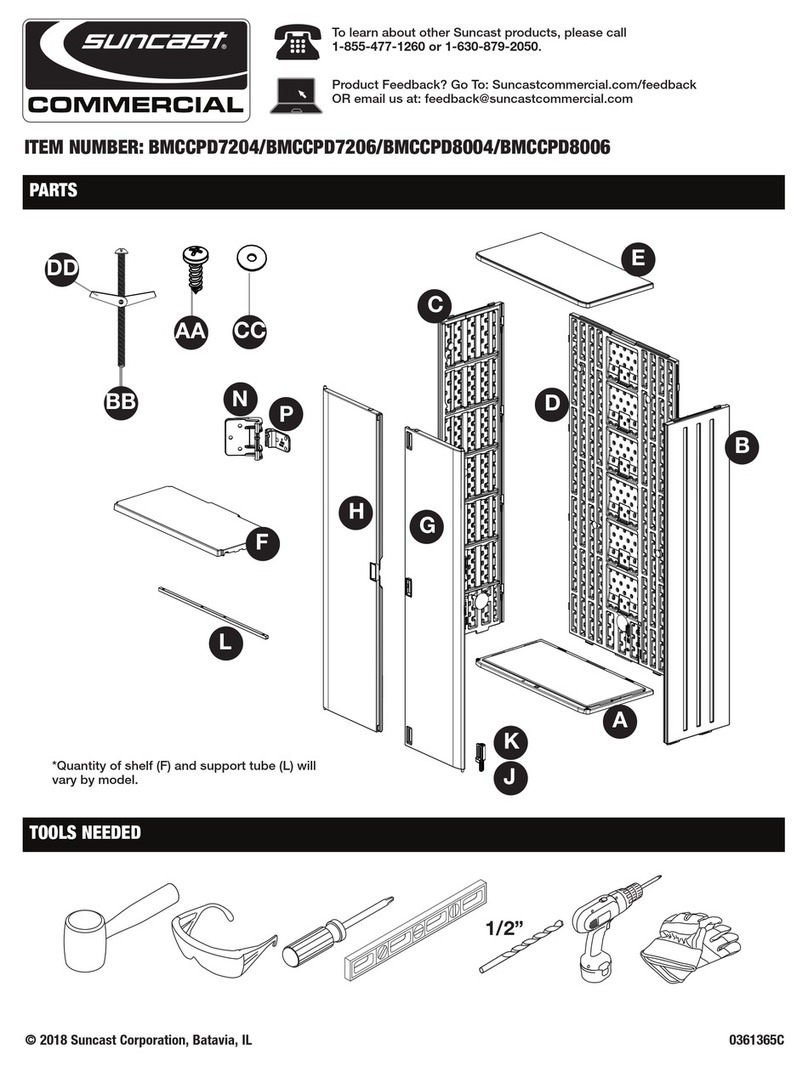

Suncast

Suncast BMCCPD7204 quick start guide

Hard Head

Hard Head 025205 Original instructions

Harbor Freight Tools

Harbor Freight Tools 96138 Assembly and operation instructions

Triton

Triton LocBoard LB18-T Installation & assembly instructions

TengTools

TengTools TC803N 3 Quick start quide

VONROC

VONROC WB502XX Original instructions

VS

VS SV90 operating manual