Feighner Hydro Max II Series User manual

hydro Max II Assembly Manual

Assembly Instructions

Hydro-Max II series, 2000# through 12,000# units.

CAUTION - PUT SAFETY FIRST

1. Before attempting to install or operate this hoist, study and fully

understand the proper operating procedures and safety precautions outlined

in this owner's manual.

2. Never exceed the recommended weight capacity of your lift. The lifted

weight will include hull, engine, fuel, battery, and added accessories

or gear. Weigh your fully loaded boat at a certified scale to be

absolutely sure of the total weight.

3. Do not allow anyone on, in or under the lift while operating.

4. NOT COMPLYING WITH THE PROCEDURES AND PRECAUTIONS

OUTLINED IN THIS MANUAL WILL INVALIDATE THE WARRANTY

AND MAY RESULT IN PERSONAL INJURY OR DEATH.

5. If you have any questions about assembly, installation, operation or

suitability of this product, contact your authorized dealer.

Assembly Instructions –Hydro-Max II, 2000# through 12,000# units.

Contents:

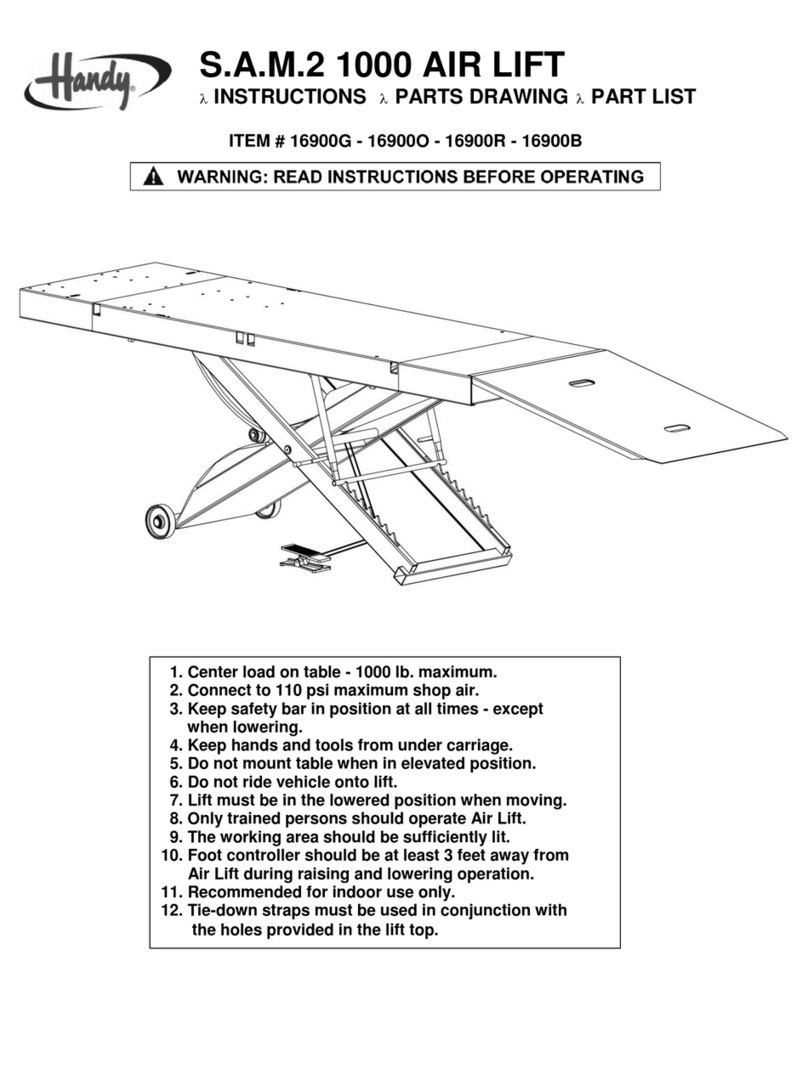

1. 1 Main Lift Assembly.

2. 1 Front Beam, 1 Rear Beam, (interchangeable).

3. 4 Leg pockets, with 3’ legs attached. (short- standard / long - canopy)

4. 1 Black Box, (or upgraded White Fiberglass box)

5. 1 Hydraulic Pump, manual control, with Keyless Remote

6. 4 Aluminum boat lift mud pads.

7. 2 Front Plates

8. 2 Rear Plates

9. Hardware Bag

Tools Required:

1. 9/16” socket wrench.

2. 9/16” box wrench.

3. (2) Large 12” adjustable wrenches

4. For step sand guides: ¾” socket or box end wrench

Assembly:

1. Assemble lift on smooth level surface, free from obstructions. Unpack all components at this

time, except for the hydraulic hoses. Leave this item wrapped for now to avoid contaminants

from entering the fluid system.

2. Assemble Rear Beam: 1 Rear Beam, 2 Rear Plates, (8) bolts 3/8 x 3 1/2” long and (8) nuts.

Center Beam, left to right, with Main Lift Assembly. Loosely fasten bolts to aid in centering

this beam. Tighten bolts.

3. Assemble Front Beam: 1 Front Beam, 2 Front Plates,(8) bolts 3/8 x 3 1/2” long and (8) nuts.

Center Beam, left to right, with Main Lift Assembly. Loosely fasten bolts to aid in centering

this beam. Tighten bolts.

4. Assemble Feet to Leg Pockets: 1 Foot, 1 Leg, bolt 3/8 x 3 1/2” long and nut.

5. Assemble Foot/Leg Pocket assembly (from previous step) to Rear and Front Beams (step 2

and 3): (4) bolts, 3/8 x 1” long, and (4) nuts.

7. For Models 10,000 LB and up. Attach center leg with the same directions as the other 4

leveling legs. Installer MUST CUT off extra leg that extends above beam. So the boat

doesn’t hit the center leg.

8. Unpack hoses. Use caution not to cut into hose wall. Push hoses through Black or

fiberglass box holes. Locate the corresponding hoses on the hose assembly. Match the red

hoses to the red hoses and the black to the black. Snap connectors into each other.

Connect 12v battery source. Red lead from pump to positive (+) and black lead to negative

(-).Press the UP control button. Lift should rise until button is released.

Note: If you have trouble with your initial hose connection, press the up or down button for a

moment to release pressure in the system. Attempt to connect fittings again. Repeat if

necessary.

9. If lift rises but will not lower –open Flow Control screw valve on pump adjacent to male screw

connector. This valve should be open 1.5 turns for now. Factory preset is 1.5 turns.

Installation:

Tools required:

1. ¾” box wrench

Instructions:

Survey the installation area for rocks, stumps or other obstructions, remove debris or

relocate lift site.

1. Inspect boat hull for any protrusions, such as turn fins, speedometer pickups, live well inlets,

cruise control pickups, etc. Compare location of obstruction with Bunk spacing. Remove or

relocate if needed. In some cases, Centering Guides may be all that’s required to position

your boat for interference free lifting.

2. Lift or float unit into position.

For the Normal Water Depth Series: Lift or float unit into position. Front of lift (bow) is the

cylinder end of the lift.

For the Shallow Water Depth Series: When the lift is in the lowest position, the bunk rail

overhangs the beam on the stern (back) of the lift.

DO NOT DRAG. Dragging may cause unnecessary fatigue on Side Beams and Front/Rear

Beams welds.

3. For Normal Water Depth Series: Place your lift in the farther most down position. Place

your lift in a minimum 29” of water depth or more. Half of boat draft plus 29. This much

water over bunk

4. Raise bunks until they are even with the water. Adjust legs until all 4 ends of the bunks are

level. To do this: Remove leg pin, place leveling leg at desired position. Replace leg pin.

5. Ensure only the 4 Foot Pads are firmly placed on the leg bottom.

6. Float (DO NOT DRIVE) your boat on at this time. Do not raise the lift yet. Check for potential

interference. Adjust bunks and or centering guides as necessary.

7. Raise the lift until the bunks just contact the hull bottom. STOP. Check for clearance one

more time

8. If all is clear between the hull and lift bunks, raise lift 6” more. WAIT. In softer areas lift feet

may settle into lake bottom, causing tilt situation. Lower lift, remove boat and repeat step 5

thru 9 until lift is on solid footing. Relocate lift unit or shore up soft areas with sand, gravel or

plywood sheets. Boat lift may settle throughout the season and require addition leveling.

9. Adjust Flow Control Valve (located on the pump next to the top screw connector). A flow

control valve is used to regulate the decent (downward movement) of the lift.

To open and the boat lowers to fast causing stress on the frame during abrupt stops. To

shut, and undue stress on the battery is encountered. Ideally, your boat will lower at the

same ‘rate’ as it rises. This should be about 1.5 turns open (turn clockwise until totally shut

–then counter clockwise 1.5 turns). Heavier boats will require this valve closed more, and

lighter boats will work better with this valve more open. If boat lift is hopping or chattering

tighten flow control (s) and repeat above process. This will generally happen when the fluid

becomes very warm due to sunlight or rapid use.

12. Use caution operating your lift during low battery conditions. Although the our 12 DC motor

can survive lower voltage conditions, the starter solenoid for this motor requires the full 12

volts to energize the magnetic switch to ‘clamp’ the contacts without arcing. Keep battery fully

charged at all times.

Troubleshooting:

1) Lift won’t elevate:

a) Check battery level –Even new batteries could be low.

b) Check fluid level

2) Lift will elevate but won’t lower:

a) Flow Control Valve may be shut. Open 1.5 turns initially, then open or close to control

‘rate’ of decent. Refer to page 5 and step 11.

Even though the lift does not use a large amount of fluid to lower, it initially needs fluid to

start its downward motion. You may have enough oil to go up but not enough to go down.

3) Battery life seems to be short:

a) Several factors enter this equation:

i) Boat weight, including fuel, and gear: heavier load = fewer cycles.

ii) Flow Control too closed: Refer to page 6 step 11

iii)Cooler ambient temperatures: fluid is thicker, requiring more amperage.

iv)Battery may not be charging fully due to faulty charger or bad cell in the battery

itself. Even new batteries have been found with bad cells.

b) After exploring the above avenues without satisfaction, contact your dealer for an

optional Solar Panel to keep battery at its peak condition.

c) Use caution operating your lift during low battery voltage conditions. Although the safe 12

DC motor can survive lower voltage conditions the starter solenoid for this motor requires

the full 12 volts to energize the magnetic switch to ‘clamp’ the contacts without arcing.

4) Fluid appears to be low:

a) Units are shipped with more of the fluid in the cylinders than the tank. Your lift should arrive

with about ½ of the reservoir filled with fluid, this amounts to about one gallon. As the lift

elevates, more fluid is pumped into the cylinders than the reservoir. Conversely, as lift

lowers, more fluid is pumped into the reservoir than the cylinders. With the lift in the lowest

position the reservoir should be half or ¾ full. The majority of your fluid is in the reservoir at

this time.

b) Should you have a spill, don’t worry, Hydro Max II series lifts are filled with

biodegradable hydraulic fluid. Contact your authorized dealer for replacement

fluid.

5) Lift rises a few feet, then stops, motor runs at a higher pitch:

a) Check fluid level in the reservoir. There may not be enough fluid in the reservoir to

complete the motion.

b) Check the quality of the fluid. See annual maintenance section for more instruction.

Annual Maintenance and Winterization Instructions:

Post Removal

1. When removing lift, place lift in the lowest position. DO NOT DRAG PADS ON LAKE BOTTOM.

Hidden debris can obstruct feet and bend legs. Soft sand and morrow bottoms will restrict

forward movement causing stress on frame. Float lift using inner tubes, float drums, or paddle

boats using the power of the double acting cylinders to lift feet off the lake bottom. USE

CAUTION NOT TO CRUSH FLOATION DEVICES WITH THE POWER OF THE CYLINDERS /

OR CAUSE FRAME DAMAGE.

2. After the lift is on shore, inspect all hoses and cylinders for any signs of wear or damage.

3. Inspect all bolts and nuts. Tighten if necessary.

4. Inspect frame components for excessive wear. Disconnect battery and charge before storing.

Store pump indoors if possible.

5. Check fluid level in the reservoir. Since the lift is in the lowest position, the reservoir should be

½ to ¾ full. Your reservoir cap has a dipstick connected. DO NOT add water or oil to your

system. Only use authorized biodegradable hydraulic fluid.

6. Inspect the quality of the fluid. If the fluid appears milky or sludgy, this means that water or

foreign particles have entered your hydraulic system. There is a drain plug located on the

bottom side of the black reservoir. Empty your reservoir. Replace with one gallon of new

hydraulic fluid.

Pre Installation

1. Fully charge your battery. Use a charge controller to help monitor levels.

2. Check the level of fluid in your reservoir. If you see that you have lost fluid throughout the

season, look at all hoses and fittings for fluid residue. Tighten if necessary. DO NOT add water

or oil to your system. Only use authorized biodegradable hydraulic fluid.

Table of contents

Popular Lifting System manuals by other brands

MSW

MSW MSW-HB-1500 user manual

J. D. NEUHAUS

J. D. NEUHAUS JDN mini Series Operation and assembly instructions

Ergotron

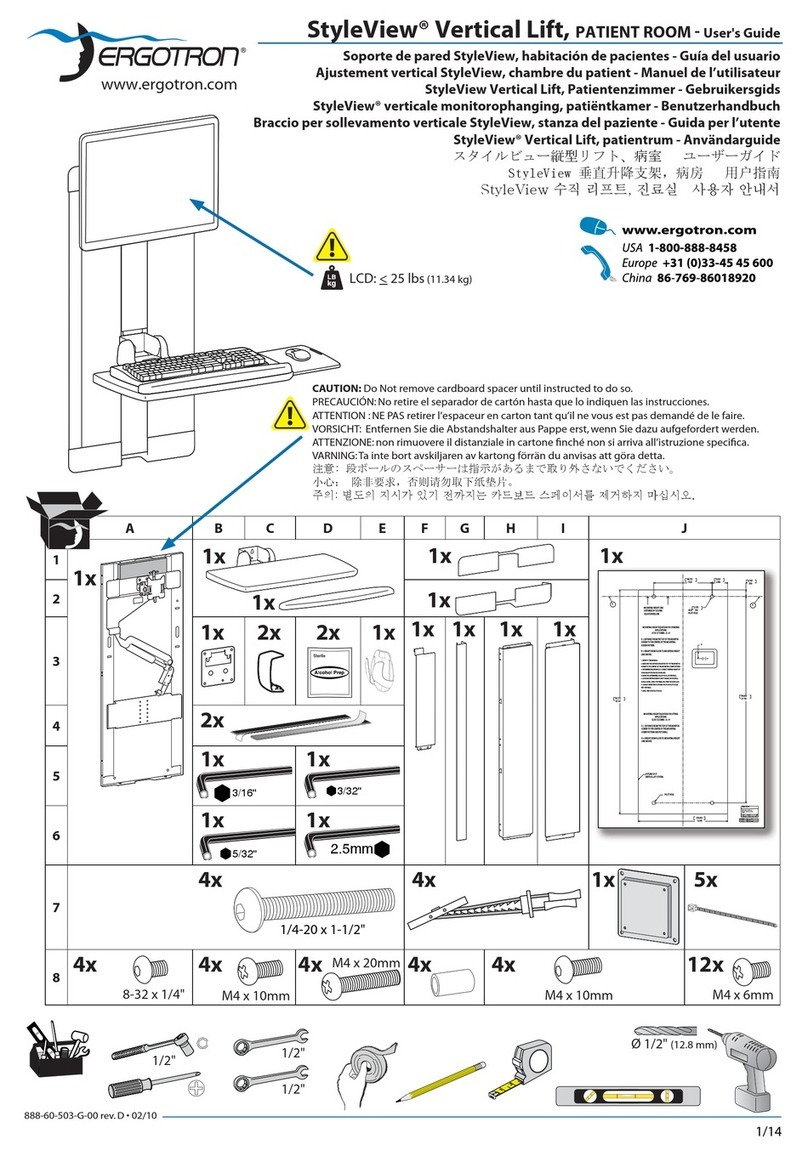

Ergotron StyleView 888-122 user guide

Southworth

Southworth PUN Installation, operation & maintenance manual

Hy-Brid Lifts

Hy-Brid Lifts 1 Series MAINTENANCE & TROUBLESHOOTING MANUAL

Vestil

Vestil PRRJ-DOL quick start guide