FOG QUADRA 493 9021 Owner's manual

QUADRA

493 9021

493 9023

493 9031

VEHICLE LIFT

4 COLUMNS 3,5 TONNE

(AUXILIARY LIFT 3 TONNE)

Installation

Operation

Maintenance

E 167 GB

ISSUE 6 : 02/2003

English

E 167 - GB - 6 2Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

CONTENTS

HEALTH AND SAFETY PRECAUTIONS ............................................................................................................... 3

WARNINGS, CAUTIONS AND NOTES ............................................................................................................. 3

INSTALLATION ................................................................................................................................................ 6

Location and layout, Floor Specification

ASSEMBLING THE SUPERSTRUCTURE ............................................................................................................... 8

Identification of main components

Preparing the cross member

Component position

Platform level adjustment

Column adjustment

Motor column assembly

Fitting the wire ropes

Fitting the ladder racks

Fitting the hydraulic hose and electrical connections

CONNECTING TO THE ELECTRICITY SUPPLY .................................................................................................. 15

COMMISSIONING THE PUMP ....................................................................................................................... 15

Fitting accessories

Adjusting the level of the platform

Adjusting the wire ropes

Fitting and adjusting the Tie rods

Checking the column adjustment

Checking the latches

Checking the rocker arm retaining system

Checking the safety brake cam

Checking the wire rope safety switches

Checking the adjustment of the wire rope safety switches

Checking the obstruction/wire rope failure sensor

Checking the ladder latching

Checking the ram safety valve

COMMISSIONING THE AUXILIARY LIFT .......................................................................................................... 21

OPERATION .................................................................................................................................................. 22

Positioning the vehicle, Raising the platform, Lowering the platform

RAISING & LOWERING THE AUXILIARY PLATFORMS (493 9031) ...................................................................... 23

“LOWER” CONTROL...................................................................................................................................... 23

Changing the position of the lever

RAM SAFETY VALVE ....................................................................................................................................... 24

Check and adjustments, Thread torque

LOWER THE PLATFORM AND AUXILIARY WITHOUT ELECTRICAL POWER ......................................................... 24

MAINTENANCE ............................................................................................................................................ 26

General, Monthly, Annual lift test

OVERLOAD TESTS .......................................................................................................................................... 27

FAULT FINDING ............................................................................................................................................ 28

TECHNICAL SPECIFICATION .......................................................................................................................... 36

ADD-ON FOR 493 9021 ................................................................................................................................. 37

ADD-ON FOR 493 9031 ................................................................................................................................. 44

SPECIFICITY OF SINGLE PHASE WIRING DIAGRAM ........................................................................................ 55

PROCEDURE ADJUSTMENT OF THE FLOW CONTROL VALVE (POWER UNIT HPI) ............................................... 56

WARRANTY RETURN FORM .......................................................................................................... 57

DECLARATION OF CONFORMITY .................................................................................................................. 59

QUADRA

3 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

I HEALTH AND SAFETY PRECAUTIONS

In order to comply with your responsibilities under the Health and Safety at Work Act 1974, it is essential

that the Quadra and any optional accessories are sited, installed, operated, and maintained by *competent

persons in accordance with the instructions in this manual.

* A competent person should be a minimum of 18 years of age and have a minimum

qualification of NVQ 3 (or an equivalent qualification) and / or experience within their

own field of responsibility, e.g. installation engineering, automobile engineering etc.

It is important that all persons installing, operating or maintaining the Quadra and

optional accessories must also be familiar with the layout of the equipment, safety

precautions and vehicle lifting points. Appropriate training will be required,

prior

to

installing, using or maintaining the lift

WARNINGS, CAUTIONS AND NOTES

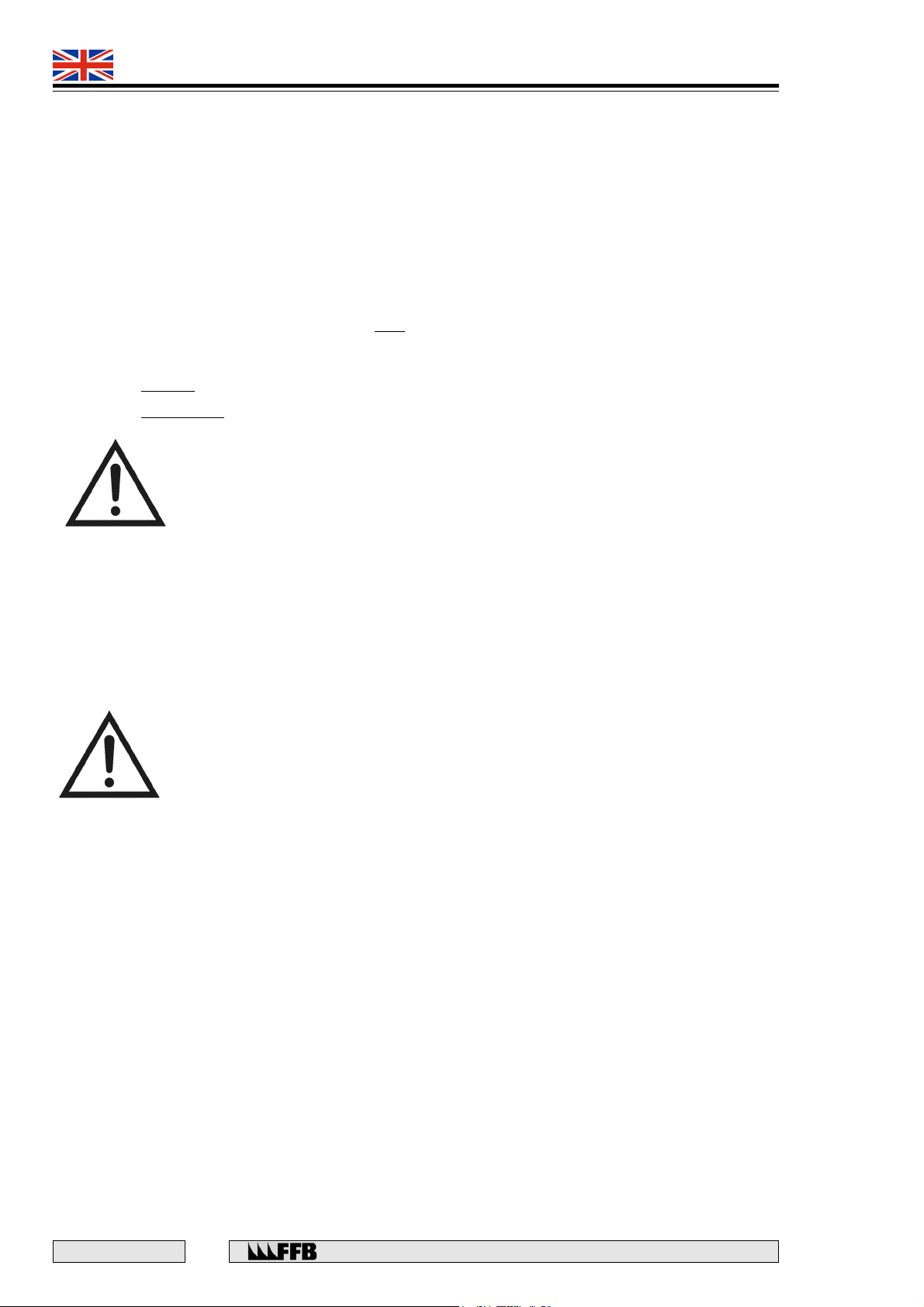

‘WARNING’ is used in the text of this manual to identify specific hazards which can cause injury or death.

‘CAUTION’ is used in the text of this manual to identify incorrect procedures which can cause damage to the

Quadra.

‘NOTE’ is used in the text of this manual to draw attention to specific points of importance.

WARNING SYMBOLS

WARNING

ELECTRICAL

DANGER

230V OR 400V

READ THIS

MANUAL

BEFORE USE

WARNING

OR

CAUTION

E 167 - GB - 6 4Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

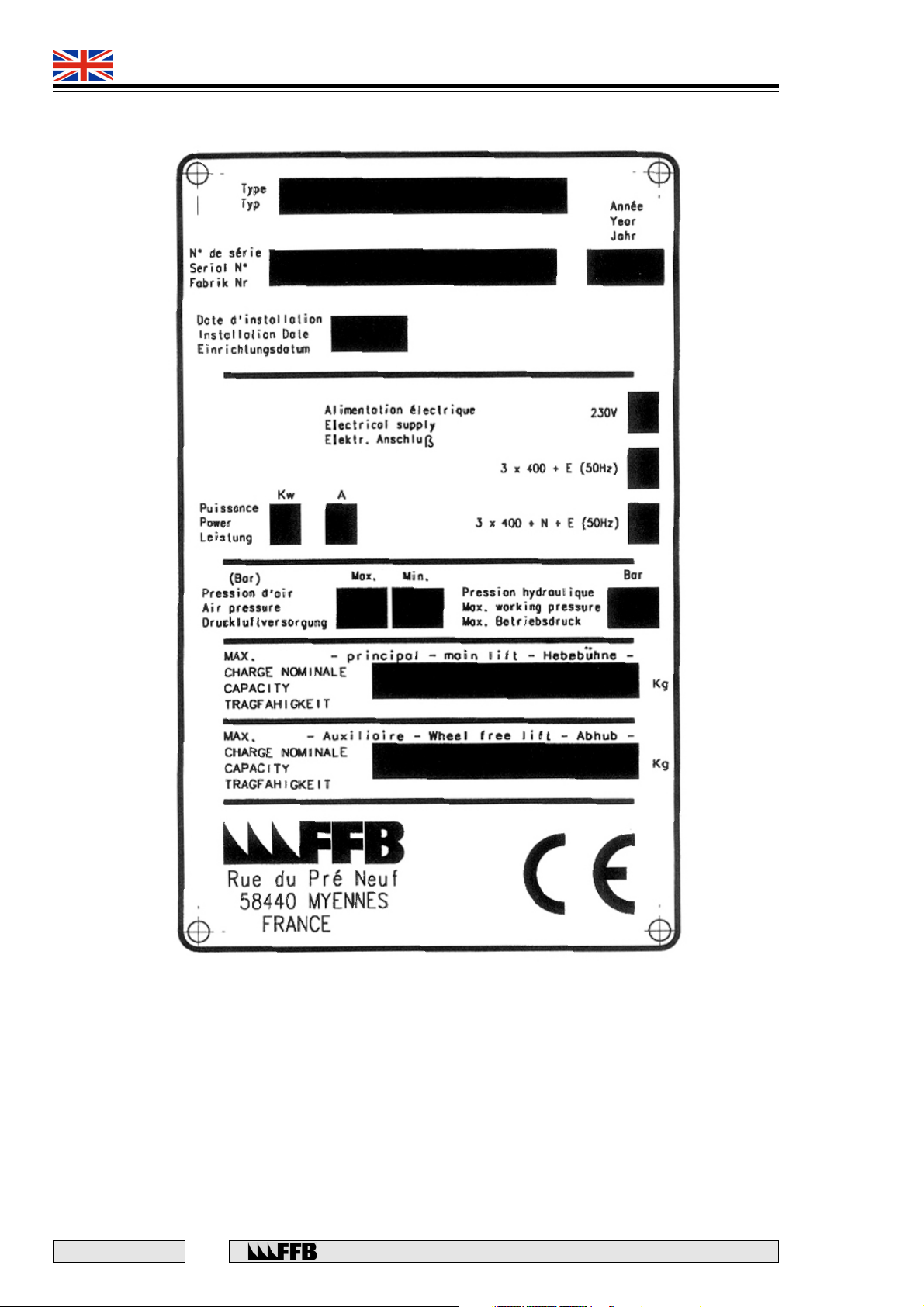

CE IDENTIFICATION PLATE

QUADRA

5 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

Changes to this manual are as shown below. Revised or additional issues of this manual are available

from F.F.B. S.A. Rue du Pré Neuf 58440 MYENNES - FRANCE.

Minor changes are indicated by the use of a broad line adjacent to the affected text.

PUBLICATION ISSUE CHANGES TEXT AFFECTED

26/08/97 Artwork Layout

05/99 2 euro

12/01 3 Modifications of the references in all the doc.

493 9001 --> 493 9021; 493 9003 --> 493 9023

493 9011 --> 493 9031 + insertion of additives 493 9021

& 493 9031.

05/02 4 Specificity of single phase wiring diagram and Procedure

adjustment of the flow control valve added, CE identification

plate updated, modifications of Fig. 7 p.17, Fig. 19 p.27,

Fig. 19, 20 and 21 p.37, and suppression of the paragraph

“Re-fitting the lever” p. 42 and of the Fig. 20 p. 43.

07/02 5 Suppression of the paragraph “Checking the upper limit

switch” p. 34, some modifications p. 36 and more precise

wiring diagram p. 2 of the additive 493 9031.

02/03 6 Warranty return form now included and EC declaration of

conformity updated.

MODEL NO:

SERIAL NO:

DATE OF INSTALLATION: .............................................

DATE OF LOAD TESTS: .............................................

INSTALLED BY: .............................................

E 167 - GB - 6 6Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

INSTALLATION

Location and site layout

This lift should be installed so that:

•It is sheltered from the elements.

•There is sufficient headroom.

•The “motor column” that houses the power-pack, control box etc. is positioned at the rear

on the left-hand side.

•A three-phase power supply is available nearby (400 V, 1.85 kW). This must have fused

circuit protection. NOTE: With 400 V, a neutral conductor is not required to operate the

lift, but it will allow any accessories requiring a 230 V supply e.g. lighting to be fitted.

•The front or rear of the vehicle must not come into contact with walls, doors or any

other obstructions, and all minimum safety clearances must be observed (Fig. 1).

Floor Specification

With regard to the area on which the four column base plates are to be positioned :

•The floor must be on a common horizontal plane (within +/- 4mm) including that up to

2000mm in front of the cross-member(s) so that vehicles with restricted ground clearance

can drive onto the platform. A slight downward slope towards the front of the lift is

acceptable, provided that it is compensated for by placing shims under the columns.

•The pads must be constructed from C:30 concrete extending over a minimum area of

800 x 650 mm and at least 160mm thick, excluding the thickness of any screed or paving that

may be added. In the case of an existing floor, check its suitability with qualified person

e.g. structural engineer, architect etc.

Where the lift is to be installed on an upper storey, the floor should be able to withstand the stresses given

below. This should be checked by a qualified person e.g. structural engineer, architect etc.

493 9021 493 9031

Uniformly distributed loading 242 kg/m2266 kg/m2

Point loading 1.6 kg/cm21.8 kg/cm2

CAUTION: THE OVERLOAD FIGURES GIVEN ABOVE DO NOT TAKE INTO

ACCOUNT ANY DYNAMIC OR STATIC OVERLOAD TESTS OR THE PARKING

OF A VEHICLE UNDER A LOADED PLATFORM.

Fig. 1

4430

>800

Power

supply

> 1040 2784

>650 or 800

if access

required

ACCESS

800

>650 or 800

if access

required

Depending on

vehicule ( 950)

~

QUADRA

7 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

Electrical supply

Provision may be made for a conduit in the floor (minimum 20mm internal diameter) which exits either

outside the base plate or in the column through the 25mm diameter hole (Fig. 2).

Columns

The columns are secured to the concrete pads with the anchor bolts supplied.

CAUTION: IF THE FLOOR IS SCREEDED OR TILED, THE LENGTH OF THE

ANCHOR BOLTS SHOULD BE INCREASED PROPORTIONALLY - CUSTOMER

RESPONSIBILITY.

Floor Plan

Mark clearly around the outside contour of the column base plates. (See Fig. 2)

Fig. 2

(Theoretical)

Cross-member axis

Elongated

hole

E 167 - GB - 6 8Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

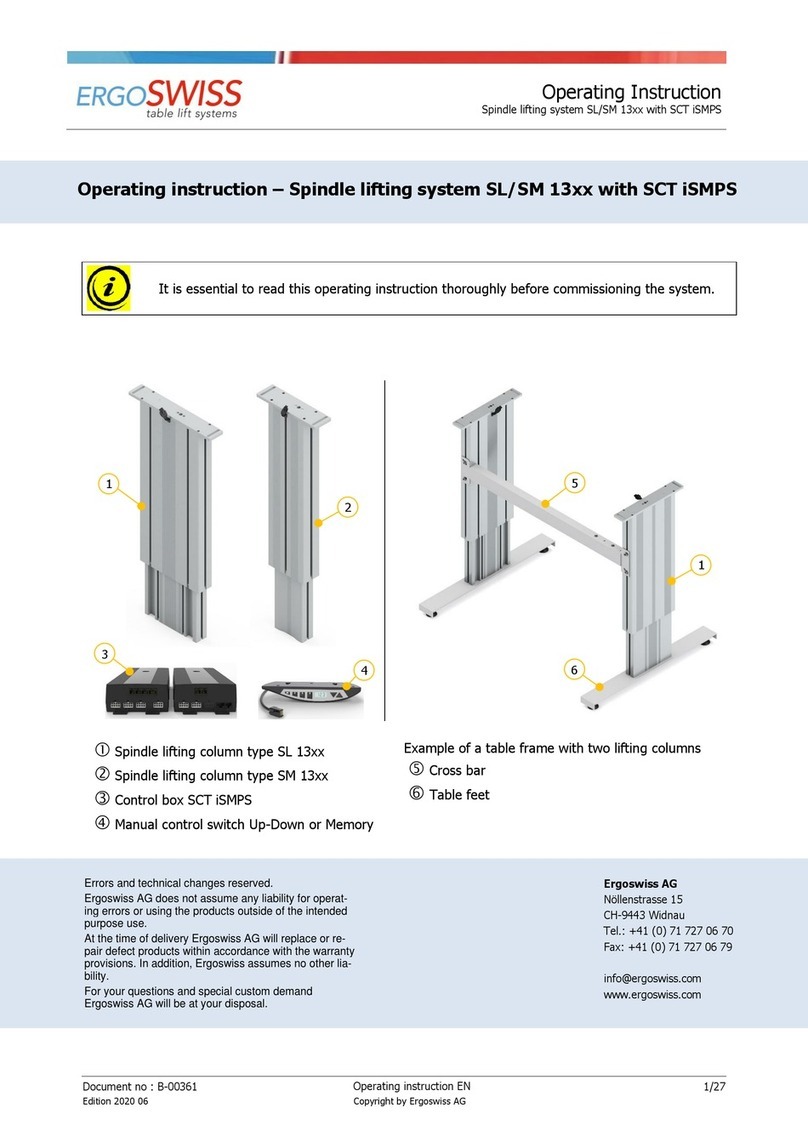

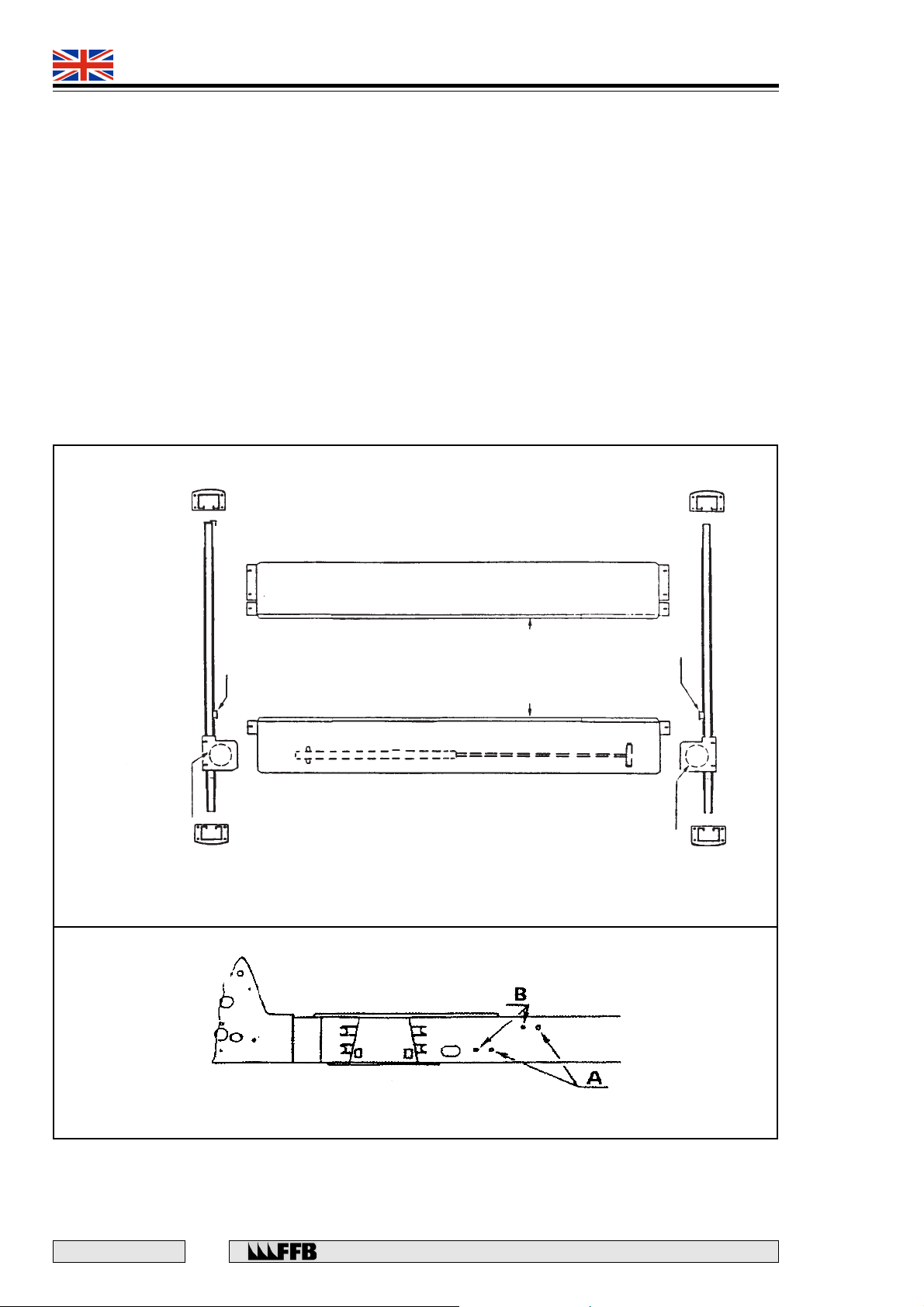

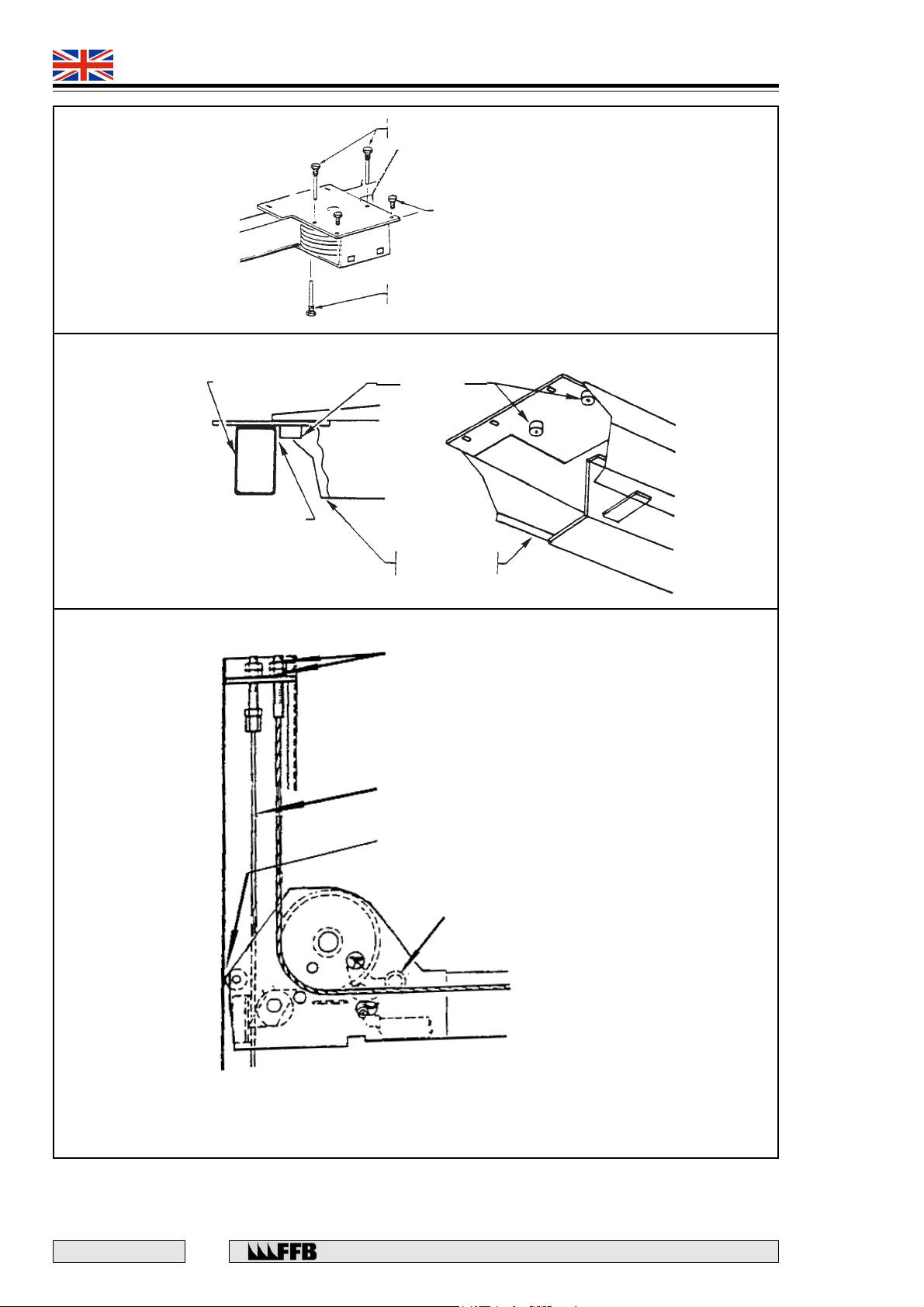

ASSEMBLING THE SUPERSTRUCTURE

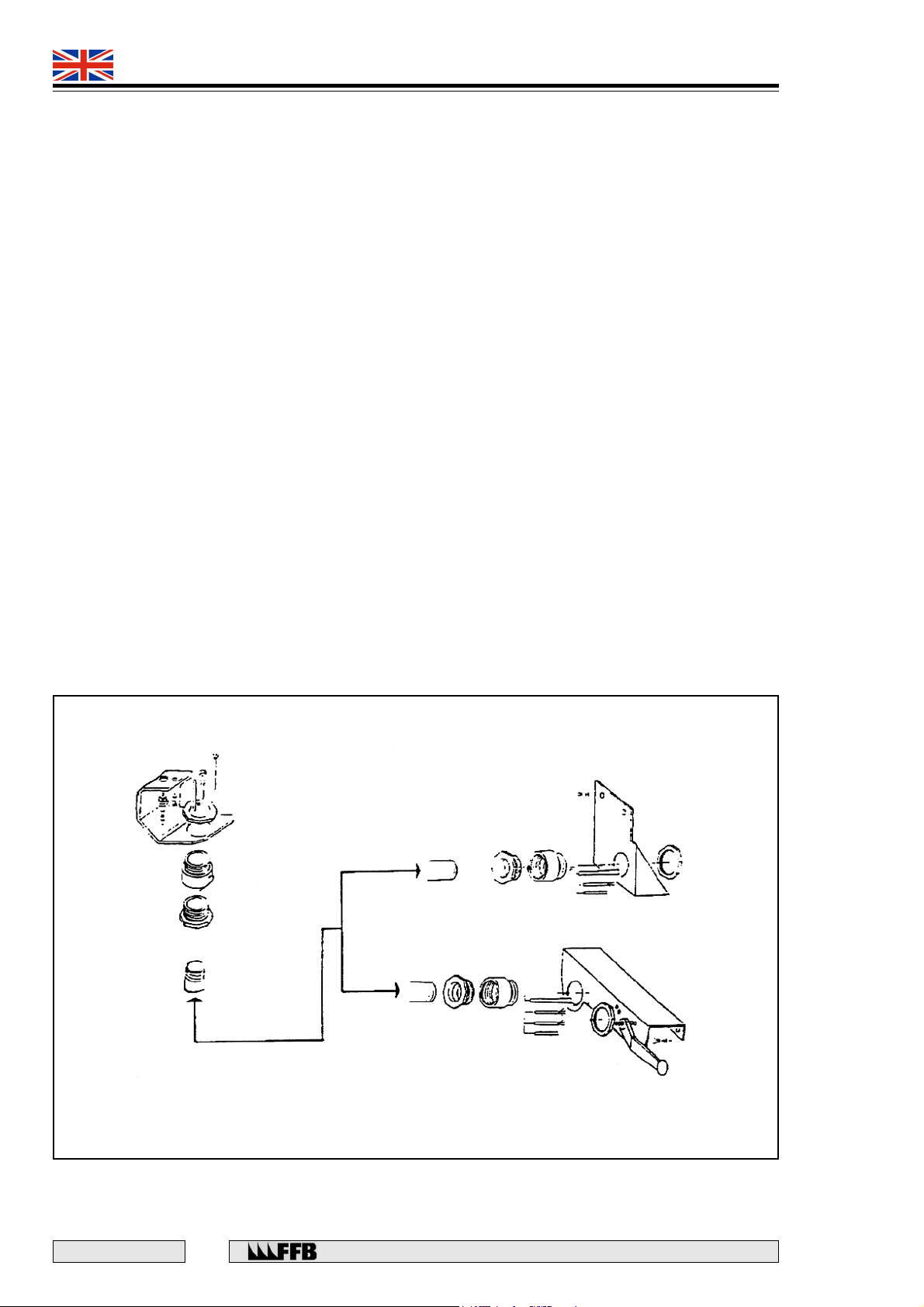

Identification of the main components

Unpack the component parts and identify them in accordance with Fig. 3.

The motor column (4) has several holes on its main face as well as the identification and instruction plates.

Columns 1, 2 and 3 are all similar, but the one that has a large vertical ‘Fog’ logo must be positioned on

the ‘drive on’ side on the left.

Preparing the cross members

Position the junction boxes correctly according to the type of lift (see Fig.4):

•in holes (A) for lift 493 9021

•in holes (B) for lift 493 9031

Fig. 3

COLUMN 1

COLUMN 4

(motor)

COLUMN 3 COLUMN 2

Junction

box

Junction

box

Wheel-guides

ADJUSTABLE

TRACK

CROSS-MEMBER 3 - 4

FIXED

TRACK

CROSS-MEMBER 1 - 2

Horizontal gusset

with single pulley Horizontal gusset

with single pulley

Fig. 4

QUADRA

9 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

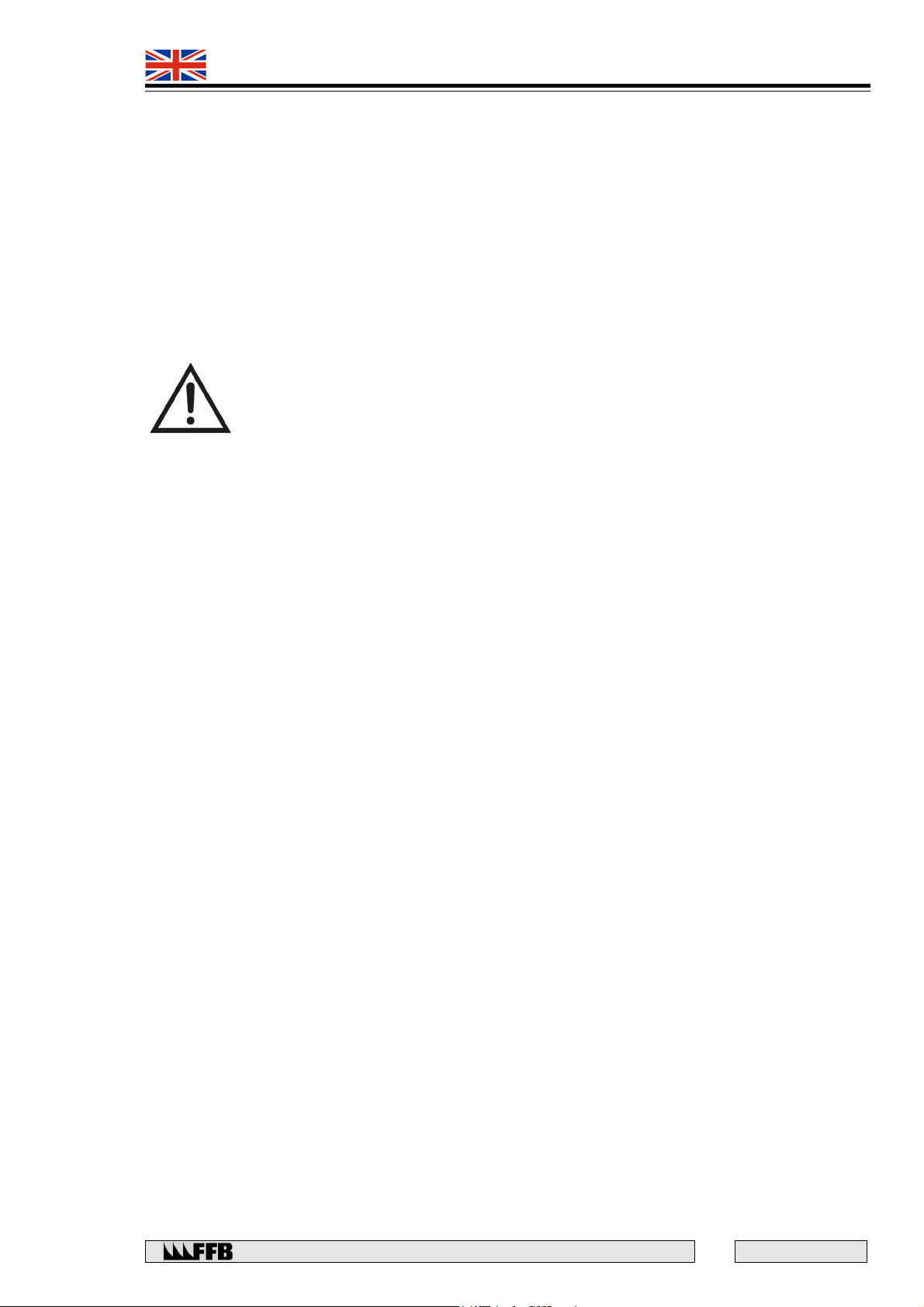

Component position

Position on the floor plan all of the components that make up the lift, in the following order:

•Cross-members: Place a suitable support under the cross-members, and under the horizontal gusset.

•Columns: Engage the columns as far as possible onto the vertical cheek-plates of the cross

members and position them correctly on the floor, move the cross-members if necessary.

•Fixed track: Place the fixed track on the cross-member horizontal gussets, with its wheel guide

flange facing inwards. Locate the connecting screws (Fig. 5) but do not tighten them. Pay

attention to the position of the wire rope guide screws.

•Adjustable track: Place the adjustable track on the cross-members as far as possible from the

fixed track and with its wheel guide flange facing inwards. Move the ends of the cross-

members so the track can fit in-between them in order to give 2 to 3 mm clearance between

the cross-member beam and the bosses at each end (Fig. 6). Tighten the connecting screws to

secure the horizontal gusset onto the fixed track.

Platform level adjustment

Adjusting the amount of shims under the cross-members. To ensure that the platform is level. This can be

verified as follows:

•laterally, using a spirit-level on the cross-members.

•longitudinally, using a spirit-level in the centre of the track.

Column adjustment

Measure and compare the distances between the column base plates and the ends of the cross-members.

A difference of 15 mm can be accommodated by adjusting the ladder rack in the column. If the difference

is greater than this, the lowest column(s) should be raised by placing shims under the base plate(s) or by

using the lifting screws.

Maintain the position of the base plate on the floor plan, then check each column in succession as follows:

•Whether it is vertical, using a plumb-line. If not, place shims under the base plate or adjust the

lifting screws.

•Whether it is square, using a rule placed on the main inside face of the column and sighting

the column opposite.

•Whether there is clearance of 1mm between the roller on the end of the cross-member and

the inside of the column (Fig. 14).

E 167 - GB - 6 10 Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

Fig. 5

SCREW M12 X 20

TOP CABLE

GUIDE

BOTTOM CABLE

GUIDE

Fig. 6

Clearance: 2 to 3 mm

CROSS-MEMBER BOSS

ADJUSTABLE

TRACK

NUT M 20

LADDER RACK

ROLLER

Approx. 1 mm clearance

(only with cross-member in

bottom position)

Fig. 14

QUADRA

11 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

Anchoring the columns

Drill the holes for the anchor bolts using the base plates as templates. Ensure that the columns are as vertical

as possible and concentric in relation to the base plate holes in order to allow column adjustment. If drilling

cannot be completed with the column in place, trace the position of the holes on the floor as accurately as

possible, remove the column and its shims, noting their positions.

Fit a large washer in position under the bolt head, locate the anchor bolts in position and tighten them.

Before anchoring the motor column, ensure all the necessary parts are fitted. Check the column adjustments

(verticality, squareness and 1mm clearance), alter the shims if necessary.

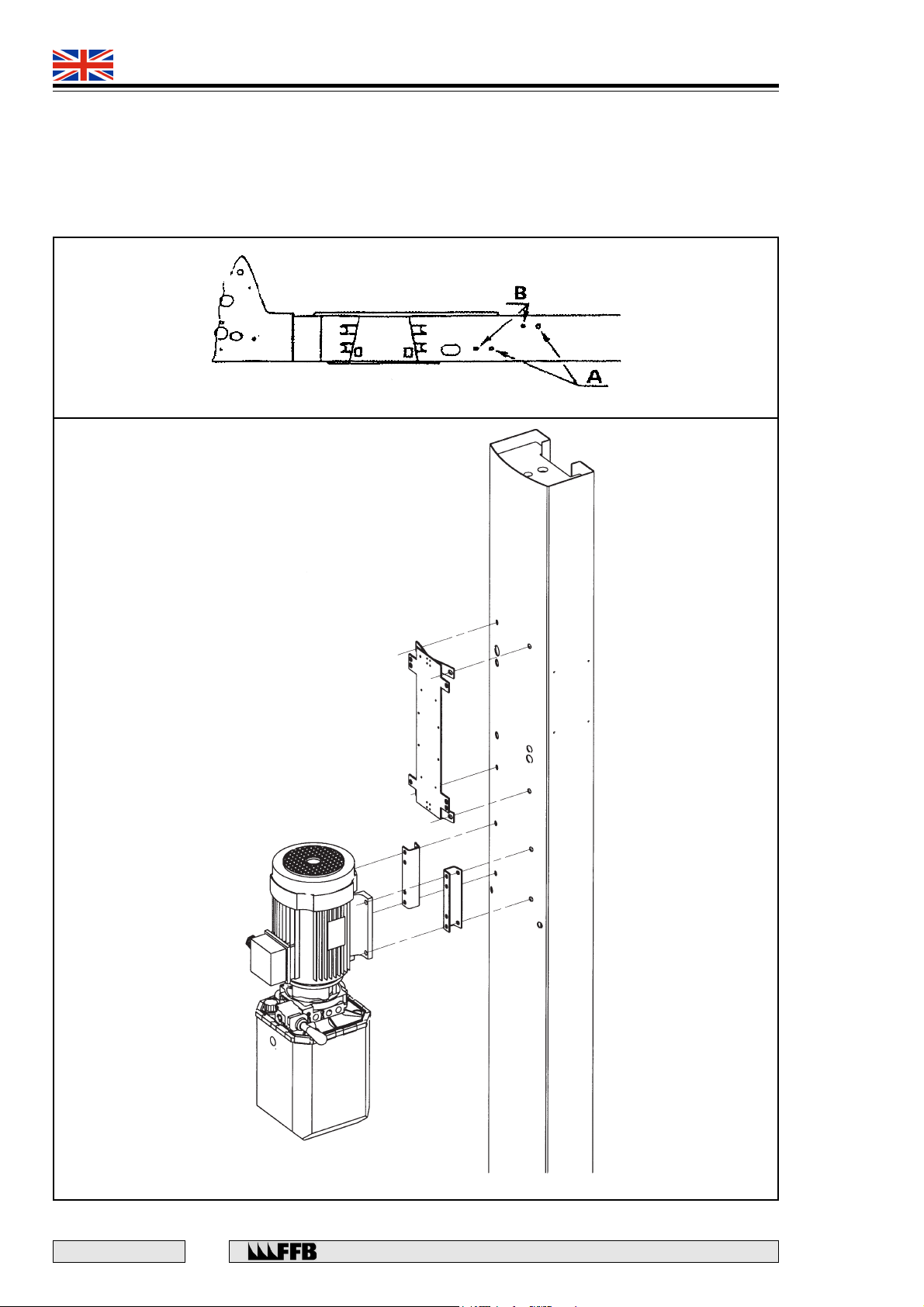

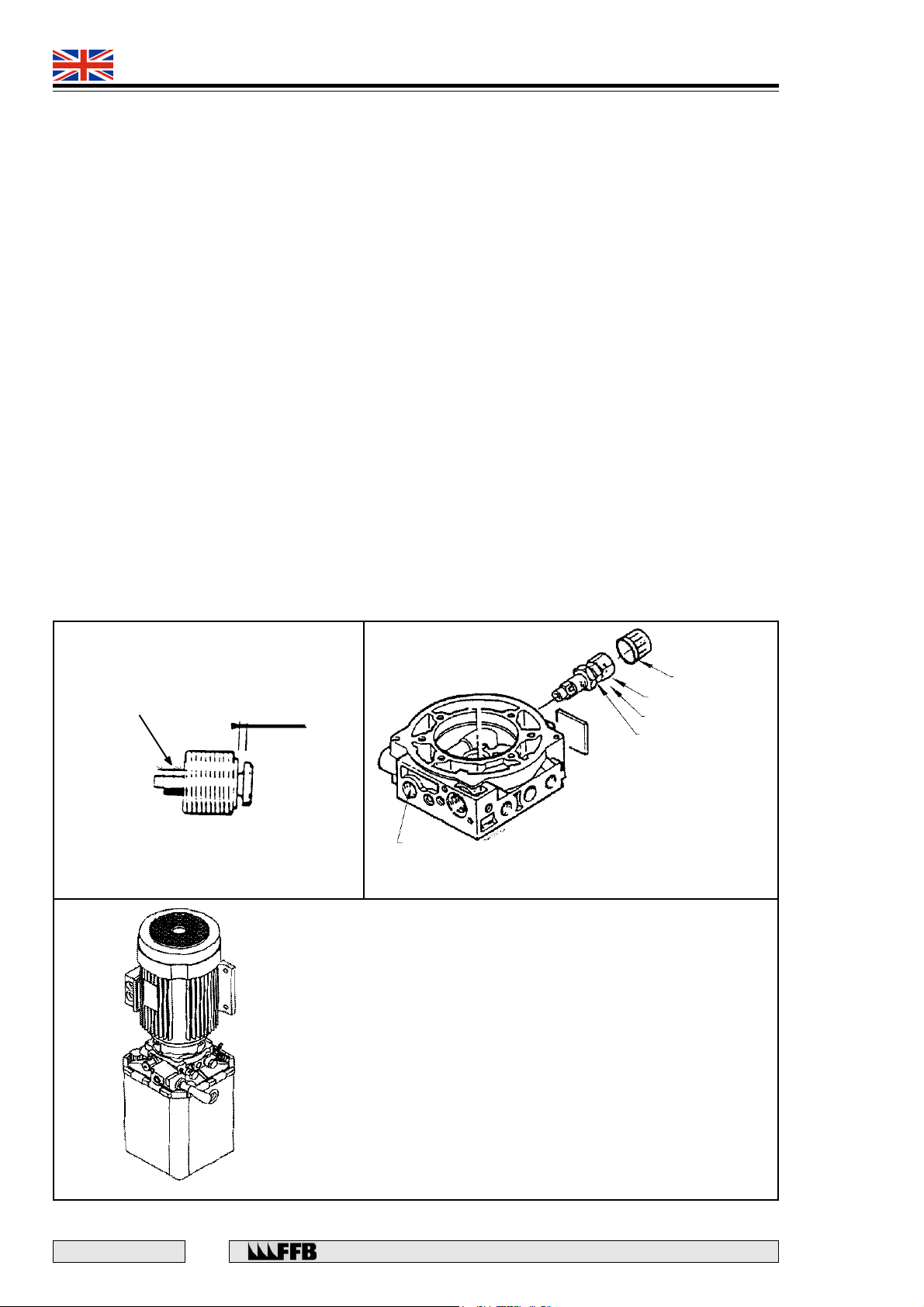

Motor column assembly

While it is more convenient to assemble the motor column when it is positioned at bench height, it is also

possible to do this with the column in an upright position, secured to the ground (See Fig. 7).

CAUTION: THE MOTOR COLUMN ASSEMBLY WILL NOT STAND UPRIGHT BY

ITSELF. THE RESERVOIR FOR THE MOTOR PUMP UNIT IS MADE OF PLASTIC.

•Attach the control panel mounting plate using four TH M8 x 16 screws and serrated lock washers.

•Attach the power-pack using four TH 8 x 16 screws and serrated lock washers between the 'U' bracket

and the column and four M8 x 20 screws, serrated lock washers and M8 nuts between the motor and

the 'U' brackets).

•Position the motor coupling links as appropriate and connect the cable, route it to the left of the motor.

• Attach the upper limit switch to its bracket using two C M4 x 25 screws and serrated lock washers.

Fit the bracket to the top of column on the inside with two TH M6 x 10 screws and serrated lock washers.

• Feed the cable through the column and connect it onto the control panel.

Fitting the wire ropes

•Bring the platform to rest on the latches at about 1000 mm from the floor, by alternately raising each

cross-member 2 or 3 slots, using a crane, jack or a lever engaged in one slot of the ladder rack and a

wooden block inserted between the lever and the bottom of the vertical cheek plate.

•At each end of the fixed track, remove the wire rope guide screws (Fig. 4).

•Unwind the wire ropes over a clean floor, they have a steel core and must not be subjected to any

kinking or bending during their installation. The ends of the wire ropes are colour-coded and should

be threaded over pulley grooves of the same colour as the rope.

Insert the following into the rectangular aperture on the cross-member beam 1-2:

•The loop of the white and yellow wire ropes to the left of the twin pulleys and then route it over the

crossbar, so that the yellow wire rope (the shortest) is uppermost.

•The end of the white wire rope to the right of the twin pulleys and then bring it along the track and out

through the rectangular aperture in the side of the cross-member 3-4.

•The loop of the red and blue wire ropes to the right of the twin pulleys and then route it over the crossbar

so that the red wire rope (the shortest) is uppermost.

•The end of the blue wire rope to the left of the twin pulleys and then in a similar way as the white wire

rope and out through the other end of the track.

•Attach the nylon roller by its shoulder screw onto the end of the crossbar, on the side of the red and blue

wire ropes (inner side of the platform).

•Remove the vertical pulleys from cross-member 1-2 and then feed the end of the red and yellow wire

ropes in through the beam until they reach their respective columns. Ensure that the wire ropes are

correctly positioned in the grooves of the twin pulleys and replace the three wire rope guide screws.

E 167 - GB - 6 12 Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

At each end of the cross-member, feed the wire rope under the sensing roller which should always be kept

in the upper position, then insert it into the groove of the vertical pulley and then insert the end of each wire

rope through the top of the column, fit the shoulder collar and the two nuts.

In a similar way, route the white and blue wire ropes in cross-member 3-4 and fit them to their respective

columns.

Fig. 7

Fig. 4

QUADRA

13 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

Fitting the ladder racks

CAUTION: UNDER NO CIRCUMSTANCES SHOULD THE LADDER RACKS BE

PAINTED. IF NECESSARY, CLEAN THEM, SCRAPE OFF ANY EXCESS RUST

AND THEN COAT WITH THICK OIL.

The top of the platform must not be more than 300mm from the ground, when fitting the ladder racks.

On each column:

•Raise the wire rope sensing roller and retain in elevated position.

•Insert the ladder rack into the vertical cheek plate of the cross-member.

•Insert a stud bolt into the top of the column, screw a M16 locknut onto its lowest end, before

screwing it fully into the ladder rack. Then lock the nut into position.

•Fit the shoulder screw through the ladder rack then into the threaded hole at the base of the

column.

•Screw an M16 nut onto the top end of the bolt until the ladder rack no longer rests on the

shoulder screw at the bottom of the column, then add an M16 locknut.

Fitting the hydraulic hose and electrical connections - 493 9021

•Connect the high pressure hose onto the ram, forming a large loop around the horizontal

pulleys.

•Connect the oil return hose onto the ram.

•Bring the coiled electrical cable into the cross-member.

•Fit the conduit entry fittings at each end and fit them onto their respective brackets.

•Thread the two hoses and the electrical cable through the conduit.

•Attach the conduit support lug onto the track using two M8 x 16 screws with serrated lock

washers.

•Connect both the high pressure hoses and oil return hose onto the power-pack.

•Fix the conduit support lug onto the power-pack using a screw and serrated lock washer.

•Connect the electrical cable onto the mounting plate.

•Check that the circuit breaker has been set correctly as follows:

6.3 A in 400 V

10 A in 230 V

•Connect the two junction boxes mounted on the cross-members, using the designated cable.

E 167 - GB - 6 14 Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

Fitting the hydraulic hose and electrical connections - 493 9031

•Connect the high pressure hose onto the auxiliary lifting ram in the adjustable track. The oil

return hose must be attached as soon as the auxiliary unit is mounted in position.

•Route the hoses into the chain and secure the chain along the cross-member using two M6 x 16

screws with serrated washers. Fit the angle bracket using two M8 x 16 screws with serrated

lock washers.

•Fit the inversion valve angle bracket onto the track using three M8 x 16 screws with serrated

lock washers.

•Connect the conduit and glands onto these two angle brackets.

•Connect the electrical cables into the junction boxes on the cross-members.

•Connect the HP hoses according to Fig. 11.

•Thread the HP and oil return hoses together with the electrical cable into the conduit and

connect them onto the power-pack.

•Fit the conduit angle bracket onto the power-pack using one M8 x 16 screw with serrated lock

washers.

•Connect the electrical cables onto the control panel.

•Check the settings of the circuit breaker are as follows:

6.3 A for 400 V

10 A for 230 V

Fig. 11

LIFT 493 9021

LIFT 493 9031

QUADRA

15 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

CONNECTING TO THE ELECTRICITY SUPPLY

IMPORTANT: THE ELECTRICAL SUPPLY MUST CONFORM WITH THE

CURRENT EDITION OF THE IEE REGULATIONS.

The rating [SIZE] of the supply control fuses should be as follows:

- 230 V Three phase 10 A aM

- 400 V Three phase 6 A aM

The conductor section for the supply should be as follows:

VOLTAGE LENGTH OF LINE CONDUCTOR CROSS-SECTION

400 V less than 100 m 1.5 mm2

100 to 150 m 2.5 mm2

230 V less than 35 m 1.5 mm2

35 to 55 m 2.5 mm2

•Check that the transformer voltage and the circuit breaker rating and its settings all correspond

to the voltage. Connect the electrical supply to the control panel.

•Check that the fuse-holder mounted on the terminal block carries the correct fuse.

•Check the direction of rotation of the motor: rotate the circuit breaker to position 1, then observe

the direction of rotation of the motor fan by briefly rotating the control knob towards RAISE.

If the fan does not turn in a clockwise direction, isolate the electrical supply. Interchange two of

the phases in the electrical supply and re-check.

COMMISSIONING THE PUMP

Fill the pump unit reservoir with the correct grade of oil as follows:

493 9021 8 litres of S.A.E.: 10W30, 10W40 oil or hydraulic oil Ref. 4939031

493 9031 8 litres of hydraulic oil - ONLY USE that supplied with the lift (Ref. 256 8011)

Engler viscosity at 20 C : 4 to 4.5

NOTE: An extra two litres of oil will be required after the rams have been bled.

Tension the wire ropes by turning the control knob towards 'RAISE', checking regularly that none of the wire

ropes have slipped out of the pulley grooves. Raise the platform by about 100mm and check the following:

•That none of the wire ropes are fouling a metal part or an electrical cable.

•That the latches retract simultaneously when the control knob is turned towards 'LOWER'.

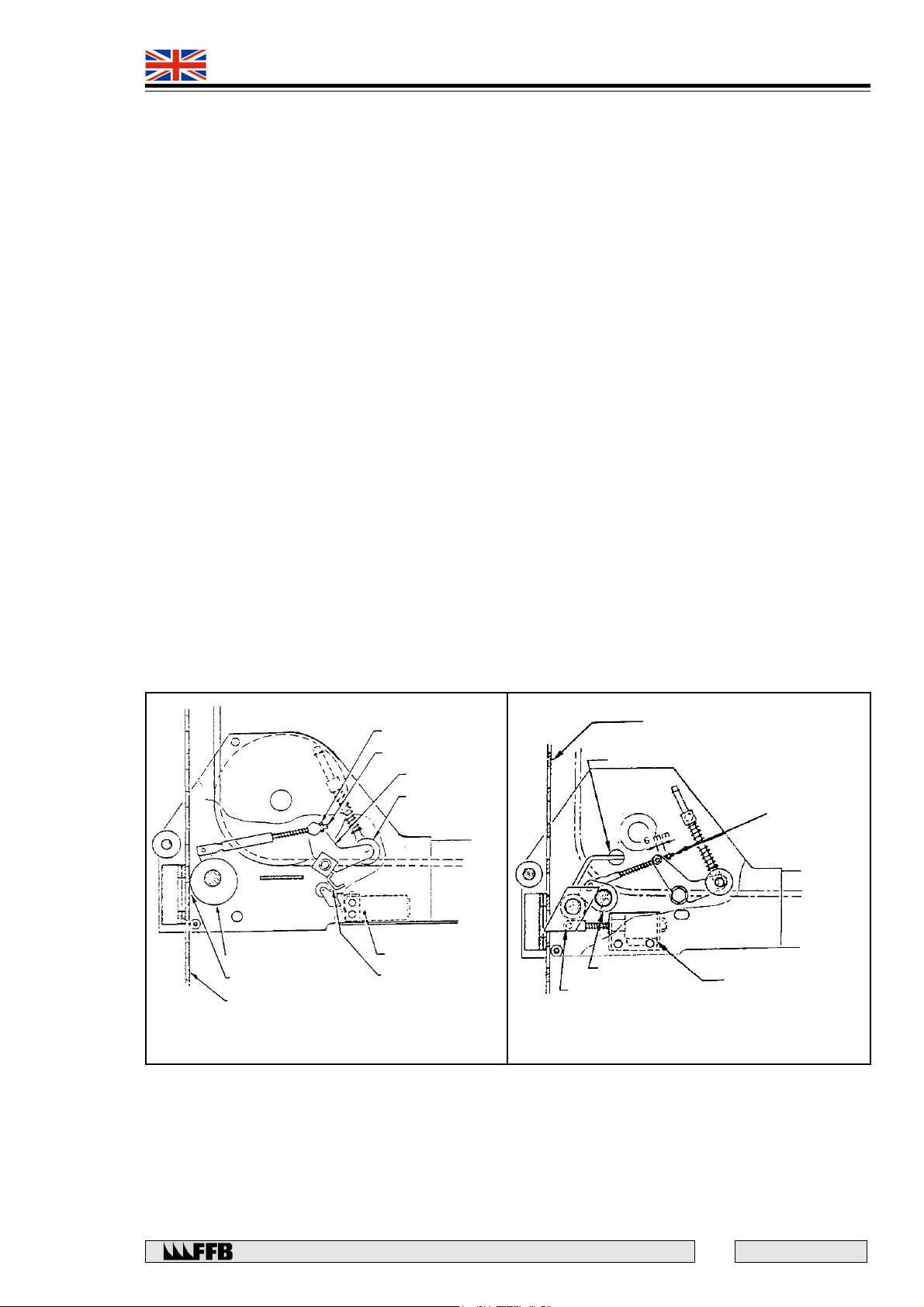

•At each end of the cross-member, check that there is clearance of between the limit switch roller

and the rocker arm cam (Fig. 12).

Fig. 12

LOCKNUT

RETAINING ROD

ROLLER

SWITCH

ROCKER

Clearance: 0 to 0.5 mm

Clearance: 1.2 to 1.5 mm

CAM

LADDER RACK

LOCKNUT

RETAINING ROD

ROCKER

SWITCH

Clearance: 0 to 0.5 mm

CAM

LADDER RACK

ROLLER

Clearance:1.2 to1.5 mm

E 167 - GB - 6 16 Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

Fitting accessories

•Fit the blanking (inspection) plate to the end of each cross-member in the (fixed track) axis.

•Hang the access ramps onto the end of the tracks on the 'drive on' side, and then insert the

retaining rod into the hooks and locate and fit the split pins in position.

•Attach the end stops onto the tracks at the opposite end to the drive on direction. (Fig. 19).

•Fit the blanking plates onto the tracks.

Adjusting the level of the platform

Rest the platform on the latches at about 500mm from the ground and fully slacken the wire ropes by

operating the ‘LOWER’ lever for a short period, after the platform comes to a stop.

By adjusting the nuts on the ladder suspension stud bolts, check that the platform is level:

•laterally, using a spirit level on each of the cross-members

•longitudinally using a spirit level in the centre of a track

CAUTION: WHEN ADJUSTING THE NUTS ON THE LADDER SUSPENSION

BOLTS, CHECK THAT THE RETAINING SCREW ON THE LOWER END OF THE

LADDER RACK IS NOT CLAMPED IN ITS ELONGATED HOLE AND THAT THE

WIRE ROPE IS KEPT SLACK, IF NECESSARY, OPERATE THE ‘LOWER’ LEVER

FOR A MOMENT.

Adjusting the wire ropes

This adjustment is necessary in order to:

•prevent one or more of the wire rope safety switches from operating when the platform is in its

lowest position.

•allow the latches to be engaged simultaneously, by eliminating any stretch in the wire ropes

under load. NOTE: a long wire rope should be shortened more than a short one to

compensate for 'elastic' stretch.

CAUTION: WHEN ADJUSTING A WIRE ROPE NUT, ALWAYS HOLD THE END

OF THE WIRE ROPE FERRULE TO PREVENT THE ROPE TWISTING.

•Lower the platform to the ground. Release the button that unlocks the latches and then the

‘LOWER’ lever, after having pulled on the wire rope in column 4 (Fig. 13) so that the ram is

fully extended.

•Adjust each wire rope end in turn until a measurement of 62 +/- 2 mm is obtained between the

bottom of the cross-member cheek plate and the top of the column base plate. A clearance of

7 to 10 mm is to be obtained between the bottom of the cheek plate and the lower column stop

(1 turn of the nut = 2 mm).

•Position a vehicle weighing approx. 2,500 kg on the platform and raise it to eye level, leaving

it suspended on the wire ropes.

•Measure the dimension 'X' (See Fig. 13) for each column and identify the highest cross-member

end in relation to the ladder slots.

•Raise the other ends by turning the nut on the wire rope end fitting until they are brought

to the same level as the highest end (1 turn of the nut = 2 mm).

•Fit a and fully tighten locknut onto each wire rope.

•Fit the column covers in position.

QUADRA

17 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

Fitting and adjusting the tie rods

Raise the platform, without letting it rest on its latches. At each end of the fixed track:

•Insert the threaded rods into the tubes located in the track (Fig. 15).

•Screw two M12 nuts (a) and (b) onto the rod.

•Position an M12 nut in the cross-member cheek plate. Tighten the M12 nut (a) fully against

the bracket.

•Screw a M12 nut (c) onto the other end.

•Adjust nuts (b) and (c) until the flanges of the vertical cheek plate are parallel in the column

and tighten them fully.

Fig. 15

CHEEKPLATE FLANGE

PLASTIC STUD

TIE BOL

T

NUT M 12

THE BOLT

CHEEKPLATE FLANGE

NUT M 12

PLASTIC STUD

Fig. 19 Fig. 13

FIXED END-STOP

2 WAY VALVE

for levelling

SOLENOID

Emergency lowering

‘LOWER’ Lever

Cross member

vertical gusset

Ladder

E 167 - GB - 6 18 Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

Checking the column adjustment

Raise the unloaded platform to 300mm from the ground, suspended by the wire ropes.

Check the following:

•That each column is square, using a rule placed firmly on the outer surface, and which is then

used to sight the opposite column.

•That each column is centred on its cross-member cheek plate to prevent excessive friction on the

plastic studs on the column aperture.

•That the clearance between each cross-member and column is between 1 to 3 mm.

•That each column is vertical, by means of a plumb line. In order to eliminate any clearance

between cross-members when the platform is in its operating position, the distance between the

tops of the columns of one particular cross-member must be slightly less (5 to 15 mm).

NOTE: If a cross-member is too tight between columns, an unladen platform could jam when

being lowered, causing the wire rope to slacken and the latches to engage in the ladders.

If necessary, adjust the position or the vertical plane of one or more columns, by placing shims under the

base plate and adjusting one or more of the tie-rods under the ends of the fixed track.

Check inside the columns with the platform at three different heights e.g. low, medium, high, that the ladder

edges do not rub on the inner surfaces of the cheek plate flanges.

Checking the latches

With the platform raised and suspended on the wire ropes, check at each end of the cross-members that the

latch operates freely without sticking. If necessary, identify the cause of the problem and rectify (e.g. rust,

using too thick an oil to lubricate it, latching solenoid sticking due to ingress of dirt etc.)

Checking the rocker arm retaining system

With the unloaded platform raised and suspended on the wire ropes, proceed as follows at each cross-

member end:

•Pull on the retaining rod to check that the bush turns freely.

•Check the rod clearance (Fig. 17). This clearance must be 6 mm. Correct if necessary by

adjusting the stop nut on the end of the rod.

Checking the safety brake cam

With the unloaded platform raised and suspended on the wire ropes, proceed as follows at each cross-member

end:

•Measure the clearance between the cam and the ladder rack. This should be between 1.2

and 1.5 mm. If necessary, release the locknut and adjust the cam retaining rod (See Fig. 12)

and check that the cam turns freely.

Checking the wire rope safety switches

The tension of each platform suspension wire rope is monitored at each end of the cross-member by a

sensing roller mounted on a rocker arm.

If one of the wire ropes becomes slack because of an obstacle under the platform or a broken wire rope, the

corresponding rocker arm pivots and activates the first contact on the switch which in turn causes the latches

to become engaged, thereby stopping the platform. The second contact is also activated and this prevents

the platform from being raised again.

If, when the platform is being lowered onto the latches, these do not engage in the same ladder slots on the

same horizontal plane, or if one of the latches engages unintentionally when the lift is being lowered, the

supporting latch retaining system restricts the rotation of the rocker arm in such a way, that only the first

electrical contact on the switch is actuated. This causes the other latches to engage.

NOTE: It is still possible to raise the platform again in order to re-adjust the platform so that it is level.

QUADRA

19 E 167 - GB - 6

Rue du Pré Neuf - 58440 MYENNES FRANCE

493 9021

493 9031

Fig. 12

LOCKNUT

RETAINING ROD

ROLLER

SWITCH

ROCKER

Clearance: 0 to 0.5

mm

Clearance: 1.2 to 1.5 mm

CAM

LADDER RACK

LOCKNUT

RETAINING ROD

SWITCH

Clearance: 0 to

0.5 mm

CAM

LADDER RACK

Clearance: 1.2 to

1.5 mm

ROCKER

ROLLER

Checking the adjustment of the wire rope safety switch

With the unladen platform raised and suspended on the wire ropes, check at each cross-member end that

there is a clearance of approx. 0 to 0.5 mm between the switch roller and the cam that is part of the sensor.

If necessary, adjust the position of the switch in order to obtain this clearance (Fig. 12).

Checking the obstruction/wire rope failure sensor

•Place an obstruction under one end of a cross-member.

•Lower the platform until the latches fall back against the ladders and the lift stops.

•Check that it is no longer possible to operate the RAISE control. If necessary, check the switch

position and electrical circuit.

•In order to free the obstruction, raise the sensing roller, then whilst keeping it raised, rotate the

control knob towards RAISE, until this obstruction can be removed.

•Repeat this sequence for all of the cross-member ends.

Checking the ladder latching

With the unloaded platform raised and suspended on the wire ropes, check each cross-member end as

follows:

•Disconnect one conductor from the latch solenoid and then start to lower the platform until the

latches fall back against the ladders and the platform is stopped. The latter must occur before

there is a 100 mm maximum offset between the heights of the cross-member ends. Ensure that

this is correct and check that the ‘RAISE’ command is still possible.

If the results of one of these tests are not satisfactory, bring the platform back to level, suspended on the wire

ropes and then check the 6 mm clearance of the retaining rod (see Fig. 17), as well as the switch position

and electrical circuit.

Reconnect the solenoid and then check another end.

Fig. 17

LADDER RACK

RETAINING

ROD

VISUAL FLAG

RING

LATCH ELECTROMAGNET

E 167 - GB - 6 20 Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

Checking the ram safety valve

Should a hose fail, this valve stops the lift from lowering by locking up the fluid in the ram. Correct operation

of this valve is depends on the correct oil grade/viscosity, it should be checked whether the oil is of the

correct grade before carrying out this test. If it is too cold, fully raise the loaded platform a few times.

In order to check the valve setting:

•Place a FOUR Tonne load onto the platform and then raise it.

•Slowly move the ‘LOWER’ lever and mark its position as soon as the valve operates (about 3/4

of the way).

•Raise the platform again to its uppermost position.

•Move the ‘LOWER’ lever until it is brought slightly in front of the previously marked position so

that the valve is not made to function. Record the time it takes to lower the platform fully. This

should be between 23-26 secs.

•If it is necessary to adjust its setting, refer to Fig. 16.

NOTE: This valve must function with a load of 300 kg on the platform. The bursting of a hose can be

simulated by opening a valve that has been fitted between the hose and the power-pack.

Lubrication

Lubricate as following parts:

•The platform load bearing wire ropes with the special grease supplied.

•The cam, latch and wire rope sensor pins.

Fit the cheek plate covers onto the cross-member ends.

Fig. 16

e

0.5 mm

Adjusting

nuts

Fig. 20

Tamper-proof

Cap

Cap nut

Adjustment screw

Locknut

Pressure

gauge port

Replacement tamper-proof cap

Part No. 9420081

Fig. 21

A hydraulic power pack includes :

4 920 1604 14,4 x 18,1,5 copper seal

2 920 1613 M14 x 150 hollow bolt

1 920 1625 D6 Banjo adapter

1 937 1268 Motor 1,8 Kw / 2750 r.p.m

1 942 0067 Hyd Pump unit HPI 2cc

1 993 4109 120 x 180 Plastic pocket

1 Procedure adjustment limiting device

(See at the end of the document)

This manual suits for next models

2

Table of contents

Other FOG Lifting System manuals

Popular Lifting System manuals by other brands

Handicare

Handicare FREECURVE Basic user manual

morse

morse 510-125 Operator's manual

Air Lift

Air Lift RideControl 59544 installation guide

Eagle Equipment

Eagle Equipment MTP-9F Installation & operation manual

HORCHER

HORCHER UNILIFT PRO operating instructions

Mcombo

Mcombo 6360-SEC212W Operating instruction