Felder ERM 1050 User manual

Operating Manual

Corner rounding machine

ERM 1050

GER = Original operating manual language

Other languages = Translation of the original operating manual

Dok.ID: 016-0-06002 • Englisch • 2021-01-27

Keep this manual handy and in good condition for continual reference!

2

FELDER

!

Corner rounding machine

ERM 1050

A product of the FELDER GROUP!

FELDER KG

KR-Felder-Straße 1, 6060 Hall in Tirol, AUSTRIA

Tel. +43 (0) 5223 / 58 50 0

Fax: +43 (0) 5223 / 56 13 0

info@felder-group.com

www.felder-group.com

For the safety of all personnel, it is necessary to conscientiously study this manual before assembly and

operation. This manual must be kept in good condition, and should be considered as part of the machine.

Furthermore, the manual must be kept to hand and within the vicinity of the machine so that it is

accessible to operators when using, maintaining or repairing the machine.

Attention! The machine must be inspected immediately upon arrival. If the machine has been damaged

during transport, or if any parts are missing, a written record of the problems must be submitted to the

forwarding agent and a damage report compiled. Also be sure to notify your supplier immediately.

3

Corner rounding machine

ERM 1050

Table of contents

1 General ...........................................................................................................................................................4

1.1 Explanations of the symbols ................................................................................................................4

1.2 Information about the manual .............................................................................................................4

1.3 Spare parts .......................................................................................................................................4

1.4 Liability and warranty ........................................................................................................................5

1.5 Copyright .........................................................................................................................................5

1.6 Warranty notice ................................................................................................................................5

1.7 Disposal ...........................................................................................................................................5

2 Safety .............................................................................................................................................................6

2.1 Intended use .....................................................................................................................................6

2.2 Manual contents ................................................................................................................................6

2.3 Making changes and modifications to the machine ................................................................................6

2.4 Responsibilities of the operator ............................................................................................................7

2.5 What is required of personnel .............................................................................................................7

2.6 Work safety ......................................................................................................................................7

2.7 Personal protective equipment .............................................................................................................8

2.8 Machine hazards ..............................................................................................................................9

2.9 Other risks ........................................................................................................................................9

3 Declaration of Conformity ..............................................................................................................................10

4 Technical specifications...................................................................................................................................11

4.1 Dimensions and weight ....................................................................................................................11

4.2 Operating conditions .......................................................................................................................11

4.3 Standard and optional equipment...................................................................................................... 12

4.4 Operator’s position ..........................................................................................................................12

4.5 Particle emission ..............................................................................................................................13

4.6 Noise emission ...............................................................................................................................13

5. Operator‘s position .......................................................................................................................................14

5.1 Lifting and transport .........................................................................................................................14

5.2 Array of the machine .......................................................................................................................14

5.3 Vacuum connection ..........................................................................................................................14

5.4 Compressed air supply connection .....................................................................................................15

6 Safety ...........................................................................................................................................................16

6.1 Overview .......................................................................................................................................16

6.2 Data plate ......................................................................................................................................16

6.3 Panel positioning .............................................................................................................................17

6.4 Corner rounding unit adjustment ........................................................................................................18

6.5 Pneumatic control ............................................................................................................................19

7 Maintenance .................................................................................................................................................20

7.1 Cleaning ........................................................................................................................................20

7.2 Operating conditions .......................................................................................................................20

8 Replacing/changing the tooling ......................................................................................................................21

9 Pneumatic diagrams ......................................................................................................................................22

Table of contents

4

!

!

Corner rounding machine

ERM 1050

1.3 Spare parts

If unauthorised spare parts are installed in the machine,

all warranty, service, compensation and liability claims

1 General

1.1 Explanations of the symbols

Important technical safety instructions in this manual are

marked with symbols.

These instructions for work safety must be followed.

In all these particular cases, special attention must be

paid in order to avoid accidents, injury to persons or

material damage.

1.2 Information about the manual

This manual describes how to operate the machine

properly and safely. Be sure to follow the safety tips and

instructions stated here as well as any local accident

prevention regulations and general safety regulations.

Complying with the following described regulations will

guarantee the correct operation of the machine, a longer

useable life and lower costs.

Before beginning any work on the machine, ensure that

the manual, in particular the chapter entitled “Safety”

and the respective safety guidelines, has been read in its

entirety and fully understood. This manual is an integral

part of the machine and must therefore be kept in the

direct vicinity of the machine and be accessible at all

times. If the machine is sold, rented, lent or otherwise

transferred to another party, the manual must accompany

the machine.

against the manufacturer and their contractors, dealers

and representatives shall be rejected.

General

Attention! Risk of material damage!

This symbol marks instructions which, if not observed, may lead to material damage, functional failures and/

or machine breakdown!

Warning! Risk of injury or death!

This symbol marks instructions that must be followed in order to avoid harm to one‘s health, injuries, perma-

nent impairment or death!

Warning! Danger! Electric current!

This symbol warns of potentially dangerous situations relating to electric current. Not observing the safety

instructions increases the risk of serious injury or death. All electrical repairs must be carried out by a qualified

electrician!

Note:

This symbol marks tips and information which should be observed to ensure efficient and failure-free operati-

on of the machine.

Attention! Non genuine, counterfeit or faulty spare parts may result in damage, cause malfunction or

complete breakdown of the machine.

5

!

Corner rounding machine

ERM 1050

1.4 Liability and warranty

The contents and instructions in this manual were

compiled in consideration of current regulations and

state-of-the-art technology as well as based on our know-

how and experience acquired over many years. This

manual must be read carefully before commencing any

work on or with this machine. The manufacturer shall

not be liable for damage and or faults resulting from the

disregard of instructions in the manual. The texts and im-

ages do not necessarily represent the delivery contents.

The images and graphics are not depicted on a 1:1

scale.

The actual delivery contents are dependent on custom-

build specifications, add-on options or recent technical

modifications and may therefore deviate from the descrip-

tions, instructions and images contained in the manual.

Should any questions arise, please contact the manufac-

turer. We reserve the right to make technical modifica-

tions to the product in order to further improve user-friend-

liness and develop its functionality. The manufacturer also

reserves the right to cease production and supply of parts

of the machine.

1.5 Copyright

This manual should be handled confidentially. It is

designated solely for those persons who work on or with

the machine. All descriptions, texts, drawings, photos

and other depictions are protected by copyright and

other commercial laws. Illegal use of the materials is

punishable by law.

This manual, in its entirety or parts thereof, may not be

transferred to third parties or copied in any way or form,

and its contents may not be used or otherwise communi-

cated without the express written consent of the manufac-

turer.

Infringement of these rights may lead to a demand for

compensation or other applicable claims. We reserve all

rights in exercising commercial protection laws.

1.7 Disposal

If the machine is to be disposed of, separate the compo-

nents into the various materials groups in order to allow

them to be reused or selectively disposed of. The whole

structure is made of steel and can therefore be disman-

tled without difficulties. This material is also easy to

dispose of and does not pollute the environment or jeop-

ardise public health. Always comply with international

environmental regulations and local disposal laws.

1.6 Warranty notice

The guarantee period is in accordance with

national guidelines. Details may be found on our

website www.felder-group.com

General

Attention! Used electrical materials, electronic components, lubricants and other auxiliary substances must

be treated as hazardous waste and may only be disposed of by specialised, licensed firms.

6

!

Corner rounding machine

ERM 1050

2 Safety

At the time of its development and production, the

machine was built in accordance with prevailing

technological regulations and therefore conforms to

industry safety standards.

However, hazards may arise should the machine be

operated by untrained personnel, used improperly or

employed for purposes other than those it was designed

for. The chapter entitled “Safety” offers an overview of

all the important safety considerations necessary to opti-

mise safety and ensure the safe and trouble-free opera-

tion of the machine.

To further minimise risks, the other chapters of this

manual contain specific safety instructions, all marked

with symbols. Besides the various instructions, there are

a number of pictograms, signs and labels affixed to the

machine that must also be heeded. These must be kept

visible and must not be removed.

2.1 Intended use

The function of the CRH is to trim off the excess of edge

from the corners, straight or shaped, of the panels previ-

ously edgebanded with edge not thicker than 3 mm.

The machine is made to function exclusively within the

dimensions of the technical charateristics specified.

When using the CRM it is advisable to connect the machine to a compressed air system (see Chap. 5.4)

and a dust extraction system (Chap. 5.3).

Attention! Any use outside of the machine‘s intended purpose shall be considered improper and is there-

fore not permitted. All claims regarding damage resulting from improper use that are made against the

manufacturer and its authorised representatives shall be rejected. The operator shall be solely liable for

any damage that results from improper use of the machine.

The term “proper use” also refers to correctly observing

the operating conditions as well as the specifications and

instructions in this manual.

The machine may only be operated with original manu-

facturer parts and accessories.

2.2 Manual contents

All those appointed to work on or with the machine must

have fully read and understood the manual before

commencing any work. This requirement must be met

even if the appointed person is familiar with the

operation of such a machine or a similar one, or has

been trained by the manufacturer. Knowledge about the

contents of this manual is a prerequisite for protecting

personnel from hazards and avoiding mistakes so that

the machine may be operated in a safe and trouble free

manner. It is recommended that the

operator requests proof from the personnel that the con-

tents of the manual have been read and understood.

2.3 Making changes and modifications to the machine

In order to minimise risks and to ensure optimal perform-

ance, it is strictly prohibited to alter, retrofit or modify the

machine in any way without the express consent of the

manufacturer. All the pictograms, signs and labels af-

fixed to the machine must be kept visible, readable and

may not be removed. Pictograms, signs and labels that

have become damaged or unreadable must be replaced

promptly.

Safety

7

Corner rounding machine

ERM 1050

2.4 Responsibilities of the operator

This manual must be kept in the immediate vicinity of

the machine and be accessible at all times to all persons

working on or with the machine. The machine may only

be operated if it is in proper working order and in safe

condition. The general condition of the machine must be

controlled and the machine must be inspected for visible

defects every time before it is switched on. All instruc-

tions in this manual must be strictly followed without

reservation.

Further to the safety advice and instructions stated in this

manual, it is necessary to consider and observe local

accident prevention regulations, general safety regula-

tions and current environmental stipulations that apply to

the operational range of the machine.

The operator and designated personnel are responsible

for the trouble-free operation of the machine as well

as for clearly establishing who is in charge of install-

ing, servicing, maintaining and cleaning the machine.

Machines, tools and accessories must be kept out of the

reach of children.

2.5 What is required of personnel

Only authorised and trained personnel may work on and

with the machine. Personnel must be briefed about all

functions and potential dangers of the machine. „Spe-

cialist staff“ is a term that refers to those who – due to

their professional training, know-how, experience, and

knowledge of relevant regulations – are in a position to

assess delegated tasks and recognise potential risks. If

the personnel lack the necessary knowledge for work-

ing on or with the machine, they must first be trained.

Responsibility for working with the machine (installation,

service, maintenance, overhaul) must be clearly defined

and strictly observed. Only those persons who can be

expected to carry out their work reliably may be given

permission to work on or with the machine. Personnel

must refrain from working in ways that could harm oth-

ers, the environment or the machine itself. It is absolutely

forbidden for anyone who is under the influence of

drugs, alcohol or reaction-impairing medication to work

on or with the machine. When appointing personnel to

work on the machine, it is necessary to observe all local

regulations regarding age and professional status. The

user is also responsible for ensuring that unauthorised

persons remain at a safe distance from the machine.

Personnel are obliged to immediately report to the opera-

tor any irregularities with the machine that might compro-

mise safety.

2.6 Work safety

Following the safety advice and instructions given in this

manual can prevent bodily injury and material

damage while working on and with the machine. Failure

to observe these instructions can lead to bodily injury

and damage to or destruction of the machine. Disregard

of the safety advice and instructions given in this manual

as well as the accident prevention regulations and

general safety regulations applicable to the operative

range of the machine shall release the manufacturer and

their authorised representatives from any liability and

from all compensation claims.

Safety

8

Corner rounding machine

ERM 1050

When working on or with the machine, the following

must be strictly observed:

Protective clothes

Sturdy, tight-fitting clothing (tear-resistant, no wide sleeves).

Persons with long hair who are not wearing a hairnet are not permitted to work on or with the machine!

When working on or with the machine, the following must always be worn by personnel:

Protective footwear

That protect the feet from heavy falling objects and prevent sliding on slippery floors.

Hearing protection

To protect against loss of hearing.

Gloves

Safety glasses

2.7 Personal protective equipment

The user must wear suitable clothing when operating the

machine as protection against moving machine parts.

Operators should not wear wide or flapping clothing,

baggy sleeves, trousers or shirts that are too long or too

wide etc.

Particular attention should be paid to belts, scarves, back

belts, necklaces, bracelets, long hair etc. Such items may

become caught in the moving parts of the machine and

pose a considerable danger.

Operators are strictly forbidden to wear mocassins,

clogs, crocs, slippers or any other footwear which

jeapardises their freedom of movement or stability.

Safety

9

Corner rounding machine

ERM 1050

2.8 Machine hazards

The machine has undergone a hazard analysis. The

design and construction of the machine are based on the

results of this analysis and correspond to state-of-the-art

technology.

The machine is considered operationally safe when used

properly.

Nevertheless, there are some remaining risks that must be

considered.

The machine runs with high electrical voltage.

2.9 Other risks

• Before carrying out any maintenance, cleaning and

repair work, switch off the machine and ensure that it

can not be accidentally switched on again.

• When carrying out any work on the electrical equip-

ment, ensure that the voltage supply is completely

isolated.

• Do not remove any safety devices or alter them to

prevent them from functioning correctly.

Safety

Warning! Danger! Electric current!

Electrical energy can cause serious bodily injury. Damaged insulation materials or defective individual

components can cause a life-threatening electrical shock.

Only on machines with spindle moulder unit:

• Danger of injury due to contact with the rotating moulder tool.

• Risk of injury from ejected tool pieces (e.g. cutting pieces).

• Therefore never stand directly within sight of the machining units when the machine is operating (whether the

machine is working or on stand-by mode)!

General safety rules:

• Be wary of sharp edges to avoid cutting yourself, in particular when changing the tooling.

• Risk of injury due to ejected work pieces and parts of work pieces (e.g. branches, chips).

• Risk of injury from workpiece kickback.

• Hearing damage as a result of high noise levels.

• Risk of damage to health from dust especially when working hard woods.

• Risk of injury through being crushed, cut, caught, wound up or sliced.

Warning! Risk of injury!

Even if the safety measures are complied with, there are still certain associated risks that must be considered

when working on the machine:

10

Hall in Tirol, 1.12.2020 Prof. h.c. Ing. Johann Georg Felder

CEO FELDER KG

KR-Felder-Straße 1, 6060 Hall in Tirol, AUSTRIA

Corner rounding machine

ERM 1050

3 Declaration of Conformity

Manufacturer: FELDER KG

KR-Felder-Straße 1, 6060 Hall in Tirol, AUSTRIA

Product designation: Corner rounding machine

Make: FELDER

Model designation: ERM 1050

The following EC guidelines were applied: 2006/42/EG

The following harmonised norms were applied: EN ISO 12100:2011-03

EG-Declaration of Conformity

according to Machine Guidelines 2006/42/EG

We hereby declare that the machine indicated below, which corresponds to the design and construction of the model

we placed on the market, conforms with the health and safety requirements as stated by the EC.

This EC Declaration of Conformity is valid only if the CE label has been affixed to the machine.

Modifying or altering the machine without the express written agreement of the manufacturer shall render the war-

ranty null and void.

The signatory of this statement is the appointed agent for

the compilation of the technical information

Declaration of Conformity

11

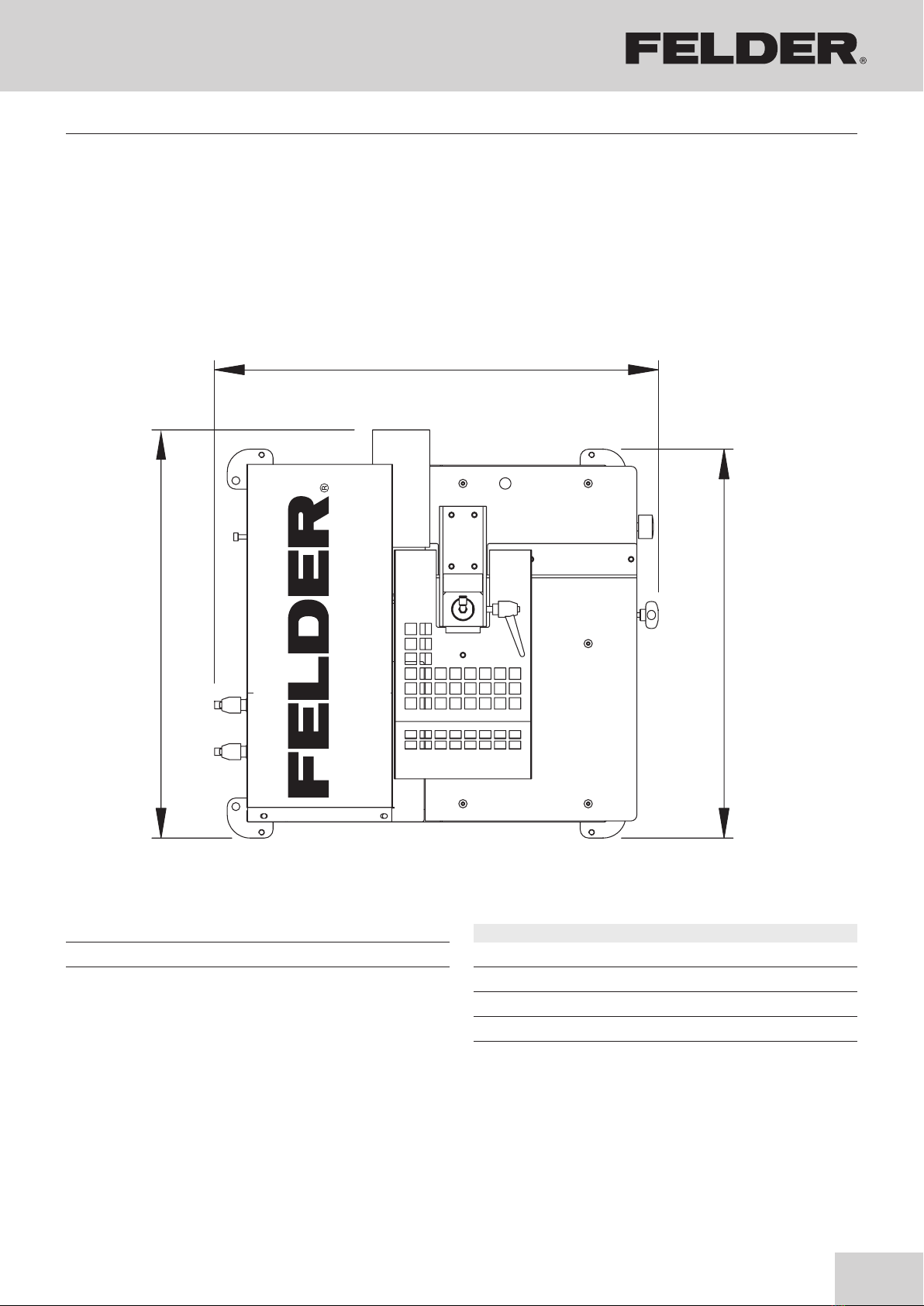

CRH Arrotondatore per spigoli diritti e sagomati Ed. 08/2005 Pag. 6

ITA FRA D

CRH Arrondisseur copieur hydropneumatique Ed. 08/2005 Pag. 6 CRH Hydropneumatischer Eckenkopierer Ed. 08/2005 Pag. 6

72 cm

78 cm

68 cm

Fig. 1.4.1

Dimensioni d'ingombro

Dimensions d'encombrement

Ausmaße

ERM 1050

Corner rounding machine

ERM 1050

4 Specifications

4.1 Dimensions and weight

4.2 Operating conditions

Operation/room temperature +15 to +35 °C

Net weight 100 kg

Workpiece thickness (min./max.) 10–50 mm

Fig. 4-1: Dimensions

Standardaus equipment

Flush trimming U/min. 24.000 rpm

Pneumatic motor power* 0,37 kW

WIDIA cutters** Ø 30 mm Z2 R= 2 mm

Vacuum connector Ø 100 mm

* Compressed air at 6,5 bars - 95 PSI and with constant and good supply.

** Max cutterhead diameter Ø 30 mm

Technical data

12

Corner rounding machine

ERM 1050

4.3 Standard equipment and optionals

4.4 Operator’s position

• Working table in high pressure laminate

• Panel locking unit with height adjustment

• Pneumatic flush trimmer motor

• Filter and air pressure regulator unit with automatic

lubricator

• Cutterhead with 6 mm shaft Z 2 Radius 2–3 mm

• Starting cycle pedal

• Protection guard complete with emergency switch

• Adjustable side stop for trimming adjustment with

numerical indicator

• Adjustable stops for corner rounding rotation

adjustment

• Hydraulic adjustment of the rotating speed

• Dust collection tube

• Service wrenches

• Service key

• CE norms

A: 1000 mm + twice the total length of the workpiece

B: 1000 mm

C: 500 mm + max. workpiece width

D: 700 mm

CRH Arrotondatore per spigoli diritti e sagomati Ed. 08/2005 Pag. 10

ITA FRA D

CRH Arrondisseur copieur hydropneumatique Ed. 08/2005 Pag. 10 CRH Hydropneumatischer Eckenkopierer Ed. 08/2005 Pag. 10

A

D

C

B

LEGENDA FIG. 1.8.1

A:1000 mm + 2 volte lunghezza massima pezzo da lavorare B: 1000 mm

C:500 mm + larghezza massima pezzo da lavorare D: 700 mm

: Zona di rispetto : Zona di lavoro

LEGENDA FIG. 1.8.1

A:1000 mm + deux fois la longuer maxi de la piece à plaquer B: 1000 mm

C:500 mm + largeur maxi de la piéce à plaquer D: 700 mm

: Zone de précaution : Zone de travail

LEGENDA FIG. 1.8.1

A:1000 mm + 2 mal die gesamte Länge des Werkstücks B: 1000 mm

C:500 mm + max. Breite des Werkstücks D: 700 mm

: Gesamter Platzbedarf : Arbeitsbereich

The operator position displayed allows the operator to

reach and operate the control elements and the Emer-

gency stop switch easily.

In addition, the figure shows the total space required for

machine servicing and cleaning purposes.

Technical data

13

Corner rounding machine

ERM 1050

4.6 Noise emission

The specified values are emission values and therefore

do not represent safe workplace values. Even though a

relationship exists between particle emission and noise

emission levels, an inference cannot be made about

whether additional safety measures need to be imple-

mented. Factors which can significantly affect the emis-

sion level that presently exists at the workplace include

duration of the effect, characteristics of the workspace,

and other ambient influences. The permissible workplace

values may also differ from country to country. Neverthe-

less, this information is provided to help the operator

better assess hazards and risks. Depending on the loca-

tion of the machine and other specific conditions, the

actual noise emission values may deviate significantly

from the specified values.

Note: To keep the noise emission as low as possible, always use sharpened tools and operate the

machine at the correct speed.

Ear protection must always be worn; however, such

protection cannot be considered a substitute for properly

sharpened tools or the correct speed.

As per ISO 3744/94 - ISO 7960/95 Annex norms:

Idle functioning without

dust extractor:

Medium level of

acoustic pressure

Level of acoustic pressure of

operator’s entrance place

Level of acoustic pressure of

operator’s exit place

Idle 72 Decibel (A) 71 Decibel (A) 70 Decibel (A)

When working with

dust extractor

Medium level of

acoustic pressure

Level of acoustic pressure of

operator’s entrance place

Level of acoustic pressure of

operator’s exit place

Operating mode 74 Decibel (A) 73 Decibel (A) 74 Decibel (A)

4.5 Particle emission

The machine was tested for particle emissions according

to DIN 33893. The Wood Authority ascertained,

according to the “Principles for Testing Particle Emis-

sions” (workplace-related particle concentrations) of

woodworking machines, that the particle emission values

for this machine are notably below the currently valid

atmospheric limit of 2.0 mg/m³. This is certified by the

blue label “BG Wood Particle Tested”.

Note:

Flush trimming is the only operation which produces dust emission. Connecting the machine to an efficient

dust extractor system, which guarantees a speed of at least 20m/min. to the suction outlet, results in dust

emission values below the limit of 2mg/m³ as prescribed by current legislation.

Technical data

14

Corner rounding machine

ERM 1050

5. Installation

5.1 Lifting and transport

5.2 Array of the machine

5.3 Dust extraction port

Preferably use a fork lift or transpallet to handle transport

of machine, since its frame allows their use.

The machine is delivered with a thermal shrinked nylon

protection or carton.

Locate the machine in a suitable place, considering the

dimensions of the machine, space needed for stacking,

loading and offloading workpieces, leaving sufficient

space for the operator to move freely.

Connect to an efficient dust extraction system to the two

flexible hoses Ø 100 mm, situated at the rear of the

machine.

To avoid any accidents during transport make sure that

the machine is firmly secured to the forklift with ropes or

other suitable systems.

Note: Make sure, by using a water level or any other equivalent good quality level, that the

working table is levelled in both directions. Tolerance ± 0,25 mm in longitudinal direction.

Note: When working with machine with flush trimming in function, the dust extraction system

must be in use.

The machine base must be layed on a even solid surface.

For a correct functioning it is necessary that the air speed

of the dust outlets is not below 20 m/min.

Installation

15

CRH Arrotondatore per spigoli diritti e sagomati Ed. 08/2005 Pag. 14

ITA FRA D

CRH Arrondisseur copieur hydropneumatique Ed. 08/2005 Pag. 14 CRH Hydropneumatischer Eckenkopierer Ed. 08/2005 Pag. 14

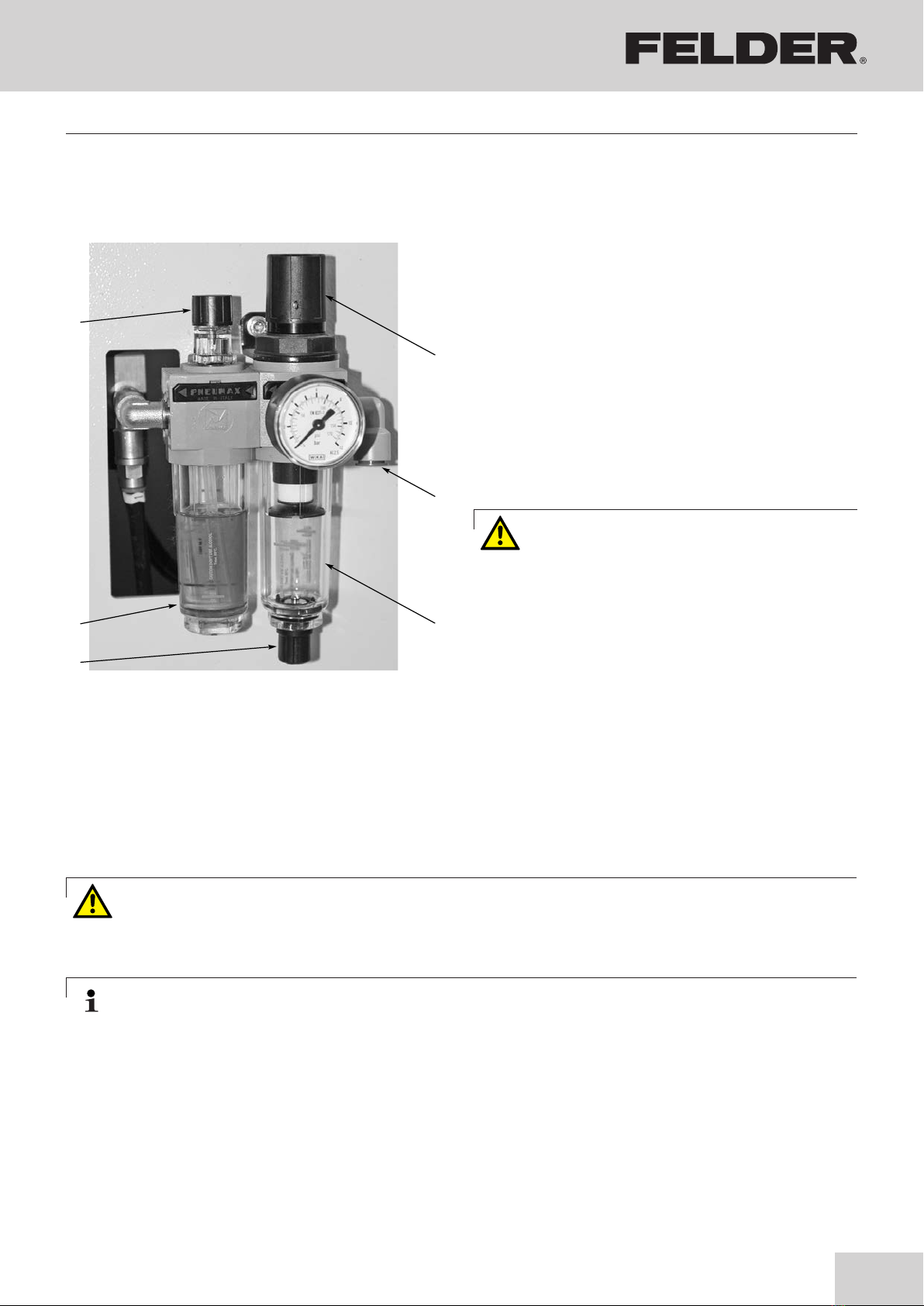

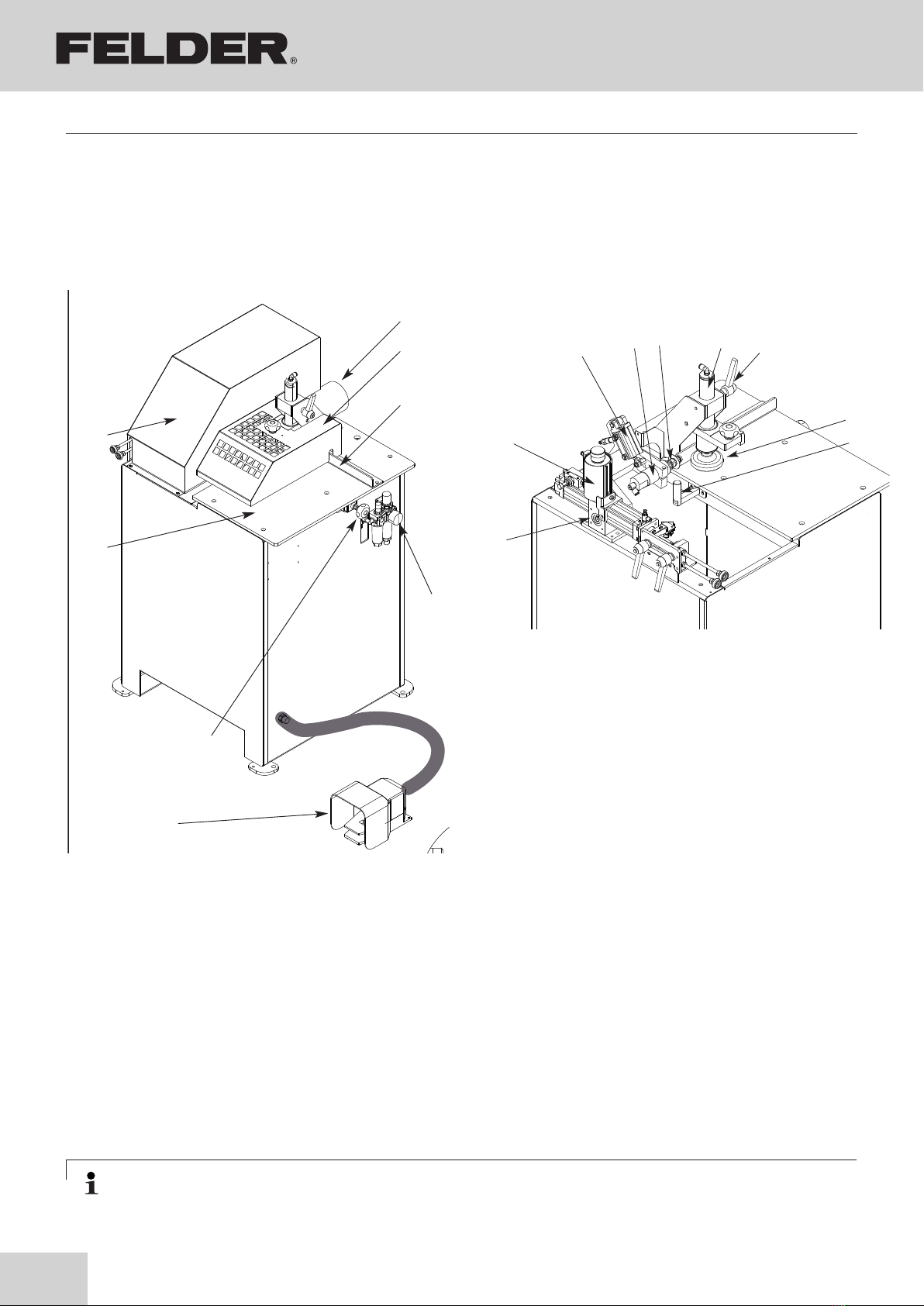

fig. 2.3.1

A

B

CD

F

E

Corner rounding machine

ERM 1050

5.4 Compressed air supply connection

The filter/pressure regulator with outflow of condensation

and a lubricator together with quick fitting are located

on the right-hand side of the machine. The fitting is for

10 mm ext. diameter pneumatic hoses (Type RISLAN).

Ensure that the compressed air reaches the connecting

area at least 7–8 bars and that the pressure is free from

humidity and has been suitably filtered.

The length and the inside diameter of the pneumatic

hoses must be proportioned for a correct functioning of

the CRM.

Adjust the air pressure to 6.5 bars.

The machine is adjusted and tested with this pressure.

Minimal power of the compressor: 3 HP

Note: Before proceeding to any maintenance operation, it is necessary to disconnect the

compressed air system.

Attention!

NEVER supply the CRM using a pneumatic

hose with an internal diameter measuring

less than 4 mm.

Attention!

Never add lubricant oils in the condensation collecting cup C.

Fill up periodically the oil cup D fig. 2.3.1 with the

following kind of oil: -SAE #10

Adjust the lubricator F at 2 drops per minute. To outflow

the condensation it is sufficient to push upwards the tap

C with the filter/regulator under pressure.

Installation

16

CRH Arrotondatore per spigoli diritti e sagomati Ed. 07/2010 Pag. 16

ITA ENG ESP

CRH Copying rounder for straight or shaped corners Ed. 07/2010 Pag. 16 CRH Redondeadora para angulos rectos y moldurados Ed. 07/2010 Pag. 16

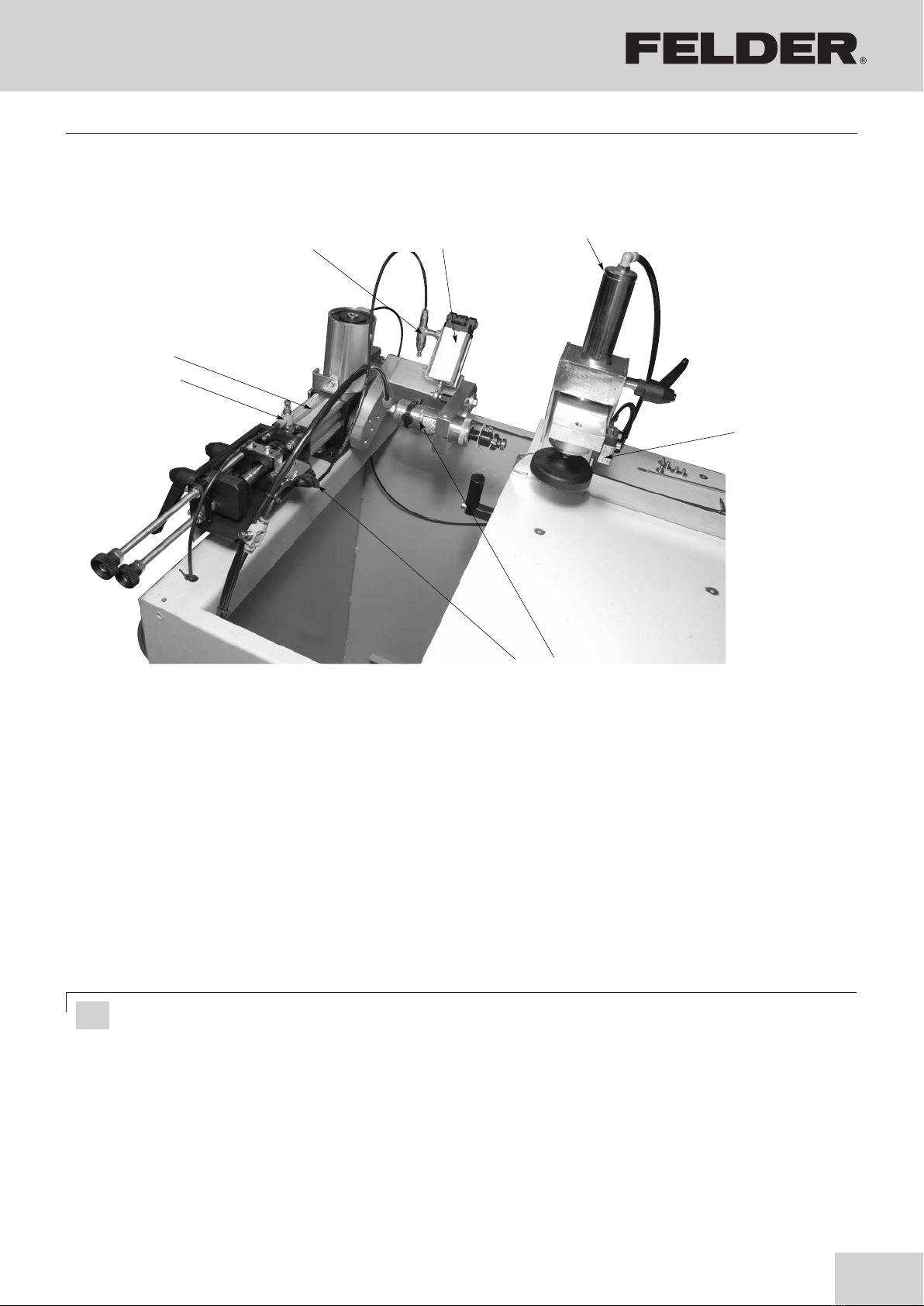

fig. 3.1.1 fig. 3.1.2 fig. 3.1.3

A

I

H

M

N

O

PQRS

T

U

B

C

D

E

F

G

L1B

L2A

LB LA

PH: HZ: A:

Baujahr / year of construction / ANNEE DE CONSTR.:

KW:

V:

NR.:

TYPE :

XXX-XXX/XX-XX

XXXXXXXX

20xx

KR-Felder-Straße 1, 6060 HALL in Tirol

AUSTRIA, Tel. +43 (0) 5223 58500

350 X.X400

X.X S1

Corner rounding machine

ERM 1050

6. Assembly

6.1 Overview

Fig. 6-2: Data plate

6.2 Data plate

The data plate displays the following specifications:

• Manufacturer information

• Model designation

• Machine number

• Voltage

• Phases

• Frequency

• Motor

• Power supply

• Year of construction

• Motor specifications

A: Chip extraction

B: Removable protection guard

C: Fixed fence

D: Air filter/pressure regulator with lubricator

E: Adjusting knob for side stop

F: Working table

G: Fixed protection guard

H: Start/stop pedal for working cycle

I: Corner rounding speed adjustment

L: Adjustable stops for rotation

M: Cylinder for flush trimming unit rotation

N: Oil tank

O: Follower cylinder

P: Pneumatic flush trimming motor

Q: Cutterhead with tracing ball bearing

R: Cylinder panel clamping

S: Handle to adjust the panel clamping

T: Rubber pad for panel clamping

U: Adjustable side stop

Assembly

17

CRH Arrotondatore per spigoli diritti e sa gomati Ed. 07/2010 Pag. 20

ITA ENG ESP

CRH Copying rounder for straight or shaped corners Ed. 07/2010 Pag. 20 CRH Redondeadora para angulos rectos y moldurados Ed. 07/2010 Pag. 20

fig. 3.3.1

fig 3.3.2

A

H

N

B

C

D

E

F

G

M

OPQRS

TU

U

fig. 3.3.4 “2 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE AR RIBA

Ufig. 3.3.3 “0,4 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE AR RIBA

CRH Arrotondatore per spigoli diritti e sa gomati Ed. 07/2010 Pag. 20

ITA ENG ESP

CRH Copying rounder for straight or shaped corners Ed. 07/2010 Pag. 20 CRH Redondeadora para angulos rectos y moldurados Ed. 07/2010 Pag. 20

fig. 3.3.1

fig 3.3.2

A

H

N

B

C

D

E

F

G

M

OPQRS

TU

U

fig. 3.3.4 “2 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE AR R IBA

Ufig. 3.3.3 “0,4 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE AR R IBA

CRH Arrotondatore per spigoli diritti e sagomati Ed. 08/2005 Pag. 20

ITA FRA D

CRH Arrondisseur copieur hydropneumatique Ed. 08/2005 Pag. 20 CRH Hydropneumatischer Eckenkopierer Ed. 08/2005 Pag. 20

fig. 3.3.1

fig. 3.3.2

A

H

M

N

OPQRS

T

U

B

C

D

E

F

G

U

U

fig. 3.3.3 “0,4 mm”

fig. 3.3.4 “2 mm”

VISTA DALL’ALTO

VUE PAR L’HAUTE

ANSICHT VON OBEN

VISTA DALL’ALTO

VUE PAR L’HAUTE

ANSICHT VON OBEN

Corner rounding machine

ERM 1050

6.3 Panel positioning

Raise the panel locking unit T by slackening the handle

S.

Place the panel against the fence C and against the

adjustable stop U.

Lower the panel locking unit T leaving it 5 mm higher

than the panel to allow to move it.

Tighten the handle S.

The working stroke of the panel locking cylinder is

10 mm. If the panel locking unit is set too high then the

panel is not locked correctly.

The panel locking unit locks the panel when the pedal H

is pressed and it unlocks the panel when the pedal H is

released.

The adjustable side stop U can be moved to place the

panel in the right position in accordance to the cutter-

head.

The adjustment can be changed by setting the knob E.

Turn the knob clockwise to push the panel off the cutter-

head, in this way the flush trimming decreases.

Turn the knob anticlockwise to put the panel near the

cutterhead, in this way the flush trimming increases.

This adjustment is equipped with a numerical indicator.

Attention! If the cutterhead is changed with a new one it is necessary to set the numerical indicator again!

When the corner rounding process is satisfactory,

slacken the locking grain of the index ring of the indica-

tor. Turn the index ring until the numbers of the indicator

correspond to the corner rounding process.

For example, corner rounding on 2 mm edge, the

numerical indicator has to show “002.0”.

Figures 3.3.3 and 3.3.4 explain the function of the „U“

side stop.

Assembly

18

CRH Arrotondatore per spigoli diritti e sagomati Ed. 07/2010 Pag. 22

ITA ENG ESP

CRH Copying rounder for straight or shaped corners Ed. 07/2010 Pag. 22 CRH Redondeadora para angulos rectos y moldurados Ed. 07/2010 Pag. 22

fig. 3.4.3

A

B

A

B

A

B

L1B L2A

L1B L2A

L1B L2A

fig. 3.4.4

Vista laterale pannello

Panel side view

Vista lateral del panel

Vista laterale pannello

Panel side view

Vista lateral del panel

Vista laterale pannello

Panel side view

Vista lateral del panel

N

M

OPQRS

T

U

L1B

L2A

LB

LA

LB

LA

N

M

OP

Q

RS

TU

LB

LA

CRH Arrotondatore per spigoli diritti e sagomati Ed. 08/2005 Pag. 22

ITA FRA D

CRH Arrondisseur copieur hydropneumatique Ed. 08/2005 Pag. 22 CRH Hydropneumatischer Eckenkopierer Ed. 08/2005 Pag. 22

fig. 3.4.2

I

L1

L2

fig. 3.4.3

M

N

O

PQ

R

S

T

U

A

B

A

B

A

B

L1 L2

L1 L2

L1 L2

fig. 3.4.4

Vista laterale pannello

Vue latérale panneau

Seitliche Werkstückansicht

Vista laterale pannello

Vue latérale panneau

Seitliche Werkstückansicht

Vista laterale pannello

Vue latérale panneau

Seitliche Werkstückansicht

Corner rounding machine

ERM 1050

6.4 Corner rounding unit adjustment

The unit flush trims the excess of edge from straight or

shaped profiled panels.

By pressing the pedal H, the following sequence starts:

1. The flush trimming pneumatic motor starts and the

cylinder O moves the trimmer to the panel. The pneu-

matic flush trimmer motor uses a 2-knife cutterhead

that trims off the excess of edge and a copying ball

bearing that traces the surface of the panel. The pres-

sure of the cylinder O is set to avoid the copying ball

bearing from damaging the panel.

2. the cylinder M allows the flush trimming unit to rotate

from the top of the panel to the bottom executing the

corner rounding function.

3. releasing the pedal H, the flush trimmer moves away

from the panel, the cylinder M moves back into start-

ing position and the clamp releases the panel.

4. The ERM is ready for a new cycle.

By moving the handle L2 to the left, the rotation will be

limited to the top side of the panel. By moving the handle

L1 to the right, the rotation will be limited to the bottom

side of the panel. Before setting the handles L1 and L2,

always switch off the compressed air.

The fine adjustments LA and LB allow you to adjust the

starting and end point of the rounding. In this way it is

possible to join properly the radius of the milled edge

with the radius of the rounded corner. L1/L2 Release,

LA/LB Set, L1/L2 clamp again.

LA: Starting point

LB: End point

Look at the figures above for examples of handle settings

depending on the profile to be machined. Points A and

B represent the start and the end of the corner rounding

process. The speed of the rotation of the flush trimming

unit can be adjusted in accordance to the thickness of

the edge. To attain the best results, it is recommended

to reduce the speed of rotation when working with edge

material 2 or 3 mm thick. The speed of rotation can be

reduced with the regulator, loosen to decrease the speed

and tighten to increase it.

Assembly

19

CRH Arrotondatore per spigoli diritti e sagomati Ed. 07/2010 Pag. 24

ITA ENG ESP

CRH Copying rounder for straight or shaped corners Ed. 07/2010 Pag. 24 CRH Redondeadora para angulos rectos y moldurados Ed. 07/2010 Pag. 24

A

B

G

H

fig. 3.5.1

CD

E

F

!

Corner rounding machine

ERM 1050

6.5 Pneumatic control

A Speed adjustment regulator for cylinder B returning:

This regulator is adjusted at the factory and it does

not need any further adjustment.

B Cylinder for corner rounding unit rotation

C Pressure regulator Cylinder D

This regulator is adjusted at the factory and it does

not need any further adjustment. Tighten to increase

the pressure and as a result, increase the thrust on

the copying bearing. Unscrew to decrease the pres-

sure.

D Corner rounding unit copying cylinder

E Panel locking cylinder

F Emergency microswitch for protection guard:

Dismount guard G and press pedal H to ensure that

the pneumatic motor will not operate.

G Flush trimming pneumatic motor:

The rotating speed depends on the pressure adjusted

on the filter-regulator B. The pneumatic motor needs

constant lubrication.

H Copying end switch

Assembly

Attention! Risk of material damage!

Never fill the condensation receptable with lubricant oils!

20

CRH Arrotondatore per spigoli diritti e sagoma ti Ed. 07/2010 Pag. 20

ITA ENG ESP

CRH Copying rounder for straight or shaped corners Ed. 07/2010 Pag. 20 CRH Redondeadora para angulos rectos y moldurados Ed. 07/2010 Pag. 20

fig. 3.3.1

fig 3.3.2

A

H

N

B

C

D

E

F

G

M

OPQRS

TU

U

fig. 3.3.4 “2 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE ARRIBA

Ufig. 3.3.3 “0,4 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE ARRIBA

CRH Arrotondatore per spigoli diritti e sa goma ti Ed. 07/2010 Pag. 20

ITA ENG ESP

CRH Copying rounder for straight or shaped corners Ed. 07/2010 Pag. 20 CRH Redondeadora para angulos rectos y moldurados Ed. 07/2010 Pag. 20

fig. 3.3.1

fig 3.3.2

A

H

N

B

C

D

E

F

G

M

OPQRS

TU

U

fig. 3.3.4 “2 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE ARRIBA

Ufig. 3.3.3 “0,4 mm”

VISTA DALLALTO

TOP SIGHT

VISTA DE ARRIBA

Corner rounding machine

ERM 1050

7. Maintenance

7.1 Cleaning

7.2 Lubrication

Machines needs to be cleaned periodically.

Always disconnect the compressed air power supply

hose.

● Clean glue residuals from the cutters of the

cutterhead.

None of the mechanical movements require lubrication.

The pneumatic flush trimmer motor requires daily lubrica-

tion.

● Clean fence C and stop U.

● Remove any dust and shavings from the extraction

hood, if necessary.

Note: Adjust the lubricator F at 2 drops per minute.

The pneumatic flush trimmer motor does not need to be

dismounted for lubrication but it is sufficient to fill the

lubrication cup D with this oil: -SAE #10

Maintenance

Table of contents

Other Felder Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Wilo

Wilo DrainLift SANI-M Installation and operating instructions

SUHNER ABRASIVE

SUHNER ABRASIVE UAK 30-RF SPZ-L Technical document

Verlinde

Verlinde PEV-1 Manual of instructions

MR

MR ECOTAP VPD I operating instructions

ABB

ABB Power2 800-M Assembly instructions

Epiroc

Epiroc Secoroc COP 32 Operator instructions

Rodix

Rodix FEEDER CUBE FC-40 Plus Series Adjustments and Set Up

Siemens

Siemens SIRIUS 3RK1901-1MX02 Original operating instructions

Rockwell Automation

Rockwell Automation RELIANCE ELECTRIC INVERTRON DBU-50 instruction manual

Graco

Graco ProMix PD2K Operation

Salda

Salda AVS Series Mounting and installation instructions

Siemens

Siemens DX791 Installation