Epiroc Secoroc COP 32 Specifications

Secoroc COP

down-the-hole hammers

COP 32 / 32HD, COP 42

Operator’s instructions

2

Any unauthorized use or copying of the contents or any part

thereof is prohibited.This applies in particular to trademarks,

model denominations, part numbers and drawings.

© Copyright 2018

Epiroc DrillingTools AB, Fagersta, Sweden

Contents

Safety regulations ������������������������������������������������������� 3

Technical data �������������������������������������������������������������� 3

General ������������������������������������������������������������������������� 4

Application (drill rigs)..........................................................................4

Technical description...........................................................................4

Preparing to drill ���������������������������������������������������������� 5

Hose connection ................................................................................. 5

Setting up the drig.............................................................................. 5

Drilling �������������������������������������������������������������������������� 6

Rotation to the right ........................................................................... 6

Collaring .............................................................................................. 6

Feed and rotation................................................................................ 6

Feed force.............................................................................................6

Rotation speed .................................................................................... 7

Flushing – air blowing........................................................................ 7

Extra flushing...................................................................................... 7

Changing the choke plug ................................................................... 7

Drilling in wet holes............................................................................ 7

Water injection.................................................................................... 8

Foam injection .................................................................................... 8

Tools������������������������������������������������������������������������������ 9

Tools for removing the drill bit and top sub from the DTH hammer ...9

Breaking the driver chuck joint using percussion only.................... 9

Breaking the driver chuck joint using the bit removal tool ........... 10

Dirt in the hammer���������������������������������������������������� 10

Other instructions������������������������������������������������������ 10

Wear of driver chuck and hammer cylinder .................................... 10

Checking the wear of the driver chuck and cylinder ....................... 11

Shimming........................................................................................... 11

Assembly of the drill bit and driver chuck ....................................... 11

Regrinding the drill bit ���������������������������������������������� 12

Grinding equipment �������������������������������������������������� 12

Care and maintenance ���������������������������������������������� 13

Lubrication ����������������������������������������������������������������� 13

Lubricators .........................................................................................13

Choice of lubrication oil .................................................................... 13

Recommended lubricants .................................................................14

Wear limits ����������������������������������������������������������������� 15

Trouble shooting�������������������������������������������������������� 15

Overhaulilng.......................................................................................15

3

Safety regulations

• Before starting, read these instructions carefully.

• Important safety information is given at various points in these

instructions.

• Special attention must be paid to the safety information con-

tained in frames and accompanied by a warning symbol (triangle)

and a signal word, as shown below.

Indicates immediate hazards which WILL result in serious or

fatal injury if the warning is not observed.

DANGER

Indicates hazards or hazardous procedures which COULD result

in injury or damage to equipment if the warning is not observed.

WARNING

Indicates hazards or hazardous procedures which COULD result

in injury or damage to equipment if the warning is not observed.

CAUTION

• Read through the operator’s instructions for both the drill rig and

the DTH hammer thoroughly before putting the DTH hammer into

service. Always follow the advice given in the instructions.

• Use only authorized parts. Any damage or malfunction caused

by the use of unauthorized parts is not covered by Warranty or

Product Liability.

The following general safety rules must also be observed:

• Make sure that all warning signs on the rig remain in place and

are free from dirt and easily legible.

• Make sure there are no personnel inside the working area of the

drill rig during drilling, or when moving the rig.

• Always wear a helmet, goggles and ear protectors during drilling.

Also observe any local regulations.

•The exhaust air from air driven hammers and grinding machines

contains oil. It can be dangerous to inhale oil mist. Adjust the lubri-

cator so that the correct rate of lubrication is obtained.

• Make sure that the place of work is well ventilated.

• Always check that hoses, hose nipples and hose clamps are prop-

erly tightened and secured, and that they are not damaged. Hoses

that come loose can cause serious injury.

• Local regulations concerning air hoses and connections must

always be strictly observed.This is especially the case if the DTH-

hammer is to be operated at pressures above 10 bar (145psi).

• The machine must not be used for purposes other than those

prescribed by Secoroc. See “Application” on page 8.

Technical data

Dimensions and weights COP 32 COP 42

Length without drill bit 925 mm 960 mm

Length excl. thread 849 mm 884 mm

Outside diameter 77 mm (82

mm*) 96 mm

Piston diameter 60 mm 76 mm

Stroke 100 mm 100 mm

Male connection thread 2 3/8 API Reg 2 3/8 API Reg

Female connection thread Rd 50-6 (-*) -

Spanner flat on top sub 50 mm 65 mm

Weight without drill bit 23 kg (26 kg*) 35 kg

Drilling parameters

Working pressure 6-12 bar, 87-

174 psi

6-18 bar, 87-

260 psi

Rotation speed with button bit 30-40 r/min 25-35 r/min

Feed force 2-6 kN 3-8 kN

Feed force, normal, approx 3,5 kN 5 kN

Hole diameter range 85-100 mm (90-

100 mm*) 100-152 mm

Air consumption at different working pressures (with standard choke

plug)

6 bar 40 l/s 56 l/s

10.5 bar - 110 l/s

12 bar 90 l/s -

16 bar - 200 l/s

Blowing capacity

6 bar 180 l/s 120 l/s

10.5 bar - 200 l/s

12 bar 325 l/s -

16 bar - 330 l/s

Impact rate (strokes/min)

6 bar 1290 1344

10.5 bar - 1650

12 bar 1750

16 bar - 1950

Penetration rate in Swedish granite, 2200 bar, 30% SiO, mm/min

(Standardized laboratory test)

Bit size 90 mm 115 mm

6 bar 110 mm/min 112 mm/min

10.5 bar - 276 mm/min

12 bar 300 mm/min -

16 bar - 468 mm/min

* COP 32HD

Performance figures are average values for new hammers at sea

level.

Specifikations and other data subject to alteration without prior

notice.

4

General

The down-the-hole hammer is a percussion hammer drill. As

the name implies, the hammer works down the hole at the

end of the drill string, where the impact piston strikes the

drill bit directly.

Compressed air is led to the hammer via the rotation spindle

and drill pipes. Exhaust air from the hammer is discharged

through holes in the drill bit and used to flush clean the

drill hole. Rotation is provided by a rotation unit on the feed

beam and transmitted to the hammer via the drill pipes.The

drill pipes are threaded so that the drill string can be ex-

tended as drilling progresses and the hole becomes deeper.

Feed force is also transmitted to the hammer via the rotation

unit and drill pipes. One of the main advantages of DTH

hammers is that the drilling rate is not affected very much by

the length or depth of the drill hole.

DTH hammers are very productive and have many applica-

tions in the mining, quarrying, civil-engineering and water-

well drilling industries.

Application (drill rigs)

A= Drill pipe

B= Down-the-hole hammer

C= Drill bit

D= Rotation unit

E= Feed

F= Drill rig

Secoroc COP down-the-hole hammers are designed for use

on DTH or ITH drill rigs.They can also be used on rotary and

auger type drill rigs, provided that such rigs meet the specifi-

cations for DTH applications.The main demands on the drill

rig are as follows:

• It should be equipped with a rotation unit that has a vari-

able rotation speed of 0–90 r/min and a rotation torque of

750–3000 Nm (75–300 kpm). Naturally, the torque demand

for a recommended rotation speed will depend on the ham-

mer size and bit diameter.

• A variable feed force of 3–43 kN (300–4300 kp) for shallow

holes (less for deeper holes, bearing in mind the weight of

the drill string). Obviously, the feed must be strong enough

to pull the hammer and drill string out of the drill hole.This

is an especially important consideration when drilling deep

holes.The weight of the drill string varies between 9 and 34

kg/m, depending on the pipe- and bit diameters.

Technical description

The Secoroc COP down-the-hole hammer and drill bit operate at

the bottom of the hole as a unit.

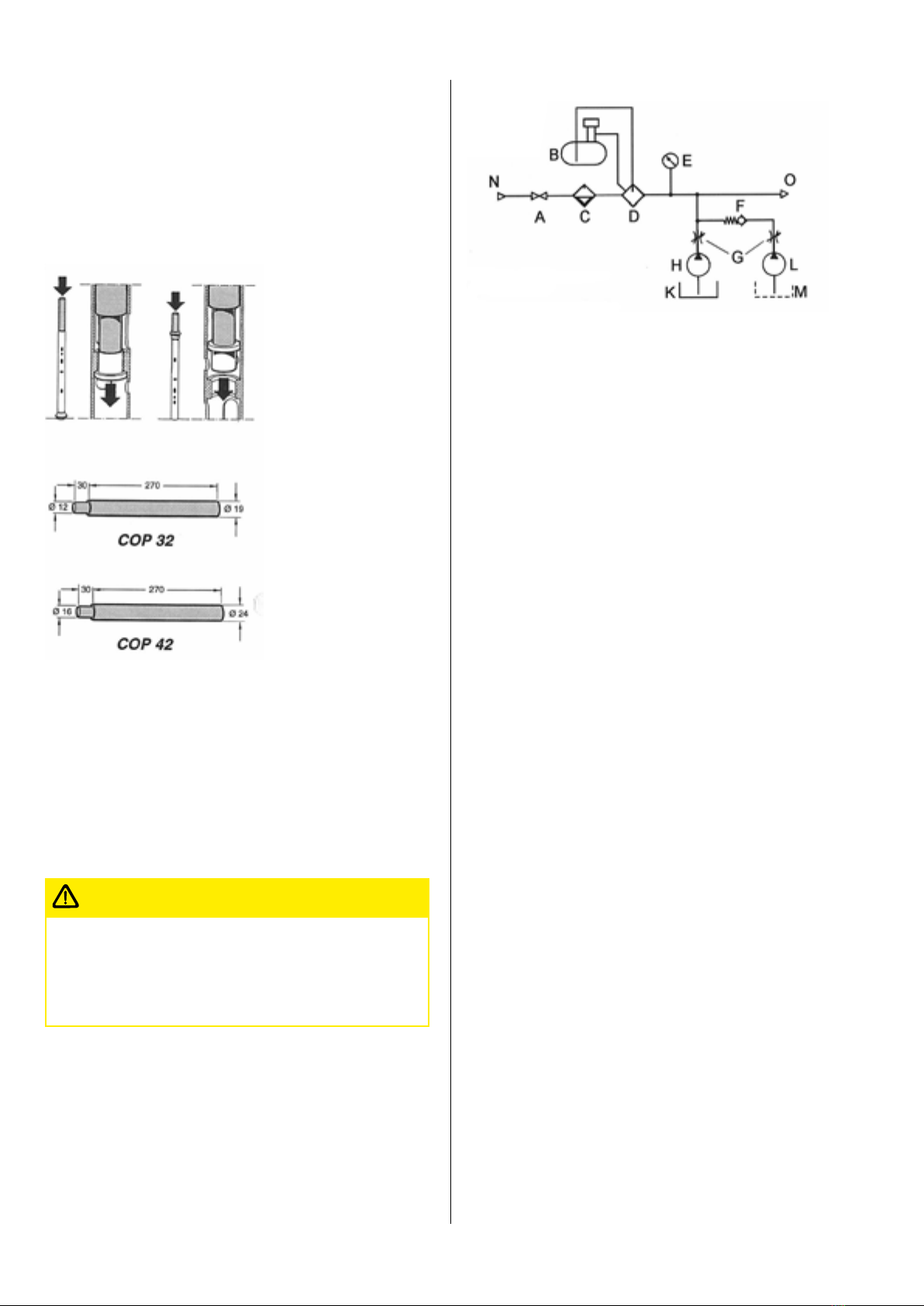

The COP 32/42 consists of a long cylinder G,

which houses a check valve B, compression

ring C, piston E, control tube E, control tube D,

bushing H, stop ring Jand drill-bit shank K�The

rear end of the cylinder is closed by a threaded

top sub A� The top sub has a male thread for

connection to the drill pipes, and also a spanner

flat. (For the COP 32, a top sub with female

thread is also available.)

A driver chuck Lthreads into the front end

of the cylinder. A splined union between the

driver chuck and the drill bit shank Kseves to

transmit rotation to the drill bit.The front end of

the driver chuck transmits feed force to the drill

bit.The check valve Bprevents impurites from

entering the hammer when the working air

pressure is switched off.

When feed force is applied, the drill bit is

pushed into the hammer, where it presses

against the bushing H.The piston Estrikes the

shank K of the drill bit directly.The path of the

working air through the hammer is controlled

by the piston, with the aid of the control tube D.

Both components contain regulation ducts. A

built-in damping chamber cushions the return

stroke of the piston and increases the impact

frequency. After the working air has imparted

most of this pressure energy to the impact

piston, it is led into the flushing galleries in the

drill bit and cut through the flushning holes in

the head of the drill bit. From here it expands

upwards out of the hole, carrying the drill cut-

tings with it.

When the hammer is lifted off the bottom of the

drill hole, the drill bit drops down to its outer

position in the machine. When this happens,

the piston fails into the blowing position.The percussion mecha-

nism then stops working and only air blowing takes place, i.e. a

large volue of air flows straight through the hammer and drill bit.

Blowing also starts if the drill bit loses contact with the bottom of

the hole while drilling is in progress.The hammer then restarts as

soon as the drill bit is pressed back against the driver chuck. Blow-

ing is used when extra powerful cleaning of the hole is required,

and also in certain difficult conditions.

In difficult drilling conditions, extra flushing can be obtained by

exchanging the plug F in the control tube for a special choke plug,

which has an air duct through it.The duct enables extra flushing

air to flow directly to the flushing galleries in the drill bit.This can

be desirable, e.g. when large volumes of water flow into the drill

hole, or when there is a large difference between the diameter of

the drill bit and the diameter of the drill pipes, or when the pen-

etration rate is abnormally fast.

Friction between the drill pipes and the hole wall can sometimes

reduce the penetration rate.This can often be counteracted by

increasing the air pressure, which gives greater impact enenrgy

and faster penetration.

With the aid of Epiroc ODEX equipment, COP down-the-hole

hammers can be used to simultaneously drill and case holes in

overburden. Secoroc equipment for the precision dillilng of long

straight holes is also available.

5

Preparing to drill

Hose connection

Connecting and securing the air hoses

For a compressed air system to

be efficient, reliable and

economic, there must be:

• sufficient compressed-air ca-

pacity (volume and pressure);

• minimal pressure loss between

the compressor and the hammer;

• minimal air leakage between

couplings.

This can be realized by ensuring

that:

• the correct size of compressor

is selected;

• the correct hose size is used

between the compressor and the

hammer;

• there is no leakage in hose con-

nections between the compres-

sor and hammer.

• Compressed-air hoses between the compressor and the

drill rig must be secured by means of an external or internal

safety wire, which must be fastened safely to the drill rig. If

the DTH hammer is to work at pressures above 10 bar (145

psi), any local regulations regarding air hoses and couplings

must be strictly observed.

• Always check that hoses, hose nipples and hose clamps

are not damaged, and that they are properly tightened and

secured.

DANGER

• Always check the condition of drill string components. Bent

or worn pipes can cause damage and excessive wear to the

hammer and rig.

CAUTION

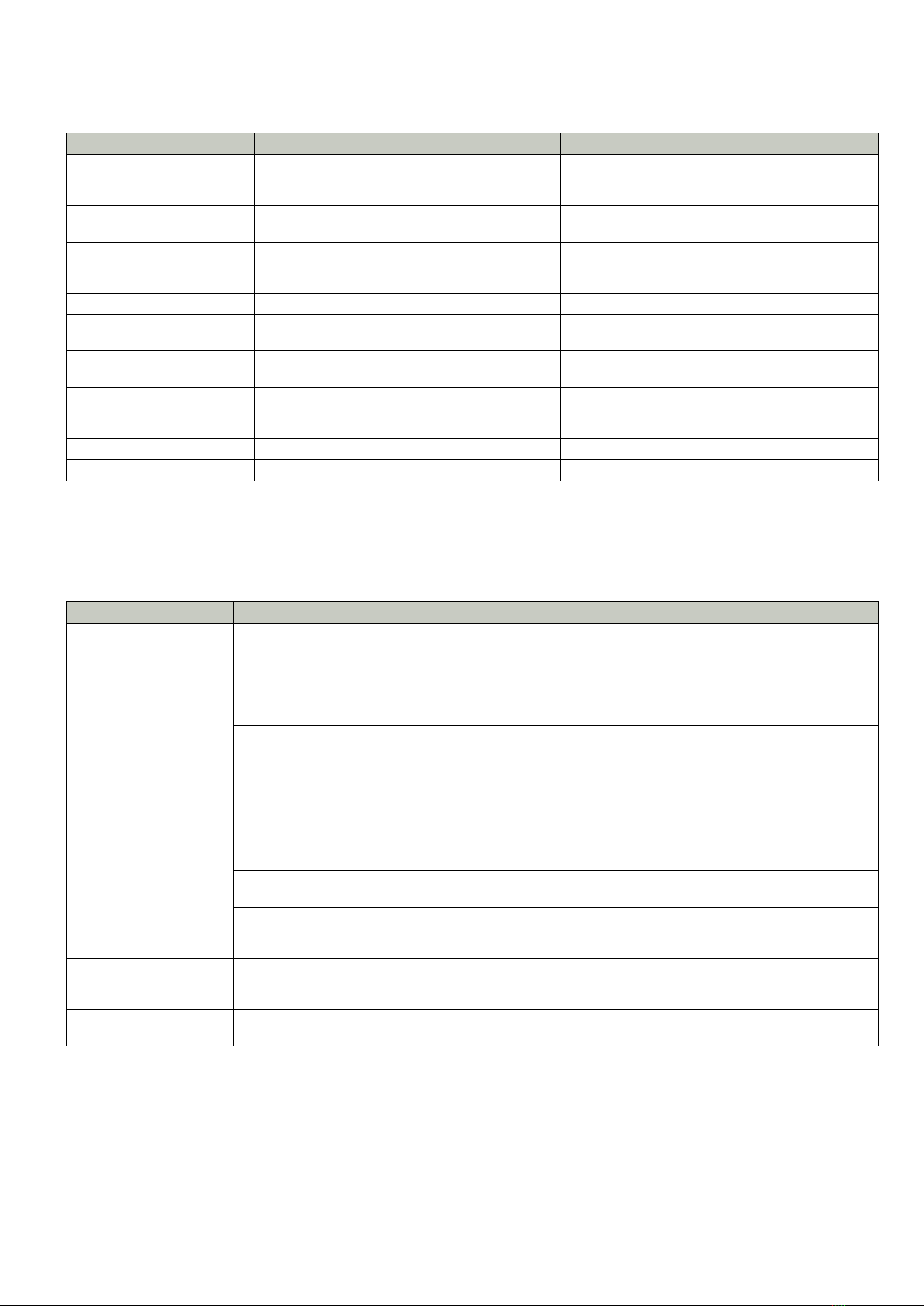

Setting-up the rig

Before drilling with the DTH hammer, the rig must be set-up cor-

rectly in order to give stability and safety. If this is not done, the

effects of feed force and rotation torque can cause the rig to move.

This will have a negative effect on drilling, especially when drilling

deep, straight holes.

When setting up a drill wagon or crawler

drill rig, a stable three-point set-up must be

obtained, with the weight of the rig distrib-

uted between the base of the feed beam and

the two rear corners of the rig. It is of the

utmost importance that the rear loading

points are as far to the rear of the rig as

possible, with most of the rig weight being

loaded on to the base of the feed.

When drilling in soil or other non-consolidat-

ed formations, the weight of the rig must not

be loaded on to the feed near the mouth of

the hole, since this could easily cause the

hole to cave-in. Instead, the load should be

distributed some distance to either side of

the hole. Suitable support can be obtained

by placing a sturdy U-beam under the base

of the feed beam, and supporting the beam

on planks at both ends. A two inch (50 mm)

plank should then be placed inside the

U-beam to prevent mechanical chatter and

damage to the base of the feed beam.

If the rig is wheel-bound, it should be raised

off the ground completely using the jacks,

so that all wheels are clear of the ground.

•The rig must be set-up correctly in order to give stability

and safety. If this is not done, the effects of feed force and ro-

tation torque can cause the rig to move or even to overturn.

This can incur the risk of serious or fatal injury as well as

damage to the drill rig and equipment.

DANGER

• Heavy lift.Take care when

handling the hammer.The

hammer and its internal

components are heavy and

difficult to handle, espe-

cially in the case of the

larger hammers.

When lifting using mechanical lifting equipment, sling the

hammer as shown in the fig. Alternatively, a lifting-eye cou-

pling can be screwed on to the top sub.

•Transportation. Do not let the hammer lie unsecured on a vehi-

cle or drill rig. Always secure the hammer for transportation.

WARNING

• Always wear goggles during drilling!

•The exhaust air from the hammer (and also from the top

sub if a unit for extra flushing is fitted) has a very high

velocity. Objects such as small stones, drill cuttings, sand,

earth and oil residue that are entrained in the flushing air

can cause serious injury to unprotected eyes. Pay special

attention to this danger during collaring, when a top sub with

extra flushing is in use, an when the hammer is fed through

the drill steel support or down into the hole.

WARNING

6

Drilling

Rotation to the right

DTH hammers must be rotated to the

RIGHT (clock wise) during drilling, since the

driver chuck and top sub are threaded into

the cylinder with RIGHT-HANDTHREADS.

Rotation must always be to the right when

the hammer is operating. Left-hand rotation

(or no rotation) will cause the driver chuck

to loosen, which could mean losing the drill

bit (or even the entire hammer) down the

hole.

The drill string should be rotated to the

right even when the hammer is not operat-

ing. For example, this should be done when cleaning the drill hole

and when lifting up the drill string. It can be said that rotation to

the right should be switched on as long as other operations are

in progress with the hammer in the hole.The risk of the drill bit

working loose should also be considered when breaking the joints

between drill pipes. When adjusting the breaking wrenches, bear

in mind that the drill string must not be rotated anti-clockwise any

more than is absolutely necessary.

• Always switch on rotation to the right before starting the

feed or hammer.

• Let the hammer rotate to the right (clockwise) even during

lifting or lowering of the hammer.

• Do not switch off rotation to the right until all other func-

tions have been switched off.

IMPORTANT

•Take great care when jointing drill pipes. Make sure there

is no danger of your fingers being pinched or clothing being

entangled when the drill string is rotated.

• When a pipe wrench is used during jointing, there is a risk

of the wrench flying off and causing injury when rotation is

applied.

WARNING

• When drilling on soft or unstable ground, great care must

be taken because the flushing air from the hammer can

erode the material around the drill hole, and so undermine

the ground beneath the drill rig.This can pose a great danger

to personnel and risk damaging the equipment.

DANGER

• Always wear ear protectors during drilling.

CAUTION

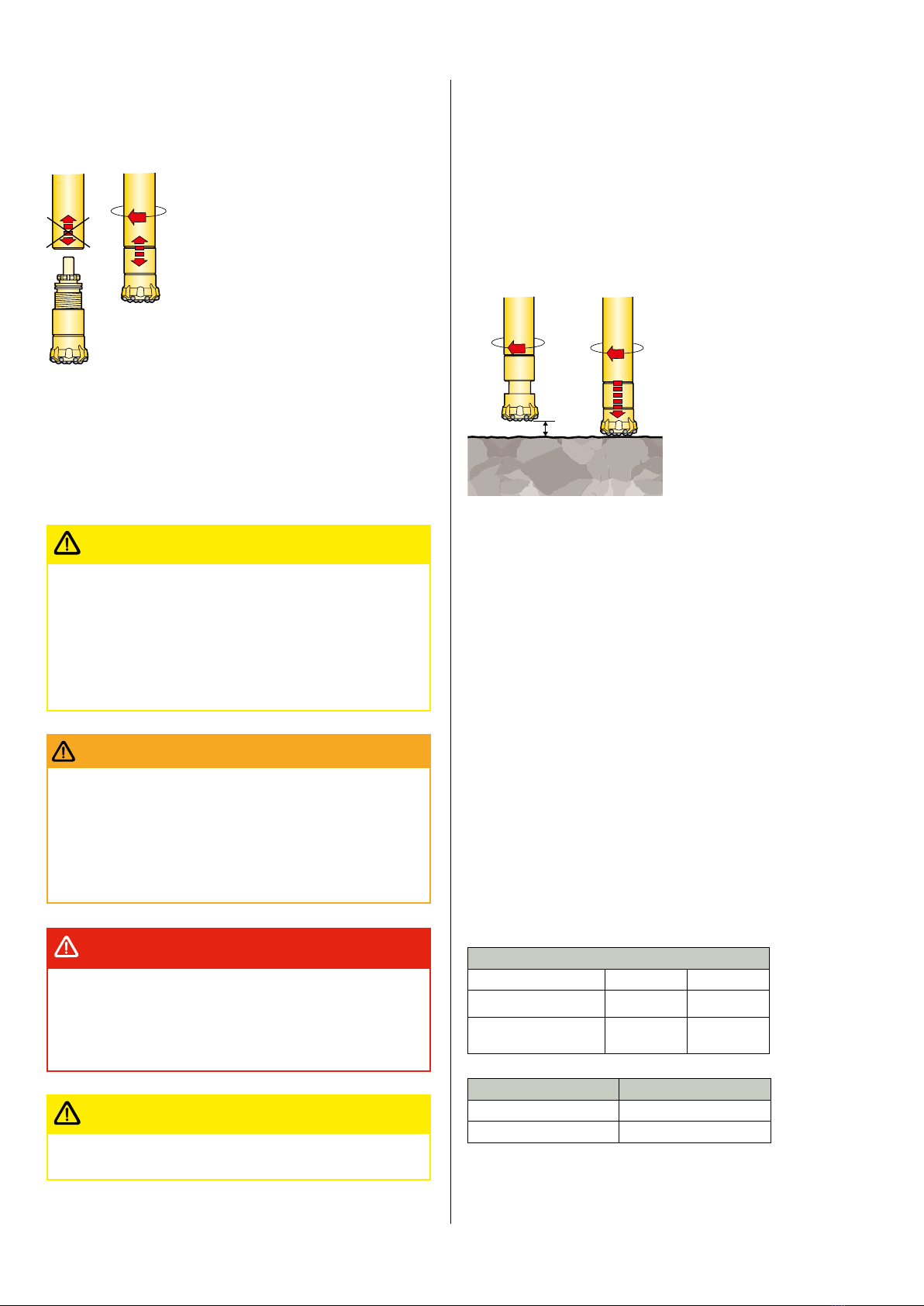

Collaring

• Feed the hammer downward until the drill bit is about 5 cm from

the collaring point.

• Start rotation to the right at low speed (creeping).

• Feed the hammer on to the rock using minimal feed force, so that

the bit is pressed into the hammer, and into the impact position.

• Start collaring the hole with reduced impact and feed, until the bit

has entered the rock.

• Open the impact mechanism control fully and adjust the rotation

and feed so that the hammer drills smoothly and steadily.

5 cm

Feed and rotation

With holes of relatively shallow depth, the setting of feed and rota-

tion is usually a simple matter in DTH drilling, since the hammers

are comparatively insensitive to small variations in the “normal”

flow and pressure settings.The settings can be regarded as correct

when the drill string turns evenly without jerks or jamming, and a

steady penetration rate is obtained.

Feed force

When drilling with COP DTH-hammers, the feed force should be

high enough to keep the shank of the drill bit pressed into the ham-

mer during drilling.

•Too low a feed force will give easy rotation, excessive vibration

and reduced penetration.The resultant reflex shock waves can

damage the rotation unit and feed beam.

•Too high a feed force causes the rotation to jam (either erratically

or completely) and can subject the drill string to severe bending

stresses. It can also damage the rotation unit and feed beam.

The feed force often needs to be corrected during drilling, depend-

ing on the rock formation and the weight of the drill string, which

obviously varies with the hole depth.

A rough guide to drill pipe weights for different sizes of DTH-ham-

mer are given in the table below:

Feed force – recommendations

COP 32 COP 42

Feed force 2-6 kN 3-8 kN

Feed force, normal

approx.

3,5 kN 5 kN

Pipe dimension, mm Approx� weight

76 mm 9 kg/m

89 mm 15 kg/m

Bit diameter, rock formation, hole depth and available rotation

torque will have a considerable influence on the setting of the feed

force. What is important is that the feed force is adjusted to give

7

steady penetration and a constant, even rotation speed with no

jamming (see table).

N�B. It is important that the feed force be adapted to suit the

weight of the drill string. When drilling deep holes, this requires

control facilities for “negative feeding”, a so-called “holdback”

function.

Rotation speed

In hard rock, the rotation speed for COP 32/42 should be set

between 20-35 r/min, depending on the hammer size and bit

diameter (the larger the bit diameter, the slower the speed).The

upper limit generally produces the best penetration rate. In very

abrasive rock formations, however, the rotation speed should be

reduced to avoid excessive wear of the drill bit.

When drilling in softer rock or in the case of the COP 42, when

drilling with high air pressure (above 16 bar) in non-abrasive for-

mations, higher rotation speed may be used.The following should

be noted:

Rotation speed – recommendations ( r/min)

Penetration rate

Rock characteristics

COP 32

ø 90 mm

COP 42

ø 115 mm

0,7 - 1 m/min.

Soft, abrasive rock

Soft, non abrasive rock

(Air pressure above 16 bar)

40-55

–

35–50

35–70

0,4 - 0,7 m/min.

Medium-hard,

abrasive rock

non abrasive rock

(Air pressure above 16 bar)

30–40

–

25–35

25–55

<0,4 m/min.

Hard, abrasive rock

Hard, non abrasive rock

(Air pressure above 16 bar)

25–35

–

20–30

20–50

Too high a rotation speed will cause increased wear to the drill bit,

hammer and drill pipes. Stresses to the feed and rotation unit will

also increase.

Too low a rotation speed results in a poor drilling output and

uneven operation.

Flushing — Air-blowing

To avoid wasteful re-crushing and the risk of

jamming, drill cuttings must be flushed out

of the drill hole at the same rate as new

cuttings are produced. It is good drilling

practice to clean out the hole at regular

intervals by means of air-blowing.This is

especially important in non-consolidated

formations and when there is a danger of the

hole wall collapsing. Air-blowing is done by

lifting the hammer off the bottom of the hole

(fig. a) and running the feed back and forth.

N�B� Rotation must always be to the right.

The impact mechanism stops as soon as the

hammer is lifted and the bit drops down-

wards, which causes a considerable volume

of air to flow through the hammer and flush-

out the hole. When the hammer is lowered

back on to the bottom of the hole, the bit is

pressed back into the impact position, which

re-starts the impact mechanism.

• Always wear goggles during drilling.The backward-direct-

ed flushing air from the top sub contains drill cuttings and oil

residue which can injure the eyes.

WARNING

Extra flushing

The need for extra flushing is greater when drillingt with lowe

working pressures and in difficult drilling conditions, e.g. when

there is a high flow of water inteo the drill hole.

Extra flushing is obtained by changing the plug in the control tube

to a special "choke plug", which has an air duct passing straight to

the flushing ducts in the drill bit.

Changing the choke plug

The choke plug can be changed when the control tube has been

removed from the DTH hammer. The choke plug is then removed

and fitted as follows:

Place the control tube on a workbench wiith the collar downwards.

Knock out the plug with the aid of a mandrel.

Now turn the control tube so that the collar is uppemost.Tap in the

new plug with the aid of a mandrel.To make it easier to fit the plug

into the control tube, the guide of the plug can be smeared qwith a

soap solution or similar substance.

Air consumption

COP 32 6 bar 12 bar

With choke

plug ø 4 mm

50 l/s

120 l/s

COP 42 6 bar 10�5 bar 18 bar

With choke plug

ø 5 mm

ø 7 mm

71 l/s

85 l/s

132 l/s

149 l/s

250 l/s

280 l/s

Drilling in wet holes

The inflow of water into the drill hole is expected when drilling

water wells, but can also occur when drilling deep holes for other

purposes. Water inflow does not normally create problems for

drilling, although both “too little” and “too much” can be trouble-

some.

8

Too little water tends to bind the drill cuttings into a paste, which

sticks to the drill pipes or the hole wall and can easily form collars

or plugs.The problem can be lessened by adding water to the

flushing air, thus increasing the fluidity of the cuttings. Fluidity can

be further improved by adding washing detergent to the water.

N�B� Remember to increase the lubrication dosage when injecting

water into the flushing air!

If the inflow of water is so great that it restricts the bailing of cut-

tings and water from the hole, then extra flushing will be needed.

See "Extra flushing".

Water injection

Water injection is normally used to suppress dust when drilling

dry holes. COP down-the-hole hammers are designed to function

with a certain amount of water injection. As an example, only 2—6

litres of water per minute (at 18 bar air pressure), injected into the

main air line, is sufficient to control the dust when drilling with the

COP 64.Too much water injection will have a very negative influ-

ence on the penetration rate of the hammer.

Rule of thumb: 0,25 l water per m

3

compressed air consumed by

the hammer during the drilling sequence�

The injection point for water and foaming concentrate should

always be located after the main shut-off valve on the rig.

If not, there is a danger of the mixture being pumped back

through the main air line and into the compressor.This could

seriously damage the compressor.

CAUTION

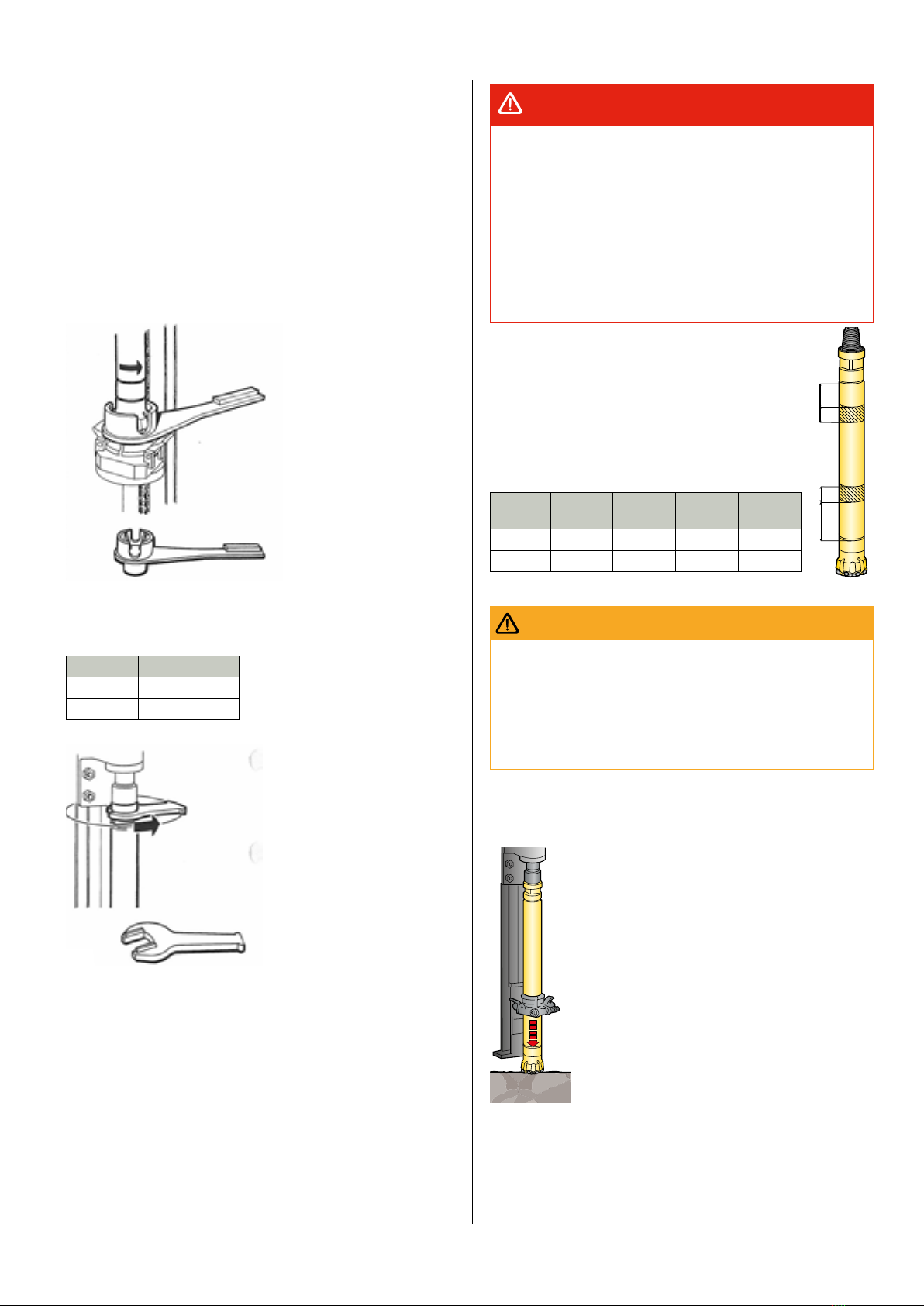

Flow chart for water flushing

A = Main inlet valve on drill rig K = Water tank

B = Container for air tool oil N = Compressor

C = Filter O = DTH-hammer

D = Lubricator valve

E = Pressure gauge Optional

F = Check valve L = Separate foam pump

G = Valves M = Separate foam tank

Foam injection

Foam can be used in DTH drilling to improve the flushing perfor-

mance (especially in non-consolidated formations). It does this by

“lifting up” the cuttings out of the hole, and also has the desirable

effect of sealing the hole walls. Foaming concentrate is pumped

into the compressed-air line in the form of a concentrate/water

mixture. Atlas Copco foaming concentrate has lubricating proper-

ties and contains corrosion inhibitors, which prevent seizing in the

hammer.

N�B� Before using foaming concentrates not supplied by Atlas

Copco, please consult your Epiroc representative for advice.

With Atlas Copco foaming concentrate, a mixture of 0,5–2 percent

concentrate/water is normally recommended. When drilling in

water-bearing rock and other difficult formations, it might be nec-

essary to increase the percentage of concentrate, and also to add

polymers to the operating air.This will help to stabilize the hole

walls and increase the lifting capacity of the foam.The concentrate/

water mixture is injected into the main air line by means of a high-

pressure pump.

Minimum requirements for the water-injection pump are as fol-

lows:

• min. pressure = 30 bar

• min. flow = 20 l/min.

After drilling with foam, it is recommended that residual foam

should be flushed out of the hammer to prevent corrosion.This is

done by injecting water only into the air, and so flushing the foam

out the hammer. Oil should then be poured into the drillstring and

the hammer operated for a few minutes before the drill string is

withdrawn from the hole. If the hammer is then to be stored for a

long time, it should be dismantled and all parts cleaned and oiled

thoroughly.

9

Tools

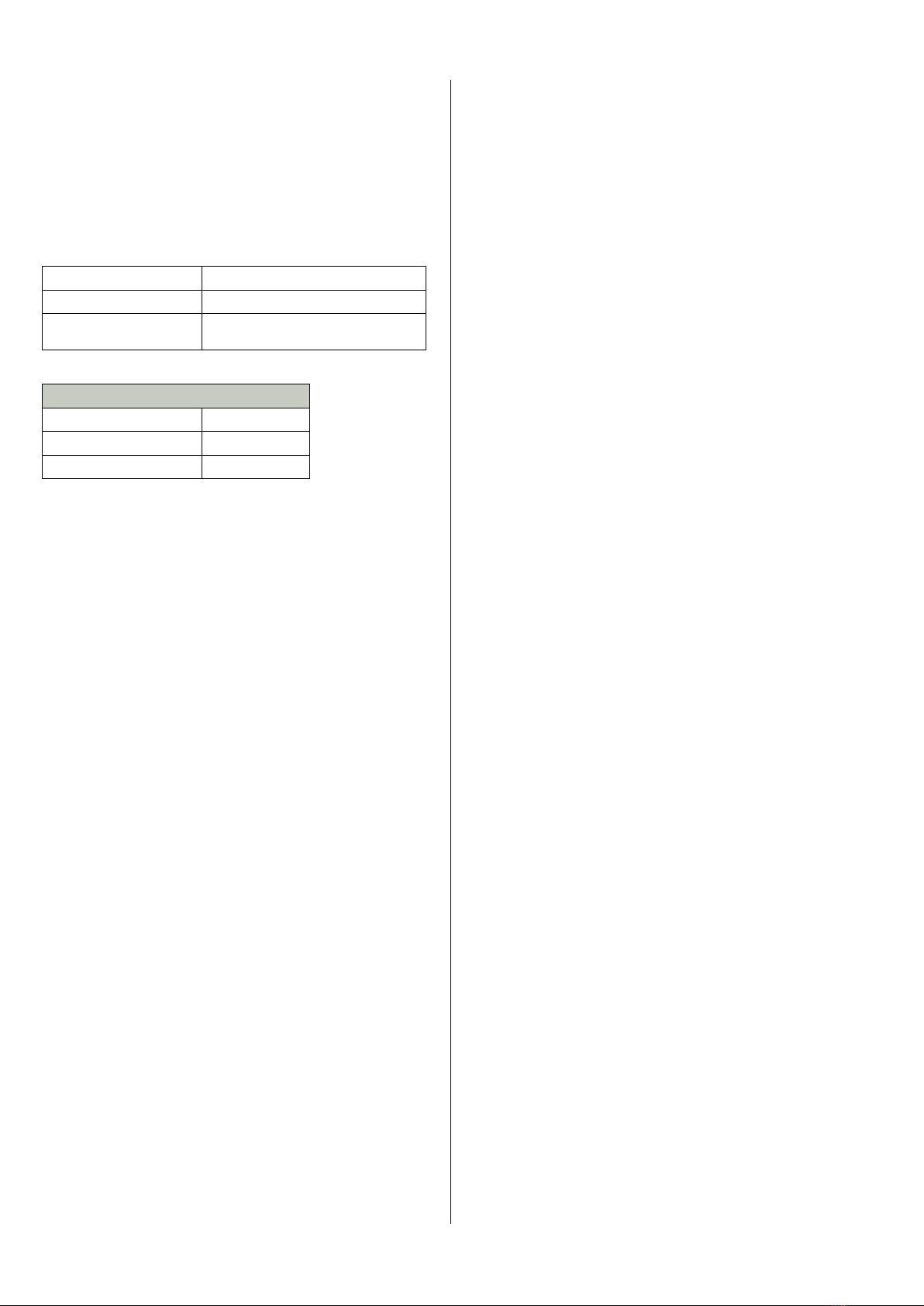

Tools for removing the drill bit and top sub

from the DTH hammer

The threaded connections of the driver-chuck and top sub can be-

come very tightly tensioned during drilling.There are special tools

for removing the bit and top sub from the cylinder of the DTH

hammer, and these should be used whenever possible.

Bit removal tool

Wrench for pipe-jointing and top sub

Wrench Ordering No�

55 mm 8484-0211-43

65 mm 8484-0211-00

Loosening the threads of the hammer

If special tools like chain wrenches or other types of wrench are

used to break the hammer joints, then the tool must be attached

around the hammer cylinder as shown in the figure. Do not attach

at other points!

NB� Failure to attach the wrench as illustrated may result in dam-

age to the cylinder. Any such damage will not quality for compnsa-

tion.

•Take great care when breaking the driver-chuck joint using

the bit removal tool in combination with reverse rotation. If

the shaft of the tool is not locked or touching the edge of the

feed beam, the shaft can turn with great force when breaking

the driver chuck joint.

• Keep your hands and clothing well clear of the hammer/drill

string when it is rotated. Entanglement can result in serious

injury.

• Blows against hammer or bit can cause fragments of metal

to fly. Always wear goggles when breaking joints.

DANGER

A

B

C

D

A

mm (in)

B

mm (in)

C

mm (in)

D

mm (in)

COP 32 90 (3.5) 50 (2.0) 60 (2.4) 110 (4.3)

COP 42 140 (5.5) 60 (2.4) 60 (2.4) 110 (4.3)

•Take great care when jointing the drill pipes and handling

the drill bit.

• Mind you fingers!

• Keep your clothing, hair, etc. well clear of rotating compo-

nents! Carelessness can result in serious injury.

WARNING

A� Breaking the driver-chuck joint using percussion only

Run the hammer into the rock or a thick plank.

• Apply light feed force.

• Carefully start the impact mechanism of the ham-

mer.

• Stop the impact mechanism as soon as the driver-

chuck joint “cracks”.

• Run the hammer up the feed beam to a suitable

working height, and unthread the driver chuck and

drill bit.

N�B. Beware of the weight of the drill bit. It could

be too heavy to hold.

10

B� Breaking the driver-chuck joint using the bit

removal tool

If the driver-chuck joint is very tight, the special

bit-removal tool should be used to break the joint.

Important: Never use a sledge-hammer on down-

the-hole hammers�

• Place the bit-removal tool in the drill steel support.

N�B� Looking from behind the feed beam, make sure

that the shaft of the bit-removal tool is touching the

left-hand edge of the feed beam.

• Carefully run the bit down into the bit removal tool.

• Slowly start up the impact mechanism of the ham-

mer.

• Stop the impact mechanism as soon as the

driver-chuck joint “cracks”.

• Unscrew the driver chuck by rotating the COP hammer to the

LEFT (anti-clockwise).

Dirt in the hammer

Stoppages and breakdowns caused by dirt in the percussion

mechanism are practically inevitable with all rock drills, and DTH

hammers are no exception. However, it should be remembered

that, while DTH hammers are no more sensitive to dirt than top-

hammers, there is obviously a greater risk of dirt ingress in down-

the-hole drilling, especially during pipe jointing. Any dirt that

enters the drill pipes goes straight into the percussion mechanism.

To ensure reliable operation of the hammer, every effort should

therefore be made to prevent dirt from entering the drill pipes.The

following rules should be observed:

• Always keep drill pipes clean. Always store or stack drill pipes

in such a way that the risk of dirt ingress is minimized. Do not let

the thread ends rest on grit or mud. Use thread covers wherever

practicable.

• Always keep the open thread end of the drill pipe covered during

jointing, and remove the cover just before the pipe is coupled up.

• Before coupling up, check that the drill pipe is clean around the

threads and on the inside. If in doubt, blow clean the pipe.

Remember to cover the pipe end that is already in the hole.

• If threads are dirty, they should be cleaned using a strong bristle

brush or a cloth.

N�B� Always clean away from the hole in the pipe. Do NOT let

grit fall into the hole in the pipe. After cleaning, always coat the

threads with Atlas Copco thread grease before jointing.

•Take extra care during jointing operations when drilling in abra-

sive rock formations, since the ingress of quartz particles into the

hammer will cause heavy wear.

• When drilling holes in water-bearing rock, never leave the ham-

mer at the hole bottom with the air supply switched off. If drilling

is to be suspended temporarily, always pull up the hammer by at

least two pipe lengths.

• Clean around the driver chuck before changing the drill bit. Make

sure the shank of the new drill bit is clean.

• Keep the hammer clean and plug both ends when not in use.

Change worn or damaged parts in good time.

A

B

All Secoroc COP down-the-hole hammers

contain a check valve that is designed to trap a

quantity of air inside the hammer when the air

supply is switched off. In most conditions, this

prevents the ingress of water and dirt into the

hammer during jointing operations.The check

valve A and O-ring B must be fault-free when

drilling in water-bearing formations. When

drilling deep holes in rock with a high water

inflow, however, it is possible that some

seepage of water into the front of the hammer will take place

during jointing. Since only very small particles of dirt would be

able to penetrate the hammer in this way, the threat to the hammer

is not serious.

The sealing efficiency of the check valve

can be checked by pouring a small

quantity of lubricant through the top sub

of the hammer, with the hammer held

vertical. If the lubricant passes through

the checkvalve, then the valve spring

and/or valve seal is worn or damaged

and should be replaced immediately.

Other instructions

Wear to the driver chuck and hammer

cylinder

Since the driver chuck and hammer

cylinder are “sand-blasted” continuously

by large volumes of abrasive cuttings

during drilling, they eventually become

worn out.The areas adjacent to the

cuttings grooves in the drill bit will be

subjected to the most wear.To prevent

uneven wear of the hammer cylinder,

therefore, the driver chuck and bit should

be marked as shown in figure, before the

chuck is lifted off the bit.

When fitting the driver chuck back on to

the drill bit after grinding or replacing a

drill bit, its radial location on the bit

shank should be advanced by one spline

section.This will give a more even

distribution of wear on the driver chuck

and hammer cylinder.

If the driver chuck is exposed to exceptionnally heavy wear, e.g.

when drilling in rock formations with a high quartz content (gran-

ite, quartzite etc.), it may be necessary to turn the driver chuck by

more than one spline section in order to prevent the driver chuck

and hammer cylinder from wearing out too quickly. As a rule, the

cuttings grooves in the bit should always be pointing towards the

part of the driver chuck that is least worn.

Since the hammer cylinder has three thread inlets, the part of the

driver chuck that is worn the most can be located against the part

of the hammer that is worn the least.

11

Checking the wear of the driver chuck and

hammer cylinder

Wear to the driver chuck and hammer cylinder should be checked

regularly, e.g. every time the bit is reground or changed. Meas-

ure the diameter of the hammer cylinder using a sliding calliper.

Measure along the full length of the cylinder, with the exception

of the outermost 100 mm at each end. At any point between these

points, the diameter of the hammer cylinder must not be less than

the minimum permissible diameter given for the respective DTH

hammer sizes in the table below.

Minimum permissible diameter

COP 32 69 mm

COP 42 87 mm

50 mm

The outside diameter of the driver chuck must not be less than

that of the hammer cylinder.

N�B� When the hammer cylinder has to be changed, the driver

chuck must be replaced at the same time (see the section “Wear

limits”).

The hammer should be overhauled at suitable intervals, depend-

ing on the operating conditions.The abrasiveness of the rock will

affect the overhauling intervals, since it has a strong bearing on

the rate of wear.

• When checking the play between the top sub and the cylin-

der, the O-ring F on the top sub must always be removed.

• If this is not done, the shimming will not be correct and

there will be a risk of breakdown in the hammer. After check-

ing the clearance and fitting shims (if necessary), the O-ring F

must be fited back on the top sub.

IMPORTANT

Shimming

Checking the clearance

between the top sub and the

cylinder

When fitting the top sub to the hammer, the clearance between the

top sub and the cylinder must be checked with a feeler gauge.This

is done as follows:

•Remove the control tube from the hammer. Fit back the other

parts and thread the top sub into the cylinder, tightening it by hand

only.The clearance between the top sub A and cylinder C must not

be less than 0,75 mm, then shims must be fitted.

Fitting the shims

Place 1-3 shims D (ordering NO:s: COP 32 / 3161-1146-00, COP 42 /

3161-1054-00) between the top sub A and valve body B as neces-

sary. After the shims have been fitted, the clearance between the

top sub and the cylinder should be between 1,5 and 2,5 mm.

• After the clearance have been checked and shims fitted (if neces-

sary), the control tube must be fitted back into the hammer.

• If the clearance is less than 0,75 mm in spite of max. 3 shims

having been fitted, and if the top sub ahs been tightened by hand

only, this indicates that the compression ring E is worn and must

be changed.

• Finally, the top sub must be screwed firmly into the cylinder and

tightened with the aid of a rod spanner.The clearance between

the top sub and the cylinder should now have disappeared almost

completely.

Clearance before/after shimming

Ordering No�

shims (1–4)

Min�

clearance

Clearance after

shimning

COP 44 3161-1422-00 1,5 mm 1,9–2,5 mm

COP 54 3161-1522-00 1,8 mm 2,2–3,0 mm

Assembly of the drill bit and driver chuck

• Smear the splines of the bit shank with Atlas Copco thread

grease.

• Smear the O-ring of the stop ring with silicone grease.

• Assemble the bit 1, driver chuck 2 and stop ring 3 as shown in

figure.

NB� The stop ring halves must be fitted so that the O-ring grooves

line up with each other. Make sure the stop ring faces the right

way.

3

2

1

Make sure the stop ring is located

correctly, and that it faces the

right direction. Incorrect fitting

will result in severe damage to

the hammer.

IMPORTANT

• Smear the thread on the driver chuck with Atlas Copco thread

grease.

• Screw in the bit assembly into the cylinder and tighten the driver

chuck securely with the aid of the special bit removal tool.

12

Regrinding the drill bit

The rate of bit wear depends on the rock formation, and is highest

in rocks with a high quartz content. A suitable grinding interval

should be determined according to the rate of bit wear. It is more

economical to regrind too early rather than to suffer poor penetra-

tion rates and risk damaging the drill bit through overdrilling. A

few hints about the care of drill bits:

• Before grinding, always check the flushing holes of the drill

bit for traces of explosive. Contact with the grinding wheel

can cause the explosive to explode causing serious or fatal

injury as well as damage to the equipment.

To clean the flushing hole, use only a wooden rod, copper

wire or flushing water.

DANGER

• Always wear ear protectors, protective clothing, gloves and

goggles when grinding.

• Use a dust extraction system or an approved dust mask.

This is of special importance when dry grinding indoors.

CAUTION

• Always use water flushing when grinding wheels.

• Use water if possible also with grinding cups and hand-held

grinders.

IMPORTANT

When to regrind

Button bits should be reground

when the penetration rate

drops, or if any of the cemented

carbide buttons are damaged

(fractured buttons should be

ground flat). It is both practical

and economical to redress the

buttons when the wear flat

reaches about ½ of the diameter of the button.

Note: This is a general recommendation.

Look out for “snake skin”

If microscopic fatigue cracks –

so-called “snake skin” – begin to

appear on the cemented carbide

buttons, they must be ground away.

In any event, bits should be reground

after 300 metres of drilling at the

most.This should be done even if

there are no visible signs of wear and the penetration rate

continues to be good. If snakeskin is not removed, the cracks will

deepen and ultimately result in button fracture.

Do not grind away too much cemented carbide

Do not grind too much on the top of the

buttons. Let a few millimetres of the wear flat

remain on top of the button.

Always grind broken buttons flat

A drill bit can remain in service as long as

the gauge buttons maintain the diameter of

the bit. Fractured buttons must always be

ground flat to prevent chips of cemented

carbide from damaging the other buttons.

Avoid grinding the perimeter

Gauge-button anti-taper has to be removed by grinding, although

excessive reduction of the bit diameter should be avoided. Leave

about 2 mm of the wear flat.

If necessary, remove some of the bit-body steel below the gauge

buttons, so that a clearance (taper) of 0,5 mm is maintained.

If the flushing holes start to deform, open them up with the aid of a

rotary burr or steel file.

2 mm

Min

0,5

Grinding equipment

The Grind Matic HG is a portable,

hand-held, air-powered grinding

machine for button bits, ideal for use at

the worksite. It is used with diamond-

impregnated grinding cups, which can

be used with or without water flushing.

The Grind Matic Manual B-DTH is a

mechanized air-powered grinding

machine for button bits. It is mounted in

a steel box-barrow, which can be

wheeled easily around the worksite.The

Grind Matic Manual B-DTH uses

diamond-impregnated grinding wheels.

For “permanent” grinding stations, a

mechanized stationary grinding

machine is available, the Grind Matic

BQ3-DTH. It is equipped with automatic

feeding devices and grinds both the

cemented-carbide buttons and the

bit-body steel in one operation.The

machine uses diamond-impregnated

grinding wheels.

Further information about grinding equipment can be found in the

respective product leaflets.

13

Care & maintenance

The service life and performance of DTH hammers depends to a

large extent on good operating practice and regular maintenance.

The following recommendations should be observed:

• Make sure that the compressed air is always clean and dry.

• Always blow clean the air hoses before connecting them to the rig.

• Make sure that the drill pipes are stored properly in the pipe rack,

or stacked on trestles in such a way that dirt cannot enter the pipes.

• Fit thread guards to the ends of the drill pipes whenever practica-

ble. Keep the threads and the insides of the pipes clean.

• Always cover the “open” thread end of the drill pipe during

pipe-jointing operations.The ingress of dirt into the drill string will

cause blockages and/or seizure in the hammer, which can result in

breakdown.

• Check regularly that the dosage of lubricating oil into the operat-

ing air is sufficient. Check that the lubricating-oil tank on the rig is

filled with oil of the correct type and quality. See “Recommended

lubricants”.

• Check the wear on the driver chuck and hammer cylinder regularly.

The diameter of the driver chuck must never be less than that of

the hammer cylinder.The service life of the hammer cylinder can

be prolonged by always fitting a driver chuck with a greater outside

diameter than that of the hammer cylinder. When the components

are approaching their minimum permissible diameters, frequent in-

spection is necessary. Alternatively, change the components in good

time – it makes good economic sense.

N�B� When the hammer cylinder is replaced, the driver chuck should

be replaced at the same time (see “Wear limits”).

A general overhaul of the hammer should be carried out at suit-

able intervals, depending on the operating conditions and empiri-

cal statistics.The abrasiveness of the rock will have a considerable

effect on the rate of wear, and will affect the overhauling intervals

accordingly.

Lubrication

Lubricating oil is vital for the satisfactory

operation of DTH hammers. Apart from

regular checking of the oil level in the

lubricating-oil tank, always make sure that

there is oil in the compressed air.This can be

checked whenever the rotation unit is free, i.e.

disconnected from the drill string.

Simply place a plank over the drill-steel sup-

port and blow operating air on to the plank.

After a few moments, the surface of the plank

should become oily, which confirms that lu-

bricant is being carried to the hammer in the

operating air.

The importance of adequate lubrication of the hammer cannot be

over-emphasized. Poor lubrication will accelerate wear and ultimate-

ly result in breakdown.The effective lubrication of the DTH hammer

is not always a straight-forward matter, owing to wide variations

in operating conditions, e.g. extreme temperature differentials

between the hammer and the lub-ricator, water or foaming concen-

trate added to the operating air, etc.

Different lubricants have different properties. Mineral oils have the

best lubricating properties and are preferable in most cases. Min-

eral-base oils have good adhesion properties and are produced in

different viscosity and temperature- range grades.

Since mineral oils have good resistance to water, they are suit-

able for use even when comparatively large volumes of water are

injected into the operating air. In this case, however, the dosage

must be increased.

Glycol-based lubricants, such as Atlas Copco Air Oil, are water

soluble, and must not be mixed with mineral oils.They are used

primarily to prevent freezing, and should be used only when

there is a minimal water content in the operating air. Glycol-based

lubricants are used extensively in water-well drilling for reasons of

water hygiene. If there is a lot of condensation in the drill string,

which is often the case in long drill strings, then lubrication may

become unsatisfactory because dilution seriously affects the func-

tion of glycol-base lubricants.

Other lubricants worth mentioning are the so-called “edible” oils,

which consist of vegetable oils, synthetic lubricants of the ester

type, or a mixture between these two. Edible oils can be mixed

with mineral oils, have good lubricating properties and are non-

toxic.

Lubricators

Both plunger-pump and nozzle-type lubrication systems are avail-

able.

The plunger pump is relatively insensitive to the viscosity of the

lubricant and gives a more reliable dosage compared with the

nozzle-type lubricator.This is of major importance when the ambi-

ent temperature is low.

About 1 ml of oil per m

3

of operating air consumed should be the

minimum dosage for bench drilling. As a rule, higher dosages are

needed in water-well drilling.

Normal lubrication dosage

COP 32 0,2–0,4 l/hr

COP 42 0,3–0,5 l/hr

In case of water injection, increase dosage by 0,1–0,2 l/hr.

N�B�The distribution of lubricating oil through the compressed air

system generally takes place in the form of so-called “wall flow”.

If the air system has been shut off for a long period of time, it can

take quite some time for the lubricant to reach the hammer. In

such cases, a small amount of oil must be poured directly into the

hammer or air hose before drilling.

Choice of lubricating oil

For COP down-the-hole hammers it is recommended to use Atlas

Copco COP oil. When choosing between other types of lubricants,

the oil should have:

• Suitable viscosity

Ambient temp�°C(°F) Viscosity grade

–20 to +15 (-4 to +59 ISO VG 46-100

+15 to 35 (59 to 95) ISO VG 100-150

> +35 (95) ISO VG 150-220

• Good adhesion properties

• High film strength

• Corrosion inhibitors

14

For reasons of water hygiene, lubricating oils used in water-well

drilling should be non-toxic.

The temperature limits given above refer to the temperature of the

oil in the tank, i.e. the ambient temperature. In cases where the

hammer is powered by warm compressed air at high operating

pressures, e.g. when connected to a nearby portable compressor,

the temperature of the operating air must be taken into considera-

tion. In such cases it may be necessary to choose a thicker oil than

what is recommended in the table.

Recommended lubricants

Lubricating oil tank Atlas Copco COP oil

Threads and splines Atlas Copco thread grease

O-rings and rubber parts Silicone grease (temperature limits

-20 to +120°C)

Ordering No� Atlas Copco COP oil:

Can 10 litres 3115 3125 00

Can pallet 48 x 10 litres 3115 3126 00

Drum 208 litres 3115 3127 00

15

Wear limits

Component Wear limit Action Comments

Drill bit (diameter). Min. 6–10 mm (COP 34 4–7

mm) greater than the max.

diam. of the cylinder.

Fit new bit. Min. measurement at lower working pressures.

Max. measurement at higher working pressure.

Driver chuck (diameter). Never less than the diameter

of the cylinder.

Replace. Failure to replace in good time will cause severe

wear to hammer cylinder.

Cylinder (diameter). COP 44 – min. 89 mm

COP 54/54Qm – min. 111 mm

COP 64/64qm – min. 132 mm

Replace. Measure the diameter along the full length of the

cylinder, with the exception of the outermost 100

mm at each end. Risk of fracture.

Bit bushing (inside diameter). COP 64 max. 87,6 mm Replace. Measure the bit bushing at its waist.

Piston / Cylinder. Diametric clearance:

max. 0,20 mm

Replace worn

parts.

Outside diameter of piston should be measured at

the sealing surface of the piston.

Piston / Control tube. Diametric clearance:

max. 0,20 mm

Replace worn

parts.

Inside diam. of the piston against outside diam. of

the control tube.

Check valve. Valve seat worn or damaged. Replace worn or

damaged parts.

Tightness of check valve can be tested by pouring a

small amount of oil into the valve with the hammer

in vertical position.

Sleeve (flushing valve). Worn or damaged. Replace.

Buffer. Worn or damaged. Replace.

Trouble shooting

Fault Cause Remedy

Impact mechanism does

not operate, or works with

reduced effect.

Air supply throttled or blocked. Check the air pressure. Check that all air passages leading to

the hammer are open.

Oil is not reaching the impact mechanism

of the hammer. Poor or no lubrication,

causing increased wear, scoring or seizure.

Let operating air blow through rotation spindle on dry

plank or similar. After a few moments, plank surface should

become oily. Inspect lubricator. Top-up with oil if necessary

or increase lube oil dosage.

Too large clearance (wear) between the

piston and cylinder, or between piston and

control tube.

Disassemble the hammer and inspect the wear (see ”Wear

limits”). Replace worn parts.

Hammer clogged with dirt. Disassemble the hammer and wash all components.

Compression ring worn or damaged. Check clearance between top sub and cylinder. (See

”Checking the clearance between the top sub and cylinder”,

page 10) Replace worn or damaged compression ring.

Worn buffer rings in the cover. Disassemble the hammer and replace the buffer rings.

O-rings in bit bushing (COP 64) are worn or

damaged.

Disassemble the hammer and replace the O-rings.

Dirt enters the hammer when drilling in

water-bearing formation.

Make sure the check valve seals against the seat in the top

sub (see ”Dirt in hammer”, page 9). Remove the top sub and

replace check valve.

Lost drill bit and chuck Impact mechanism has been operated

without rotation to the right.

Fish out the lost equipment using a fishing tool. Remember

to always use right-hand rotation, both when drilling and

when lifting the drill string.

Excessive air

consumption

Flushing valve parts damaged.

Foot valve worn or damaged.

Disassemble and replace damaged parts, see page 7.

Replace foot valve, see page 12.

Overhauling

DTH hammers should be overhauled at suitable intervals depending on the drilling conditions and empirical service records. Since the

abrasiveness of the rock has a considerable bearing on the rate of wear, it will affect the overhauling intervals accordingly. Before the DTH

hammer is sent to an authorized Epiroc service workshop for overhauling, the joints at the top sub and driver chuck should be ”cracked” on

the rig.

9866 0066 01 Subjected to alterations without prior notice. © Epiroc Drilling Tools AB. All rights reserved. 2018.01.

United in performance.

Inspired by innovation.

Performance unites us, innovation inspires us, and

commitment drives us to keep moving forward.

Count on Epiroc to deliver the solutions you need to

succeed today and the technology to lead tomorrow.

epiroc.com

Epiroc Drilling Tools AB

Box 521, SE-737 25 Fagersta, Sweden

Phone: +46 223 461 00

This manual suits for next models

2

Table of contents

Other Epiroc Industrial Equipment manuals

Epiroc

Epiroc CB Series Maintenance and service guide

Epiroc

Epiroc MB 750 Maintenance and service guide

Epiroc

Epiroc SmartROC T35 Guide

Epiroc

Epiroc COP RR14 Guide

Epiroc

Epiroc BQ3-DTH User manual

Epiroc

Epiroc 90T Maintenance and service guide

Epiroc

Epiroc HB Series Maintenance and service guide

Epiroc

Epiroc MG 100 Maintenance and service guide

Epiroc

Epiroc LPHB-M Maintenance and service guide

Epiroc

Epiroc HB 5800 Maintenance and service guide