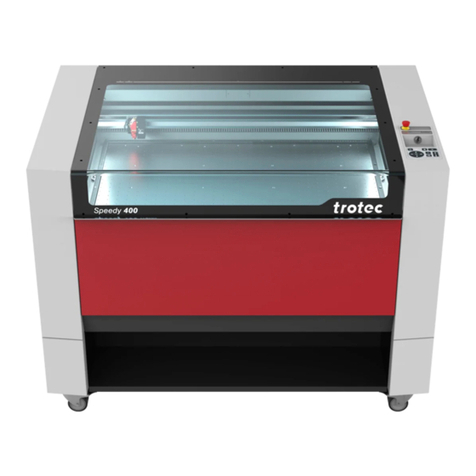

Fenix Imvico SM3000 User manual

SM3000 THERMAL PRINTER

Operation manual - Version 1

January-2013

FENIX IMVICO SM3000 OPERATION MANUAL

SM3000 thermal printer operation manual revision:

V1 Date: 15-1-2013

Page Revision type efore change After change

2/55

FENIX IMVICO SM3000 OPERATION MANUAL

INDEX

IMPORTANT NOTES IN SM3000 THERMAL PRINTER MANAGEMENT...........4

0 – OVERVIEW.................................................................................................... 6

1 – GENERAL SPECIFICATIONS....................................................................... 7

1.1- Printing specifications.................................................................................................. 7

1.2- Character specifications.............................................................................................. 7

1.3- Paper loading............................................................................................................... 8

1.4- Autocutter..................................................................................................................... 8

1.5- Paper specifications..................................................................................................... 8

1.6- Internal buffer............................................................................................................... 8

1.7- Electrical specifications................................................................................................ 8

1.8- Environmental conditions............................................................................................. 8

2 – INSTALLATION.............................................................................................. 9

2.1- POWER SUPPLY........................................................................................................ 10

2.2- RS-232 SERIAL INTERFACE...................................................................................... 10

2.2.1- RS-232 Serial interface specifications......................................................... 10

2.2.2- Change between online and offline mode.................................................... 10

2.2.3- Assigning RS-232 connector terminals.................................................... 11

2.2.5- Serial interface connection examples...........................................................11

2.3- US INTERFACE.........................................................................................................12

2.3.1- Assigning US connector terminals ............................................................ 12

2.4- DRAWER INTERFACE............................................................................................... 12

2.4.1- Assigning drawer connector terminals ................................................12

3 – ASIC OPERATIONS.....................................................................................14

3.1- PAPER LOADING........................................................................................................ 14

3.2- CLEANING A PAPER JAM.......................................................................................... 15

3.3- UTTONS AND SWITCH............................................................................................ 15

3.3.1- Power supply switch..................................................................................... 15

3.3.2- Paper feed button (FEED)........................................................................... 15

3.3.3- Cover open button....................................................................................... 16

3.4- PANEL LED..................................................................................................................16

3.5- SPECIAL PRINTING MODES......................................................................................17

3.5.1- Self-test mode.............................................................................................. 17

3.5.2- Hexadecimal dump mode............................................................................ 18

3.6- ERROR PROCESSING............................................................................................... 18

3.7- PAPER SENSORS...................................................................................................... 21

3.8- OPEN COVER SENSOR............................................................................................ 21

4 – CONTROL COMMANDS................................................................................ 22

4.1- COMMAND NOTATION.............................................................................................. 22

4.2- TERM DEFINITIONS.................................................................................................. 22

APPENDIX A – SPECIFICATIONS...................................................................... 45

APPENDIX – MECHANICAL DIMENSIONS..................................................... 46

APPENDIX C – CODE128 AR CODE................................................................ 47

APPENDIX D – INTERNAL CHARACTER TA LE.............................................. 51

APPENDIX E – INTERNAL CONNECTION......................................................... 52

APPENDIX G – TESTING/SETTING SOFTWARE.............................................. 53

APPENDIX F – FONT LOADER SOFTWARE.................................................... 54

3/55

FENIX IMVICO SM3000 OPERATION MANUAL

IMPORTANT NOTES IN SM3000 THERMAL PRINTER MANAGEMENT

In order to preserve the life of the printer, it is necessary to keep in mind some precautions in the

handling of the SM3000 printer. Please read carefully the following points in order to make a good use of

the printer.

SECURIT PRECAUTONS

•efore using the printer, read carefully section 2-INSTALLATION.

•NEVER connect the external power supply with the wrong polarity. This could permanently damage

the printer.

•Turn off the printer immediately if it produces smoke, a strange smell or an unusual noise. Keeping

on using the printer could cause fire. Unplug the equipment immediately and contact your official

distributor.

•NEVER connect cables with different connectors from the ones mentioned in this manual. Making

different connections (for example, connecting a telephone line in the coins drawer connector) could

permanently damage the printer.

•Use a power supply voltage whose output voltage is within the specifications range stated in this

manual. Over voltage can permanently damage the printer. Under voltage can cause malfunctions.

•NEVER wet SM3000 thermal printer with water or any other liquid. If any liquid is spilled inside of the

equipment, unplug the power cable immediately and then contact your technical service.

•Make sure the printer is on a steady, horizontal, securely fixed surface. If the printer fell down, it could

break or damage.

•NEVER use the printer in high humidity or dirty places.

•NEVER place heavy objects on top of the printer and never lean on it.

•NEVER put any object inside of the printer, as it could cause hardware damage on it, such as short-

circuit, print head breaking or general failure of the printer.

•NEVER shock the SM3000 printer.

•NEVER disassemble or modify the SM3000 printer.

•NEVER try to repair the SM3000 printer. Please contact your official distributor in case of failure.

•As the printer contains electromagnets (inside of the motor), it should not be used in excessively dirty

environments or places with dust or metal particles.

•NEVER print without paper loaded or without the cover closed, as the thermal print head life can be

highly shortened.

•NEVER pull the paper out when the cover is closed. Use the paper advance button instead.

•Avoid touching with metal objects, such as screwdrivers or tweezers, the print head thermal elements

as well as the electronic printed circuit. They are delicate parts.

•Never touch with your hands the areas around the print head and the motor surface as they become

very hot during and just after printing; wait 15 seconds to let them cool down.

•NEVER touch the surfaces of the print head thermal elements or the electronic printed circuit, as dust

and dirt can stick to their surface and cause damage by electrostatic discharge.

•The thermal paper contains Na+, K+ and Cl- ions that can cause harm to the print head elements.

Therefore, use only the specified paper.

•If the printer has not been used for long period of time and the paper was loaded, the paper could

become deformed by the drive roller pressure. It is recommended to make it advance at least 30 mm

before printing again.

•For security reasons, unplug the printer if it is not going to be used over a long period of time.

•Don’ t print continuously (without stopping) for more than 6 minutes.

4/55

FENIX IMVICO SM3000 OPERATION MANUAL

•CLEANING PROCEDURE AND PRECAUTIONS

In order to clean the thermal print head, proceed as indicated by the following steps:

1. Open the printer cover. Wet a cotton sponge in alcohol (ethanol, methanol or IPA), and use it in

order to clean the thermal elements of the print head and to remove the possible accumulation

of paper particles found on the cover, roller and nearby surfaces.

2. Wait for alcohol to evaporate before inserting the paper roll and closing the cover.

FENIX recommends cleaning the thermal print head periodically (each 2 or 3 months) in order to

keep the print quality.

NOTES:

The print head could be hot after printing. Make sure it has thoroughly cooled down

before proceeding to clean it.

Unplug the power supply cable before the cleaning.

Never touch the thermal elements of the print head with your hands.

Never use metallic or piercing elements for the cleaning of the print head, as they

could scratch it.

Fig a. Thermal print head cleaning.

RECOMMENDATIONS

•The plug have to be located near the printer and have to be easily obtainable.

•efore connecting any communication data cable, check the printer is working properly by executing

the self-test.

•Set the SM3000 in a place where the connection cables do not suffer stretching or cross with each

other.

5/55

Thermal printing

line

FENIX IMVICO SM3000 OPERATION MANUAL

0 – OVERVIEW

The SM3000 is a high performance thermal printer. Its compact and functional design covers many

professional uses (as in supermarkets, hotels, hospitals, restaurants, and so on.)

It is capable of printing text, graphics, logos and bar codes.

It can be used in laboratories, industrial and commercial environments.

The main features of the SM3000 are:

•Simple installation and easy maintenance.

•Paper width of 80 mm.

•High speed printing: up to 250mm/s (NOTE 1).

•Low noise thermal printing.

•In-line printing method: printing is done every time a text line is completed.

•High reliability: The SM3000 is capable of printing up to 100 millions of pulses.

•24 V DC power supply.

•Easy paper load and automatic receipt cut.

•Includes several sensors: ‘near-end paper’, 'out of paper’ and ' ticket pickup' .

•High printing resolution (8 dots per mm).

•Port interface: Serial RS232C (up to 230400bps) and US (US 2.0).

•The characters can be scaled up to 64 times their regular size.

•old, underline, reverse and rotate character capabilities

•Provides several types of bar codes: Code39, EAN13, ITF and Code128.

•Provides several 2D bar code: QR and AZTEC.

•Two internal character fonts (A font= 12x24 dots. font= 8x16 dots).

•The printer includes an interface for two different coins drawers.

•Input buffer of 32K ytes.

•Control code based on ESC / POS commands (NOTE 2).

•Multiple logo load capability through Windows driver or command.

•Upgrading of firmware version through communication port (NOTE 3).

•TrueType font loading capability (NOTE 3).

•Windows XP and Windows 7 drivers and demo/configuration program.

•Linux Driver.

(1) Print speed changes acc rding t the baud rate in RS232 c nnecti n and temperature. Higher printer speed rates are

achieved at higher baud rates and USB c nnecti n.

(2) ESC/POS are registered trademarks f Seik Eps n C rp rati n.

(3) In rder t upl ad new firmware r new TrueType f nt, FWL ader and F ntL ader applicati n pr grams are available

n ur website.

This manual is the printer operations’ guide and is intended for the designer's application. The following

sections contain a detailed description of both the hardware and the configuration software that allow

obtaining the maximum benefit of the printer possibilities.

6/55

FENIX IMVICO SM3000 OPERATION MANUAL

1 – GENERAL SPECIFICATIONS

1.1- Printing specifications

1) Printing method: Thermal line printing

2) Dot density:203 dpi x 203 dpi

(‘dpi’: dots per inch. 1 inch=25.4mm)

(203 dpi= 8 dots per mm)

3) Printing direction: Unidirectional with friction feed.

4) Printing width: 72 mm (576 dots).

5) Printing speed: High speed mode: up to 220mm/s

(The printing speed could vary automatically depending on the print

head temperature as well as the command processing and the data

transmission speed).

NOTES:

Printing speed depends on the data transmission interface, the combination of

control commands and the print head temperature.

Low printing speed could cause intermittent printing. It is recommended to transmit

data to the printer as quickly as possible.

6) Paper feed speed: 220 mm/s (continuous paper feed)

7) Characters per line (by default): A font: 42

font: 56

8) Space between characters (by default): 2 dots (0.25 mm)

9) Line spacing (by default): 4.25 mm

1.2- Character specifications

1) Number of characters: Alphanumeric characters: 95

Extended graphics: 128 per page

2) Character structure:A font: 12 x 24 dots (1.5 x 3 mm).

font: 8 x 16 dots (1 x 2 mm).

A font is selected by default.

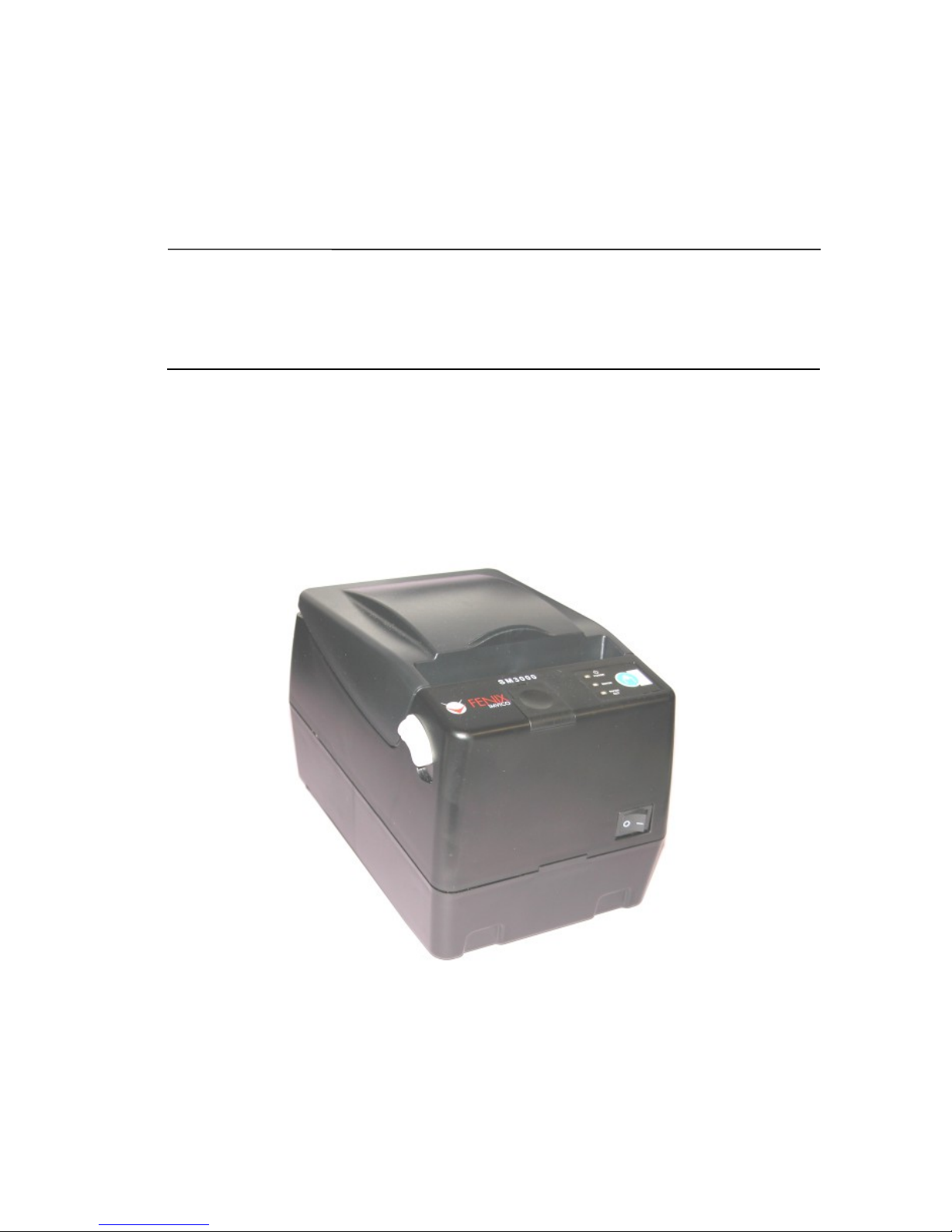

3) Character size:

Standard Double height Double width Double width/

Double height

cpl W x H

(mm)

cpl W x H

(mm)

cpl W x H

(mm)

cpl W x H

(mm)

A Font 1,5 x 3 42 1,5 x 6 42 3 x 3 21 3 x 6 21

Font 1 x 2 56 1 x 4 56 2 x 2 28 2 x 4 28

The space between the characters is not included.

Characters can be scaled up to 64 times bigger than their normal size.

cpl: characters per line.

7/55

FENIX IMVICO SM3000 OPERATION MANUAL

1.3- Paper loading

One of the main advantages of the SM3000 printer is its paper loading system. It is so simple to do it

that can be carried out by any final user, without having to disassemble the printer or loading the paper

in a complex paper path.

1.4- Autocutter

The SM3000 performs a partial cut of the receipt automatically, leaving an uncut section of

approximately 2 mm in the center.

1.5- Paper specifications

1) Paper type: thermal paper roll

2) Paper width: 80 +0/-1mm

3) Paper roll size: up to a maximum of 100 mm of diameter

4) Specified thermal paper: TF50KS-E2C (Nippon Paper Industries)

PD160R-N (Oji Paper Co.)

HP220A 1 (Mitsubishi Paper Mills Limited)

1.6- Internal buffer

The SM3000 printer has a 32 Kbytes internal memory buffer, whose functionality is dynamically shared

by the receiving buffer.

The buffer is being filled at the same time that buffered data is being printed, for that reason high

transmission speed is required in order to ensure that data is available for printing at any time. Data

transfer of at least 115200 bauds or US connection increase the printing performance substantially.

1.7- Electrical specifications

1) Power supply voltage: 24V DC ± 10%

2) Current consumption (at 24V, ambient temperature):

High speed mode:

Average: 1.8 A approx.

(Characters in capital letters, A font, 36 continuous lines of 42 columns)

Peak: 7.7 A approx.

Low power consumption mode:

Average: 1.2 A approx.

(Characters in capital letters, A font, 36 continuous lines of 42 columns)

Peak: 6.6 A approx.

Non-printing mode:

Average: 0.2 A approx.

NOTE: 1 A maximum for the coins drawer open operation

3) Internal fuse: 4A, 250v slow (164050-4, from ELU or equivalent).

1.8- Environmental conditions

1) Temperature range: Working temperature range: 0ºC to 50ºC

Storage temperature range: -20 a 60ºC (without paper loaded, in a dry place).

8/55

FENIX IMVICO SM3000 OPERATION MANUAL

2 – INSTALLATION

The SM3000 printer should be installed horizontally on a rigid surface, avoiding locations where high

temperatures or vibration risks exist. Its location must allow the final user an easy access to all the

handling elements of the printer for their use and maintenance.

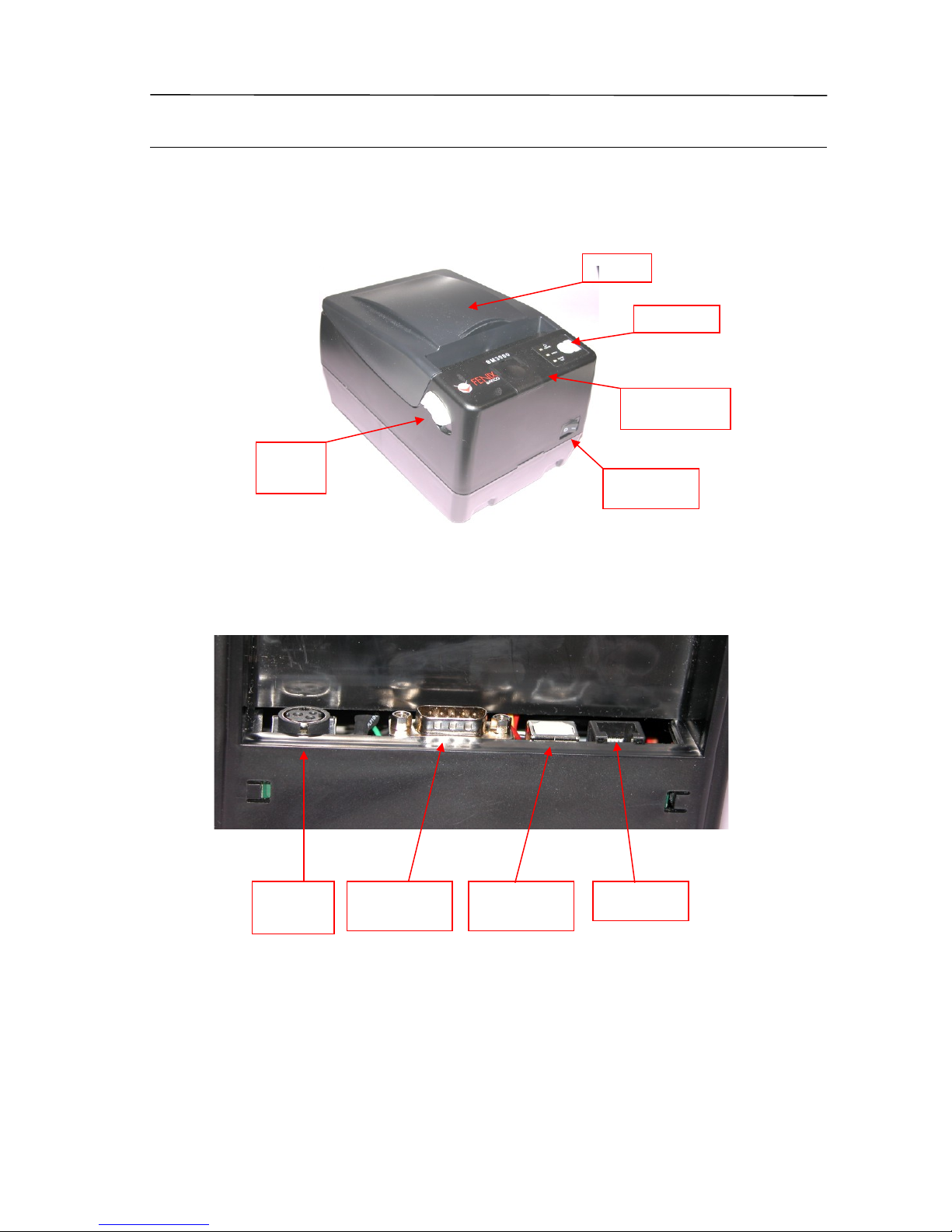

Fig. 2.1- Maintenance and use elements of the SM3000 printer.

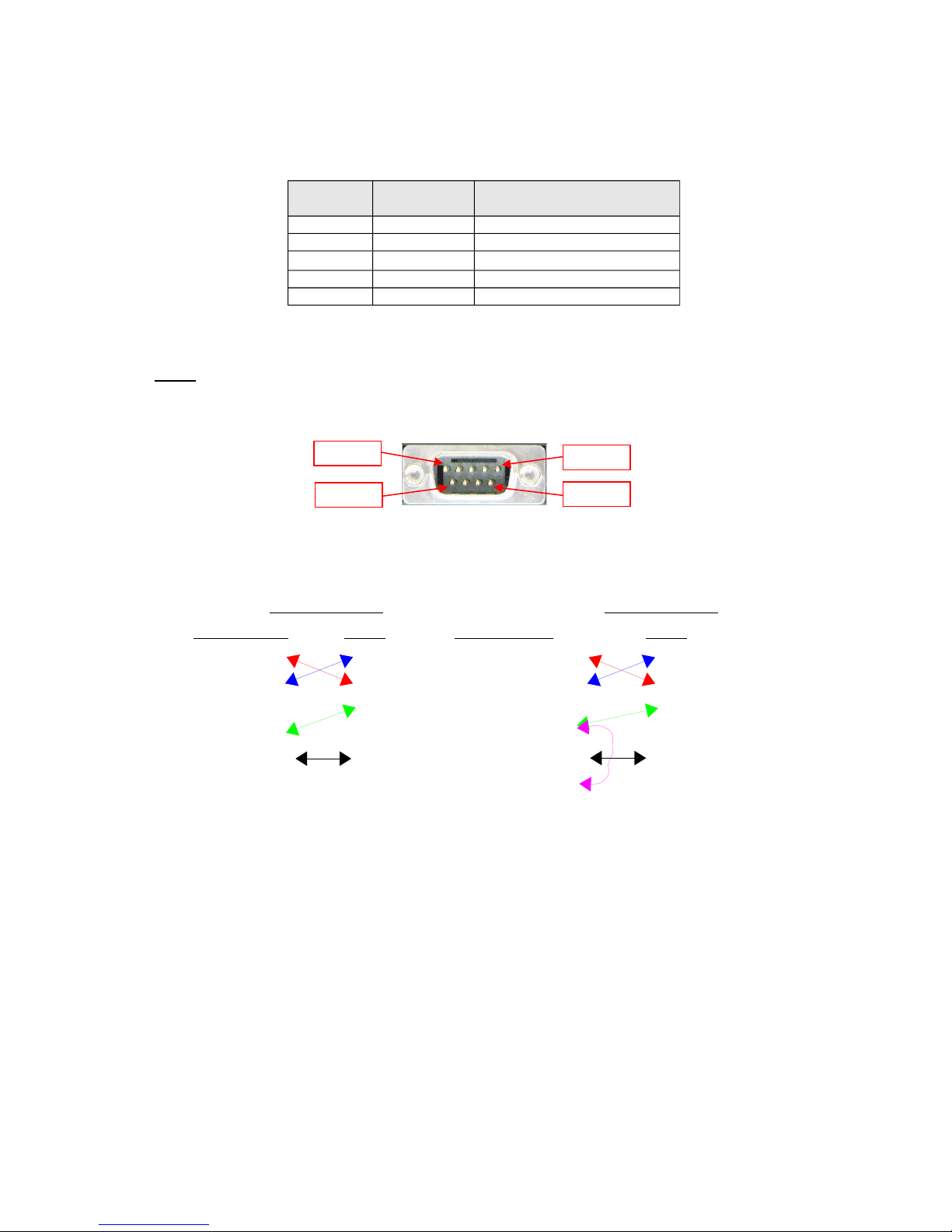

The SM3000 connectors are located in the rear part of the printer: a power supply connector, a coins

drawer connector, an US interface connector and a serial SU -D9 connector.

Fig. 2.2- Connectors location.

9/55

Power

supply

connector

Coins drawer

connector

US

communication

connector

Serial RS232

communication

connector

Power supply

switch

Front panel

Cover

open

button

Cover

Cutter unlocking

screw

FENIX IMVICO SM3000 OPERATION MANUAL

2.1- POWER SUPPL

The SM3000 is powered by an external power supply by means of a female polarized connector of 3

pins that includes a security anchor. The power supply voltage must be verified before making the

connection between the supply and the printer.

Fig. 2.3- SM3000 printer power supply connector.

The power supply male connector must be a KYCON 806-KPP-3P or an equivalent model.

It is not advisable to use a different power supply from the one provided by FENIX along with the

printer (FAPOS-1). Using a different power supply could harm the printer or prevent it from working

properly.

NOTE:

The current flow increases when the number of active dots in a horizontal graphic line increases.

Print quality can decrease if the printing ratio and the printing speed are high.

2.2- RS-232 SERIAL INTERFACE

2.2.1- RS-232 Serial interface specifications

•Data transmission type: Serial

•Synchronization: Asynchronous

•Flow control: RTS/CTS, XON/XOFF or none

•Signal levels (RS232): MARK = -3 to -15 V Logic ‘1’/OFF

SPACE = +3 to +15 V Logic ‘0’/ON

•Speed: 9600, 19200, 38400,115200 and 230400 bauds

•Data length: 8 bits

•Parity: none, even, odd

•Stop bits: Fixed to 1

•Connector (printer side): SU -D9 male pin connector

2.2.2- Change between online and offline mode

The printer is in offline mode:

1) When powering up or resetting the printer, until the printer is ready to receive data.

2) When performing the self-test.

3) When the cover is open.

4) After pressing the Paper feed button (FEED) while the paper advances.

5) When ‘out of paper’ causes the printer to stop printing.

6) During macro execution in standby mode.

7) When the power supply has a temporal abnormal voltage change.

8) When an error has occurred.

10/55

+24v

GND

nc

Frame

GND

FENIX IMVICO SM3000 OPERATION MANUAL

2.2.3- Assigning RS-232 connector terminals

The assignments of the terminals of the RS-232 connector and the functions of its signals are described

in the following table:

Pin

SUB-D9

Signal name Signal direction

(from the printer point of view)

3 TXD Output

2 RXD Input

7 RTS Output

5 SG -

Other nc ---

Table 2.1- Assignments of RS-232 connector terminals.

NOTE: RTS line is used for hardware flow control. Indicates that the internal data buffer is full. When

the SM3000 temporarily activates this line, the host should not send data because, otherwise it will lose

information and the print result will be wrong.

Fig. 2.4- SM3000 RS-232 connector.

2.2.4- Serial interface connection examples

CONNECTION- A CONNECTION- B

host (PC-D 9) printer host (PC-D 9) printer

2 - RXD RXD - 2 2 - RXD RXD - 2

3 - TXD TXD - 3 3 - TXD TXD - 3

RTS - 7 RTS - 7

8 - CTS 8 - CTS

5 - GND GND - 5 5 - GND GND – 5

6 - DSR

NOTES:

•Same configuration in the printer and in the host system should be set.

•The communication protocol should be set properly so that the transmitted data can be

received without errors.

11/55

Pin #1

Pin #9

Pin #6

Pin #5

FENIX IMVICO SM3000 OPERATION MANUAL

2.3- USB INTERFACE

The SM3000 US interface has the following general features:

•US specification US 2.0

•Transfer type ulk

•Maximum receive/transmit endpoint size 64 bytes

•Current consumption from US bus 2mA max.

2.3.1- Assigning USB connector terminals

Pin Signal name

1 Vbus

2 D –

3 D+

4 GND

Fig. 2.5- SM3000 US connector.

User has to use a standard “ ” series US connector.

2.4- DRAWER INTERFACE

The SM3000 allows controlling one or two coins drawers. Drawing opening is performed by means of

ESC p command, and drawer status (open/close) can be tested by means of DEL EOT command.

Fig. 2.6- SM3000 coins drawer connector.

Warning: DO NOT connect a telephone line to the coins drawer open connector, as it

could cause damage to the printer and to the telephone line.

The male connector that must be used in order to connect to the coins drawer to the SM3000 is

the 6 contacts RJ12 standard connector or compatible.

2.4.1- Assigning drawer connector terminals

Pin

number Signal name Direction from the

SM3000

1 Ground GND -

2 Open drawer 1 signal Output

3 Open/close drawer signal Input

4 +24 Vdc -

5 Open drawer 2 signal Output

6 GND signal -

Table 2.2- Drawer connector pins.

12/55

Pin nº1 Pin nº6

Pin nº4

Pin nº1

Pin nº3

Pin nº2

FENIX IMVICO SM3000 OPERATION MANUAL

1) Connector model (user side): 6 positions, 6 contacts (RJ12 telephone jack)

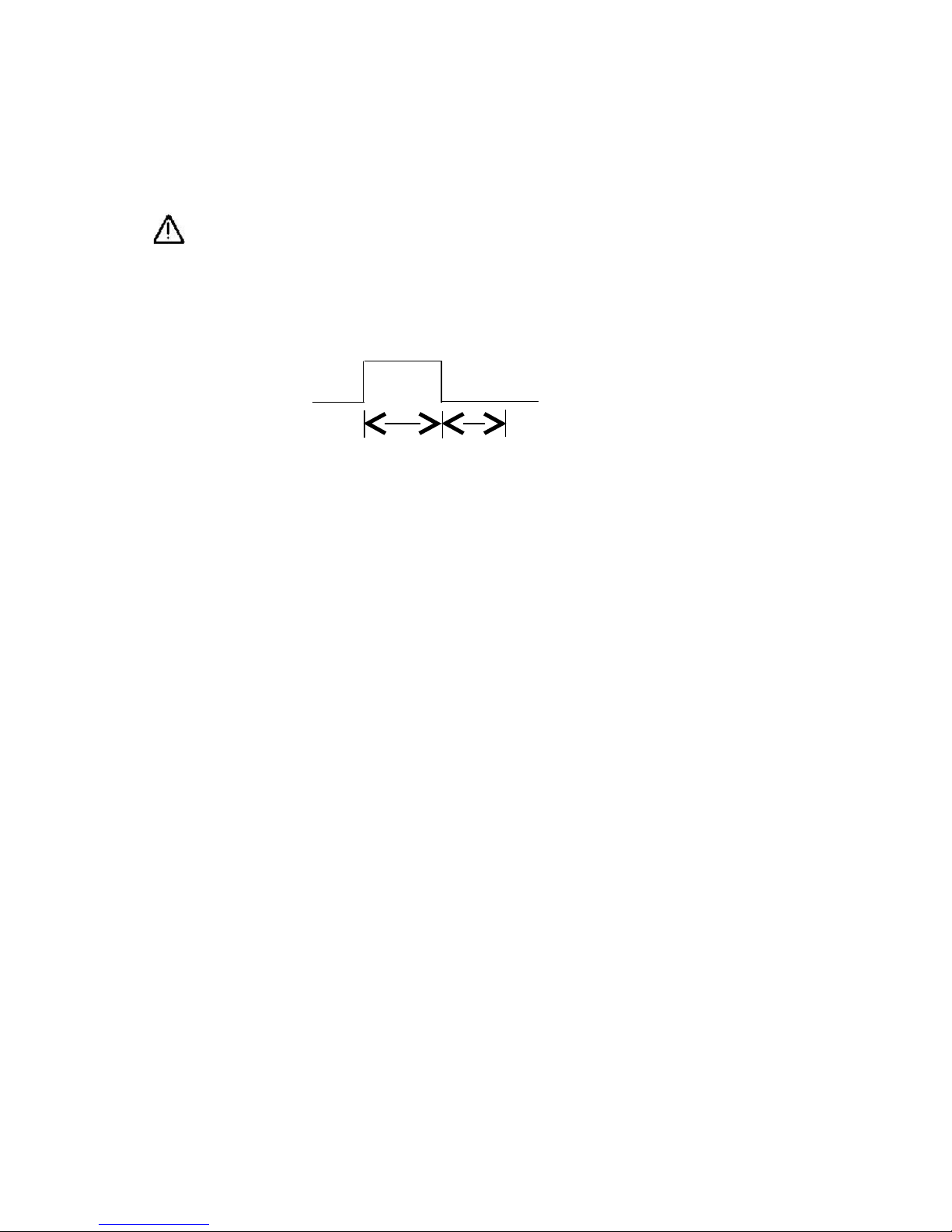

2) Open drawer signal:

•Output signal: Output voltage: 24 V approx.

Output current: 1 A or less.

Warning: In order to avoid over current and the SM3000 driver damage, the solenoid

resistance that opens the drawer must be > 24 Ω. The maximum current consumption of

the SM3000 driver for the drawer opening is 1 A (maximum 0.512 sec).

•Output wave form:

The t1 (ON) and t2 (OFF) times are specified by means of the ESC p command.

t1 x 2 ms t2 x 2 ms

Fig. 2.7- Output signal waveform for the drawer opening action.

13/55

FENIX IMVICO SM3000 OPERATION MANUAL

3 – BASIC OPERATIONS

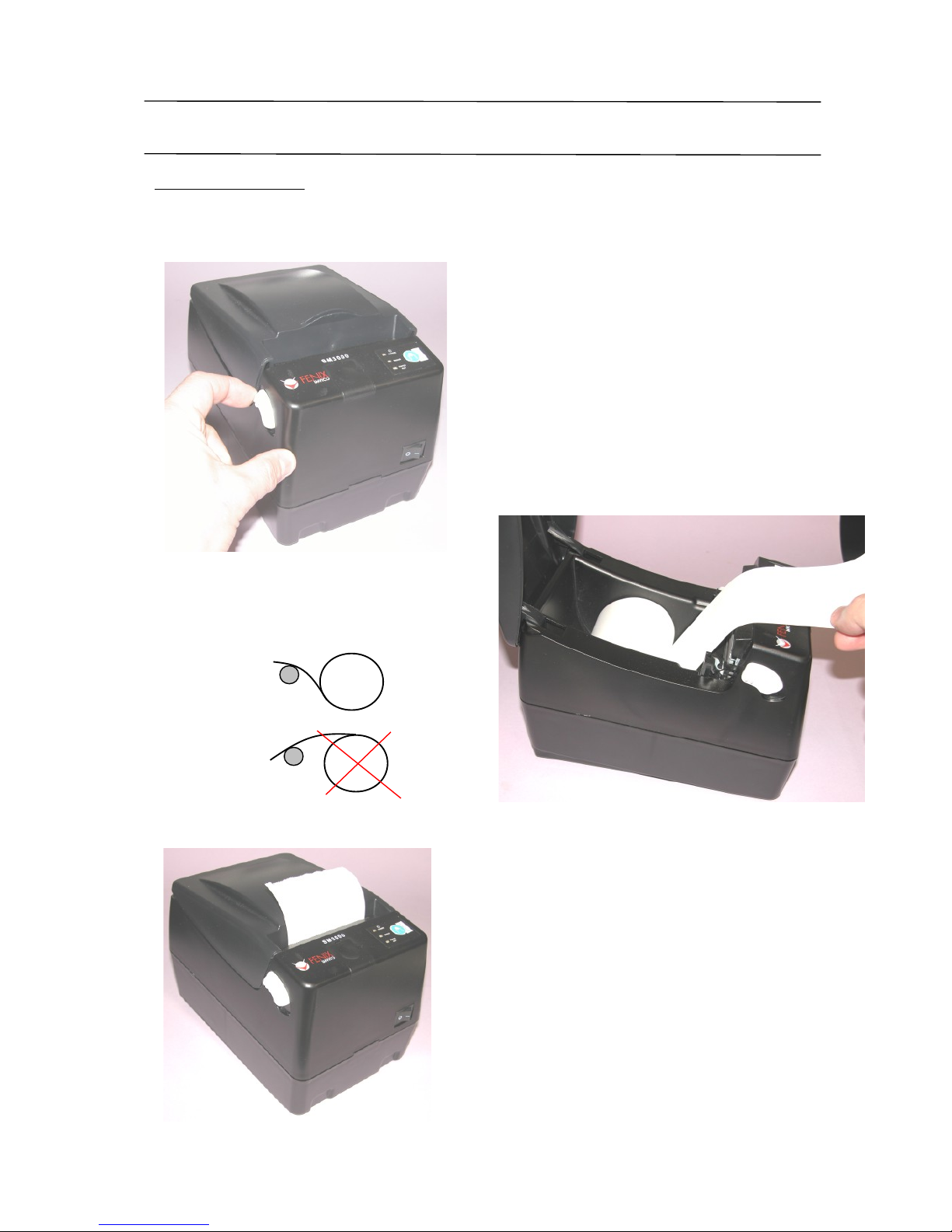

3.1- PAPER LOADING

One of the most useful features of the SM3000 printer is paper loading, which becomes very simple if

the following steps are executed:

14/55

a) Open the printer cover by pressing the

cover open button.

b) Insert the paper roll, as shown

in the picture, leaving some paper

outside the printer.

YES

NO

c) Close the cover until feeling the

roller is latched again.

Fig. 3.1- Paper roll loading.

FENIX IMVICO SM3000 OPERATION MANUAL

NOTES:

•Use paper rolls that meet the specifications indicated in this manual.

•DO NOT open the printer cover during the printing operation.

•Close the cover correctly, checking that the ‘PAPER OUT’ LED turns off.

3.2- CLEANIING A PAPER JAM

If a paper jam occurs, please proceed as indicated in the following steps:

1) Switch the printer off and press the button in order to try and open the lid.

2) If the paper is jammed in the cutter, and you can not open the lid of the printer, you must

proceed as follows: first, it should open the front cover located in the central part of the

printer sliding downward; then, manually rolling gear coupled to the cutter blade, until

backwards to its original position (until you can easily lift the lid).

Warning: Never force the opening of the cover, as the cutter blade could bend and become

permanently damaged if the paper is jammed with it.

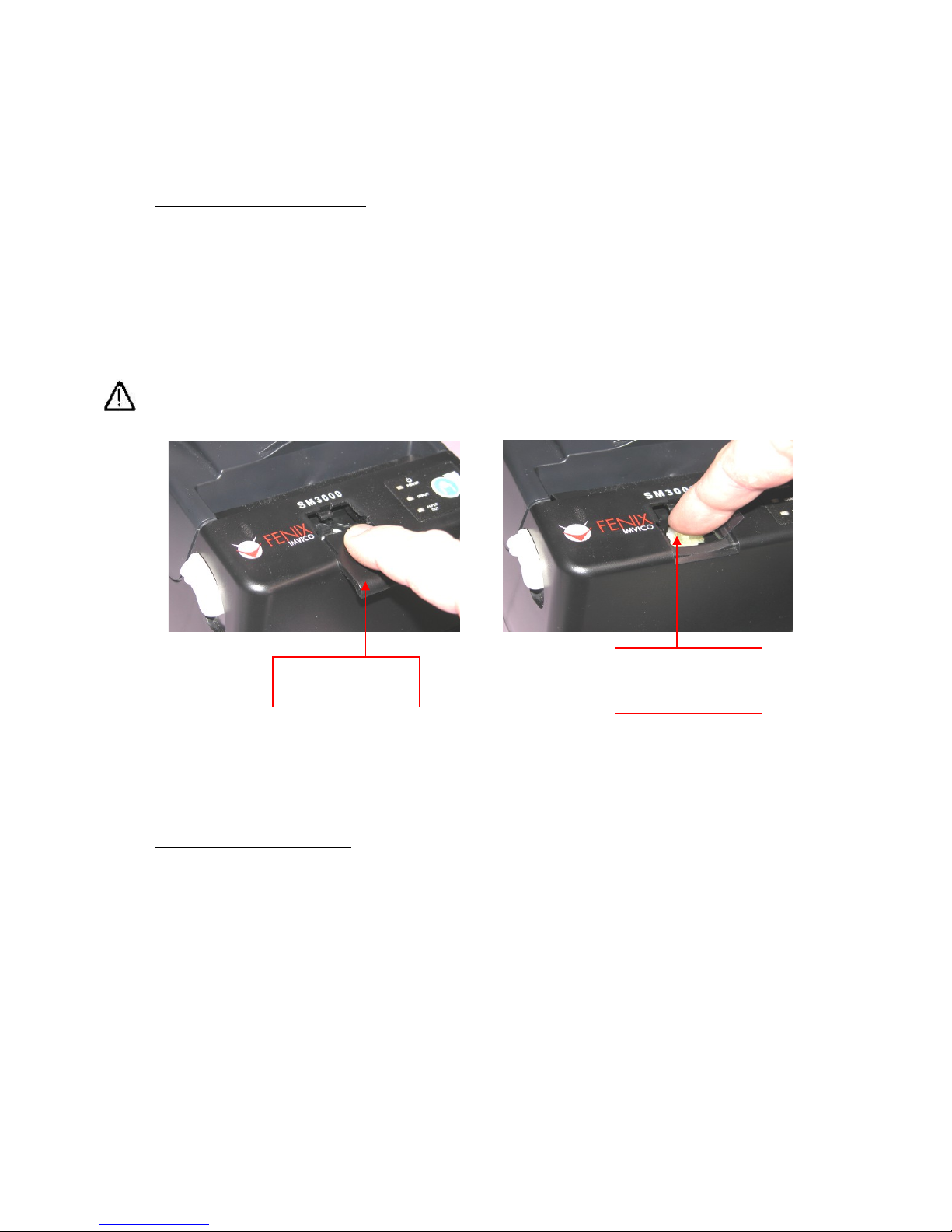

Fig. 3.2- Manual cutter positioning.

3) Remove the jammed paper and any other remaining piece of paper. Install the paper roll in the

same way as indicated in the previous section.

3.3- BUTTONS AND SWITCH

3.3.1- Power supply switch

It is placed on the lower front of the printer and acts as the switch of the external power supply. The front

panel provides a ‘POWER’ LED that indicates whether the power is on.

3.3.2- Paper feed button (FEED)

The FEED button in the front panel activates the automatic paper feed.

The paper is feeding while the button is kept pressed. The FEED button functionality is not enabled in

the following conditions:

(1) The paper sensor does not detect paper.

(2) The cover is open.

(3) The ESC c 5 command has been sent.

15/55

Manually rolling gear

coupled to the cutter

blade, until backwards

to its original position.

Open the front cover

sliding downward.

FENIX IMVICO SM3000 OPERATION MANUAL

3.3.3- Cover open button

When the cover open button, located on the left printer side (see Fig. 2.1), is pressed, the printer cover

opens.

Warnings:

DO NOT attempt to open the printer cover unless acting on the cover open button.

DO NOT open the printer cover while printing.

DO NOT open the printer cover while the cutter is working, as the mechanism could

be damaged.

3.4- PANEL LEDS

The SM3000 includes three LEDs in its front panel showing printer information.

Fig. 3.3- LEDs and FEED button.

The POWER LED (green) shows whether the SM3000 is powered on (the led is on) or it is not

(the led is off).

The PAPER OUT LED (red) shows whether the SM3000 does not have any paper and/or the cover is

open (the led is on).

The ERROR LED (red) shows if there has been any error in the SM3000 (the led is blinking) (See

section: 3.6- ERRORS PROCESSING).

16/55

FENIX IMVICO SM3000 OPERATION MANUAL

3.5- SPECIAL PRINTING MODES

esides the normal printing mode, in which all the received data are printed according to the settings or

conditions fixed by the commands, the SM3000 printer allows two special working modes: the self-test

mode and the hexadecimal mode.

17/55

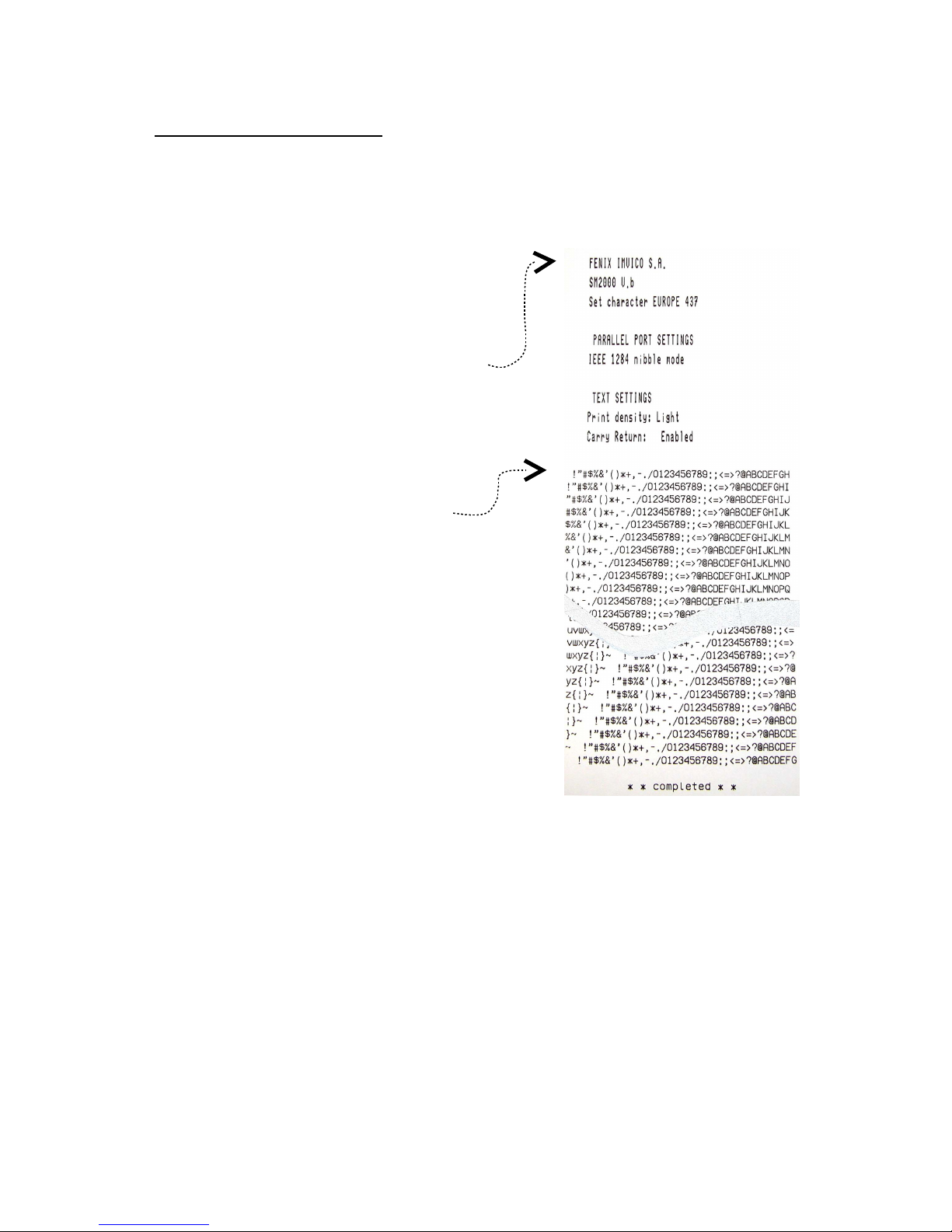

3.5.1- Self-test mode

The SMS3000 provides the self-test mode with

two different functionality: showing information on the

features of that particular printer model and verifying

the printing.

To enter the self-test mode, the printer must be

powered on while keeping pressed the paper

advance button (FEED) and with the cover closed.

The SM3000 will start printing a report, which

allows checking the features of this particular

model, like the firmware current version, control

functions of the communications protocol,

and so on.

If, once this printing has been finished, the

paper advance button FEED is still kept

pressed, the SM3000 will start printing

continuously and repetitively a character map

until it finally concludes the self-test by printing

‘* * completed * *’.

This second option of the self-test mode has the goal to

validate the printing speed and quality.

Fig. 3.4- SELF-TEST mode example.

FENIX IMVICO SM3000 OPERATION MANUAL

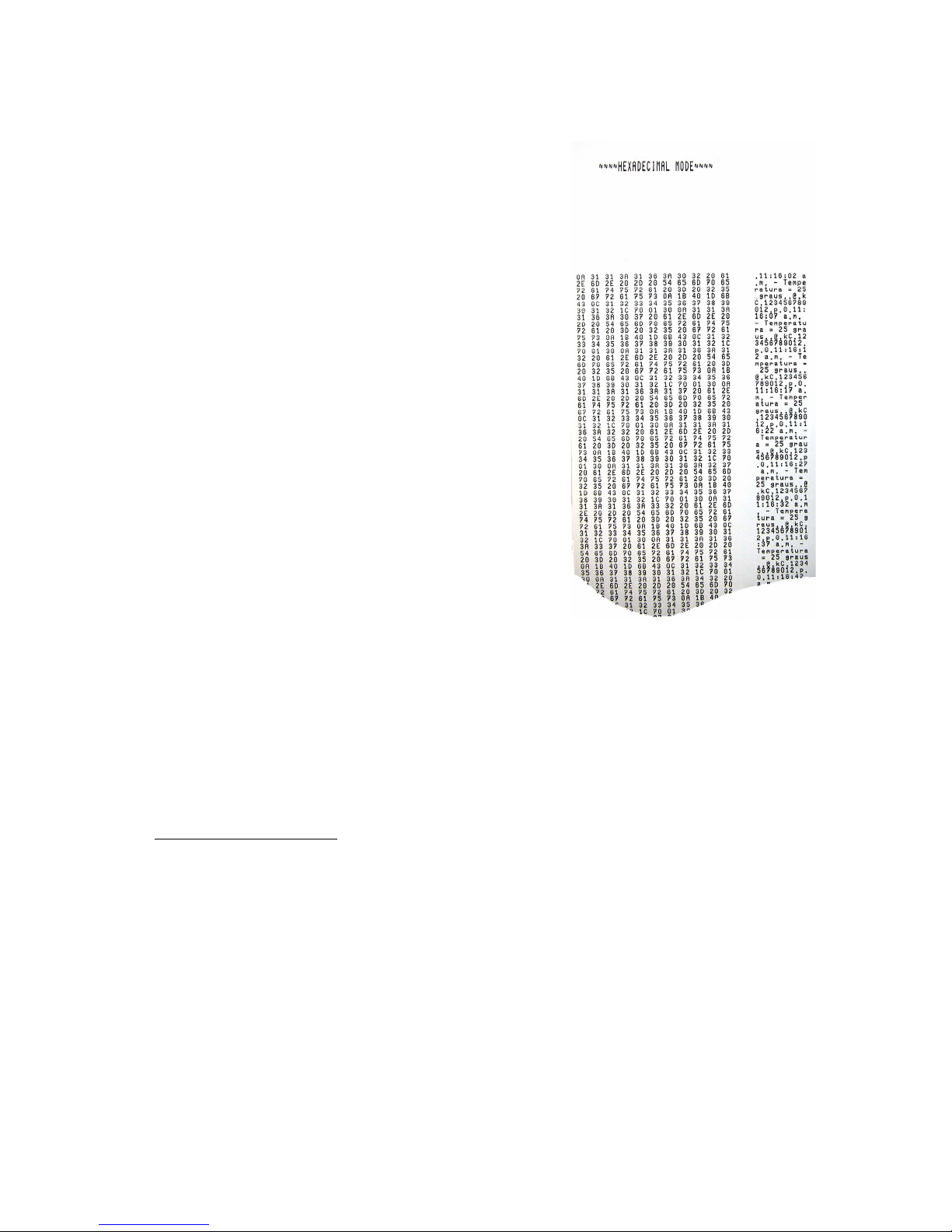

3.5.2- Hexadecimal dump mode

Fig. 3.5- Hexadecimal dump mode example.

NOTES:

(1) For any received characters that are under 20h, the ASCII ‘.’ will be printed.

(2) During the hexadecimal dump mode, the DEL EOT command does not work.

(3) It must be taken into account that if the number of bytes is not bigger than the minimum

amount required to print one line (11 bytes), the SM3000 will not print. It is recommended to

complete the hexadecimal dump by sending at least 11 bytes (for example 00h).

(4) It is also possible to enter the hexadecimal mode through the GS ( A command.

3.6- ERROR PROCESSING

When an error happens, the SM3000 visually notifies the error type through the ERROR LED and the

PAPER OUT LED, located in the front part of the printer. This fact allows, the final user to have a direct

reference on the current printer status.

On the other hand, the printer status and all its possible errors can also be obtained via software through

the DEL EOT command. In this way, the application developer can have more complete information on

the printer status, therefore being able to act accordingly.

1) The errors detected by the ERROR LED are the following: ‘near-end paper’, coins drawer open,

hardware error, cutter error, power supply voltage error and printing head temperature error.

18/55

In this mode, all the data received from the host system

is printed, without processing any command, in

hexadecimal and its corresponding ASCII.

This mode can be very helpful for the application

developer during the setup test time, as it allows to

detect and eliminate possible errors (as out of range

parameters, non valid command sequences, errors in

the communication channel, etc.), comparing what it has

theoretically been sent to the printer to what it is really

being received.

To enter hexadecimal mode, proceed with the following

steps:

a) Perform continuous self-test, explained in the

previous point, holding FEED button permanently,

until appears the text

"Enter in hexadecimal m de?...".

b) Continue pressing the FEED button for 4

seconds (approx.), until print the text

"~~~ HEXADECIMA MODE ~~~"

Turn off the printer to quit the hexadecimal mode.

FENIX IMVICO SM3000 OPERATION MANUAL

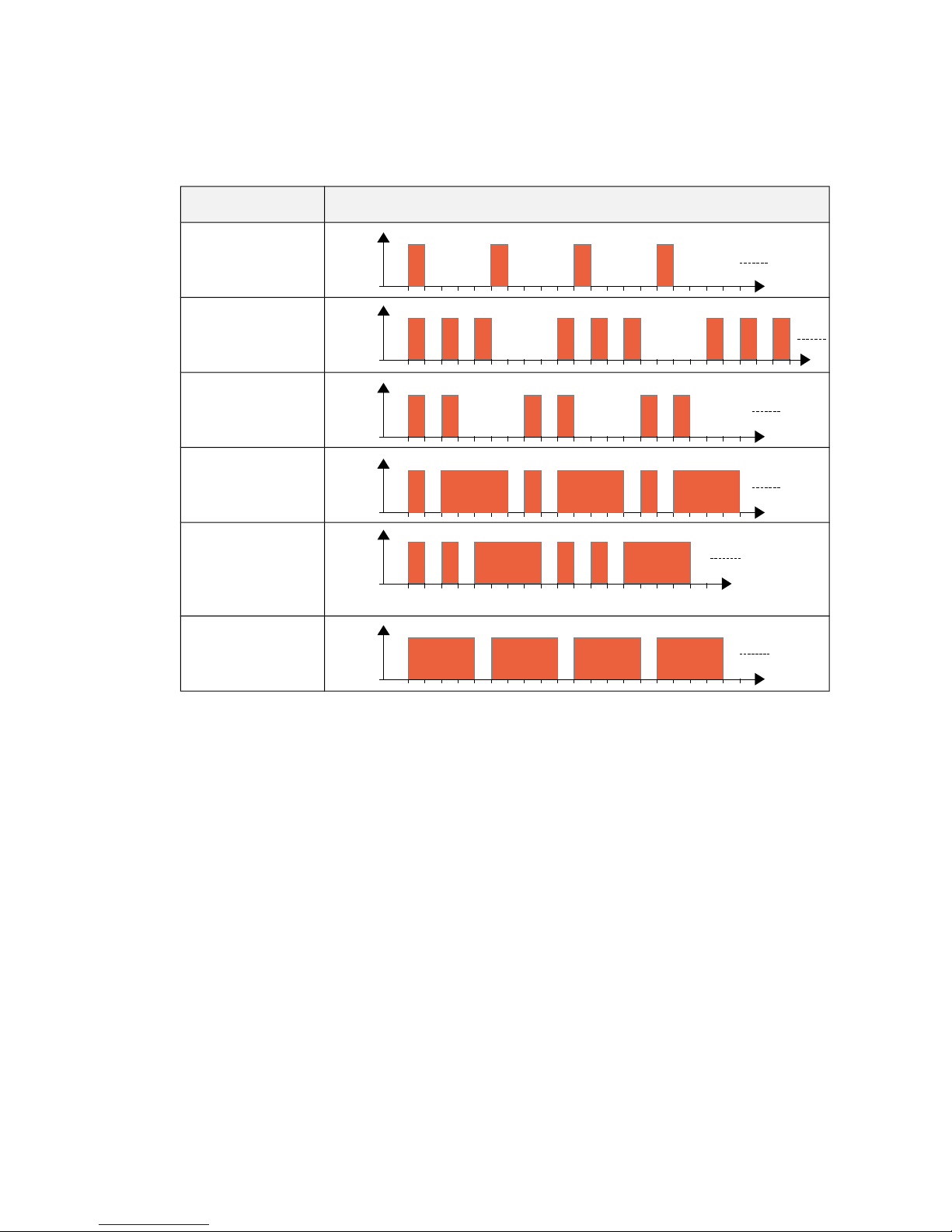

2) When any of these errors happen, the ERROR LED blinks with a different blinking timing

sequence for each of them. This fact allows the final user to understand, by visual inspection,

the error that had happened.

ERROR Sequence

PAPER NEAR

END

COINS DRAWER

OPEN

HARDWARE

CUTTER

POWER SUPPLY

(VP)

TEMPERATURE

Fig. 3.6- linking sequence of the ERROR LED.

More information on these errors can be found below:

‘Paper near-end’ error

[Description] This error happens when the ‘paper near-end’ sensor detects that the paper roll is

close to be finished. This means that using a paper roll with an external diameter of

100 mm and inner diameter of 25 mm, the sensor will trigger the error when there are

still 1.5 meters of paper approx.

This indication should be really taken as a warning, not as an error as such. The action

depends on the application and the developer’s criteria.

[Recover action] Replace paper roll.

[Notes] When this error happens the printing is not interrupted, although using the ESC c 4

command could stop it. This error is different from the ‘out of paper’ error.

Coins drawer open error

[Description] This error happens when the coins drawer is open.

This indication should be really taken as a warning, not as an error as such. The action

depends on the application and the developer’s criteria.

[Recover action] Closing the coins drawer.

19/55

t

Led ON

Led OFF

t

Led ON

Led OFF

t

Led ON

Led OFF

t

Led ON

Led OFF

t

Led ON

Led OFF

t

Led ON

Led OFF

FENIX IMVICO SM3000 OPERATION MANUAL

Hardware error

[Description] Some of the printer hardware devices are not working properly.

[Recover action] This error cannot be recovered. One of the components of the control interface might

be broken and should be replaced or repaired.

Cutter error

[Description] The cutter does not work correctly. For some reason, the cutter cannot start and come

back to its original position.

[Recover action] The printer tries automatically to recover from this error once it is initialized (ON/OFF).

If there was paper jammed or any other obstacle preventing it from recovering

automatically, the cover might not be able to open. In that case, proceed as specified in

section 3.2. Cleaning a paper jam.

Power supply oltage (Vp) error

[Description] The power supply voltage (Vp) is out of range (24V + 10%).

[Recover action] This is a non-recoverable error.

Unplug the power supply from the printer and check if the output voltage of the power

supply is within the specified range. Replace it in case it is not working properly.

Temperature error

[Description] The print head temperature is above 80ºC.

[Recover action] The printing recovers automatically from this error when the thermal print head

temperature is below 60ºC again.

[Note] This error can happen if the ambient temperature is very high and the printer is working

continuously with high-density printing.

3) The errors indicated by the PAPER OUT LED are the ‘out of paper’ and/or ‘open cover’ ones.

Out of paper error

[Description] The out of paper sensor detects there is not paper on the printing line.

[Recover action] This error disappears loading a new paper roll in the printer (see section

3.1. Paper l ading).

[Note] This error stops the printing and it cannot be restarted until it is not recovered.

Open co er error

[Description] The printer cover is open.

[Recover action] This error disappears when closing the cover.

[Note] This error stops the printing and it cannot be restarted until it is not recovered.

NOTE: Printer operation when an error happens

When the SM3000 detects an error (except the near-end paper and coins drawer open errors), it

executes the following operations:

•It stops all printing operations.

•It changes its status to USY.

•The ERROR LED blinks or the PAPER OUT LED permanently lights.

20/55

Table of contents

Other Fenix Imvico Printer manuals

Fenix Imvico

Fenix Imvico EPC1200 Series User manual

Fenix Imvico

Fenix Imvico TS1700 User manual

Fenix Imvico

Fenix Imvico TK41 User manual

Fenix Imvico

Fenix Imvico EPC1100 User manual

Fenix Imvico

Fenix Imvico TK51 Series User manual

Fenix Imvico

Fenix Imvico TK14 User manual

Fenix Imvico

Fenix Imvico KS55 Series User manual

Fenix Imvico

Fenix Imvico TK23 Series User manual