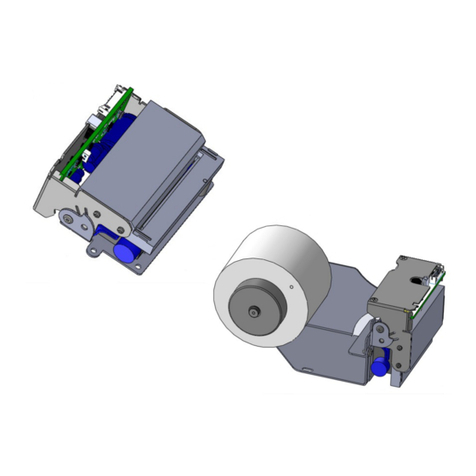

Fenix Imvico TK41 User manual

TK41 THERMAL PRINTER

Operation Manual - Version 2.0

February 2003

FENIX IMVICO TK-41 OPERATION MANUAL

2/88

Revision list for the TK41 thermal printer operation manual.

V1.0 Date: 15-10-2001

Page Type of revision Before change After change

V1.1 Date: 20-02-2002

Page Type of revision Before change After change

8change 9ª, 14ª,0,1ª 9A, 14A, 0.1A

49 change Fig.3.6.1 - Optical Mark

Characteristics Fig.3.6 – Optical Mark

Characteristics

68 addition ITF bar code

73 change Fig. C.1-

TK4160T/TK4180B

external dimensions

Fig. C.1 – TK4160T/TK4180T

external dimensions

74 change Fig. C.2-

TK4160B/TK4180B

external dimensions

Fig. C.2 – TK4160B/TK4180B

external dimensions

V1.2 Date: 4-12-2002

Page Type of revision Before change After change

addition Code128 bar code

V2.0 Date: 13-2-2003

Page Type of revision Before change After change

all general

FENIX IMVICO TK-41 OPERATION MANUAL

3/88

I N D E X

IMPORTANT NOTES ON TK41 HANDLING -------------------------------------------- 6

0- INTRODUCTION ----------------------------------------------------------------------------- 8

1- GENERAL SPECIFICATIONS ----------------------------------------------------------- 9

1.1- PRINTING SPECIFICATIONS ------------------------------------------------ 9

1.2- CHARACTER SPECIFICATIONS ------------------------------------------- 9

1.3- ELECTRICAL CHARACTERISTICS ---------------------------------------- 10

1.4- PAPER REQUIREMENTS ---------------------------------------------------- 10

1.5- OVERALL DIMENSIONS ------------------------------------------------------ 10

1.6- ENVIRONMENTAL CONDITIONS ------------------------------------------ 11

2- INSTALLATION ------------------------------------------------------------------------------ 12

2.1- FIXING THE TK41 PRINTER ------------------------------------------------- 12

2.1.1- TK41T (Top fixing model) INSTALLATION -------------------------- 12

2.1.2- TK41B (Bottom fixing model) INSTALLATION ---------------------- 13

2.2- TK41 INSTALLATION CONSIDERATIONS ------------------------------ 14

2.2.1- EXTERNAL CHUTE SYSTEM ------------------------------------------- 16

2.2.2- PAPER GUIDE SYSTEM ------------------------------------------------- 17

2.3- TK41 CONNECTORS ----------------------------------------------------------- 18

2.3.1- POWER SUPPLY CONNECTOR --------------------------------------- 19

2.3.2- SERIAL RS-232 CONNECTOR ----------------------------------------- 21

2.3.2.1- Specifications -------------------------------------------------------- 21

2.3.2.2- Serial interface connection example -------------------------- 22

2.3.3- CENTRONICS PARALLEL CONNECTOR --------------------------- 23

2.3.3.1- Specifications -------------------------------------------------------- 23

2.3.3.2- Parallel interface connection example ------------------------ 25

3- BASIC OPERATIONS ---------------------------------------------------------------------- 28

3.1- LOADING PAPER ---------------------------------------------------------------- 28

3.1.1- AUTOMATIC PAPER LOAD --------------------------------------------- 29

3.1.2- MANUAL PAPER LOAD -------------------------------------------------- 30

3.2- CHARACTER CODE TABLE -------------------------------------------------- 31

3.3- BUTTONS & LEDS --------------------------------------------------------------- 33

3.3.1- BUTTONS FUNCTIONS -------------------------------------------------- 34

3.3.2- LED INDICATORS ---------------------------------------------------------- 35

3.4- SPECIAL MODES ---------------------------------------------------------------- 36

3.4.1- SELF-TEST MODE --------------------------------------------------------- 36

3.4.2- PROGRAMMING MODE -------------------------------------------------- 38

3.4.3- HEXADECIMAL DUMP MODE ------------------------------------------ 40

3.5- ERROR PROCESSING --------------------------------------------------------- 41

3.5.1- NO PAPER / HEAD-UP ERROR ---------------------------------------- 42

3.5.2- PAPER-NEAR-END SENSOR ------------------------------------------- 43

3.5.3- THERMAL HEAD TEMPERATURE ERROR ------------------------ 44

3.5.4- AUTOCUTTER ERROR --------------------------------------------------- 45

3.5.5- THERMAL HEAD VOLTAGE (Vp) ERROR -------------------------- 46

3.5.6- HARDWARE ERROR ------------------------------------------------------ 47

3.5.7- OPTICAL MARK ERROR ------------------------------------------------- 48

3.5.8- SERIAL PORT ERROR DETECTION FLOW CHART ------------ 49

3.5.9- PARALLEL PORT ERROR DETECTION FLOW CHART ------- 50

3.6- OPTICAL MARK ----------------------------------------------------------------- 51

3.6.1- EXAMPLE ON USING THE OPTICAL MARK ---------------------- 52

FENIX IMVICO TK-41 OPERATION MANUAL

4/88

4- CONTROL COMMANDS ------------------------------------------------------------------ 54

4.1- COMMAND NOTATION -------------------------------------------------------- 54

4.2- EXPLANATION OF TERMS --------------------------------------------------- 54

4.3- CONTROL COMMANDS DESCRIPTION --------------------------------- 55

APPENDIX A- CHARACTERS x LINE ----------------------------------------------------- 74

APPENDIX B- RECOVERY FROM AUTOCUTTER ERROR ------------------------ 75

APPENDIX C- EXTERNAL APPEARANCE ---------------------------------------------- 76

APPENDIX D- SPECIFICATIONS ---------------------------------------------------------- 78

APPENDIX E- HOW TO ORDER ----------------------------------------------------------- 79

APPENDIX F- FREQUENTLY ASKED QUESTIONS --------------------------------- 80

APPENDIX G- CODE 128 BAR CODE --------------------------------------------------- 81

APPENDIX H- TESTING SOFTWARE ---------------------------------------------------- 85

FENIX IMVICO TK-41 OPERATION MANUAL

5/88

FIGURES AND TABLES

Fig a. Head cleaning procedure--------------------------------------------------------------- 7

Fig. 1.1- Operating Temperature and Humidity Range -------------------------------- 11

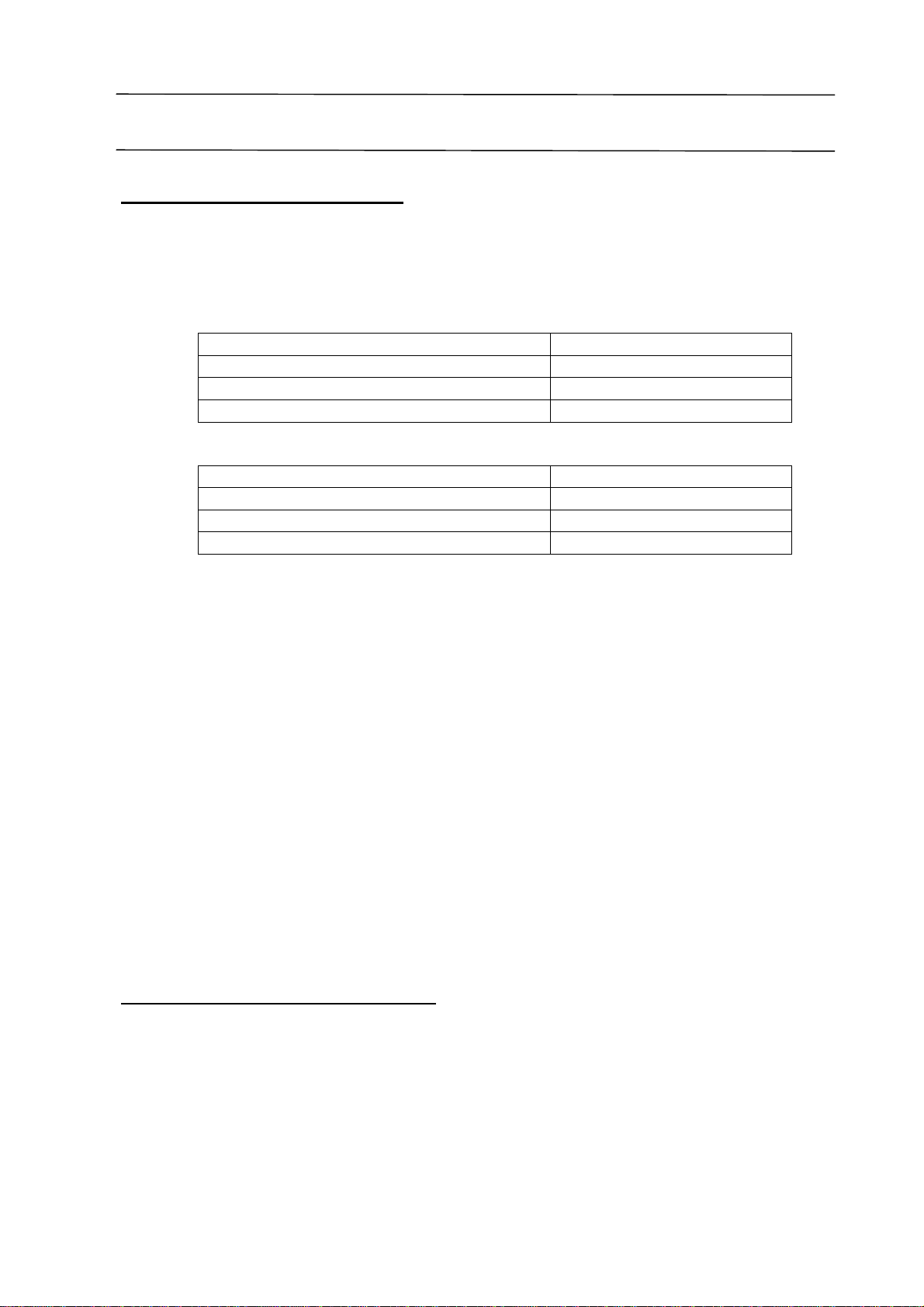

Fig. 2.1- Fixing the TK41T --------------------------------------------------------------------- 12

Fig. 2.2- Fixing the TK41B --------------------------------------------------------------------- 13

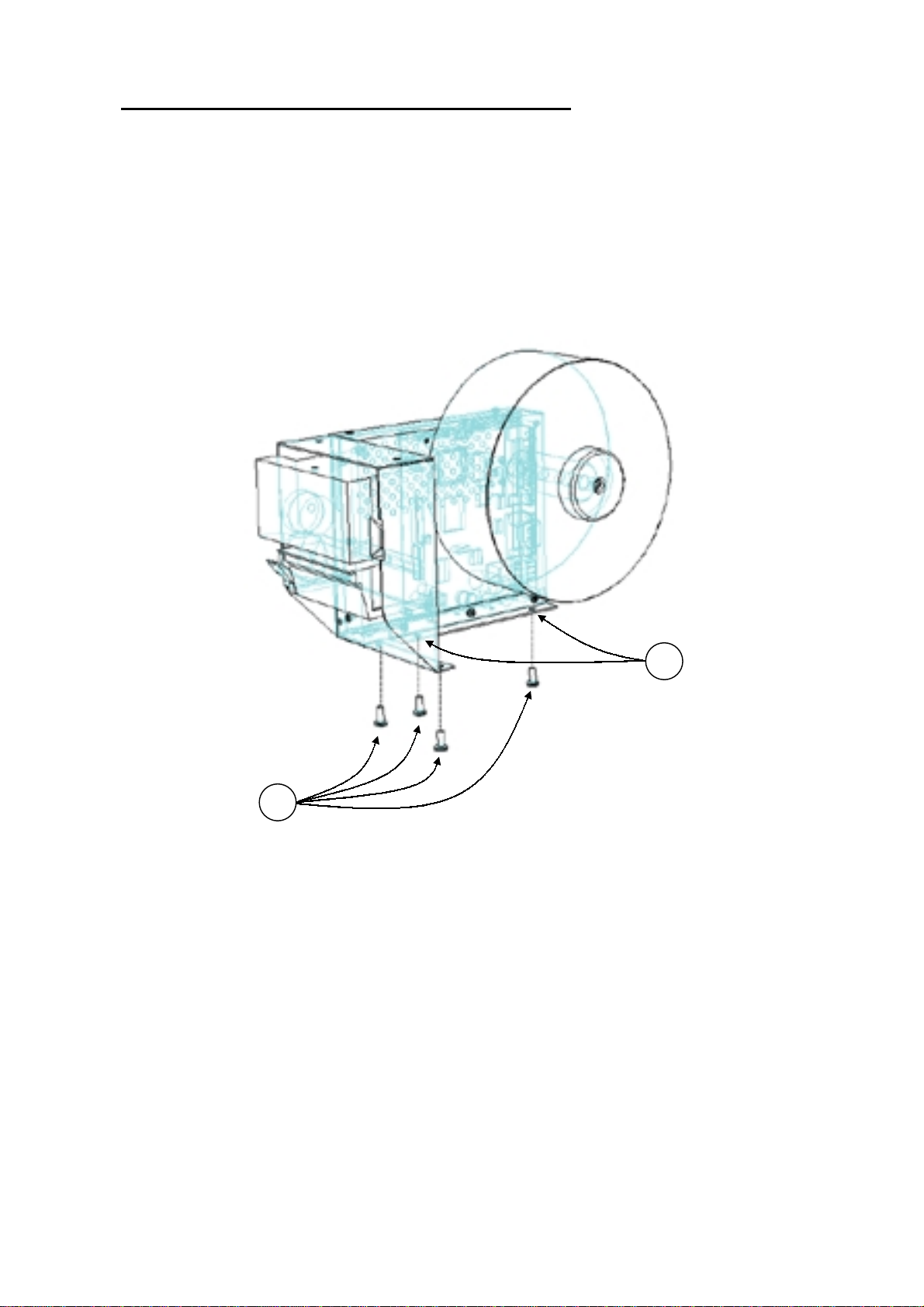

Fig. 2.3- Accessible parts of the TK41T ---------------------------------------------------- 14

Fig. 2.4- Accessible parts of the TK41B ---------------------------------------------------- 15

Fig. 2.5- Paper-near-end sensor positions ------------------------------------------------ 15

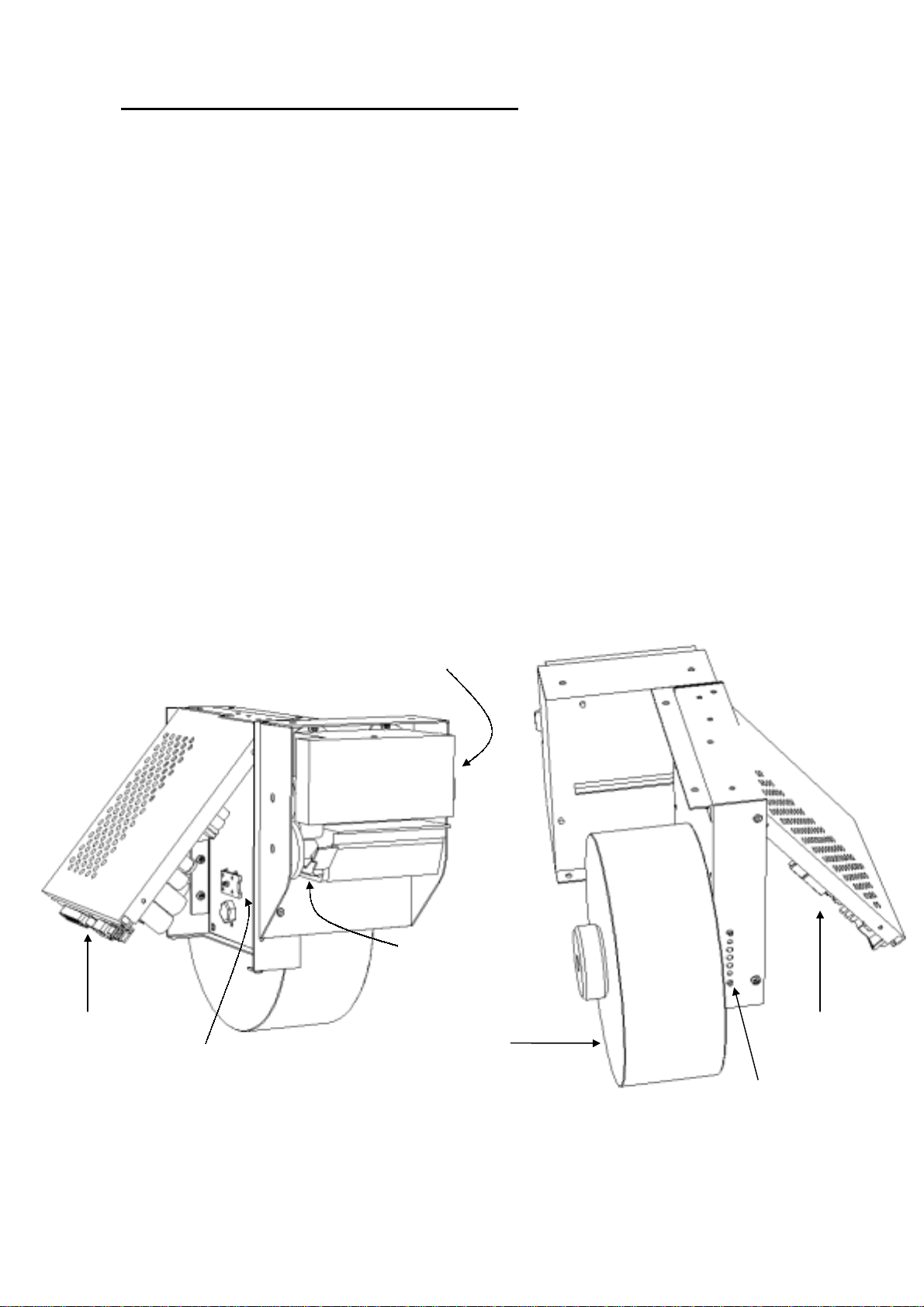

Fig. 2.6- External chute system -------------------------------------------------------------- 16

Fig. 2.7- Paper guide system ----------------------------------------------------------------- 17

Fig. 2.8- Fixing holes of the TK41------------------------------------------------------------ 17

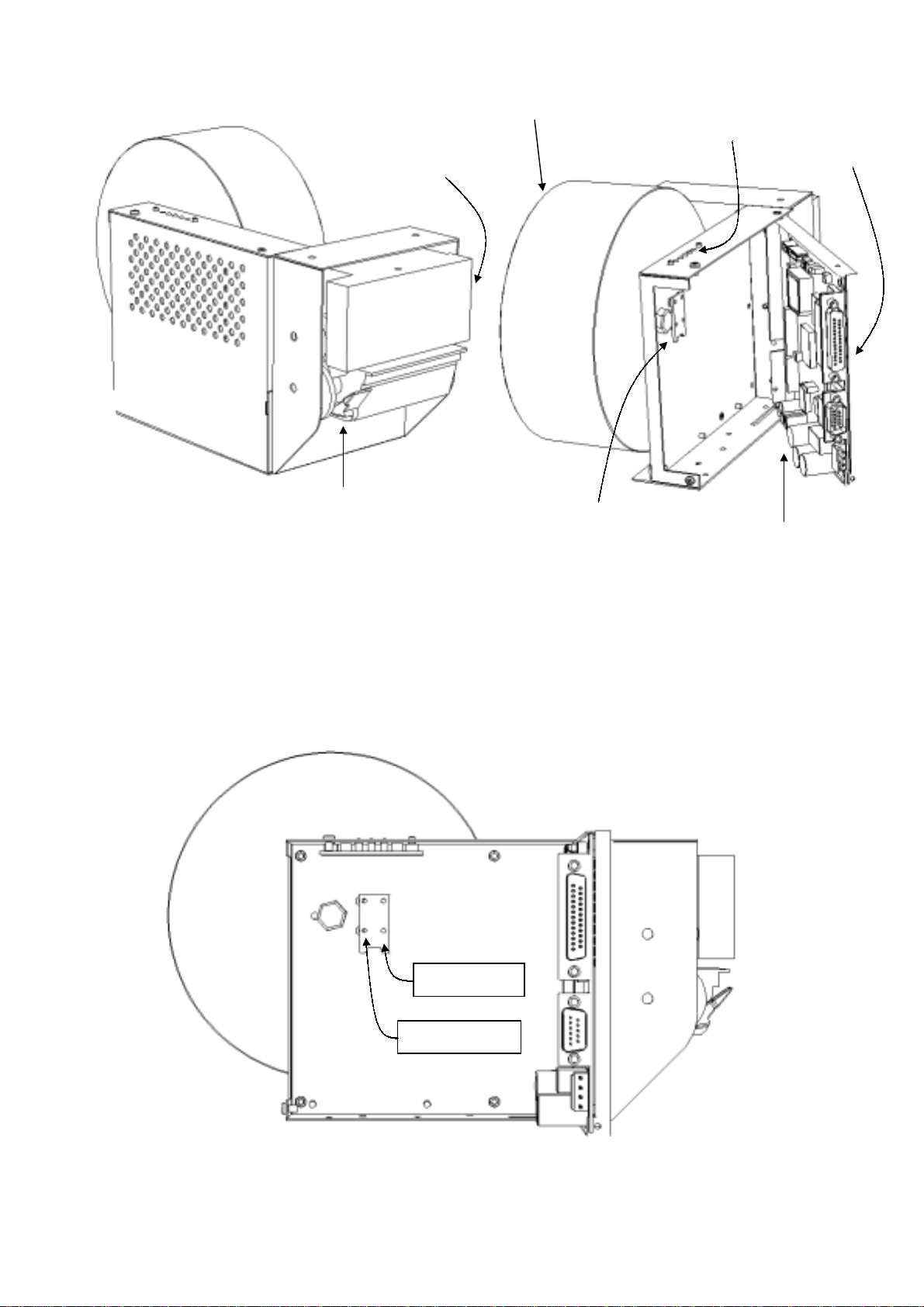

Fig. 2.9- TK41 connectors location ---------------------------------------------------------- 18

Fig. 2.10- Power supply connector as seen from outside the TK41 ---------------- 19

Fig. 2.11- RS-232 connector as seen from outside the TK41 ------------------------ 21

Fig. 2.12- CENTRONICS connector as seen from outside the TK41 -------------- 24

Fig. 2.13- Parallel input / output signal timing chart --- --------------------------------- 27

Fig. 3.1- Place the paper roll ------------------------------------------------------------------ 28

Fig. 3.2- Paper roll positioning ---------------------------------------------------------------- 28

Fig. 3.3- (1) Automatic paper load ----------------------------------------------------------- 29

Fig. 3.4- (2) Automatic paper load ----------------------------------------------------------- 29

Fig. 3.5- (1) Manual paper load -------------------------------------------------------------- 30

Fig. 3.6- (2) Manual paper load -------------------------------------------------------------- 30

Fig. 3.7- (3) Manual paper load -------------------------------------------------------------- 30

Fig. 3.8- TK41 Buttons & Leds identification --------------------------------------------- 33

Fig. 3.9- SELF-TEST MODE sample ------------------------------------------------------- 37

Fig. 3.10- PROGRAMMING MODE sample ---------------------------------------------- 39

Fig. 3.11- HEXADECIMAL DUMP MODE sample -------------------------------------- 40

Fig. 3.12- Serial port error detection flow chart -------------------------------------------49

Fig. 3.13- Parallel port error detection flow chart----------------------------------------- 50

Fig. 3.14- Optical Mark Characteristics ----------------------------------------------------- 51

Fig. 3.15- Optical Mark recommended use sequence --------------------------------- 53

Fig. 4.1- Code128 code example------------------------------------------------------------ 71

Fig. B.1- Printer mechanism. Front view --------------------------------------------------- 75

Fig. C.1- TK4160T/TK4180T external dimensions--------------------------------------- 76

Fig. C.2- TK4160B/TK4180B external dimensions--------------------------------------- 77

Table 2.1- Serial port pin-out ------------------------------------------------------------------ 21

Table 2.2- Serial interface connection example------------------------------------------ 22

Table 2.3- Parallel port pin-out --------------------------------------------------------------- 23

Table 2.4- Standard parallel connection example---------------------------------------- 25

Table 2.5- Special parallel connection example------------------------------------------ 26

Table 3.1- (1) PC437 character code table------------------------------------------------ 31

Table 3.2- (2) PC437 character code table------------------------------------------------ 32

Table 3.3- Errors explanation ----------------------------------------------------------------- 41

Table 3.4- Parallel Port Signals VS Type of error --------------------------------------- 41

Table 3.5- Parallel Port pins status at “NO PAPER / HEAD-UP” error ------------- 42

Table 3.6- Parallel Port pins status at “PAPER NEAR END” error ------------------ 43

Table 3.7- Parallel Port pins status at “HEAD TEMPERATURE” error ------------ 44

Table 3.8- Parallel Port pins status at “AUTOCUTTER” error ------------------------ 45

Table 3.9- Parallel Port pins status at “HEAD VOLTAGE” error --------------------- 46

Table 3.10- Parallel Port pins status at “HARDWARE” error ------------------------- 47

Table 3.11- Parallel Port pins status at “OPTICAL MARK” error -------------------- 48

Table 4.1- Command List ---------------------------------------------------------------------- 55

Table C.1- TK4160T / TK4180T different dimensions --------------------------------- 76

Table C.2- TK4160B / TK4180B different dimensions --------------------------------- 77

FENIX IMVICO TK-41 OPERATION MANUAL

6/88

IMPORTANT NOTES ON TK41 HANDLING

In order to guarantee a long life of the printer, it is necessary to keep some

precautions on the TK41 handling. Please read carefully next lines to make a

good use of the printer.

SAFETY PRECAUTIONS

Before using the printer, please carefully read point 2- INSTALLATION.

BEWARE not to invert power supply polarity. This may irremediably damage the

printer.

Use power supply voltage within specified range. Overvoltage may irremediably

damage the printer. Voltage under the specified range may cause incorrect

operations.

Keep TK41 away from water or any other liquid.

Do not use in locations subject to high humidity or dust levels.

DO NOT put any objects into the printer. It could cause severe damage like

shortcircuits, broken thermal head or general printer failure.

DO NOT blow the TK41.

•NEVER modify the TK41.

•DO NOT try to repair the TK41 by yourself. If some failure is detected contact

with your usual dealer technical service.

•Since the printer contains permanent magnets (in the motor) as well as

elctromagnets, it should not be used in areas containing excessive dirt, dust

and metallic particles.

•Never print without paper installed or the head away from the platen, because

the life of the thermal head may be shortened.

•Never pull the paper out (forward or backward) with the head down against

the platen.

•Since the head heating elements and the driver IC are very delicate, avoid

touching them with any metal objects, such as tweezers or screwdrivers.

•Since the head area and the motor surface reaches high temperatures right

after printing, never touch it with your bare hands; wait about 15 min. For it to

cool.

•Never touch the surface of the head heating elements and the driver IC, as

dirt may stick to them, affecting the head heating elements or causing

damage by static electricity.

FENIX IMVICO TK-41 OPERATION MANUAL

7/88

•HEAD CLEANING PROCEDURE AND PRECAUTIONS.

Do not clean the thermal head immediately after printing because thermal

head and its periphery are hot during and after printing.

Do not use sandpaper, cutter knives etc. when cleaning. They will damage the

heat elements.

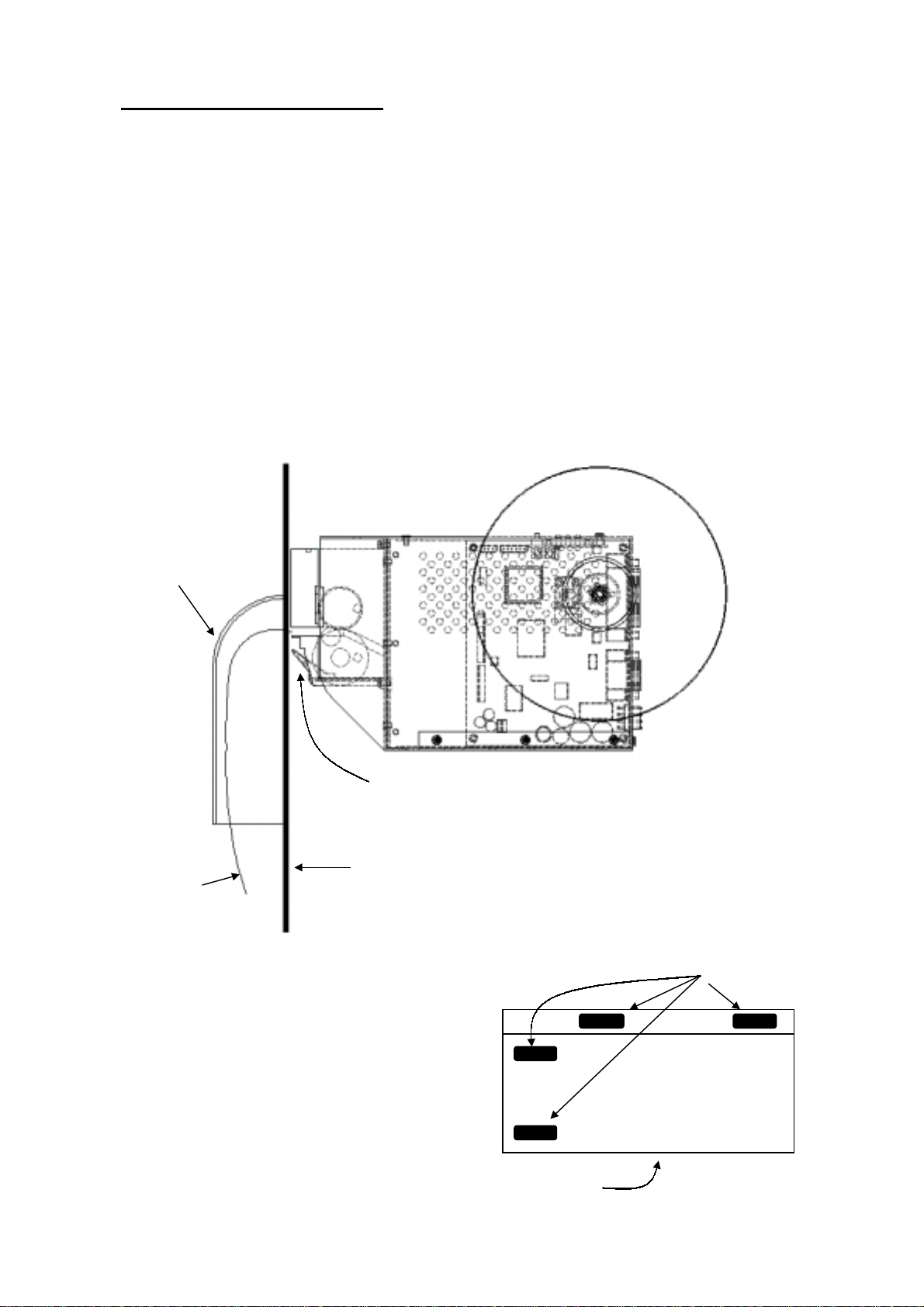

Fig a. Head cleaning procedure

Turn off the printer. Turn the release lever in the direction of the arrow. Clean

the heat elements using alcohol (ethanol, methanol, or IPA) and a cotton swab.

Wait until the alcohol dries and close the platen block. Fenix recommends

cleaning the thermal head periodically (generally every 3 months) to maintain

receipt print quality.

RECOMMENDATIONS

•Before connecting any input interface, verify the correct operation of the

TK-41 printer with self test feature.

•Place the TK41 in such a way that connection wires are not crushed or

twisted.

Thermal head

Cotton swab

Head-up

lever

FENIX IMVICO TK-41 OPERATION MANUAL

8/88

0 – INTRODUCTION

The TK41 is a very high-performance embedded thermal line printer. Its compact and

functional design covers many professional applications. It has graphics capabilities

and bar code representation.

The TK41is intended to be integrated into the user’s final system. Its structure allows

an easy access either to the interface or the critical parts of the mechanism. So,

special care must be taken at choosing the TK-41 location, access and protection

from external damage. It can be used in industrial, professional or laboratory

environments.

Main features of the TK41 printer are:

•Easy maintenance structure.

•Easy installation procedure.

•Compact and lightweight.

•Three paper widths available (60mm, 80 mm or 82 mm) depending on the printing

mechanism used.

•Upper or lower paper roll location.

•High speed printing: up to 150mm/s.

•Line printing method: Printing is performed every time a text line is filled.

•High reliability: 15 million lines.

•Single 24V DC power supply (150W).

•No-paper and paper-near-end sensors.

•High resolution printing (8 dots/mm).

•Both parallel (CENTRONICS) and serial (RS-232) data input interface.

•Scalable font (independent scale in X / Y axis).

•Programmable character and line space.

•Printing adjustments (speed, density and consumption).

•Graphic bitmap printing capabilities.

•Several formats Bar Code.

•Two different font sizes (Font A = 12x24dots. Font B = 8x16dots).

•Control code based on ESC / POS commands(*).

•Hexadecimal mode for easy software debugging.

•Scissors type autocutter.

•Self test feature.

•Windows 95, 98, NT & 2000 drivers and demo/configuration program.

This manual is a guide of the printer operations and is addressed to the application’s

designer. In following chapters there is a detailed description of hardware and

software configuration to take advantage of the features of the TK41 printer.

(*) ESC/POS are registered trademarks of Seiko Epson Corporation.

FENIX IMVICO TK-41 OPERATION MANUAL

9/88

1 – GENERAL SPECIFICATIONS

1.1-PRINTING SPECIFICATIONS

1) Printing method: Thermal line printing.

2) Print Head:

Total number of dots:

Printing mechanism model type Number of dots

M-522AF (59.5mm paper-width model) 448 dots (= 56mm)

M-532AF (79.5mm paper-width model) 576 dots (= 72mm)

M-542AF (82.5mm paper-width model) 640 dots (= 80mm)

Printing width:

Printing mechanism model type Maximum printing width

M-522AF (59.5mm paper-width model) 56mm (448-dot positions)

M-532AF (79.5mm paper-width model) 72mm (576-dot positions)

M-542AF (82.5mm paper-width model) 80mm (640-dot positions)

3) Dot density: 203 dpi x 203 dpi (dpi: dots per inch (25.4mm)).

(8 dots/mm)

4) Printing speed: High speed mode: 150mm/s (5,9”/s) max.

Normal mode: 100mm/s (3,9”/s)

Low speed mode: 80mm/s (3,1”/s)

Very low speed mode: 50mm/s (2”/s)

Printing speed may be slower, depending on the

data transmission speed and combination of control

commands, environmental conditions, or selection of

the print density.

5) Paper feeding: Feeding method: unidirectional with friction feed.

Feeding pitch: 0,125mm (0,0049”)

Feeding speed: 150mm/s (5,9”/s) maximum.

1.2- CHARACTER SPECIFICATIONS

1) Number of characters: Alphanumeric characters: 95

(Refer to point 3.2- CHARACTER CODE TABLE).

2) Character structure: Font A: 12 x 24 dots (1,5 x 3 mm).

Font B: 8 x 16 dots (1 x 2 mm).

Font B is selected as the default.

FENIX IMVICO TK-41 OPERATION MANUAL

10/88

1.3- ELECTRICAL CHARACTERISTICS

1) Supply voltage: +24V DC ±2.4V (±10%)

2) Current consumption (at 24V):

80mm paper-width model 60mm paper-width model

Mean current Approx. 9 A Approx. 6.5 AHigh speed

mode Peak current Approx. 14 A Approx. 10 A

Standby

mode Mean current Approx. 0.1 A Approx. 0.1 A

1.4- PAPER REQUIREMENTS

1) Paper type: Single-ply thermal paper roll

2) Specified thermal paper: Original paper No. P350 KSP

Original paper No. TF50KS-E NIPPON PAPER

INDUSTRIES CO., LTD.

Original paper No. AF50KS-E JUJO THERMAL

Original paper No. PD160R OJI

Original paper No. TF11KS-ET NIPPON PAPER

INDUSTRIES CO., LTD.

A different paper type may give a different print quality.

The paper thickness must be 56 – 180 µm.

1) Size:

Paper width:

M-532AF printing mechanism M-522AF printing mechanism

79.5 +/- 0.5mm (3.13” +/- 0.02”) 59.5 +/- 0.5mm (2.34” +/- 0.02”)

Paper roll outer diameter: 150mm (Max.)

1.5- OVERALL DIMENSIONS

1) External dimensions (with a 150mm-diameter paper roll):

M-532AF/M-542AF

mechanism M-522AF mechanism

Lower paper- roll location 130x225x210 (WxDxH) 110x225x210 (WxDxH)

Upper paper-roll location 130x265x170 (WxDxH) 110x265x170 (WxDxH)

2) Weight (with a 150mm-diameter paper roll):

For the M-532AF/M-542AF mechanism: 1500gr. Approx.

For the M-522AF mechanism: 1300gr. Approx.

FENIX IMVICO TK-41 OPERATION MANUAL

11/88

1.6- ENVIRONMENTAL CONDITIONS

1) Operating Temperature: 0 to 55ºC (32 to 131ºF)

Reliable printing: 5 to 50ºC (41 to 122ºF)

2) Operating humidity: 10 to 80% (34ºC (93.2ºF) at 80%, non-condensing)

Fig. 1.1- Operating Temperature and Humidity Range

FENIX IMVICO TK-41 OPERATION MANUAL

12/88

2 – INSTALLATION

2.1- FIXING THE TK41 PRINTER

The TK41 is an industrial printer thought to be fixed in a bigger case or structure, or

another kind of appropriate chassis. There are two models for the TK41 printer with 4

different fixing points each.

2.1.1- TK41T (Top fixing model) INSTALLATION

•Fix the TK41T to the chassis by screwing putting four metric screws (M4 / L10 mm)

through the holes marked with A in fig. 2.1- Fixing the TK41T.

•Place all the four screws in the same direction, from up to down.

•Use two metric nuts (M4) to secure the screws marked with B in the same figure.

•It is hardly recommended that the fixing holes of your chassis have an oval shape

so as the TK41 can move backward and forward for an easy manipulation (See

point 2.2- TK41 INSTALLATION CONSIDERATIONS)

Fig. 2.1- Fixing the TK41T.

M4 metric

screws

A

Screws to be fixed by

two M4 nuts

B

FENIX IMVICO TK-41 OPERATION MANUAL

13/88

2.1.2- TK41B (Bottom fixing model) INSTALLATION

•Fix the TK41B to the chassis by screwing putting four screws (M4 / L10 mm)

through the holes marked with A in Fig. 2.2- Fixing the TK41B.

•Place all the four screws in the same direction, from down to up.

•Use two metric nuts (M4) to secure the screws marked with B in the same figure.

•It is hardly recommended that the fixing holes of your chassis have an oval shape

so as the TK41 can move backward and forward for an easy manipulation (See

point 2.2- TK41 INSTALLATION CONSIDERATIONS)

Fig. 2.2- Fixing the TK41B.

M4 metric

screws

A

Screws to be fixed by

two M4 nuts

B

FENIX IMVICO TK-41 OPERATION MANUAL

14/88

2.2- TK41 INSTALLATION CONSIDERATIONS

Despite of the model, there are some general considerations to take into account

when installing the TK41.

A wrong installation can cause many serious problems like paper jam, difficult

maintenance of the printer, impossible to change the paper roll, etc.

Moreover, a correct installation can prevent the printer of being damaged by external

agents, like weather or vandalism.

The basic points that a correct installation must follow are:

•Smooth exit of the ticket. Prevent problems with static electricity due to the nature

of the used materials.

•Avoid the final user’s access to the printer outlet.

•Allow enough space and accessibility to reach the maintenance procedure points in

case it is needed. These points are:

•Printing Head.

•Paper roll.

•Interface.

•Connectors.

•Leds and Push-buttons.

(See fig. 2.3- Accessible parts of the TK41T and fig. 2.4- Accessible parts of the

TK41B)

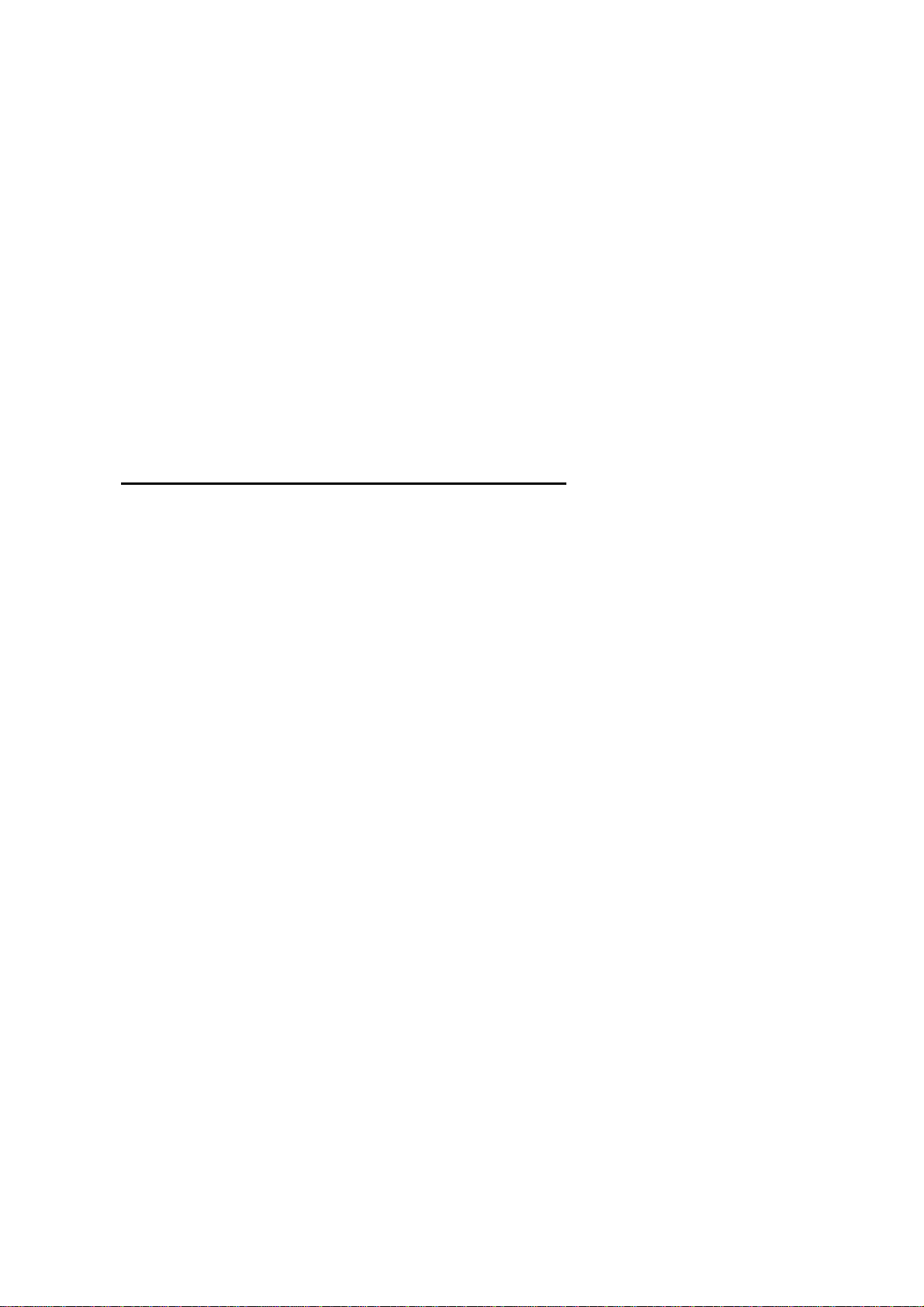

Fig. 2.3- Accessible parts of the TK41T.

Paper Roll

Leds & Buttons

Access to

interface

Printer cutter &

mechanism

Thermal head

lever

External

connectors Paper-near-end

sensor

REAR VIEWFRONT VIEW

FENIX IMVICO TK-41 OPERATION MANUAL

15/88

Fig. 2.4- Accessible parts of the TK41B.

The paper-near-end sensor can be fixed in two positions:

A) Detects paper-near-end when remaining paper is about 7m long.

B) Detects paper-near-end when remaining paper is about 30m long.

Fig. 2.5- Paper-near-end sensor positions.

REAR VIEWFRONT VIEW

Printer cutter &

mechanism

Thermal head

lever

Paper Roll Leds & Buttons

Access to

interface

External

connectors

Paper-near-end

sensor

A)

7m. left

B

)

30m. left

FENIX IMVICO TK-41 OPERATION MANUAL

16/88

For these reasons, FENIX suggests the following systems as solutions to a correct

installation:

2.2.1- EXTERNAL CHUTE SYSTEM

The idea of this system is to internally print and cut the ticket inside the machine, and

then make it fall into a receptacle where the user can have external access.

Therefore, there must exist some distance between the printer and the front side of

the user’s chassis in order to build a useful chute for the ticket, and to be able to open

the printer thermal head.

Two points must be assured to make this system work right:

•The construction of the receptacle must avoid the user to reach any internal

parts of the machine.

•The way of the ticket from the printer outlet to the receptacle must be

smooth, clean and free of obstacles to allow the ticket to actually fall into it

and avoid paper jams or tickets that do not fall. Depending on the

construction materials, care must be taken with static electricity; otherwise

tickets may get stuck inside the machine and never reach the receptacle.

Next figure shows a scheme of this system:

Fig. 2.6- External chute system.

Frontal side of

user’s chassis

Ticket

receptacle

Ticket

Make sure this distance allows

the opening of the printer

thermal head (min: 20mm)

FENIX IMVICO TK-41 OPERATION MANUAL

17/88

2.2.2- PAPER GUIDE SYSTEM

When using this system, the printer must be set quite near the front side of the user’s

chassis. The paper guide is to avoid external handling of the printer outlet.

Two points must be assured to make this system work right:

•Special care in the design of the part which goes from the printer outlet to the

paper guide (Paper jams can a occur due to an inappropriate design).

Depending on the construction materials, care must be taken with static

electricity; otherwise tickets may get stuck in the paper guide and never

reach the receptacle.

•As the printer is placed very near the user’s chassis, some system must be

implemented in order to move the printer when accessing the printing head

(i.e. giving the fixing holes of the chassis an oval shape to allow the printer

moving forward and backward). Otherwise there will be no access to the

printing head.

Next figure shows an scheme of this system:

Fig. 2.7- Paper guide system.

The distance between the mechanism

and the frontal side of the user’s

chassis may not allow the opening of

the printer thermal head. To avoid this,

one solution is to design the fixing

holes of the TK41 with an oval shape,

so as the machine can move backward

and forward to access to its head-up

lever.

Fig. 2.8- Fixing holes for TK41

Ticket

Paper guide

Frontal side of

user´s chassis

Head-up

lever

Fixing surface

of the TK41

Fixing holes

for the TK41

2.3- TK41 CONNECTORS

When using the TK41T, the external connectors are placed in the bottom side of the

printer.

When using the TK41B, the external connectors are placed in the back side of the

printer.

User can find the next connectors:

•Power supply connector.

•Serial RS-232 communications connector.

•Parallel CENTRONICS communications connector.

Fig. 2.9- TK41connectors location.

TK41T BOTTOM VIEW

TK41B REAR VIEW

SUB-D25 Female Centronics

parallel connector

SUB-D9 Male RS232

serial connector

4PIN – 24V DC power

supply connector

FENIX IMVICO TK-41 OPERATION MANUAL

19/88

2.3.1- POWER SUPPLY CONNECTOR

Attach power supply cable to the 4-pin micro connector. Verify power supply voltage

before making the connection.

NOTE: All the 4 pins must be connected.

The minimum section for the supply wires is 1mm2.

Cables more than 50cm long are not recommended.

Terminal nº Signal Name Function

1 GND Ground

2 VCC Printer power (24v DC)

3 VCC Printer power (24v DC)

4 GND Ground

Fig.2.10- Power supply connector as seen from outside the TK41.

User side connector model: Housing: VHR-4N (JST or compatible)

Contacts: SVH-21T-P1.1 (JST or compatible)

The TK-41 requires one power source: VCC (24v DC) for driving the thermal head and

motor. This voltage is internally regulated to 5V to control the electronics. The power

supply must satisfy the following conditions:

VCC: 24v DC +/- 2,4v

Example of current consumption (for the 79.5mm-wide mechanism):

Print head current consumption at a printing ratio of 25%:

(Printing ratio is defined as the number of dots/dot line (576 dots)).

1) Peak current: Approx. 6.7 A (the moment all 160 dots are energized).

NOTE: The peak current is measured at the minimum resistive value and

at the maximum voltage.

Conditions:

VH max: Head connector terminal voltage max. 26.4V

Rmin: Head resistance value min. 626.8 Ohm.

2) Mean current Approx. 1.75 A

(Head terminal voltage= 24V, head resistive value

R=657Ohm, print duty of 25%, mean energizing pulse width

of 248 µs (assumed that 50% of printed dots are energized

just before), synchronizing with 833µs).

The following formula is used to obtain the head drive current:

Imean = [V(volts)/R(Ohms)] x 576dots x printing ratio x [energizing pulse width/cycle]

1234

FENIX IMVICO TK-41 OPERATION MANUAL

20/88

NOTES:

•If the number of dots that are energized at the same time is increased, a higher

current will flow; therefore, the user should use a power supply with a current

capacity adequate for the corresponding print duty.

•When designing lines and bit images, take the printing ratio and print duty into

account.

•Print quality may be poor if the printing ratio or print duty is high.

•Definitions:

•Printing ratio: the number of printing dots (energizing pulses)/dot line.

•Print duty: the number of printing dots (energizing pulses)/ elements/ paper

feed amount (two steps, including non-printing area)

•Average energizing pulse width is defined as 107 of 160 dots per dot line that are

continuously energized.

WARNING : Beware not to invert the polarity of power supply. This may

irremediably damage the printer.

IMPORTANT NOTE ABOUTTK42 POWER SUPPLY:

The necessary power supply depends on content printed in the ticket.

A 150w power supply covers all adversed possibility (printing ratio of 100%

black at any temperature). However, if the print ratio is not over 60%, a 60w

power supply can be used. Any way, power supply must satisfy the peaks

current that mechanism requires, which are determined by the following

formula:

Ipeak = [24/657] x number of printing dots

Table of contents

Other Fenix Imvico Printer manuals

Fenix Imvico

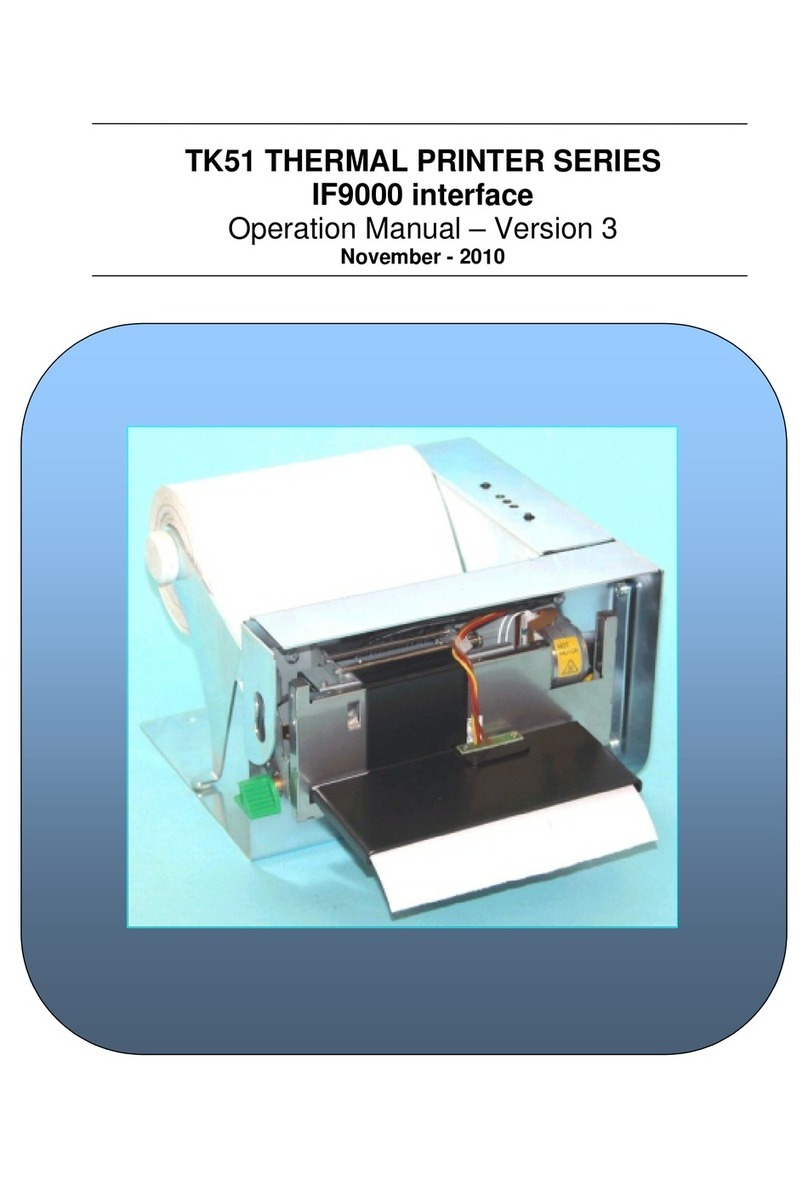

Fenix Imvico TK51 Series User manual

Fenix Imvico

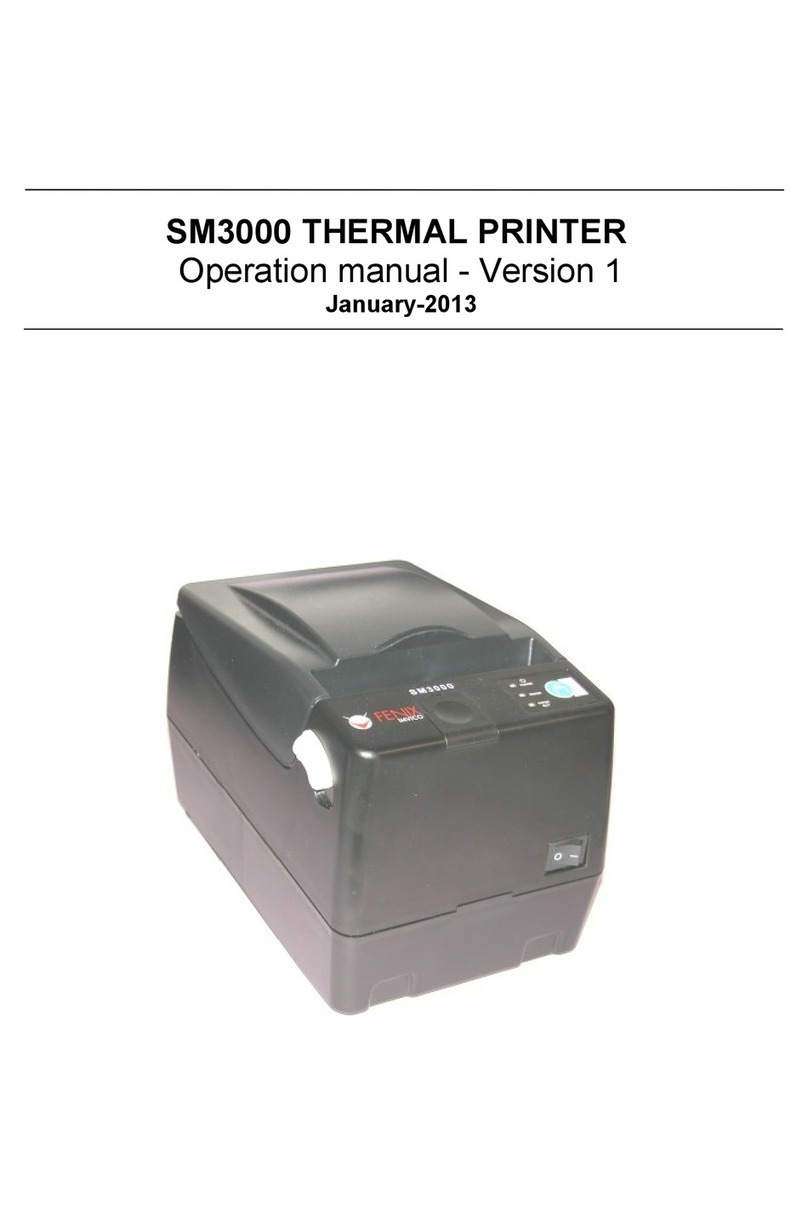

Fenix Imvico SM3000 User manual

Fenix Imvico

Fenix Imvico EPC1100 User manual

Fenix Imvico

Fenix Imvico KS55 Series User manual

Fenix Imvico

Fenix Imvico TK14 User manual

Fenix Imvico

Fenix Imvico EPC1200 Series User manual

Fenix Imvico

Fenix Imvico TK23 Series User manual

Fenix Imvico

Fenix Imvico TS1700 User manual