Fenix Imvico TK23 Series User manual

TK23 THERMAL PRINTER SERIES

Operation Manual - Version 1.0

February 2006

FENIX IMVICO TK23 OPERATION MANUAL

2/81

Revision list for the TK23 thermal printer series operation manual.

V 1.0 Date: 15-02-2006

Page Type of revision Before change After change

FENIX IMVICO TK23 OPERATION MANUAL

3/81

I N D E X

IMPORTANT NOTES ON TK23 HANDLING ....................................................... 6

0- INTRODUCTION............................................................................................. 8

1- GENERAL SPECIFICATIONS......................................................................... 9

1.1-PRINTING SPECIFICATIONS............................................................. 9

1.2- CHARACTER SPECIFICATIONS....................................................... 9

1.3- ELECTRICAL CHARACTERISTICS................................................... 10

1.4- PAPER REQUIREMENTS.................................................................. 10

1.5- OVERALL DIMENSIONS.................................................................... 11

1.6- ENVIRONMENTAL CONDITIONS...................................................... 11

2 – INSTALLATION.............................................................................................. 12

2.1- FIXING THE TK23 PRINTER .........................................................…. 12

2.1.1- TK23 INSTALLATION............................................................12

2.1- TK23 INSTALLATION CONSIDERATIONS....................................…. 13

2.1.1- EXTERNAL CHUTE SYSTEM.............................................. 14

2.1.2- PAPER GUIDE SYSTEM.......................................................15

2.2- TK23 USER INTERFACE ELEMENTS............................................... 16

2.2.1- POWER SUPPLY CONNECTOR.......................................... 17

2.2.1.1- Optional Power supply connector ............................17

2.2.2- SERIAL RS-232 CONNECTOR.............................................19

2.2.2.1- Specifications .......................................................... 19

2.2.2.2- Serial interface connection example........................ 20

2.2.3- CENTRONICS PARALLEL INTERFACE...............................21

2.2.3.1- Specification............................................................. 21

2.2.3.2 Timing diagram of data printer reception .................. 22

2.2.3.3- Parallel interface connector pin assignment............ 23

3 – BASIC OPERATIONS.................................................................................... 25

3.1- LOADING PAPER.............................................................................. 25

3.1.1- AUTOMATIC PAPER LOAD................................................. 26

3.1.2- MANUAL PAPER LOAD....................................................... 27

3.2- BUTTONS FUNCTIONS.................................................................... 28

3.3- LED INDICATORS............................................................................. 28

3.4- SPECIAL MODES.............................................................................. 29

3.4.1- SELF-TEST MODE.............................................................. 29

3.4.2- PROGRAMMING MODE...................................................... 30

3.4.3- HEXADECIMAL DUMP MODE............................................. 33

3.5- ERROR PROCESSING...................................................................... 34

3.5.1- NO PAPER / HEAD-UP ERROR........................................... 34

3.5.2- PAPER-NEAR-END ERROR................................................ 35

3.5.3- THERMAL HEAD TEMPERATURE ERROR........................ 35

3.5.4- AUTOCUTTER ERROR........................................................ 35

3.5.5- THERMAL HEAD VOLTAGE (Vp) ERROR........................... 36

3.5.6- HARDWARE ERROR........................................................... 36

3.5.7- OPTICAL MARK ERROR..................................................... 36

3.5.9- SERIAL PORT ERROR DETECTION FLOW CHART.......... 37

3.6- OPTICAL MARK................................................................................. 39

3.6.1- EXAMPLE ON USING THE OPTICAL MARK....................... 40

FENIX IMVICO TK23 OPERATION MANUAL

4/81

4 – CONTROL COMMANDS............................................................................... 42

4.1- COMMAND NOTATION..................................................................... 42

4.2- EXPLANATION OF TERMS............................................................... 42

4.3- CONTROL COMMANDS DESCRIPTION.......................................... 43

APPENDIX A – CHARACTERS x LINE................................................................ 64

APPENDIX B – CHARACTER CODE TABLES.....................................................65

APPENDIX C – RECOVERY FROM AUTOCUTTER ERROR............................. 67

APPENDIX D – EXTERNAL APPEARANCE........................................................ 68

APPENDIX E – SPECIFICATIONS...................................................................... 70

APPENDIX F – HOW TO ORDER....................................................................... 71

APPENDIX G – FREQUENTLY ASKED QUESTIONS......................................... 73

APPENDIX H – CODE128 BAR CODE................................................................ 74

APPENDIX I – TESTING SOFTWARE................................................................. 78

FENIX IMVICO TK23 OPERATION MANUAL

5/81

FIGURES AND TABLES

Fig. a. Opening the paper cutter........................................................................... 7

Fig. b. Head cleaning procedure.......................................................................... 7

Fig. 1.1- Operating Temperature and Humidity Range........................................ 11

Fig. 2.1- Fixing the TK23 ..................................................................................... 12

Fig. 2.2- TK23 elements ...................................................................................... 13

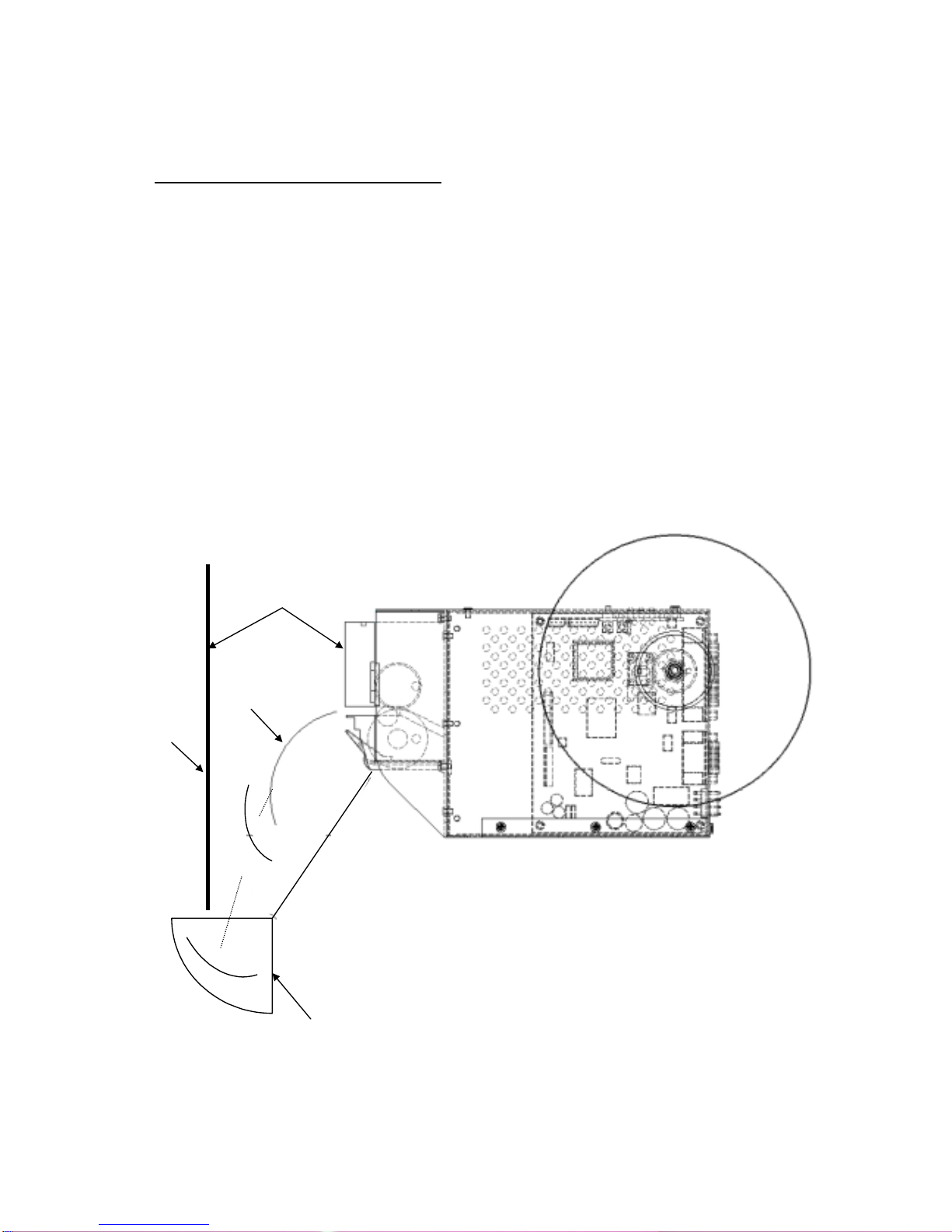

Fig. 2.3- External chute system............................................................................ 14

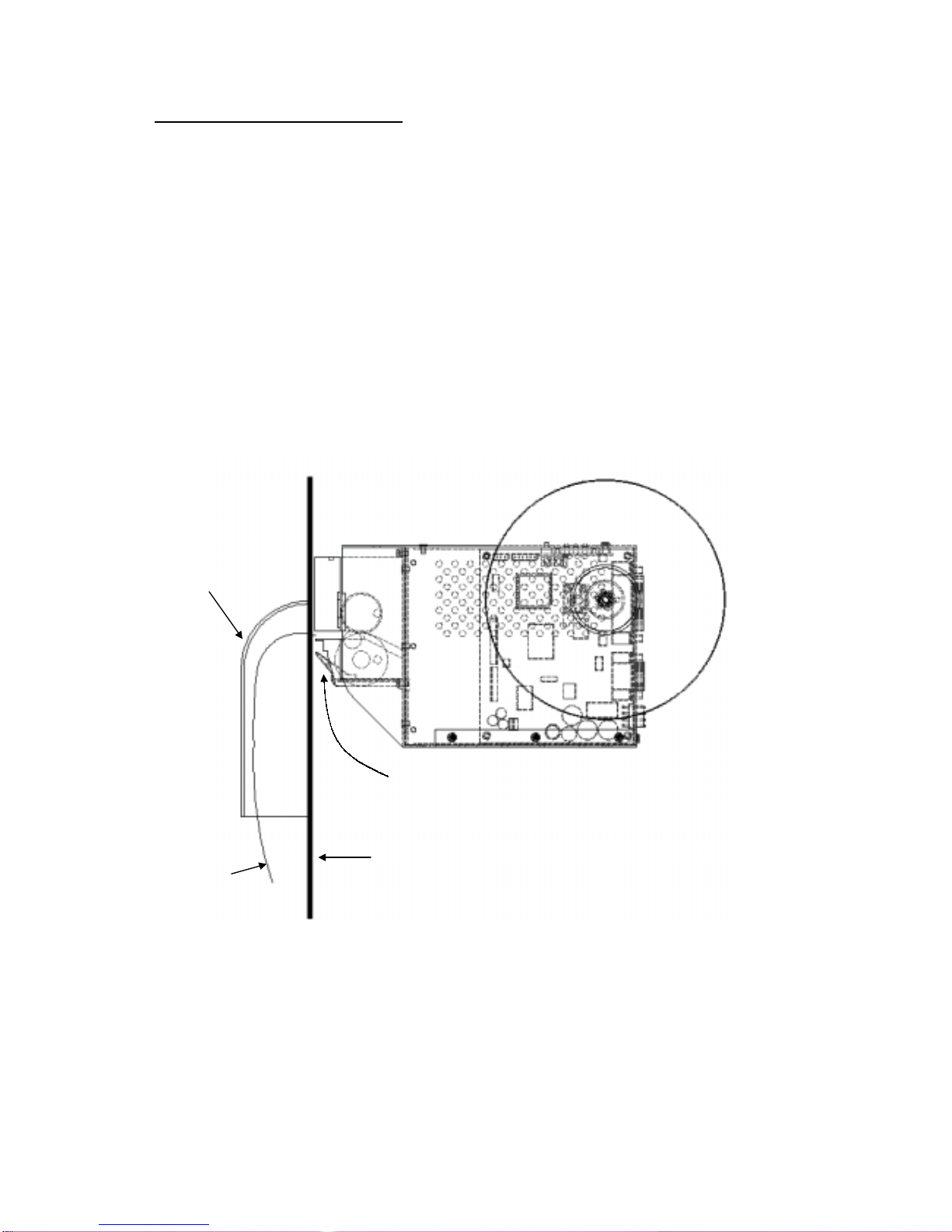

Fig. 2.4- Paper guide system............................................................................... 15

Fig. 2.5- TK23 connectors & elements location…….............................................16

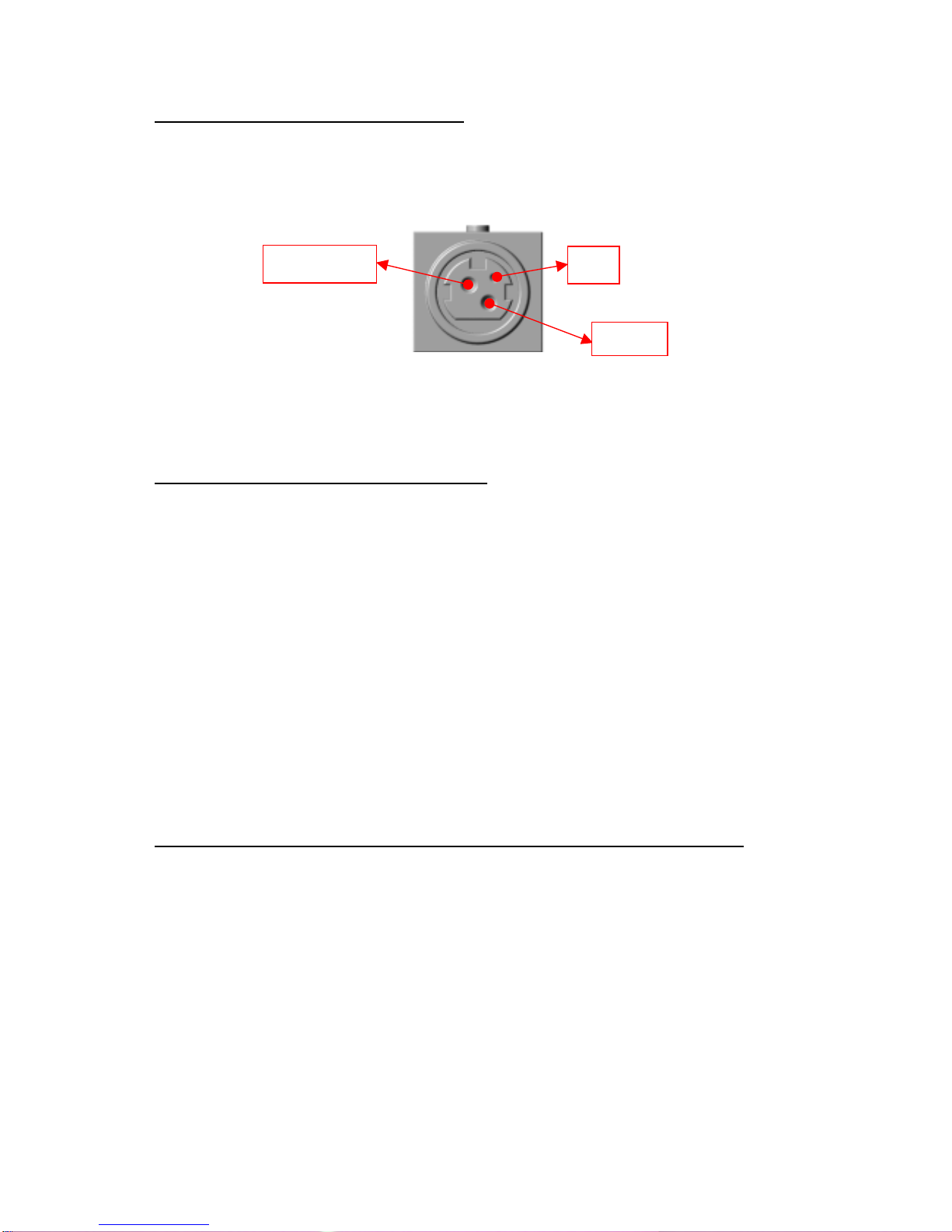

Fig. 2.6- Power supply connector as seen from outside the TK23....................... 17

Fig. 2.7- Serial interface connector as seen from outside of TK23...…................ 19

Fig. 2.8- CENTRONICS-2 parallel cable ............................................................. 21

Fig. 2.9- Timming specifications of Centronics parallel interface......................... 22

Fig. 2.10- CN6 communications connector from outside of TK23........................ 24

Fig. 3.0- Place the paper roll ................................................................................26

Fig. 3.1- Automatic paper load............................................................................. 27

Fig. 3.2- (1) Manual paper load............................................................................ 28

Fig. 3.3- (2) Manual paper load............................................................................ 28

Fig. 3.4- SELF-TEST MODE sample................................................................... 31

Fig. 3.5- Programming buttons............................................................................ 32

Fig. 3.6- PROGRAMMING MODE sample........................................................... 33

Fig. 3.7- HEXADECIMAL DUMP MODE sample................................................. 34

Fig. 3.9- Serial port error detection flow chart...................................................... 37

Fig. 3.11- Optical mark characteristics................................................................. 38

Fig. 3.12- Optical Mark recommended use sequence......................................... 40

Fig. 4.1- Jumper for cutter mode selection………………………………………….. 49

Fig. 4.2- Code128 code example......................................................................... 61

Table 2.1- Serial port pin-out................................................................................ 19

Table 2.2- Serial interface connection example................................................... 20

Table 2.3- Paralel Interface connector pin assignment........................................ 23

Table 3.1- Errors explanation.............................................................................. 33

Table 4.1- Command List..................................................................................... 42

FENIX IMVICO TK23 OPERATION MANUAL

6/81

IMPORTANT NOTES ON TK23 HANDLING

In order to guarantee a long life of the printer, it is necessary to keep some

precautions on the TK23 handling. Please read carefully next lines to make a

good use of the printer.

SAFETY PRECAUTIONS

Before using the printer, please carefully read point 2- INSTALLATION.

BEWARE not to invert power supply polarity. This may irremediably damage the

printer.

Use power supply voltage within specified range. Over-voltage may irremediably

damage the printer. Voltage under the specified range may cause incorrect

operations.

Keep TK23 away from water or any other liquid.

Do not use in locations subject to high humidity or dust levels.

DO NOT put any objects into the printer. It could cause severe damage like short-

circuits, broken thermal head or general printer failure.

DO NOT blow the TK23.

• NEVER modify the TK23.

• DO NOT try to repair the TK23 by yourself. If some failure is detected contact

with your usual dealer technical service.

• Since the printer contains permanent magnets (in the motor) as well as

electromagnets, it should not be used in areas containing excessive dirt, dust

and metallic particles.

• Never print without paper installed or the head away from the platen, because

the life of the thermal head may be shortened.

• Never pull the paper out (forward or backward) with the head down against the

platen.

• Since the head heating elements and the driver IC are very delicate, avoid

touching them with any metal objects, such as tweezers or screwdrivers.

• Since the head area and the motor surface reaches high temperatures right

after printing, never touch it with your bare hands; wait about 15 min.

For it to cool.

• Design the product so that when handled the user can not touch the edge of

the printer unit and/or the cut surface of the metal parts used in it, because the

edge of the printer unit and the cut surfaces of the metal parts are sharp. Or

include any necessary precautions regarding this matter.

• Never touch the surface of the head heating elements and the driver IC, as dirt

may stick to them, affecting the head heating elements or causing damage by

static electricity.

• When printing a black pattern at a high print rate in a low temperature or high

humidity environment, the vapour from the paper during printing may cause

condensation to form on the printer unit or may soil the paper. If water

condenses on the printer unit, keep the thermal head away from water drops as

it may corrode the thermal head, and turn printer unit power off unit it dries.

FENIX IMVICO TK23 OPERATION MANUAL

7/81

• HEAD CLEANING PROCEDURE AND PRECAUTIONS.

Do not clean the thermal head immediately after printing because thermal

head and its periphery are hot during and after printing.

Do not use sandpaper, cutter knives etc. when cleaning. They will damage the

heat elements.

a) Open the paper cutter expanding the raised edges slightly as shown in the figure

Figure a. Opening the paper cutter

b) Lift the head up/down lever until clicking. The thermal head is held in the up position.

Figure b. Head cleaning procedure

Clean the head elements using alcohol (ethanol, methanol, or IPA) and a cotton

swab. Wait until the alcohol dries and close the platen block. Fenix recommends

cleaning the thermal head periodically (advisable every 3 months) to maintain

receipt print quality.

RECOMMENDATION

Before connecting any input interface, verify the correct operation of the TK23

printer with self-test feature.

Head-up Lever Thermal Head

Pa

p

er cutter

Thermal Printer Mechanism

FENIX IMVICO TK23 OPERATION MANUAL

8/81

0 – INTRODUCTION

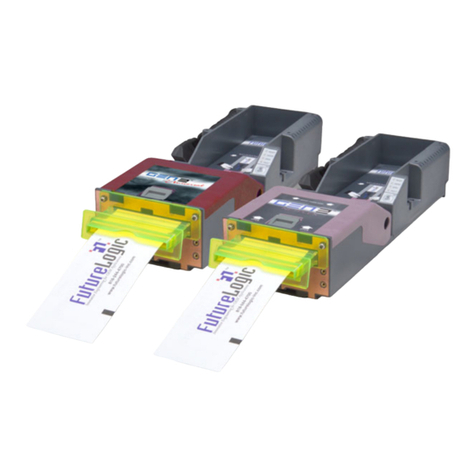

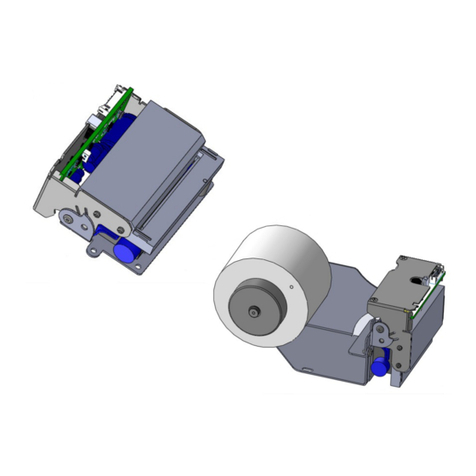

The TK23 is a very high-performance embedded thermal line interface. Its compact and

functional design covers many professional applications: It includes cyrillic characters,

two char fonts that can be bold, graphics and bar code capabilities.

The TK23 is intended to be integrated into the user’s final system. Its structure allows

an easy access both to the interface or the critical parts of the mechanism.

So, special care must be taken at choosing the TK23 location, access and protection

from external damage. It can be used in industrial, professional or laboratory

environments.

Main features of the TK23 printer are:

• Simple installation and easy maintenance structure.

• Compact design (flat design).

• Two paper widths available: 60mm or 80 mm depending on the SEIKO LTP2000

series printing mechanism used.

• High printing speed up to 90mm/s (TK23-60) or 75mm/s (TK23-80).

• Line printing method: Printing is performed every time a text line is filled.

• Paper roll outer diameter: 110mm (Max.)

• High reliability: 15 million lines.

• Single 24V DC power supply.

• No-paper, paper-near-end and head up sensors.

• High resolution printing (8 dots/mm).

• Centronics parallel or serial RS232C.

• Scalable font (independent scale in X / Y-axis), up to 64 times.

• Programmable character and line space.

• Printing adjustments (speed, density and consumption).

• Graphic bitmap printing capabilities.

• Several format Bar Code: Code39, EAN13, ITF and Code128.

• Up to 32 kbytes receiver buffer.

• Two different font sizes (Font A = 12x24dots. Font B = 8x16dots).

• Two Character Code Tables: PC437 USA, Standard Europe and PC866 Cyrillic #2

• Inverse mode and emphasited/bold mode text printing capabilities.

• Control code based on ESC / POS commands (*).

• Hexadecimal mode for easy software debugging.

• Auto-cutter, partial-cut or full cut selectable.

• Automatic paper load.

• Self test, hexadecimal mode and configuration mode features.

• Windows 95, 98, XP & 2000 drivers and demostration program.

This manual is a guide of the printer operations and is addressed to the application’s

designer. In following chapters there is a detailed description of hardware and software

configuration to take advantage of the features of the TK23 printer.

(*) ESC/POS are registered trademarks of Seiko SEIKO Corporation.

FENIX IMVICO TK23 OPERATION MANUAL

9/81

1 – GENERAL SPECIFICATIONS

1.1-PRINTING SPECIFICATIONS

1) Printing method: Thermal line printing.

2) Print Head:

Total number of dots:

Printing mechanism model type Number of dots

LTP2242 (59.5mm paper-width model) 448 dots (= 56mm)

LTP2342 (79.5mm paper-width model) 576 dots (= 72mm)

Printing width:

Printing mechanism model type Maximum printing width

LTP2242 (59.5mm paper-width model) 56mm (448-dot positions)

LTP2342 (79.5mm paper-width model) 72mm (576-dot positions)

3) Dot density: 203 dpi x 203 dpi (dpi: dots per inch (25.4mm)).

(8 dots/mm)

4) Printing speed: LTP2242 (60mm): 90mm/s max.

LTP2342 (80mm): 75mm/s max.

Automatic Paper Load: 20mm/s aprox.

Printing speed may be slower, depending on the data

transmission speed and combination of control

commands, environmental conditions, or selection of

the print density.

5) Paper feeding: Feeding method: unidirectional with friction feed.

Feeding pitch: 0,125mm (0,0049”)

Feeding speed: 90mm/s maximum

1.2- CHARACTER SPECIFICATIONS

1) Two character code tables: PC437 (USA, Europe Standard) and PC866

(Cyrillic #2). PC437 is selected by default (refer to point APPENDIX B –

CHARACTER CODE TABLES).

2) Character structure: - Font A: 12 x 24 dots (1,5 x 3 mm).

- Font B: 8 x 16 dots (1 x 2 mm).

- Font A is selected as the default.

- Vertical&horizontal char. scalable (x8 max.), bold

(emphasited) mode and inverse print capabilities by

using ESC/POS commands (refer to point 4 –

CONTROL COMMANDS).

FENIX IMVICO TK23 OPERATION MANUAL

10/81

1.3- ELECTRICAL CHARACTERISTICS

1) Supply voltage: +24V DC ±2.4V (±10%)

2) Current consumption (at 24V):

Print Ratio 60mm paper width

model

80mm paper width

model

Mean current 5.3 A 7.0 A

100% Peak current 6.4 A 8.5 A

Mean current 2.7 A 3.6 A

50% Peak current 3.3 A 4.3 A

Mean current 1.4 A 1.8 A

25% Peak current 1.7 A 2.2 A

1.4- PAPER REQUIREMENTS

1) Paper type: Single-ply thermal paper roll

2) Specified thermal paper: Original paper No. P350 KSP

Original paper No. TF50KS-E NIPPON PAPER

INDUSTRIES CO., LTD.

Original paper No. AF50KS-E JUJO THERMAL

Original paper No. PD160R OJI

Original paper No. TF11KS-ET NIPPON PAPER

INDUSTRIES CO., LTD.

A different paper type may give a different print quality.

The paper thickness must be 56 – 150 µm.

1) Size:

Paper width:

TK23-80 printer TK23-60 printer

79.5 +/- 0.5mm 59.5 +/- 0.5mm

Paper roll outer diameter: 110mm (Max.)

FENIX IMVICO TK23 OPERATION MANUAL

11/81

1.5- OVERALL DIMENSIONS

1) External dimensions

(Refer to APPENDIX D – EXTERNAL APPEARANCE).

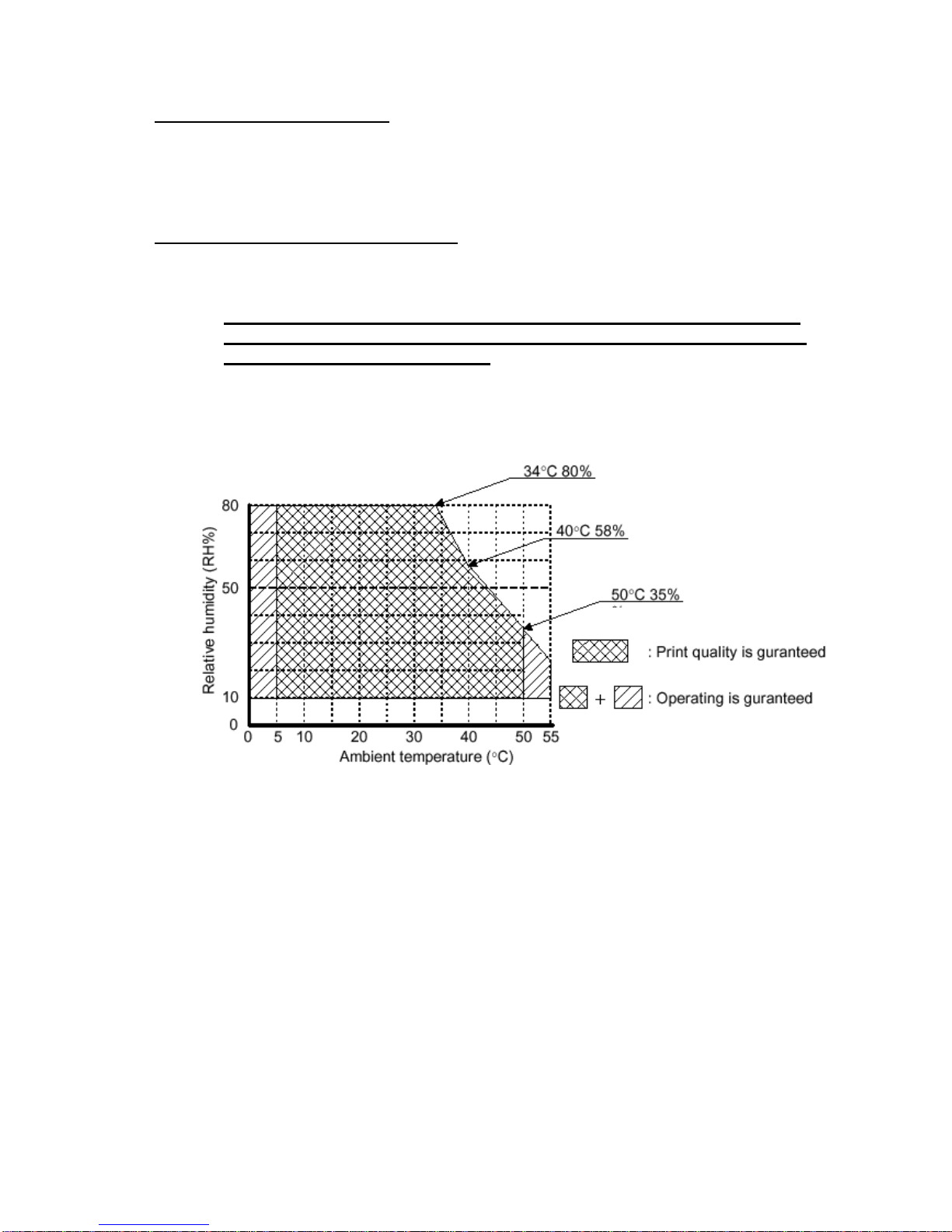

1.6- ENVIRONMENTAL CONDITIONS

1) Operating Temperature: 0 to 50ºC (32 to 131ºF)

If the printer is installed in outdoor applications in which the ambient

temperature is low, we suggest to use a blower fan heater to raise the

operating temperature over 0ºC.

2) Operating humidity: 10 to 80% (34ºC (93.2ºF) at 80%, non-condensing)

Fig. 1.1- Operating Temperature and Humidity Range

FENIX IMVICO TK23 OPERATION MANUAL

12/81

2 – INSTALLATION

2.1- FIXING THE TK23 PRINTER

The TK23 is an industrial printer designed to be fixed in a bigger case or structure, or

another kind of appropiate chassis. There are two models for the TK23 printer with 4

different fixing points each.

2.1.1 - TK23 INSTALLATION

• Fix the TK23 to the chassis by screwing, putting 4 metric screws (M4 / L10 mm)

through the holes marked with A and B in fig 2.1 - Fixing the TK23.

• Place all the screws in the same direction, from up to down.

• It is strongly recommended that the fixing holes of your chassis have an oval shape

so as the TK23 can move backward and forward for an easy manipulation.

• The paper-near-end sensor included in TK23 detects when remaining paper is about

17m long (65µm paper thickness).

A B

Fig. 2.1 - Fixing the TK23.

FENIX IMVICO TK23 OPERATION MANUAL

13/81

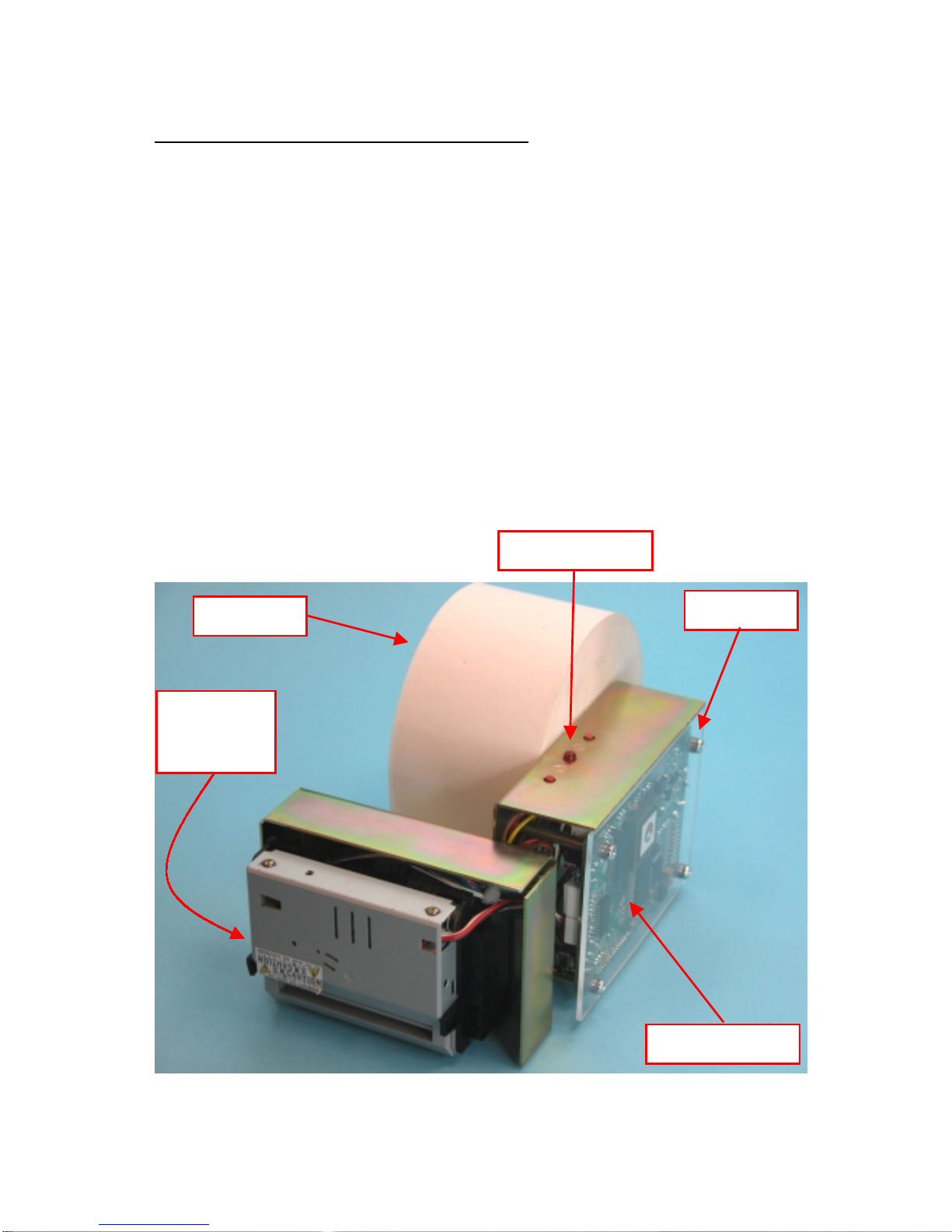

2.2- TK23 INSTALLATION CONSIDERATIONS

There are some general considerations to take into account when installing the printer

with the TK23 printer.

A wrong installation can cause many serious problems like paper jam, difficult

maintenance of the printer, difficulty in changing the paper roll, etc.

Moreover, a correct installation can prevent the printer from being damaged by external

agents, such as weather or vandalism.

The basic points that a correct installation must follow are:

• Smooth exit of the ticket. Prevent problems with static electricity due to the nature of

the used materials.

• Allow enough space and accessibility to reach the maintenance procedure points in

case it is needed. These points are:

• Thermal mechanism & Autocutter.

• Paper roll.

• Interface.

• Connectors.

• Led and Push-buttons.

Fig 2.2 - TK23 elements

Paper Roll

Thermal

mechanism

& autocutter

connectors

IF2200 interface

Led and buttons

FENIX IMVICO TK23 OPERATION MANUAL

14/81

For these reasons, FENIX suggests the following systems as solutions to a correct

installation:

2.2.1- EXTERNAL CHUTE SYSTEM

The idea of this system is to internally print and cut the ticket inside the machine, and

then make it fall into a receptacle where the user can have external access. Therefore,

there must exist some distance between the printer and the front side of the user’s

chassis in order to build a useful chute for the ticket, and to be able to open the printer

thermal head.

Two points must be assured to make this system work right:

• The construction of the receptacle must avoid the user to reach any internal

parts of the machine.

• The way of the ticket from the printer outlet to the receptacle must be smooth,

clean and free of obstacles to allow the ticket to actually fall into it and avoid

paper jams or tickets that do not fall. Depending on the construction materials,

care must be taken with static electricity; otherwise tickets may get stuck

inside the machine and never reach the receptacle.

Next figure shows a scheme of this system:

Fig. 2.3 -External chute system.

Frontal side of

user’s chassis

Ticket

receptacle

Ticket

Make sure this distance allows the

opening of the printer thermal

head (min: 20mm)

FENIX IMVICO TK23 OPERATION MANUAL

15/81

2.2.2- PAPER GUIDE SYSTEM

When using this system, the printer must be set quite near the front side of the user’s

chassis. The paper guide is to avoid external handling of the printer outlet.

Two points must be assured to make this system work right:

• Special care in the design of the part which goes from the printer outlet to the

paper guide (Paper jams can a occur due to an inappropriate design).

Depending on the construction materials, care must be taken with static

electricity; otherwise tickets may get stuck in the paper guide and never reach

the receptacle.

• As the printer is placed very near the user’s chassis, some system must be

implemented in order to move the printer when accessing the printing head

(i.e. giving the fixing holes of the chassis an oval shape to allow the printer

moving forward and backward). Otherwise there will be no access to the

printing head.

Next figure shows an scheme of this system:

Fig. 2.4- Paper guide system.

The distance between the mechanism and the frontal side of the user’s chassis may not

allow the opening of the printer thermal head. Take special care about this point when

designing your system.

Ticket

Paper guide

Frontal side of

user´s chassis

Head-up

lever

FENIX IMVICO TK23 OPERATION MANUAL

16/81

2.3- TK23 USER INTERFACE ELEMENTS

In the TK23, user can find the next connectors:

• CN1: Power supply connector.

• CN6: Serial RS-232 communications connector and

Parallel CENTRONICS communications connector.

Also, there are other interface elements that allows easy configuration of printer:

• Paper near-end sensor

• Paper Feed tact switch button

• Programming tact switch button

• Led indicator of Power ON

Fig. 2.5- TK23 connectors & elements location.

Power Supply

serial RS232 and

CENTRONICS

communications

Programming button Paper Feed button

Paper near-end sensor

Power ON indicator

FENIX IMVICO TK23 OPERATION MANUAL

17/81

GND

24V DC nc

2.3.1- POWER SUPPLY CONNECTOR

Attach power supply cable to the 3-pin micro connector. Verify power supply voltage

before making the connection.

The connector is a female 3-pin HOSIDEN type, which have the following pin-out:

Fig.2.6- Power supply connector as seen from outside the TK23.

Use a 3-pin DC jack KPP-3P model or equivalent.

2.3.1.1 - Optional Power supply connector :

A special version of TK23 (under agreement only), can use for power supply a Male 4-

pin 0.156" pitch (3,96mm) disconectable Crimp style connector.

User side connector type: Housing: VHR-4N (JST or compatible)

Contact: SVH-21T-P1.1 (JST or compatible)

NOTE: All 4 pins must be connected. Terminals 2 and 3 are VCC (24V DC)

Terminals 1 and 4 are GND

The TK23 requires one power source: VCC (24V DC) for driving the thermal head and

motor. This voltage is internally regulated to 5V to control the electronic active parts.

The power supply must meet the following conditions:

VCC: 24V DC +/- 2,4V

Example of printhead current consumption (for the 80mm-wide mechanism):

Print head current consumption at a printing ratio of 35%:

(Printing ratio is defined as the number of dots/dot lines (576 dots)).

1) Peak current: 3.05 A (when all 208 dots are powered).

NOTE: Peak current is measured at the minimum resistive value of thermal

head and the maximum operating voltage.

Conditions: VH max: Head connector terminal voltage max. 26.4V

Rmin: Head resistance value min. 1800 Ohm.

The following formula is used to obtain the head drive peak current:

Ipeak = Vmax (volts) x 576 dots x printing ratio / minimum head resistance value (ohms)

FENIX IMVICO TK23 OPERATION MANUAL

18/81

2) Mean current: Approx. 1.4 A

Conditions: - Head terminal voltage = 24V

- Head resistive value Rh = 1800Ohm

- Mean energizing pulse width of 832 µs, synchronizing with 1667µs

motor cycle.

The following formula is used to obtain the head drive current:

Imean = [V(volts)/Rh(Ohms)] x 576dots x printing ratio x [energizing pulse width/cycle]

NOTES:

(1) If the number of dots that are energized at the same time is increased, a higher

current will flow; therefore, the user should use a power supply with a current

capacity adequate for the corresponding print duty.

(2) When designing lines and bit images, take the printing ratio and print duty into

consideration.

(3) Print quality may be poor if the printing ratio or print duty is high.

(4) Definitions:

• Printing ratio: the number of printing dots (energizing pulses)/dot line.

• Print duty: the number of printing dots (energizing pulses)/ elements/ paper

feed amount (two steps, including non-printing area)

WARNING: Beware not to invert the polarity of power supply. This may

irremediably damage the printer.

IMPORTANT NOTE ABOUT TK23 POWER SUPPLY:

The necessary supply of power depends on the content to print on the

ticket. A 150W power supply covers all adverse possibility (printing ratio of 100%

black at any temperature). However, if the average print ratio is not over 25%, a

60W power supply can be used. Any way, power supply must meet the peaks

current that mechanism requires, which are determined by the following formula:

Ipeak = [24 / 1800] x number of printing dots

FENIX IMVICO TK23 OPERATION MANUAL

19/81

2.3.2- SERIAL RS-232 CONNECTOR

2.3.2.1- Specifications

• Data transmission: Serial

• Synchronization: Asynchronous

• Handshaking: CTS/RTS control

• Signal levels (RS232): Logic “1” = -3 to –15 V

Logic “0” = +3 to +15 V

• Baud rate: 4800, 9600, 19200, 38400 bps (bps: bits per second)

• Data word length: 8 bits (fixed)

• Parity Settings: None, even, odd

• Stop bits: Fixed to 1.

• Connector (printer side): Male PHD 24 pin connector JST ref. S24B-PHDSS

Recommended female crimp conector: JST ref. PHDR-24VS

NOTES:

(1) The baud rate, and parity settings can be changed

(refer to point 3.4.2- PROGRAMMING MODE).

(2) The stop bit for the printer side is fixed to 1.

(3) The data word length is fixed to 8 bits.

Pin Signal

name Signal direction

(from the printer

side) Function

21 RXD Input Receive data

20 TXD Output Transmit data

22 /RTS Output Logic “0” indicates that the printer is connected and ready to

receive data, and logic “1” indicates that the printer is offline

or is BUSY.

The printer goes OFFLINE:

1) When the power is turned on until the printer becomes

ready for data transmission after it is initialised by a reset.

2) When the platen is open.

3) When the printer stops printing due to a paper-end.

4) When an error has occurred

The printer is BUSY when reception buffer is full (*)

23,24 GND - Ground

(*) reception buffer is full when it increases till the maximum capacity (32 Kbytes).

Table 2.1- Serial port pin-out.

Fig. 2.7- Serial interface connector as seen from outside the TK23.

Pin 24

Pin 23

Pin 2

Pin 1

FENIX IMVICO TK23 OPERATION MANUAL

20/81

2.3.2.2- Serial interface connection example

The cable, which has the signal connection, as shown below must be used.

PRINTER SIDE USER SIDE (PC)

CN6

Pin Num.

Signal

Name

Signal

Name

D-SUB9

Pin Num.

DCD 1

21 RxD RxD 2

20 TxD TxD 3

/DTR 4

23,24 SG SG 5

/DSR 6

22 /RTS /RTS 7

/CTS 8

RI 9

Table 2.2- Serial interface connection example.

NOTE: Transmit data to the printer after turning on the power and initializing the

printer.

The TK23 receives data continuously, even while performing printing operation.

The TK23 serial input/output signals (RXD, /RTS and TXD) can be RS232C level or TTL

level (see APPENDIX F- HOW TO ORDER).

The TK23 receives and checks serial data according to the transmission baud rate

programmed.

If the input data is not printed correctly, the transmission conditions between the host

device and the TK23 do not probably match. If this happens, the character “?” is

continuously printed and user must adjust the transmission conditions so that they

match.

Serial data output (TXD): output pin, SUB-D9-3

• Data is output according to the programmed transmission conditions.

Serial data input (RXD): input pin, SUB-D9-2

• Data input port

• Data is input from the host device according to the programmed transmission

conditions.

Serial busy (/RTS): output pin, SUB-D9-7

• Indicates whether or not the printer is ready to receive data.

• When the /RTS signal is “LOW”, data can be input.

.

NOTE:

For more information on serial data reception see point 3.5.9- SERIAL PORT

ERROR DETECTION FLOW CHART.

Connect the communications cable before turning the TK23 ON.

Table of contents

Other Fenix Imvico Printer manuals

Fenix Imvico

Fenix Imvico EPC1200 Series User manual

Fenix Imvico

Fenix Imvico TK14 User manual

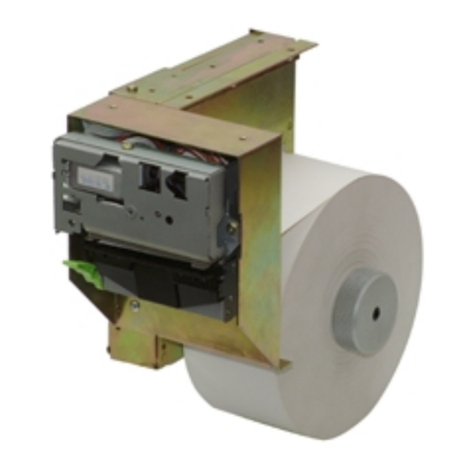

Fenix Imvico

Fenix Imvico TK41 User manual

Fenix Imvico

Fenix Imvico TK51 Series User manual

Fenix Imvico

Fenix Imvico EPC1100 User manual

Fenix Imvico

Fenix Imvico SM3000 User manual

Fenix Imvico

Fenix Imvico TS1700 User manual

Fenix Imvico

Fenix Imvico KS55 Series User manual