KS55 SERIES OPERATION MANUAL

1 - INTRODUCTION

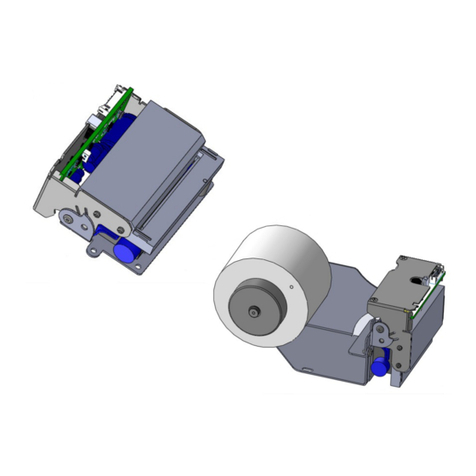

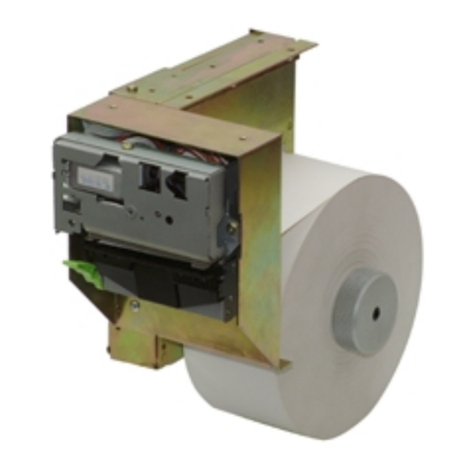

The K 55 is a very high-performance thermal printer, specially designed to control EP ON

M-T500II printer mechanism series. Its compact and functional design covers many industrial uses. It is

capable of printing text, graphics, logo and bar codes.

The K 55 incorporates a presenter: once the ticket has been printed and cut, it is presented to the

customer to pick it up. If the ticket is not picked up and a pre-set time runs out, the ticket can be stored

internally (retracting function).

Main features of the K 55 thermal printer are:

•imple installation and easy maintenance.

•Two paper widths available (59.5mm and 79.5mm) depending on the printing

mechanism used.

•High speed printing: up to 250mm/s (NOTE 1).

•ingle 24V DC power supply.

•Available sensors: No-paper, paper-near-end, optical mark, ticket pick-up and paper jam.

•Programmable optional output for user control (buzzer, LEDs, relay..)

•Printing resolution: 8 dots/mm (203 dpi).

•Port interface: - erial R 232C data input interface on-board (up to 115200bps).

- Universal erial Bus (U B2.0).

•calable font (independent scale in X / Y axis), up to 64 times.

•Programmable character and line space.

•Bold, underline, reverse and rotate character capabilities

•Graphic bitmap printing capabilities.

•everal format bar code (EAN13, Code39, Code128 and ITF).

•everal 2D format Bar Code (QR and AZTEC).

•Two internal character fonts (A font = 12x24 dots. B font = 8x16 dots).

•Control code based on E C / PO commands (NOTE 2).

•Automatic paper load.

•Four maintenance counters (On/Off times, hours, meters and cuts)

•Hexadecimal mode for easy software debugging.

•elf test mode feature

•Input buffer of 32KBytes.

•Multiple logo load capability through Windows driver or command.

•Upgrading of firmware version through communication port (NOTE 3).

•2 (A and B fonts) external I O-8859 character tables or TrueType fonts can be loaded (NOTE 3).

•Extended operating temperature range (-20ºC to +70ºC).

•torage temperature range (-35ºC to +75ºC).

•Automatic full cut capability.

•Presenter speed: 1000 mm/s.

•Double function ticket presentation: “ejecting” and “retracting”.

•Optional light indicator integrated in the nozzle. Three selectable colors

•Windows drivers and demo/configuration program.

•Linux Driver.

(1) Print speed changes according to the aud rate in RS232 connection and temperature. Higher printer speed rates are

achieved at higher aud rates and USB connection.

(2) ESC/POS are registered trademarks of Seiko Epson Corporation.

(3) In order to change the configuration of the printer, update the firmware or install the Windows driver, the Print

Management SW application is availa le on our we site.

This manual is the printer operations’ guide and is intended for the designer’s application. The

following sections contain a detailed description of both hardware and configuration software that allow

obtaining the maximum benefit of the printer capabilities.

3 of 66