DeFelsko PosiTest LPD Manual

Management Procedure 2559 Rev A Page 1of 7

Management Procedure 2559

Revision: A

Date Issued: November 9, 2016

Date Revised:

Calibration Procedure

PosiTest LPD Low voltage Pinhole Detector

Table of Contents

1!Introduction and UUC Performance Requirements ................................................................. 2!

Table 1-1 .................................................................................................................................. 2!

2!Measurement Standards and Support Equipment Performance Requirements........................ 2!

Table 2-1 UUC Accuracy Requirements and Description ....................................................... 2!

Table 2-2 Minimum Use Specification .................................................................................... 2!

Table 2-3 Actual Equipment Specification .............................................................................. 2!

Table 2-4 Calibration Environmental and Warm-up Requirements ........................................ 3!

3!Resistance Calibration.............................................................................................................. 3!

4!DC Voltage Calibration*.......................................................................................................... 5!

5!Performance Requirements ...................................................................................................... 6!

Table 5-1 Performance Requirements and Calibration Data for PosiTest LPD ...................... 6!

Management Procedure 2559 Rev A Page 2of 7

1 Introduction and UUC Performance Requirements

1.1 This procedure describes the calibration of DeFelsko Corporation PosiTest LPD.

Table 1-1

Models

Measurement Range

PosiTest LPD

80 – 400 kΩ

9 – 90 VDC

1.2 The unit being calibrated will be referred to as the UUC (unit-under-calibration).

2 Measurement Standards and Support Equipment Performance Requirements

2.1 The UUC accuracy requirements are based upon the published UUC performance

specifications.

2.2 The test uncertainty ratio applied in this Calibration Procedure is 4:1 unless otherwise

stated.

2.3 The Minimum-Use-Specifications are the minimum test equipment specifications

required to meet all the UUC accuracy requirements and the test uncertainty ratio

applied.

Table 2-1 UUC Accuracy Requirements and Description

UUC Parameter

Performance

Specifications

Test Method

Resistance

80 – 400 kΩ+ 3%

Resistance Decade

Box

DC Voltage*

9 – 90 V + 5%

Digital Multimeter

* Optional calibration

Table 2-2 Minimum Use Specification

Parameter

Range

Accuracy

Resistance

80 – 400 kΩ

0.6 kΩ

DC Voltage

9 – 90 V

0.1 V

Table 2-3 Actual Equipment Specification

Parameter

Range

Accuracy

Manufacturer/Model #’s

Applicable

Resistance

0 – 9,999 kΩ

+(0.1% of reading + 0.025Ω)

IET Labs

RS-201

DC Voltage

5 – 50 V

+(0.02% of reading + 0.004V)

Keysight

U3401A

DC Voltage

51 – 500 V

+(0.02% of reading + 0.04V)

Keysight

U3401A

Management Procedure 2559 Rev A Page 3of 7

Caution:The instructions in this Calibration Procedure relate specifically to the equipment and

conditions listed in Section 2. If other equipment is substituted, the information and instructions

must be interpreted accordingly.

Table 2-4 Calibration Environmental and Warm-up Requirements

Measurement Standards & Support Equipment

Environmental Requirements:

Temperature: 23 ±2°C.

Relative Humidity: 40 - 60%

Measurement Standards & Support Equipment

Warm-up and Stabilization Requirements:

Not Required

3 Resistance Calibration

Note: Review the entire document before starting the calibration process.

3.1 Review the Performance Requirements in Table 5-1.

Note: Whenever the test requirement is not met, verify the results of each test and take corrective

action before proceeding.

3.2 Turn on the UUC by pressing the power button. The unit will complete a self-test

indicated by flashing each of the 4 voltage lights. Once the self-test is completed the

LED corresponding to the set voltage will flash.

Note: The UUC cannot be connected to the decade box while the self-test is running.

Warning: Touching the metal end of the UUC or of the red lead attached to it while it is on may

result in a mild electric shock.

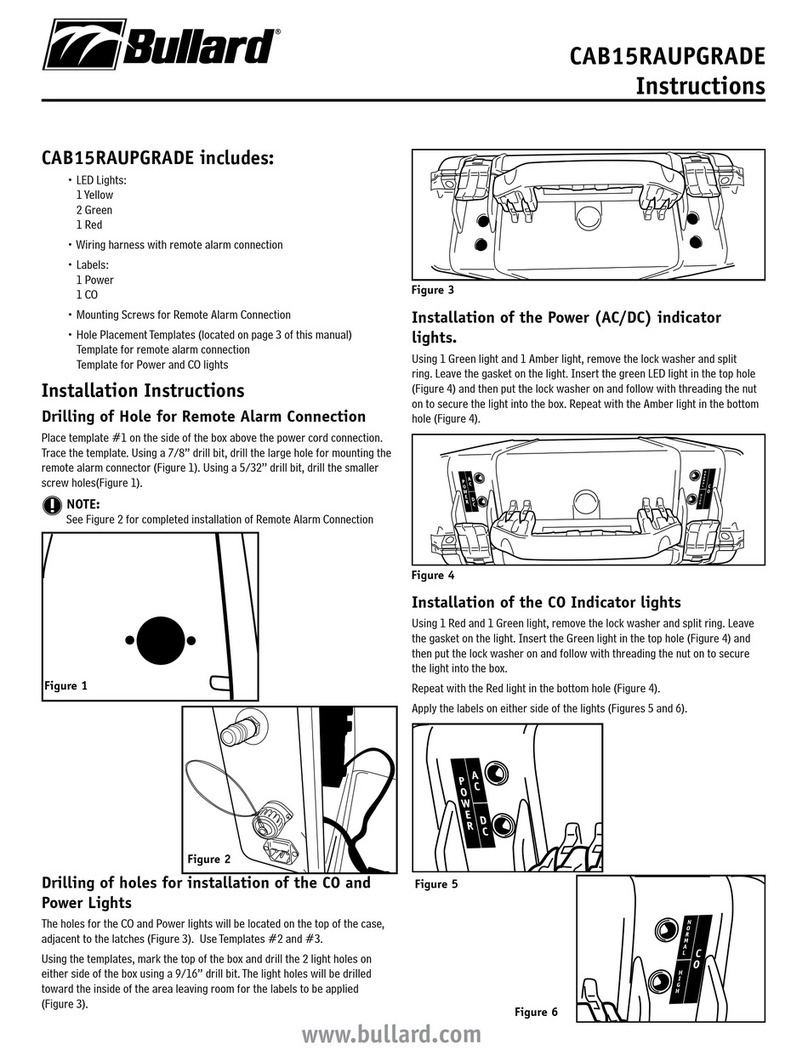

3.3 Connect a red and a black lead to the LPD and the corresponding terminals of the RS-

201 decade box as shown below.

Note: The UUC cannot be connected to the multimeter during the resistance calibration.

Management Procedure 2559 Rev A Page 4of 7

3.4 Set the UUC to 9V and adjust the decade box to 90 kΩ.

3.4.1 If the UUC is constantly alarming as indicated by flashing the remaining 3 voltage

LEDS, increase the resistance on the RS-201, 100 Ωat a time, until the UUC stops

alarming or alarms intermittently. Record the last resistance value that the unit alarmed

constantly on. Record this value as kΩ. For example 89 kΩand 700 Ωwould be

recorded as 89.7 kΩ.

3.4.2 If the UUC is not alarming or is alarming intermittently decrease the resistance value

until the UUC starts alarming constantly. Record this resistance value.

3.4.3 Set the UUC to 67.5V, 80 kΩand adjust the decade box to 80 kΩ. Repeat steps 3.4.1 and

3.4.2.

Management Procedure 2559 Rev A Page 5of 7

3.5 Set the UUC to 67.5V, 90 kΩand adjust the decade box to 90 kΩ. Repeat steps 3.4.1 and

3.4.2.

3.6 Set the UUC to 90V and adjust the decade box to 400 kΩ. Repeat steps 3.4.1 and 3.4.2

but increase the resistance on the RS-201 1 kΩat a time

4 DC Voltage Calibration*

* optional calibration requiring the use of a calibrated multimeter.

4.1 Review the Performance Requirements in Table 5-1.

Note: Whenever the test requirement is not met, verify the results of each test and take corrective

action before proceeding.

4.1.1 Set-up the UUC as described in sections 3.2 and 3.3.

4.1.2 Turn on the multimeter and set it to DC Volts and auto-ranging.

4.1.3 Connect the positive and negative leads from the multimeter to the corresponding

terminals of the RS-201 decade box.

4.1.4 Set the UUC to 9V and adjust the decade box to 90 kΩ. Record the voltage displayed on

the multimeter to 2 decimal points (xx.xx).

4.1.5 Set the UUC to 67.5V, 80 kΩand adjust the decade box to 80 kΩ. Record the voltage

displayed on the multimeter.

Management Procedure 2559 Rev A Page 6of 7

4.1.6 Set the UUC to 67.5V, 90 kΩand adjust the decade box to 90 kΩ. Record the voltage

displayed on the multimeter.

4.1.7 Set the UUC to 90V and adjust the decade box to 400 kΩ. Record the voltage displayed

on the multimeter.

5 Performance Requirements

Table 5-1 Performance Requirements and Calibration Data for PosiTest LPD

Parameter

Nominal

Min1

UUC

Reading

Max2

Resistance

90 kΩ(9V)

87.3

92.7

Resistance

80 kΩ(67.5V)

77.6

82.4

Resistance

90 kΩ(67.5V)

87.3

92.7

Resistance

400 kΩ(90V)

388

412

DC Voltage

9V (90 kΩ)

8.55

9.45

DC Voltage

67.5V (80 kΩ)

64.13

70.87

DC Voltage

67.5V (90 kΩ)

64.13

70.87

DC Voltage

90V (400 kΩ)

85.50

94.50

1) Resistance min = nominal value (kΩ) * 0.97

DC Voltage min= nominal value (V) * 0.95

2) Resistance max = nominal value (kΩ) * 1.03

DC Voltage max= nominal value (V) * 1.05

Note: Do not write in this procedure.

Management Procedure 2559 Rev A Page 7of 7

Management Procedure Change Notice

Procedure Number:

MP 2559

Revision Level:

A

Date of Change:

November 9, 2016

Title:

Calibration Procedure, PosiTest LPD Low voltage Pinhole

Detector

Reason for Change:

• New product

Description of Change:

• New procedure

I confirm I have read and understand the procedure and the change described above.

Printed Name

Signature

Date

Management Form 0010.02-05/1998

Other manuals for PosiTest LPD

1

Table of contents

Other DeFelsko Security Sensor manuals

Popular Security Sensor manuals by other brands

Guardian Fall Protection

Guardian Fall Protection 42001 instruction manual

Zeiss

Zeiss 4QBSD instruction manual

Inovonics

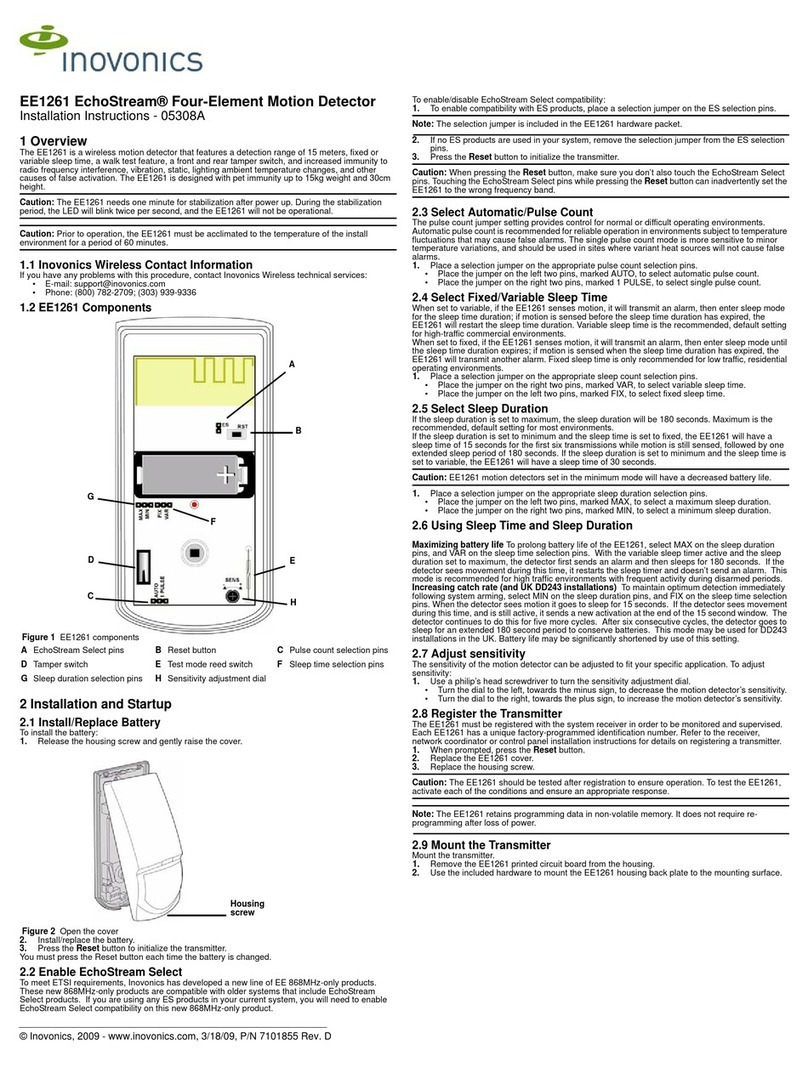

Inovonics EE1261 installation instructions

nest

nest Detect user guide

Huazheng Electric Manufacturing

Huazheng Electric Manufacturing HZJF-9008 user manual

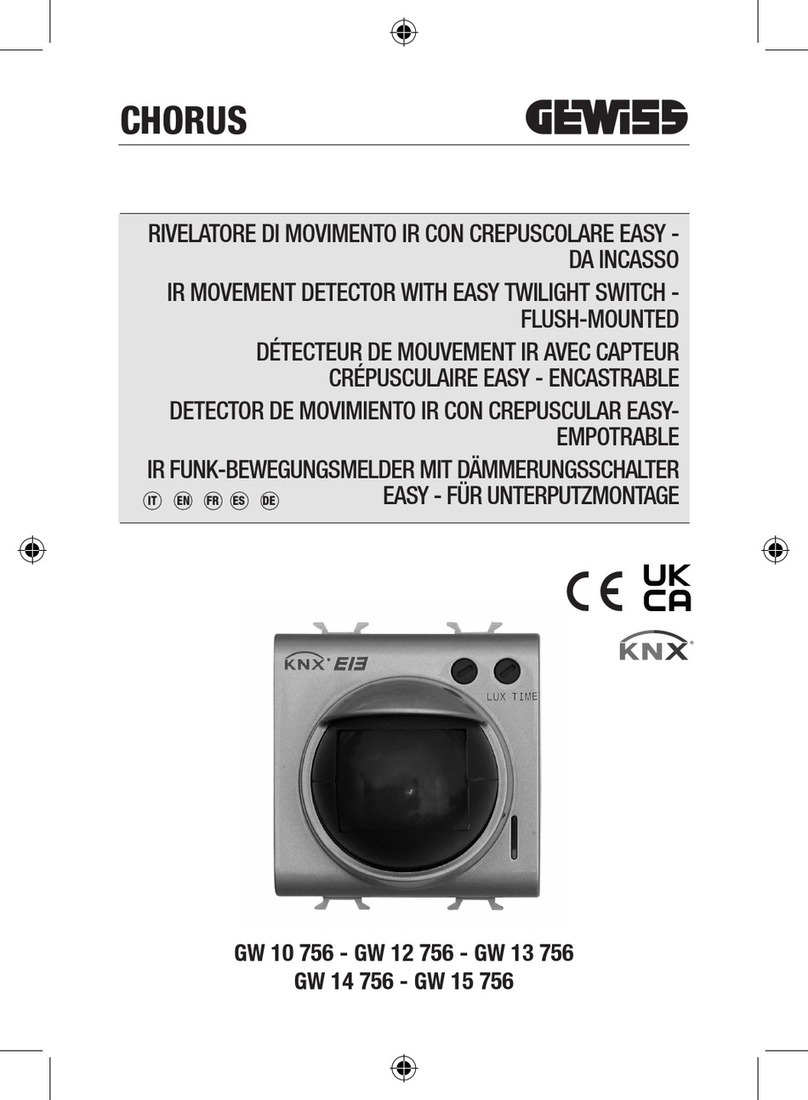

Gewiss

Gewiss CHORUS GW 13 756 installation instructions