8Single-beam Safety Sensor E3FS

Ratings and Performance

E3FS-10B4 2M/E3FS-10B4-M1-M

Engineering Data

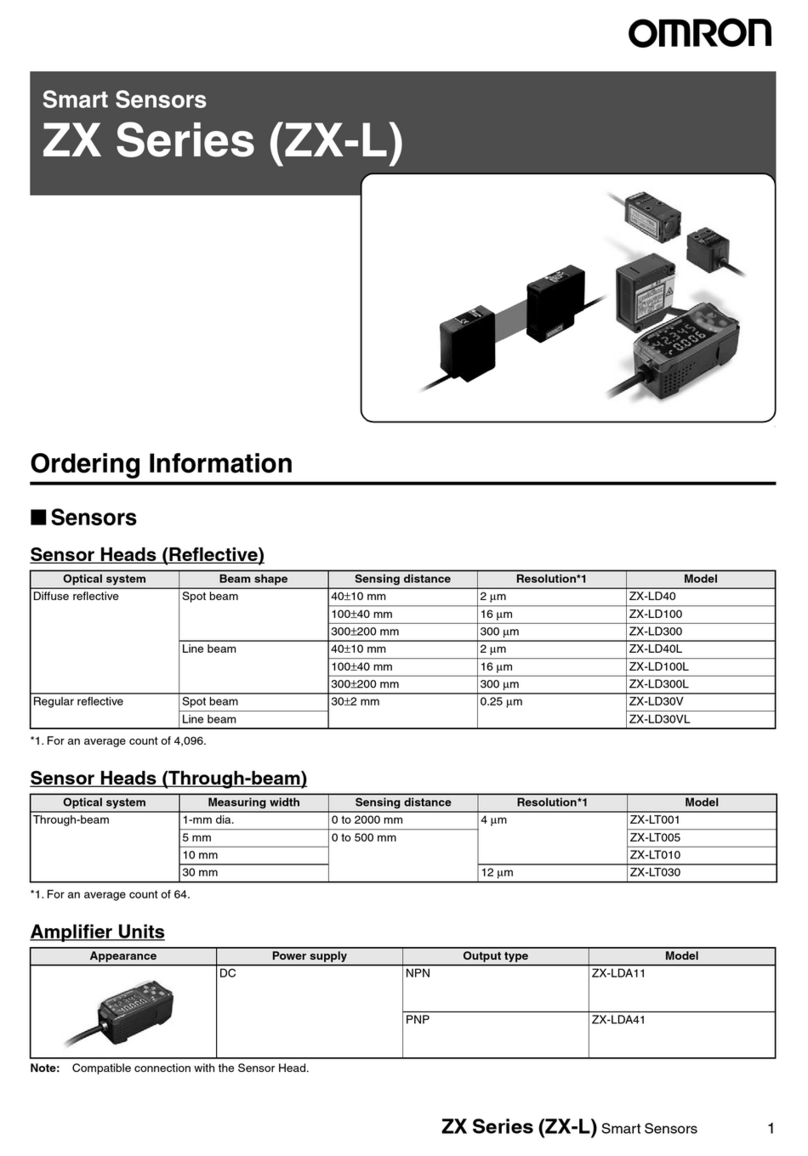

Sensing method Through-beam

Controller F3SX Series

Supply voltage 24 VDC±10% (ripple p-p 10% max.) (Connect the Sensor to an F3SX to use it as a safety device or

as part of a safety system.)

Effective aperture angle (EAA) ±5°(at 3 m)

Current consumption Emitter: 50 mA max.

Receiver: 25 mA max.

Sensing distance 10 m

Standard sensing object Opaque object: 11 mm min. in diameter

Response time 2.0 ms (E3FS only) (Depends on the F3SX model when the Sensor is connected to an F3SX.

Refer to the F3SX operation manual for details.)

Control output

PNP transistor output, load current: 100 mA max., residual voltage: 2 V max.

(except for voltage drop due to cable extension)

(Connect the Sensor to an F3SX to use it as a safety device or as part of a safety system.)

Test input (Emitter)

21.5 to 24 VDC: Emitter OFF (source current: 3 mA max.)

Open or 0 to 2.5 V: Emitter ON (leakage current: 0.1 mA max.)

(Connect the Sensor to an F3SX to use it as a safety device or as part of a safety system.)

Power supply reset time 100 ms

Ambient light intensity Incandescent lamp: 3000 lx max. (light intensity on the receiver surface)

Sunlight: 10,000 lx max. (light intensity on the receiver surface)

Ambient temperature Operating: −10 to 55°C, storage: −30 to 70°C (with no icing or condensation)

Ambient humidity Operating: 35% to 85%, storage: 35% to 95% (with no icing or condensation)

Insulation resistance 20 MΩmin. (at 500 VDC)

Dielectric strength 1000 VAC 50/60 Hz 1 min

Vibration

resistance

Malfunction 10 to 55 Hz, double amplitude: 1.5 mm, 2 h each in the X, Y, and Z directions

Operating limit 10 to 55 Hz, double amplitude: 0.7 mm, 50 min each in the X, Y, and Z directions

Shock

resistance

Malfunction 500 m/s2(approx. 50 G), 3 times each in the X, Y, and Z directions

Operating limit 100 m/s2(approx. 10 G), 1000 times in the X, Y, and Z directions

Degree of protection IP67 (IEC standard)

Light source Infrared LED

Operation indicators Emitter: Emitting (orange)

Receiver: Output ON (green), Output OFF (red)

Protection Output short-circuit protection, reverse polarity protection

Weight (in packaging) E3FS-10B4 2M (ABS resin case): approx. 150 g for 1 set (weight without cable: approx. 55 g)

E3FS-10B4-M1-M (metal case): approx. 125 g for 1 set

Applicable standard IEC61496-1, EN61496-1 Type 2 ESPE (Electro-Sensitive Protective Equipment)

IEC61496-2, prEN61496-2 Type 2 AOPD (Active Opto-electronic Protective Devices)

Accessories Emitter, two nuts for mounting the Receiver, and an instruction manual

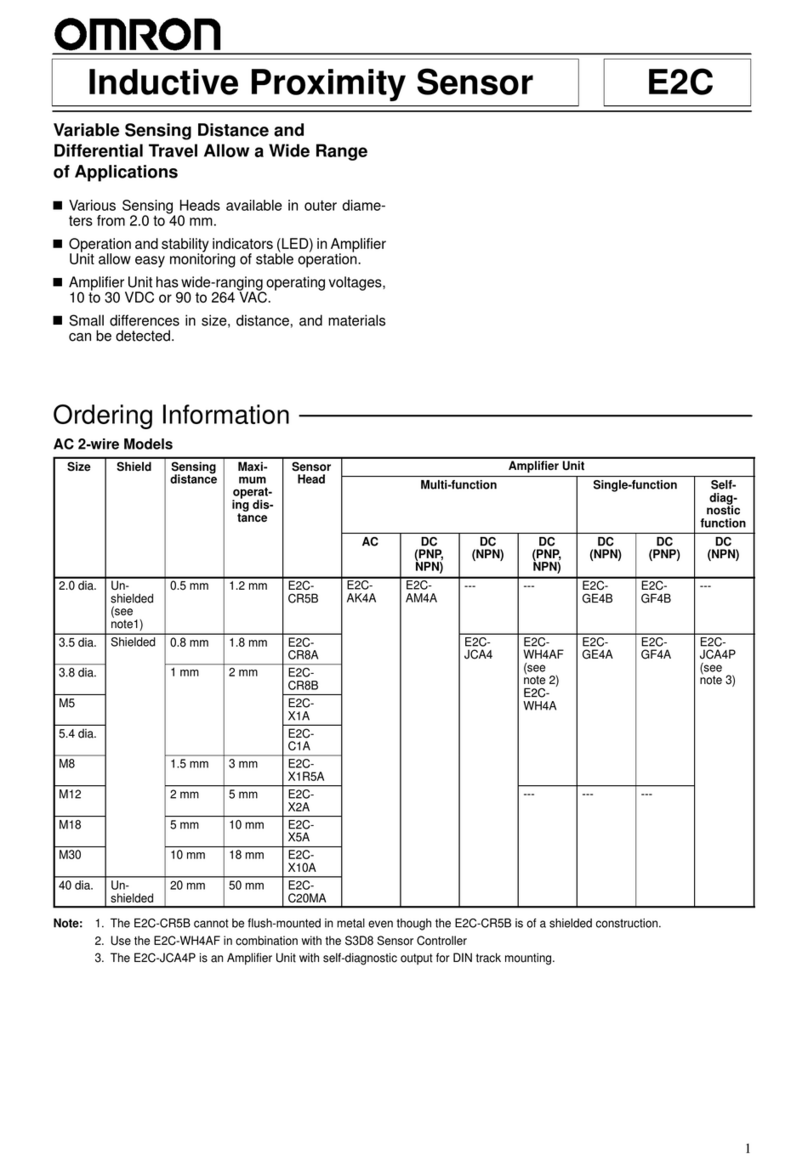

Parallel Operating Range Mutual Interference Range Reception Light Output Margin

600

400

200

0

−200

−400

−600 128104620

Distance X

m

Operating position Y (mm)

Y

X

Emitter

Receiver

800

600

400

200

0

−200

−400

−600

−800

128104620

Distance X (m)

Mutual interference range Y (mm)

Y

XEmitter

Receiver

10

9

8

7

6

5

4

3

2

1

03020 2510 1550

Distance

m

Reception Light output margin