Kit5000_GB-A

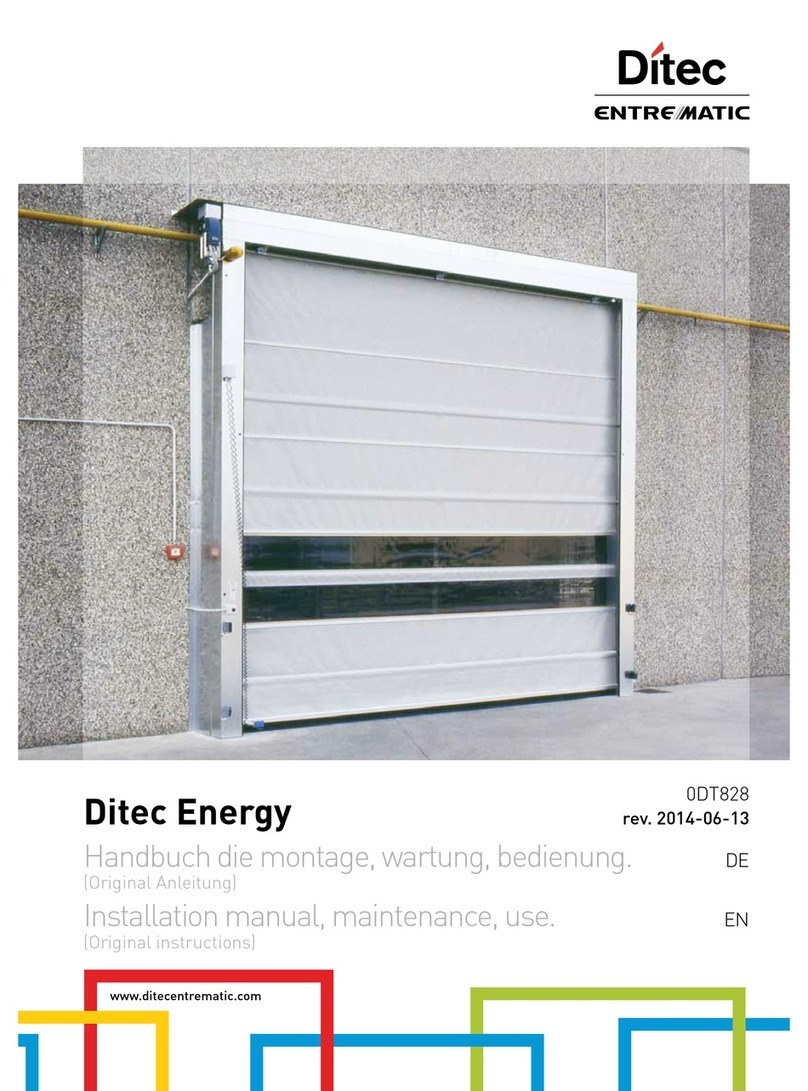

The product you have acquired is integrated into an industrial door. Its being put on the European Union market

implies EC marking by a certied agency, under the liabilities of the manufacturer and/or installer of the door.

The design, manufacture and installation of an industrial door must respect the essential requirements of health and

safety determined by the following European directives:

GENERAL INFORMATION

1.1.Regulations & Obligations

The product you have acquired is integrated into an industrial door. Its being put on the European

Union market implies EC marking by a certified agency, under the liabilities of the manufacturer

and / or installer of the door.

The design, manufacture and installation of an industrial door must respect the essential

requirements of health and safety determined by the following European directives:

European Directives Manual door Motorised door

Construction Products Directive 89/106/EEC X X

Low Voltage Directive 2006/95/CE X

Electro-magnetic Compatibility Directive 2004/108/CE X

Machines and Working Equipment Directive 2006/42/EC X

The proof of conformity to the regulation texts, mentioned above, is obtained by the respect of the

standard reference detailed by the standard of product NF EN 13241-1. - Industrial, Commercial

and Garage Doors (Part 1: products without fire and smoke proofing characteristics)

Terminology standard Safety standard Environmental

standard Electrical and DCEM

standard

EN 12433-1

Types of doors EN 12604

Mechanical aspects EN 12424

Resistance to wind EN 60204-1

Machine electrical safety

EN 12433-2

Components of doors EN 12605

Test methods EN 12444

Tests and calculations EN 61000-6-2 (DCEM)

Immunity to industrial

environment

EN 12453

Safety of use EN12425

Water penetration EN 61000-6-3 (DCEM)

Harmonic measure emission

EN 12445

Test methods EN 12489

Test methods EN 61000-6-4

Industrial environment

emission

EN 12978

Safety devices EN 12426

Permeability to air

EN 12635

Installation and use EN 12427

Test methods

EN 12428

Thermal transmission

FERMOD has taken the standards that apply to the supplied products into consideration.

- 22 -

1.2 – Liabilities

1–Themanufacturerofthedoor,theinstallerandtheusermustobservethesafetyrules(collectiveprotection,individual

protection)applicable duringtransport,assembly,use,and discardingof thedoor oritscomponents.

2– Theliabilityoftheuser maybe engagedin circumstancesthatarenotmarginal. Thus,the usermust scrupulously

complywiththerecommendationsforstorage,assembly,use,maintenance,healthandsafety,use-bydate,etc.supplied

bythemanufacturer.

Likewise,wheretheproducerbeheldliableforthenon-conformityoftheproduct,theusermayalsosharetheliability,

insofar as he has not, from his side, checked this conformity, even if the product in question is administratively in

conformity.Theuserisalsoheldliableifhehimselfincreasesthefaultintheproduct.

The proof of conformity to the regulation texts, mentioned above, is obtained by the respect of the standard reference

detailed by the standard of product NF EN 13241-1: Industrial, Commercial and Garage Doors (Part 1: products without

re and smoke proong characteristics).

FERMOD has taken the standards that apply to the supplied products into consideration.

GENERAL INFORMATION

1.1.Regulations & Obligations

The product you have acquired is integrated into an industrial door. Its being put on the European

Union market implies EC marking by a certified agency, under the liabilities of the manufacturer

and / or installer of the door.

The design, manufacture and installation of an industrial door must respect the essential

requirements of health and safety determined by the following European directives:

European Directives Manual door Motorised door

Construction Products Directive 89/106/EEC X X

Low Voltage Directive 2006/95/CE X

Electro-magnetic Compatibility Directive 2004/108/CE X

Machines and Working Equipment Directive 2006/42/EC X

The proof of conformity to the regulation texts, mentioned above, is obtained by the respect of the

standard reference detailed by the standard of product NF EN 13241-1. - Industrial, Commercial

and Garage Doors (Part 1: products without fire and smoke proofing characteristics)

Terminology standard Safety standard Environmental

standard Electrical and DCEM

standard

EN 12433-1

Types of doors EN 12604

Mechanical aspects EN 12424

Resistance to wind EN 60204-1

Machine electrical safety

EN 12433-2

Components of doors EN 12605

Test methods EN 12444

Tests and calculations EN 61000-6-2 (DCEM)

Immunity to industrial

environment

EN 12453

Safety of use EN12425

Water penetration EN 61000-6-3 (DCEM)

Harmonic measure emission

EN 12445

Test methods EN 12489

Test methods EN 61000-6-4

Industrial environment

emission

EN 12978

Safety devices EN 12426

Permeability to air

EN 12635

Installation and use EN 12427

Test methods

EN 12428

Thermal transmission

FERMOD has taken the standards that apply to the supplied products into consideration.

- 22 -

1.2 – Liabilities

1–Themanufacturerofthedoor,theinstallerandtheusermustobservethesafetyrules(collectiveprotection,individual

protection)applicable duringtransport,assembly,use,and discardingof thedoor oritscomponents.

2– Theliabilityoftheuser maybe engagedin circumstancesthatarenotmarginal. Thus,the usermust scrupulously

complywiththerecommendationsforstorage,assembly,use,maintenance,healthandsafety,use-bydate,etc.supplied

bythemanufacturer.

Likewise,wheretheproducerbeheldliableforthenon-conformityoftheproduct,theusermayalsosharetheliability,

insofar as he has not, from his side, checked this conformity, even if the product in question is administratively in

conformity.Theuserisalsoheldliableifhehimselfincreasesthefaultintheproduct.

REGULATIONS & OBLIGATIONS

1.1

- 3 -

LIABILITIES

1.2

1 – The manufacturer of the door, the installer and the user must observe the safety rules (collective protection, individual

protection) applicable during transport, assembly, use, and discarding of the door or its components.

2 – The liability of the user may be engaged in circumstances that are not marginal. Thus, the user must scrupulously

comply with the recommendations for storage, assembly, use, maintenance, health and safety, use-by date, etc... supplied

by the manufacturer.

Likewise, where the producer be held liable for the non-conformity of the product, the user may also share the liability,

insofar as he has not, from his side, checked this conformity, even if the product in question is administratively in

conformity. The user is also held liable if he himself increases the fault in the product.

The liability of the manufacturer can be reduced or eliminated, taking all the circumstances into consideration, when the

damage is caused jointly by the product, and by the fault of the victim or a person for whom the victim is responsible

(D. general safety of products 92/59/EEC et D. liability from the fact of faulty products 85/374/EEC).

3 – Safety devices tted to the doors are not intended to prevent any wilful act of the operator or persons nearby

(EN12604 §4.1.2).

4 – The choice of options follows the type of door installed. It is the manufacturer’s responsibility to ensure the compatibility

of accessories according to the characteristics of the door and the conditions of use (EN12604 § 4.2.1).

1 - GENERAL INFORMATIONS