5

Installation

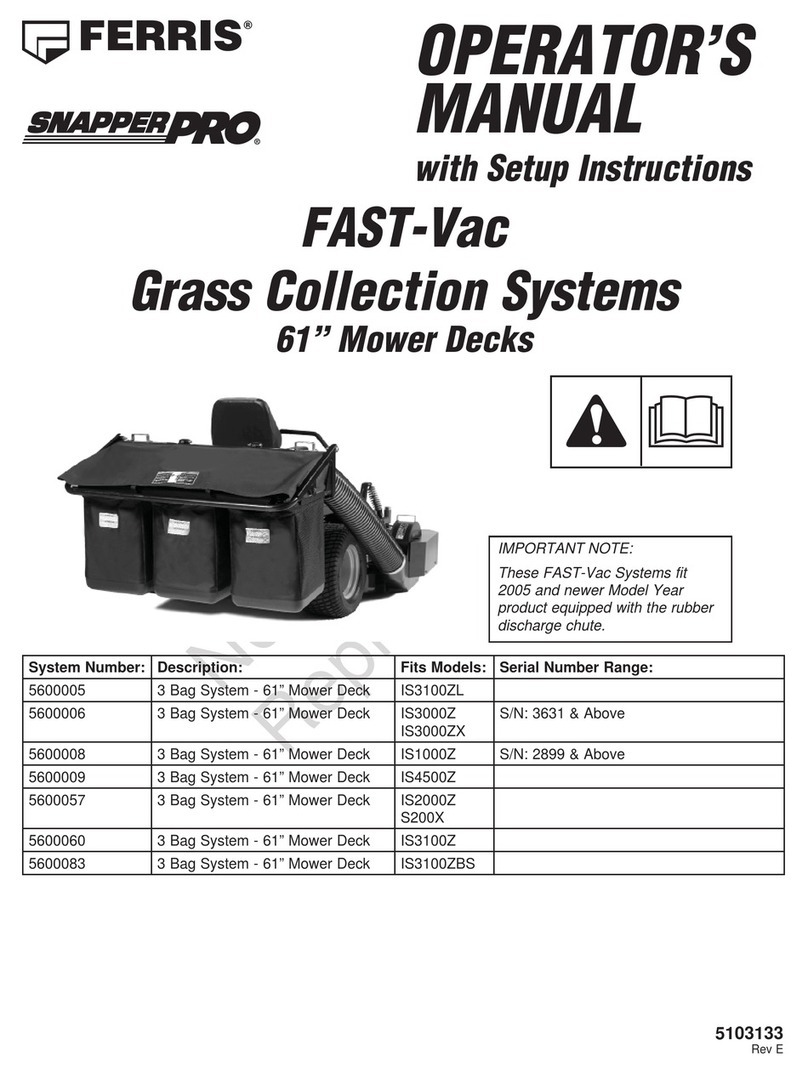

IS2100Z with a 61” Mower Deck (12 cu. ft. Hopper)

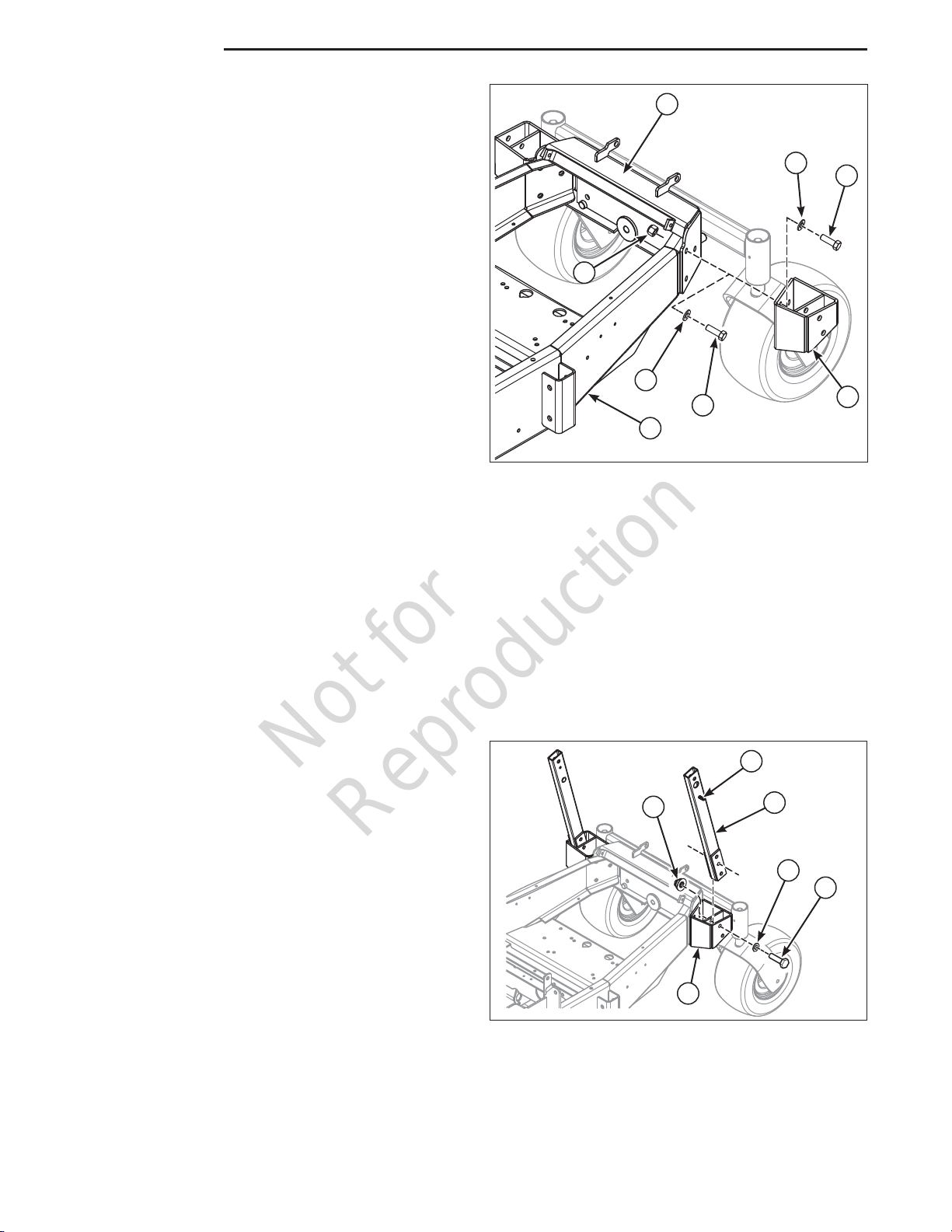

1. Position the hopper mount onto the bumper and

install two (2) U-bolts over the top bumper tube

and through the holes indicated as “A” in Figure 4

and secure with nylock flange nuts.

2. Install two (2) U-bolts over the middle bumper tube

and through the holes indicated as “B” in Figure 4

and secure with nylock flange nuts.

3. Slide the hopper mount as far as it will go towards

the discharge side of the mower deck and tighten

the hardware.

A

B

Figure 4. Hopper Mount Position - IS2100Z w/ 61”

Mower Deck (12 cu. ft. Hopper)

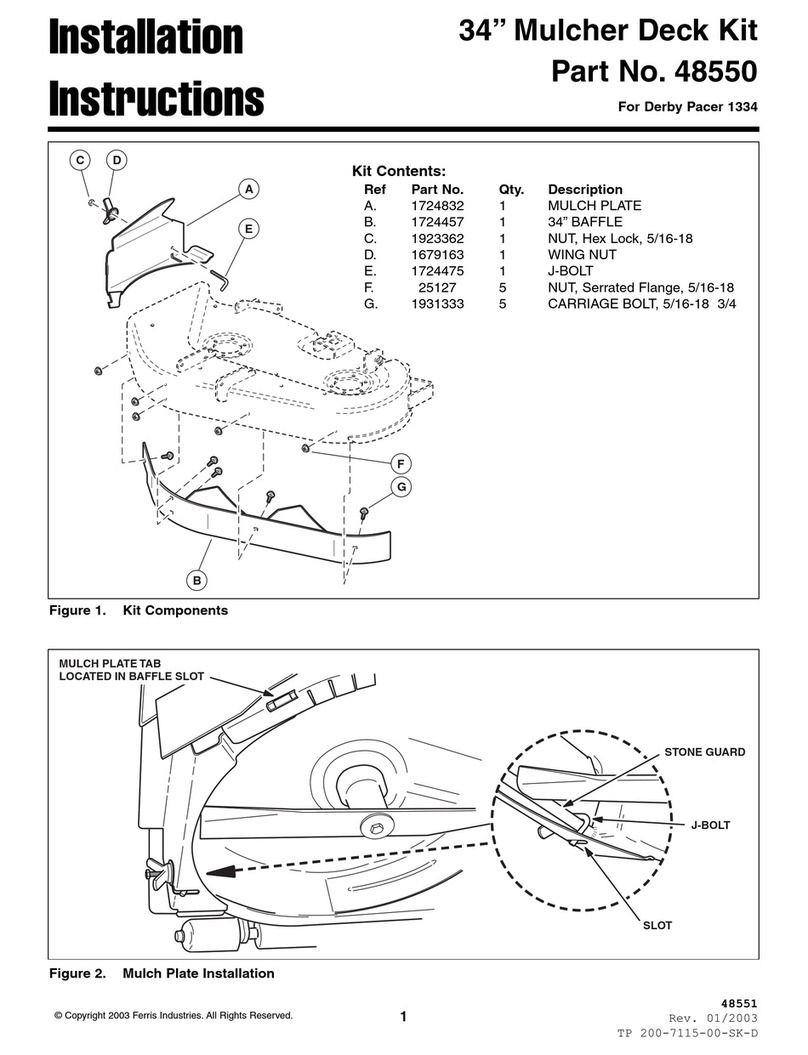

IS3100Z with a 61” Mower Deck (12 cu. ft. Hopper)

1. Position the hopper mount onto the bumper and

install two (2) U-bolts over the top bumper tube

and through the holes indicated as “A” in Figure 5

and secure with nylock flange nuts.

2. Install two (2) U-bolts over the third bumper tube

and through the holes indicated as “B” in Figure 5

and secure with nylock flange nuts.

3. Slide the hopper mount as far as it will go towards

the discharge side of the mower deck and tighten

the hardware.

A

B

Figure 5. Hopper Mount Position - IS3100Z w/ 61”

Mower Deck (12 cu. ft. Hopper)

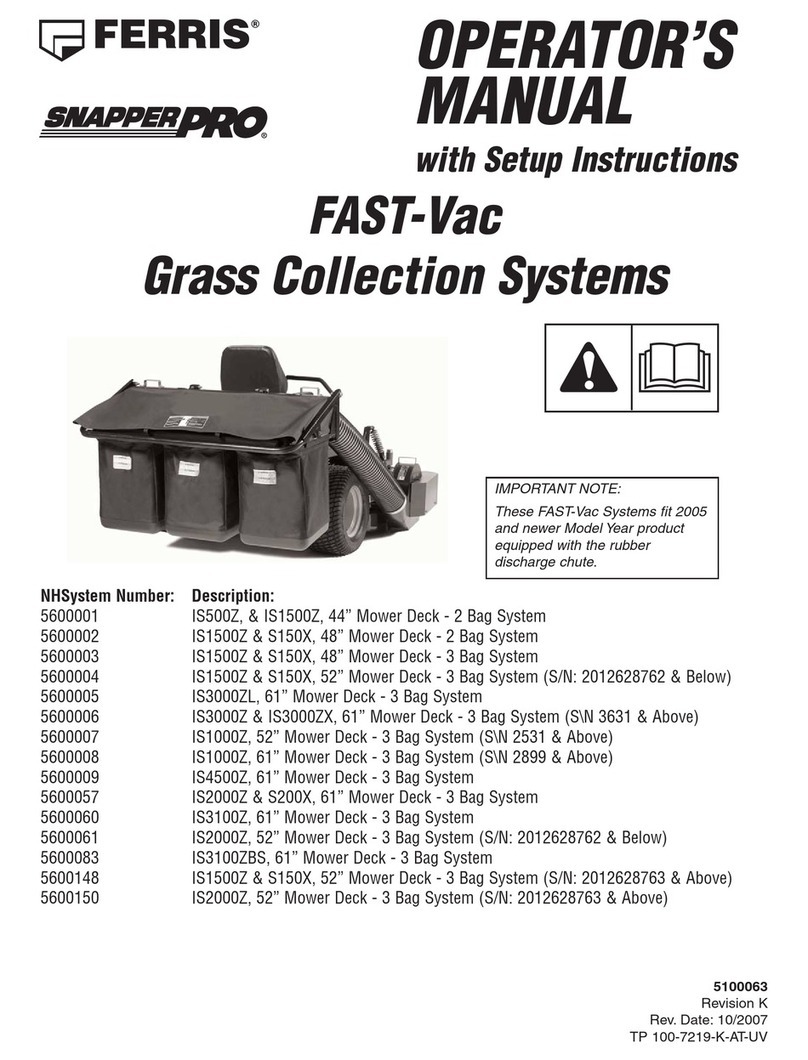

A

B

Figure 6. Hopper Mount Position - IS3100Z w/ 61”

Mower Deck (14 cu. ft. Hopper)

IS3100Z with a 61” Mower Deck (14 cu. ft. Hopper)

1. Position the hopper mount onto the bumper and

install two (2) U-bolts over the top bumper tube

and through the holes indicated as “A” in Figure 6

and secure with nylock flange nuts.

2. Install two (2) U-bolts over the third bumper tube

and through the holes indicated as “B” in Figure 6

and secure with nylock flange nuts.

3. Center the hopper mount plate on the bumper and

tighten the hardware.

A

B

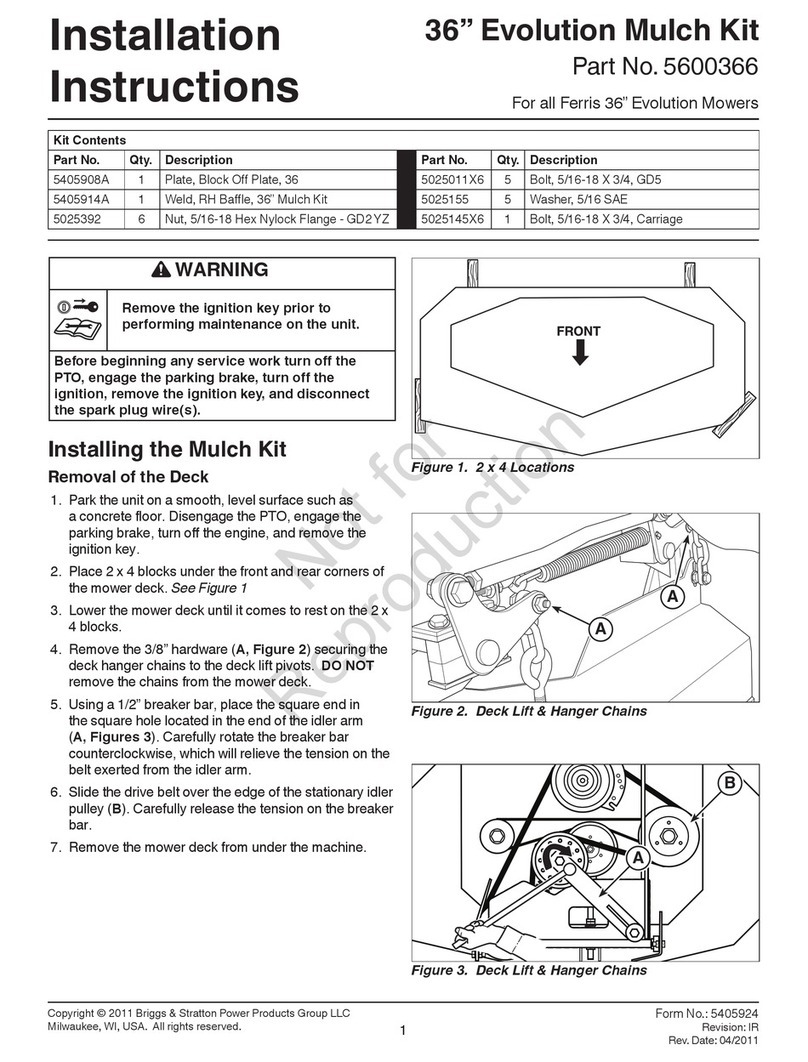

IS3200Z with a 61” Mower Deck (14 cu. ft. Hopper)

1. Position the hopper mount onto the bumper and

install two (2) U-bolts over the top bumper tube

and through the holes indicated as “A” in Figure 7

and secure with nylock flange nuts.

2. Install two (2) U-bolts over the second bumper

tube and through the holes indicated as “B” in

Figure 7 and secure with nylock flange nuts.

3. Center the hopper mount plate on the bumper and

tighten the hardware.

Figure 7. Hopper Mount Position - IS3200Z w/61”

Mower Deck (14 cu. ft. Hopper)