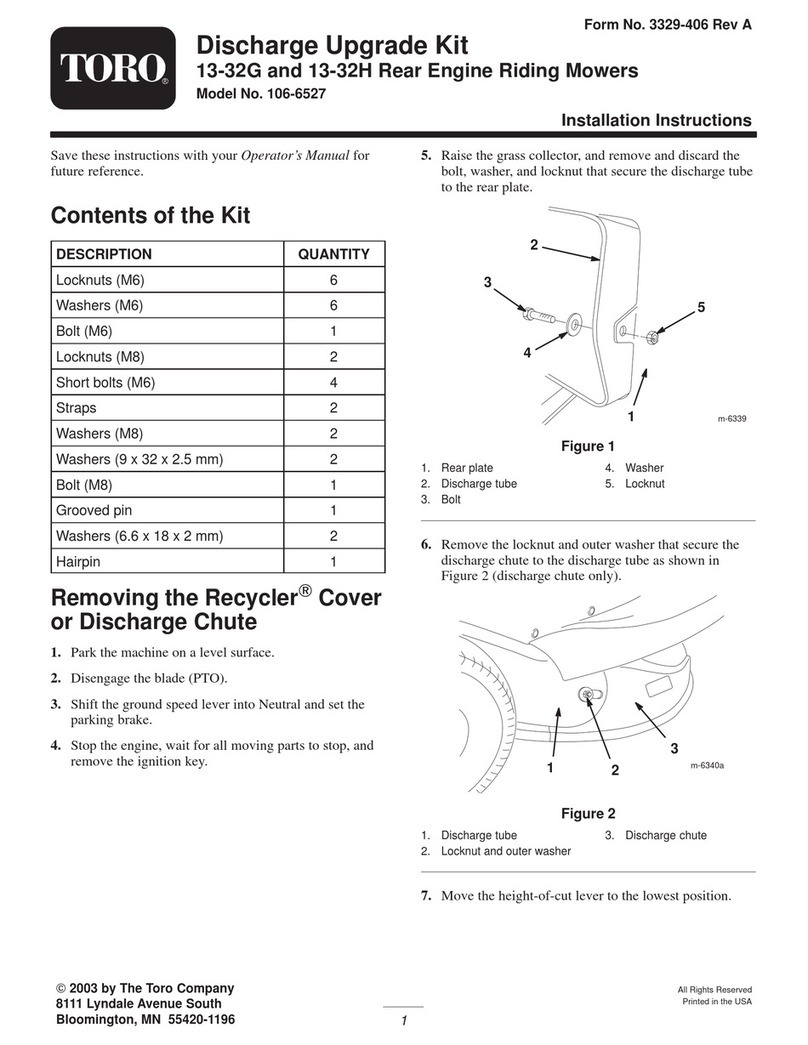

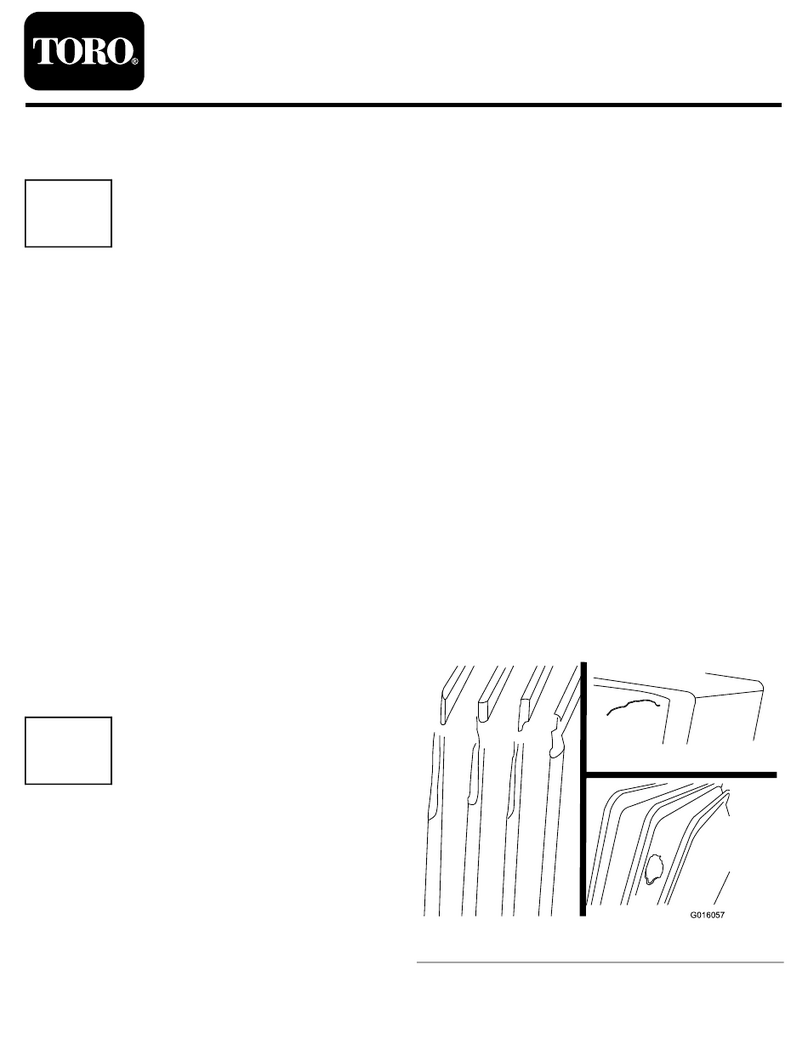

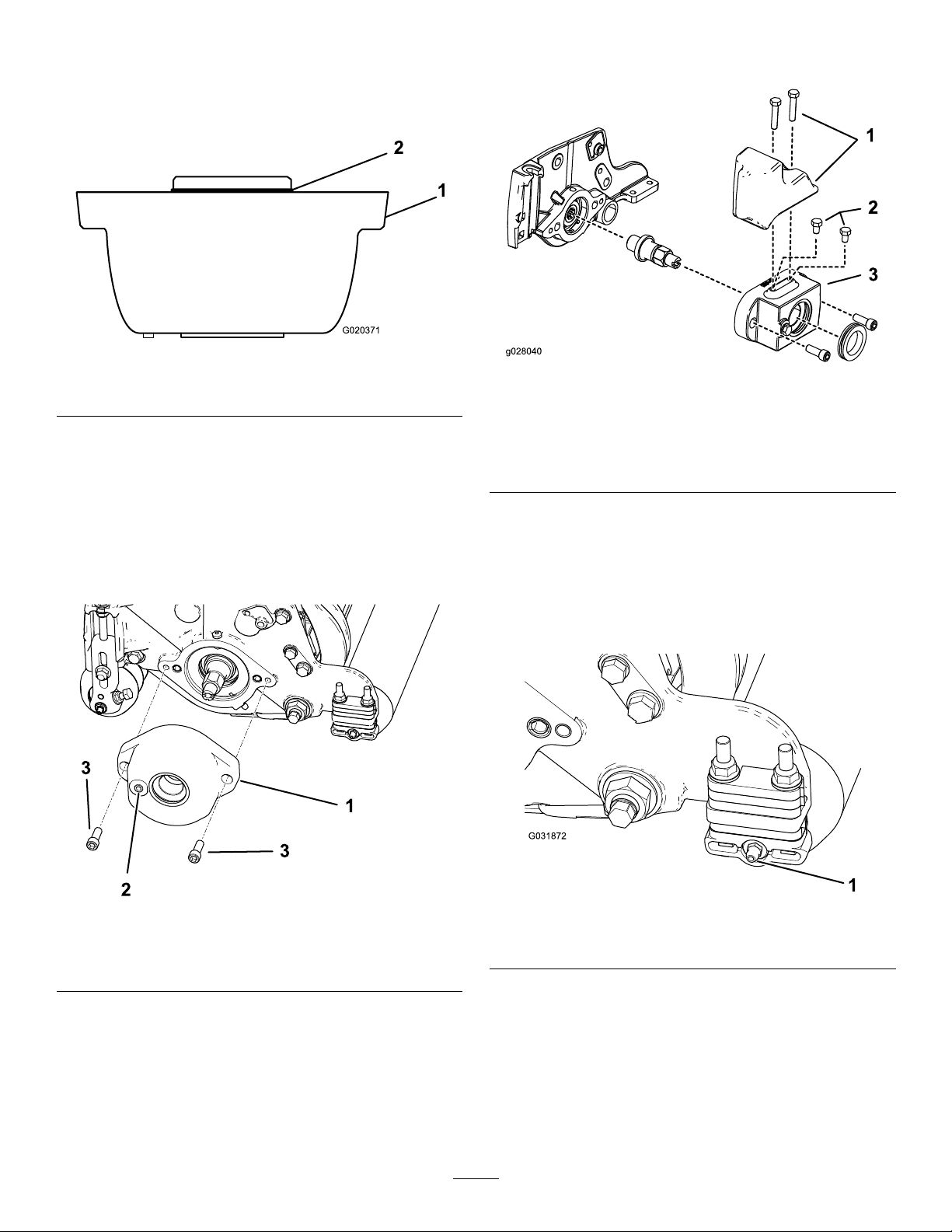

g218675

Figure10

1.Bolt4.Cleanoutanypaint

fromthethreadsusing

a5/16–18tapbefore

screwingintheshoulder

bolt.

2.Shoulderbolt5.Roller-brushhousing

3.Grommet6.Roller-brushpivotplate

assembly

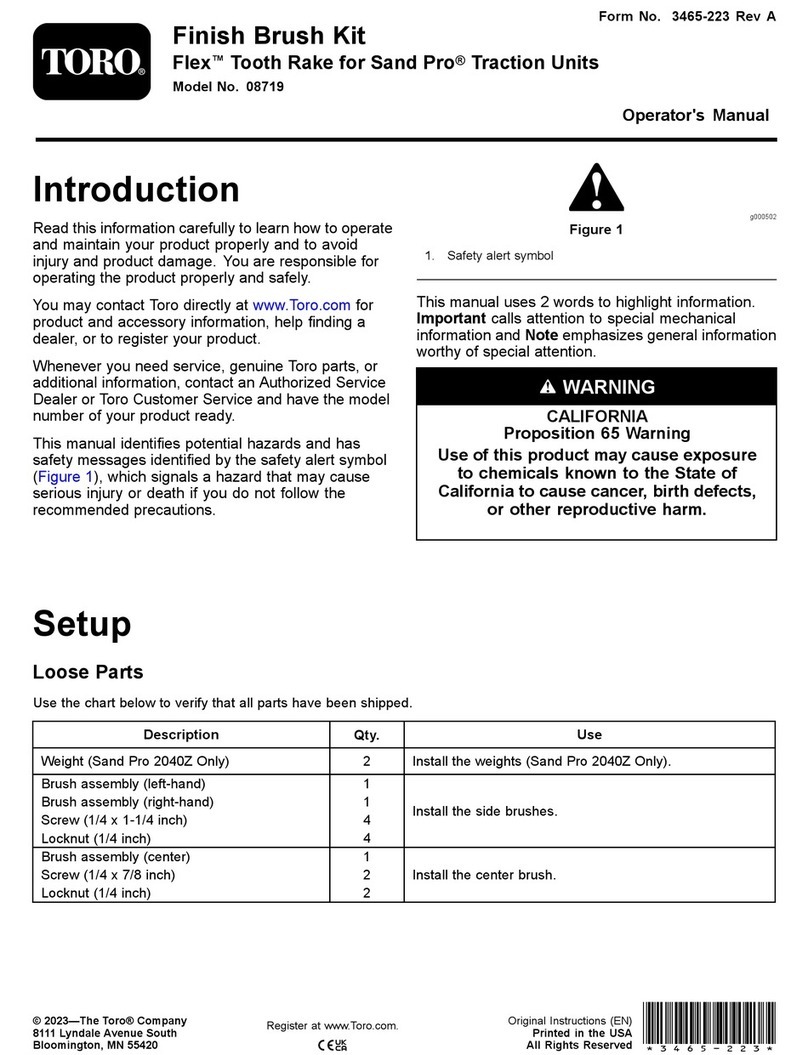

3.Installtheleftorrightroller-brushpivotplate

(Figure10).

Note:Whenyouinserttheprotrusiononthe

pivotplateintothegrommetintheroller-brush

housing,ensurethatthegrommetstaysproperly

seatedinthehousing.Theroller-brushpivot

plateisproperlyseatedwhenthereisno

resistancefromtherubbergrommetanditpivots

freely.

Note:Ensurethattheidler-pulleyassemblyis

installedonthebottomasshowninFigure10.

4.Applythread-lockingcompoundtothe2bolts

(5/16x1/2inch)andusethemtomountthe

brushplatetotheroller-brushbearinghousing

(Figure10).

Note:T orquetheboltsto20to25N·m(15to

19ft-lb).

5.Cleanoutanypaintfromthethreadsinthe

roller-brushhousing,usinga5/16–18tap,before

screwingintheshoulderbolt(Figure10).

Important:Ifthethreadsarenotcleaned

beforetheshoulderboltisscrewedin,the

boltcouldbreak.

6.Applythread-lockingcompoundtotheshoulder

bolt(Figure10).

7.Securethebrushplatetotheroller-brush

housingwiththeshoulderbolt(Figure10).

Note:Torquetheboltto20to25N·m(15to

19ft-lb).

Note:Theshoulderboltshouldnotclampthe

platetothehousing.

8.Checktoensurethattheroller-brushplateis

paralleltothecutting-unitsideplate.Ifitisnot

parallel,proceedasfollows:

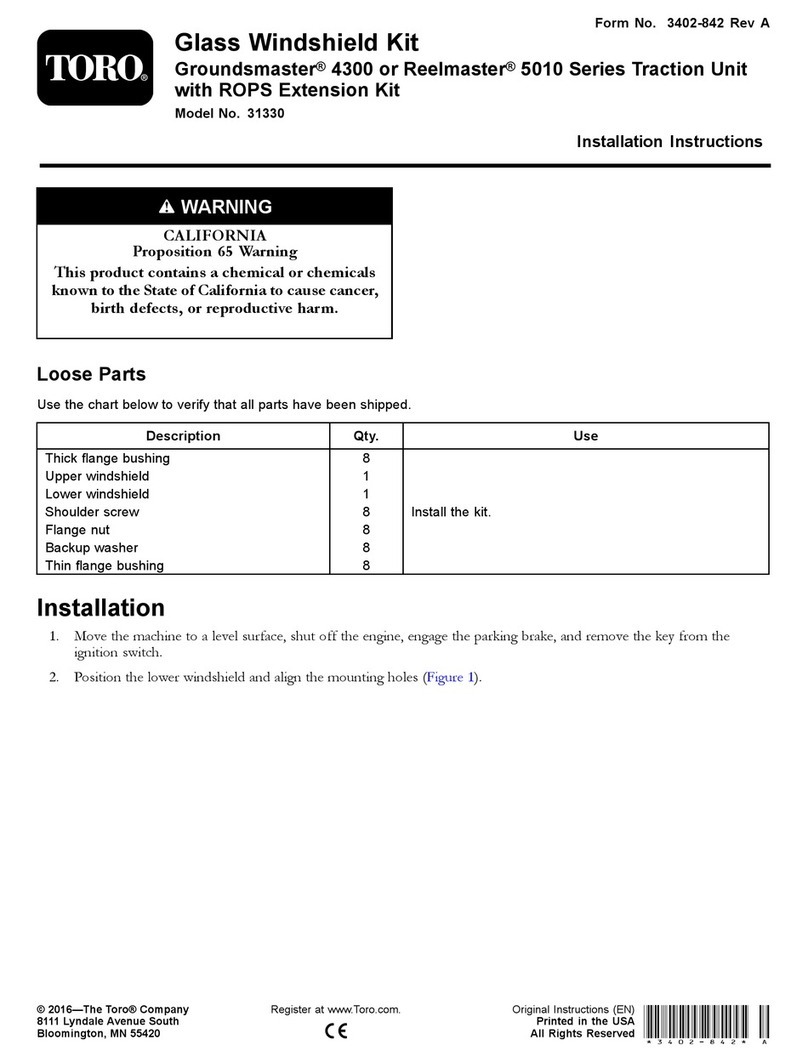

A.Loosenthe2angelocknutssecuring

theroller-brushmountingbrackettothe

cutting-unitsideplate(Figure11).

B.Rotatetheroller-brushbearinghousinguntil

thebrushplateisparalleltothecutting-unit

sideplate(Figure11).

C.Tightenthe2angelocknutssecuring

theroller-brushmountingbrackettothe

cutting-unitsideplate(Figure11).

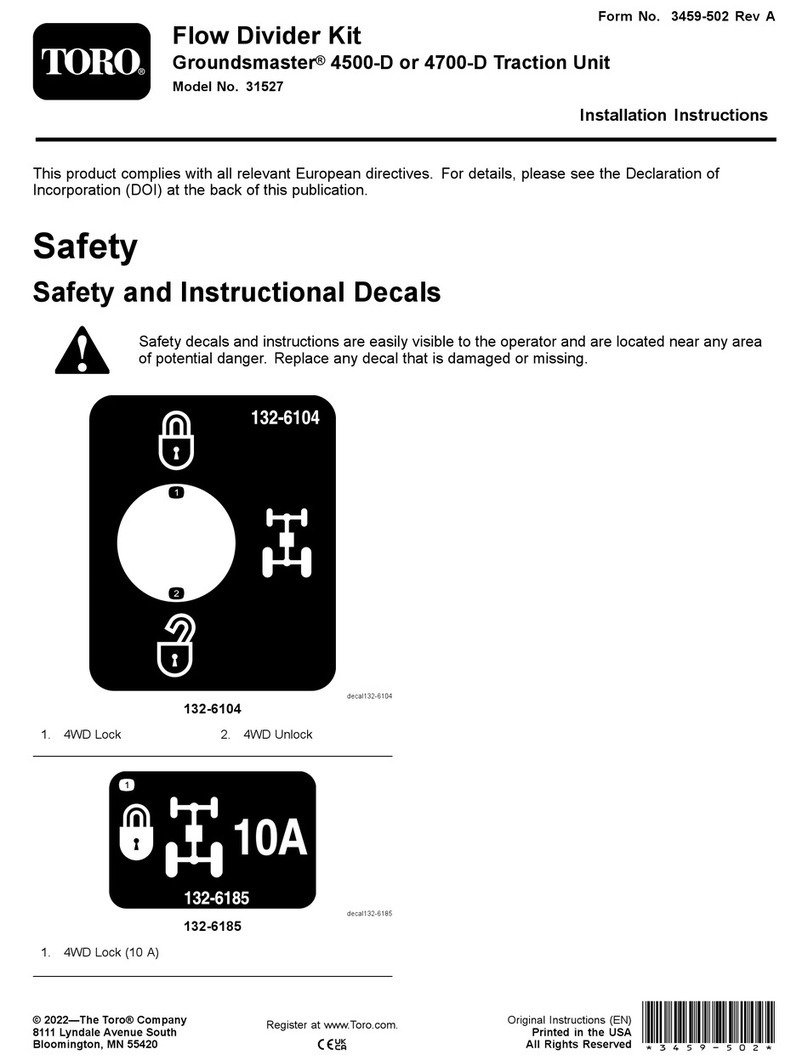

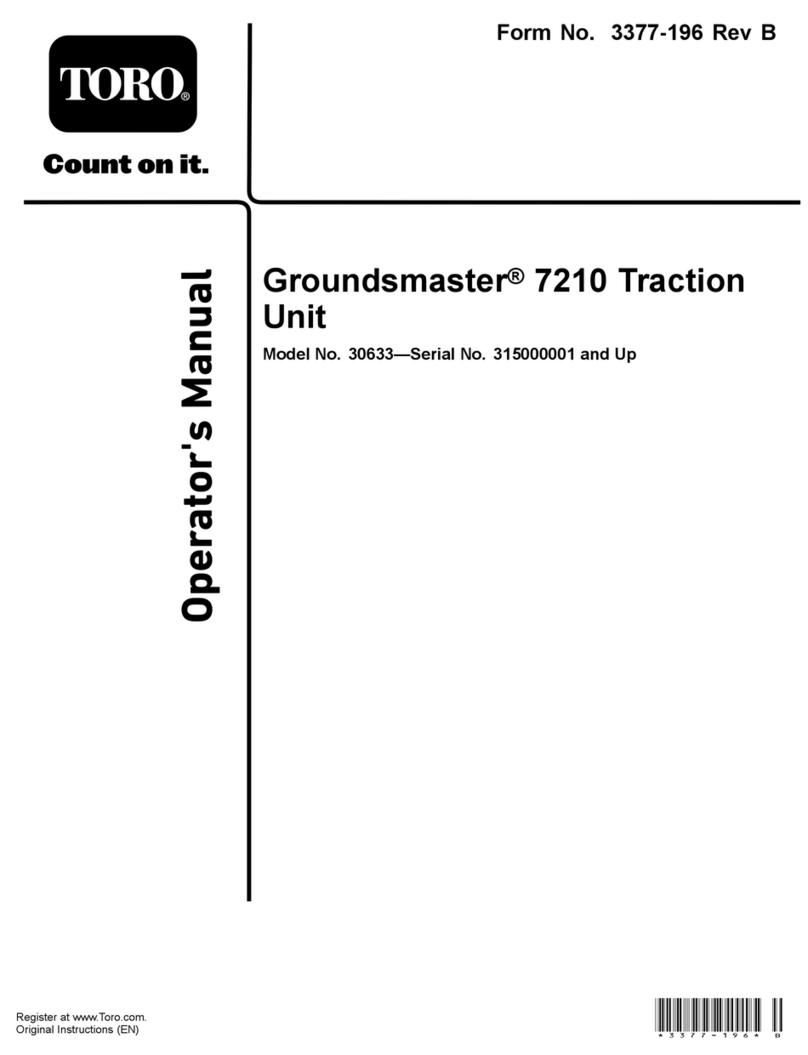

g027194

Figure11

1.Loosentheseboltsforpositioningtherollerbrush.

2.Loosenthesenutsformakingtheroller-brushplateparallel.

PositioningtheRollerBrush

1.Loosenthe2boltssecuringeachroller-brush

bearinghousingtotheroller-brushmounting

bracket(Figure11).

Note:Theboltsshouldbeloosefromthe

factory.

2.Positiontherollerbrushsothatitisjusttouching

orrestingontherearroller(Figure12).

Important:Theroller-brushshaftmustnot

contactthecutting-unitsideplate.

Important:Heavybrushcontactonthe

rollerwillcauseprematurebrushwear.

5