5

turning, going up, down, or across hills, when suddenly

changing speed, or operating on rough terrain. This shift

in load may cause possible instability, tipping, or rollover

of the machine. Reduce your speed in these situations.

• The sprayer hand wand may trap liquid under high

pressure, even when the engine is off. Accidental high

pressure spray discharge is hazardous and could cause

serious injury to you or bystanders.

•DO NOTpoint the hand wand towards or spray near

people.

• Always stay clear of the sprayer hand wand nozzle

and never point it at anything you do not intend to

spray.

• The hand wand is pressurized anytime the sprayer

pump is activated with the shutoff valve open.

• Take care to relieve the pressure in the hand wand

every time after shutting off the engine by squeezing

the trigger while pointing the wand in a safe direction.

•DO NOTpoint the hand wand at or spray electrical

components or wires.

•DO NOTattempt to disconnect the spray wand from

the unit while the system is pressurized.

Training

• Read, understand, and follow all instructions in the

manual and on the unit before starting. If the operator(s)

or mechanic(s) cannot read English it is the owner’s

responsibility to explain this material to them.

• Become familiar with the safe operation of the equipment,

operator controls, and safety signs.

• All operators and mechanics should be trained. The

owner is responsible for training the users.

• Only allow responsible adults, who are familiar with the

instructions, to operate the unit.

• Never let children or untrained people operate or service

the equipment. Local regulations may restrict the age of

the operator.

• The owner / user can prevent, and is responsible for,

accidents or injuries occurring to themselves, other

people, or property.

Preparation

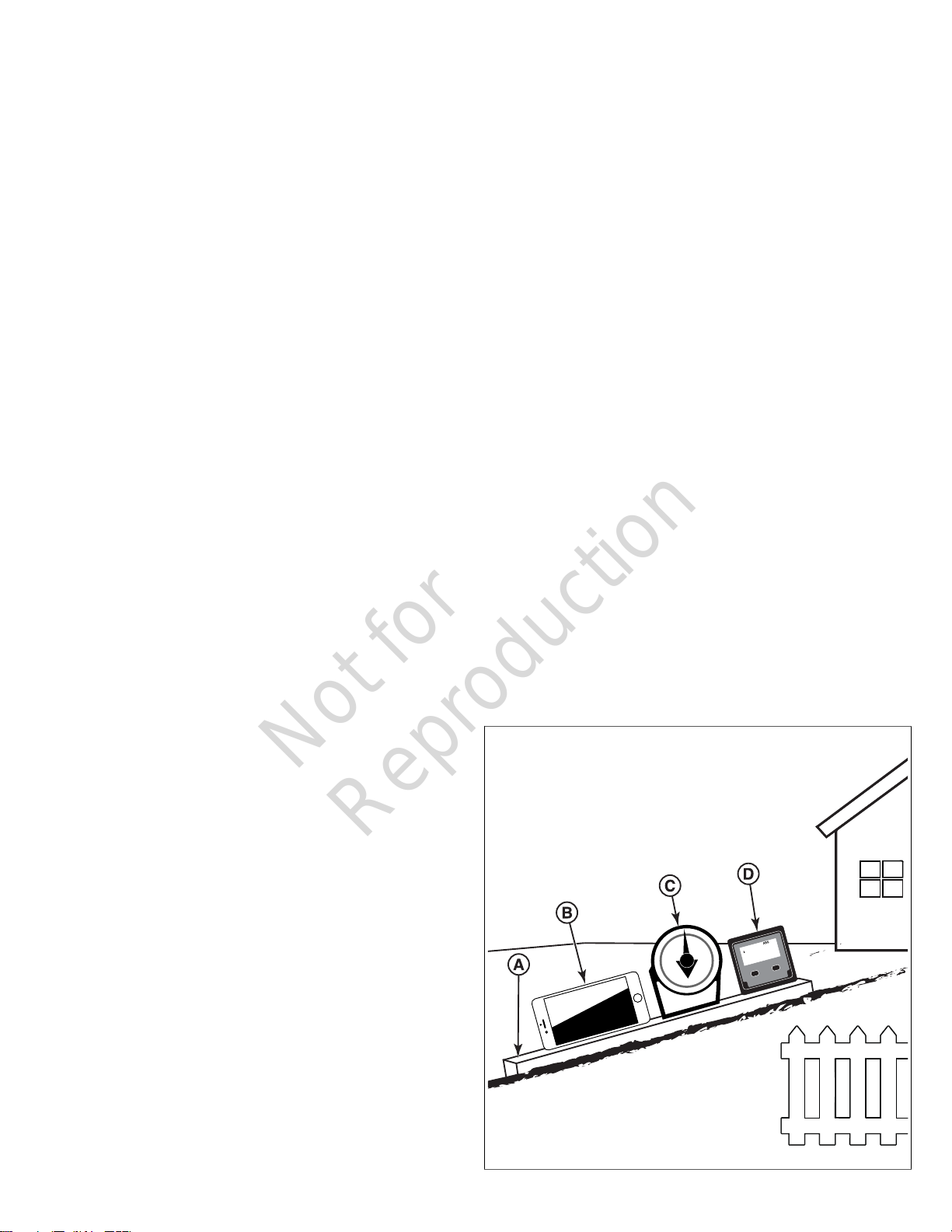

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Use only accessories and attachments approved

by the manufacturer.

• Wear appropriate clothing including safety shoes, safety

glasses, and ear protection. Long hair, loose clothing, or

jewelry may get tangled in moving parts.

• Inspect the area where the equipment is to be used and

remove all objects such as rocks, toys, and wire, which

could possibly damage the unit's tires.

• Use extra care when handling gasoline and other fuels.

They are flammable and vapors are explosive.

• Use only an approved container for gasoline.

• Never remove fuel cap or add fuel with the engine

running. Allow engine to cool before refueling. Do not

smoke. Never refuel or drain the machine indoors.

• Check that safety switches and shields are attached and

functioning properly. Do not operate unless they function

properly.

• Become familiar with and follow all warnings,

recommendations, instructions and procedures for safe

use, handling, applying, storage and disposal of all

chemicals as listed on the manufacturer’s label of any

herbicides, pesticides or other chemicals.

• Wear all personal protective equipment as recommended

on the manufacturer’s label or MSDS of any herbicides,

pesticides or other chemicals. Personal protective

equipment may include safety glasses or goggles and/or

face shields, chemical resistant gloves, rubber boots and

a respirator or filter mask.

WARNING

It is a violation of California Public Resource Code, Section

4442, to use or operate the engine on any forest-covered,

brush-covered or grass-covered land unless the exhaust

system is equipped with a spark arrester, as defined

in Section 4442, maintained in effective working order.

Other states or federal jurisdictions may have similar laws.

Contact an Authorized Service Dealer to obtain a spark

arrester designed for the exhaust system installed on this

engine.

• OSHA regulations may require the use of hearing

protection when exposed to sound levels greater than 85

dBA for an 8 hour time period.

WARNING

This machine produces sound levels in excess of 85 dBA

at the operator’s ear and can cause hearing loss though

extended periods of exposure. Wear hearing protection

when operating this machine.

Children

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and operating activity. Never assume that children will remain

where you last saw them.

• Keep children out of the operating area and under the

watchful care of another responsible adult.

• Be alert and turn the unit off if children enter the area.

• Before and while driving in reverse, look behind and

down for small children.

• Never carry children, even with the spreader spinner off.

They may fall off and be seriously injured or interfere

with the safe operation of the unit. Children who have

been given rides in the past may suddenly appear in the

operation area for another ride and could be run over or

backed over by the machine.

• Never allow children to operate the unit.