................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

Personal protective equipment

................................

................................

................................

................................

...........................

Maximum rated load capacity

................................

................................

................................

................................

................................

................................

................................

................................

Instructions to remove packaging

................................

................................

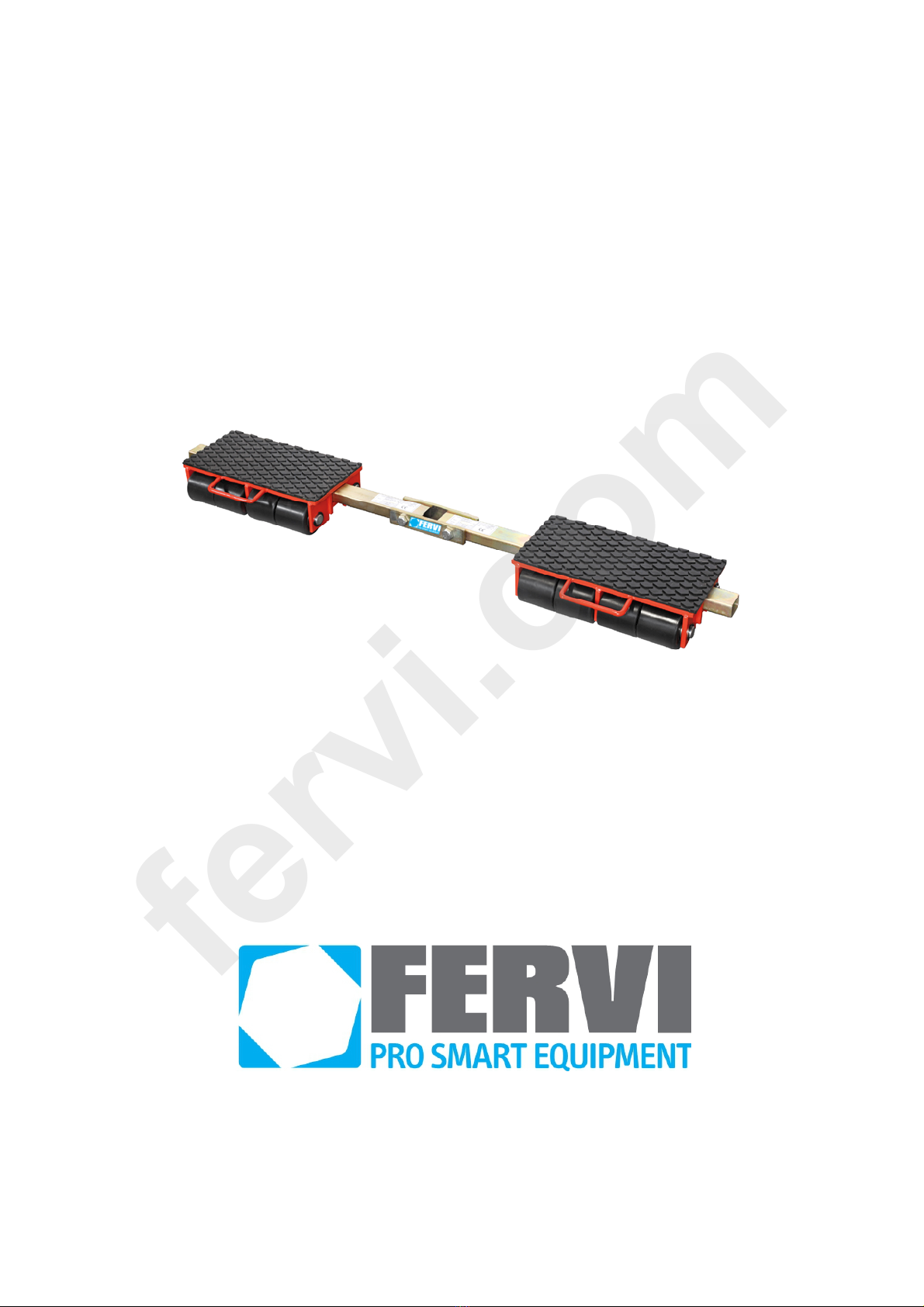

Adjusting load support rollers

................................

................................

................................

................................

................................

................................

................................

Handling loads with one trolley

................................

................................

g loads with two trolleys

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

.............................