HI GrainSaver U-Trough PS-001 Administrator Guide

U-Trough Power Sweep Installation

& Operator’s Manual

This manual applies to:

U-Trough:

Powersweep

Unload

Bin Diameters: 19’, 21’, 24’, 27’, 30’, 33’,

36’, 29’, 42’, 45’, 48’, 54’, 60’, 72’, 78’

CONTENTS

1. Introduction...............................................................................................................4

1.1. Intended Use..................................................................................................4

1.1.1 Misuse ................................................................................................4

2. Safety.........................................................................................................................5

2.1. Safety Alert Symbol and Signal Words...........................................................5

2.2. General Product Safety..................................................................................6

2.3. Rotating Flighting Safety ................................................................................6

2.4. Rotating Parts Safety .....................................................................................6

2.5. Work Area Safety ...........................................................................................6

2.6. Guards Safety ................................................................................................6

2.7. Bin Unloading Safety......................................................................................6

2.8. Bin Entry Safety .............................................................................................7

2.8.1 Roof Entry ...........................................................................................7

2.9. Bin Emergency Entry ..................................................................................... 7

2.10. Bin Entrapment ............................................................................................ 8

2.10.1 Flowing Grain.................................................................................... 8

2.10.2 Collapse of Bridged Grain.................................................................9

2.10.3 Collapse of a Vertical Wall of Grain ..................................................9

2.12. Drives and Lockout Safety ......................................................................... 11

2.12.1 Electric Motor Safety.......................................................................11

2.12.1 Hydraulic Motor Safety ..................................................................12

2.13. Personal Protective Equipment..................................................................12

2.14. Safety Equipment.......................................................................................13

2.15. Safety Decals.............................................................................................14

2.15.1 Decal Installation/Replacement .....................................................14

2.15.2 Safety Decal Locations and Details ...............................................14

3. Installation...............................................................................................................18

4. Operation.................................................................................................................20

4.1. Operation Safety .......................................................................................... 20

4.2. Bin Unload Overview ................................................................................... 20

4.3. Before Filling the Bin with Grain................................................................... 21

4.4. Operation of the Powersweep system ......................................................... 21

4.5. Emergency Shutdown.................................................................................. 22

4.6. Restarting with Full Underoor Auger .......................................................... 23

4.7. Cleanup........................................................................................................ 23

4.8. Extended Shutdown / End of Season .......................................................... 23

2

3

5. Maintenance............................................................................................................24

5.1. Maintenance Safety ..................................................................................... 24

5.2. Maintenance Schedule................................................................................. 24

5.3. Visually Inspect the Equipment .................................................................... 25

5.4. Inspect Hydraulic Hoses and Fittings........................................................... 25

5.5. Clean and Wash the Equipment................................................................... 25

5.6. Check the Gearbox Oil................................................................................. 26

5.7. Change the Gearbox Oil .............................................................................. 26

5.8. Tension the Belt Drive .................................................................................. 26

5.9. Align the Drive Belts ..................................................................................... 27

5.10. Replace the Drive Belts.............................................................................. 27

5.11. Replace the Sweep Drive Wheel................................................................ 27

5.12. Adjust the Bin Sweep Backboard ............................................................... 28

5.13. Removing the Underoor Auger Flighting .................................................. 29

6. Troubleshooting .....................................................................................................30

7. Specications .........................................................................................................34

7.1. Mechanical................................................................................................... 34

7.2. Power Requirements ................................................................................... 35

Thank you for purchasing a Grain Saver U-Trough Powersweep System. This equipment will allow safe and

ecient operation when you read and follow all of the instructions contained in this manual. With proper care,

your powersweep will provide you with many years of trouble-free operation.

Keep this manual handy for frequent reference and to review with new personnel. If any information in this

manual is not understood or if you need additional information, please contact your local distributor or dealer

for assistance.

This manual should be regarded as part of the equipment. Suppliers of both new and second-hand equipment

are advised to retain documentary evidence that this manual was provided with the equipment

The Powersweep is designed solely for use in the intended agricultural use as listed below. Use in any other

way is considered as contrary to the intended use. Compliance with and strict adherence to the conditions of

operation and maintenance as specied by the manufacturer, also constitute essential elements of the intend-

ed use.

The bin unload should be operated, maintained, serviced, and repaired only by persons who are familiar with

its particular characteristics and who are acquainted with the relevant safety procedures.

Accident prevention regulations and all other generally recognized regulations on occupational health and

safety must be observed at all times.

Any modications made to the bin unload may relieve the manufacturer of liability for any resulting damage or

injury.

Intended use for the powersweep:

• Handling grain, pulse crops, treated seeds, or other similar materials.

Use in any other way is considered as contrary to the intended use and is not covered by the warranty.

1. Introduction

Do not install/use the bin unload for/with:

• transferring material other than dry, free-owing food-grains.

• commercial or o-farm use.

1.1.1 Misuse

1.1. Intended Use

4

Indicates a hazardous situation that, if not avoided, may result in minor or moderate injury.

This safety alert symbol indicates important safety messages in this manual. When you see this

symbol, be alert to the possibility of injury or death, carefully read the message that follows, and

inform others.

Signal Words: Note the use of the signal words DANGER, WARNING, and CAUTION with the safety mes-

sages. The appropriate signal word for each message has been selected using the denitions below as a

guideline.

Indicates an imminently hazardous situation that, if not avoided, will result in serious injury or

death.

Indicates a hazardous situation that, if not avoided, could result in serious injury or death.

2.2. General Product Safety

YOU are responsible for the SAFE use and maintenance of your powersweep. YOU must ensure that you and

anyone else who is going to work around the powersweep understands all procedures and related SAFETY

information contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect you, but also the people around

you. Make these practices a working part of your safety program. All accidents can be avoided.

• It is the powersweep owner, operator, and maintenance personnel's responsibility to read and understand

ALL safety instructions, safety decals, and manuals and follow them when operating, or maintaining the equip-

ment.

• Owners must give instructions and review the information initially and annually with all personnel before

allowing them to operate the powersweep. Untrained users/operators expose themselves and bystanders to

possible serious injury or death.

• The powersweep is not intended to be used by children.

• Use the bin unload for its intended purposes only.

• Do not modify the bin unload in any way without written permission from the manufacturer. Unauthorized

modication may impair the function and/or safety, and could aect the life of the bin unload. Any unauthorized

modication will void the warranty.

• Follow a health and safety program for your worksite. Contact your local occupational health and safety orga-

nization for information.

Indicates a potentially hazardous situation that, if not avoided, may result in property damage.

2. Safety

2.1. Safety Alert Symbol and Signal Words

5

2.3. Rotating Flighting Safety

• KEEP AWAY from rotating ighting.

• DO NOT remove or modify ighting guards, doors, or covers. Keep in

good working order. Have replaced if damaged.

• DO NOT operate the bin unload without all guards, doors, and covers in

place.

• NEVER touch the ighting. Use a stick or other tool to remove an ob-

struction or clean out.

• Shut o and lock out power to adjust, service, or clean.

2.4. Rotating Parts Safety

• Keep body, hair, and clothing away from rotating pulleys, belts, chains,

and sprockets.

• Do not operate with any guard removed or modied. Keep guards in good

working order.

• Shut o and remove key or lock out power source before inspecting or

servicing machine.

2.5. Work Area Safety

• Have another trained person nearby who can shut down the bin unload in case of accident.

• The work area should be kept clear of bystanders.

• Keep the work area clean and free of debris.

2.6. Guards Safety

• Keep guards in place and do not operate unless all guards are in place.

• Do not walk on, step on, or damage guards.

• Lock out power before removing a guard.

• Ensure all guards are replaced after performing maintenance.

2.7. Bin Unloading Safety

• Never enter a bin when loading or unloading.

• Unload only as described in the operation section of this manual.

• Lock the bin door (where equipped) and close/lock all other access doors when not in use.

6

2.8. Bin Entry Safety

The information in this section applies to entry through any access point.

Always try to work and solve problems without entering a bin.

If you must enter the bin, follow the safety information below to safely enter through

the roof or door:

• Stop the unloading process if the bin is being unloaded and lockout/tagout power before

entering the bin, refer to Lockout/Tagout Safety.

• Always wear a dust-ltering respirator when entering the bin. Grain dust and spores when

inhaled into the lungs can cause severe reactions leading to hospitalization in some cases.

Persistent exposure may cause “farmer’s lung,” which can eventually be fatal.

• Before working inside the bin, ventilate the area by opening the vent or by other equivalent

means to force air into the bin to prevent oxygen-decient atmosphere. Inadequate oxygen

is very harmful to your health and can cause death. Exposure to carbon dioxide can cause

drowsiness, headache and even death due to suocation. Test the atmosphere. If the car-

bon dioxide hazard cannot be reduced or eliminated or you cannot test the atmosphere, use

correctly tted and appropriate respirator.

• Never walk on grain to make it ow.

If you ignore the safety precautions above and enter the bin, you could die from being submerged.

2.8.1 Roof Entry

The information in this section applies to entry through the bin roof only.

• Never enter a bin from the roof if you don’t know its unloading history. Bridges of stored

material can form above a void space below, causing potential for entrapment.

• Have body harness tethered to a lifeline controlled by two others outside the bin. One

worker should be able to see inside worker through the inspection hatch. If there is an ac-

cident, one worker can focus on the victim while the other goes/calls for help.

• In the event that you are trapped in the bin as it is unloading, move as quickly as possible

toward the bin wall; keep yourself elevated above the material by walking on the owing

mass while staying as close as possible to the bin wall.

2.9. Bin Emergency Entry

In an emergency situation:

• Follow protocols set by your local occupational safety and health agency.

• If you need to rescue somebody inside the bin, call emergency responders and only attempt to rescue using

non-entry rescue procedure/equipment. Do not enter the bin unless you are trained for rescue, equipped and

relieved by another attendant.

7

2.10. Bin Entrapment

It takes more than 1000 lb (4.5kN) of force to remove someone buried below the surface.

The following sections cover common ways a person gets submerged or trapped:

2.10.1 Flowing Grain

• Grain ows in a funnel-shaped path when unloading. This vortex of grain behaves very much like a water

drain. Velocity increases as grain ows from the bin wall at the top of the grain mass into a small vertical col-

umn at the center of the bin.

• Flowing grain will not support the weight of a person. Submersion happens within seconds.

Figure 1. Suocation Hazards in Flowing Grain

2-3 SECONDS 4-5 SECONDS 22 SECONDS

AFTER THE UNLOADING

EQUIPMENT STARTS,

YOU HAVE 2-3 SECONDS

TO REACT

IN 4-5 SECONDS,

YOU ARE TRAPPED

AFTER 22 SECONDS, YOU

ARE COMPLETELY COVERED.

8

2.10.2 Collapse of Bridged Grain

• Grain can “bridge” across a bin, creating an empty air space below. A person can easily break through this

bridge and become trapped, risking suocation.

• To identify bridged grain, look for a funnel shape on the surface of the grain after having removed some of

the grain. If surface is undisturbed, the grain has bridged and formed a crust.

• Never walk on the grain crust. The crust rarely becomes strong enough to support the weight of a person.

• To remove bridge, try breaking the bridge from the inspection hatch or peak. Use a pole to hit the surface,

securing it with a rope in case it is dropped. Be aware that chunks of crusted grain can move down to the au-

ger and limit ow.

Figure 2. Suocation Hazards in Bridged Grain

2.10.3 Collapse of a Vertical Wall of Grain

• Vertical walls of grain are created when the bin is partially empty. Poking at the wall can make the grain ava-

lanche and submerge a person.

• Do not enter the bin to break down grain that has set up. Break grain mass from top of the bin outside.

9

Figure 3. Suocation Hazards from a Vertical Grain Wall

2.11. Combustible Dust

The powersweep has been designed for safe use in areas where hazards due to com-

bustible dust may potentially occur. Minimize the risk of a dust explosion by following

the preventive measures below.

Control the dust:

To control dust, consider as part of your work-site safety program to:

• Clean the grain to reduce the nes.

• Use equipment to minimize the breakage. For example, corn that is broken exposes the starch, the most

explosive element of the grain.

• Use a ltering system to capture the dust.

• Use an air system to reduce the dust.

• Spray edible mineral oil on the grain to reduce air-born dust when handling.

• Paint equipment that is in the interior of a facility with a coating that is slick, not allowing the dust to accumu-

late.

• Clean up dust deposits after operation of the equipment.

• Enclose all equipment to keep the dust from escaping.

Control the ignition source:

To prevent possible sources of ignition that could cause res or dust explosions:

• Do not smoke in any potentially hazardous area.

• Use only explosion-proof lights.

10

• Do not use anything around or inside the equipment that may produce a ame, such as a match, a lighter, or

anything that may produce a shower of sparks, such as a grinder or power saw, unless the air is free of dust

and all dust deposits have been removed from the work area, or the work area is wet such that dust cannot be

dispersed in the air and smoldering processes from sparks cannot develop. Use brush-less electrical tools and

explosion proof ash lights, for example.

• Follow the maintenance schedule to keep equipment operating at normal conditions. This will further help to

prevent the risk of components overheating or wearing out which may lead to explosion risks.

• Always purchase replacement parts from the manufacturer or authorized dealer/distributor. Original manufac-

turers parts are designed with explosion proof features where applicable

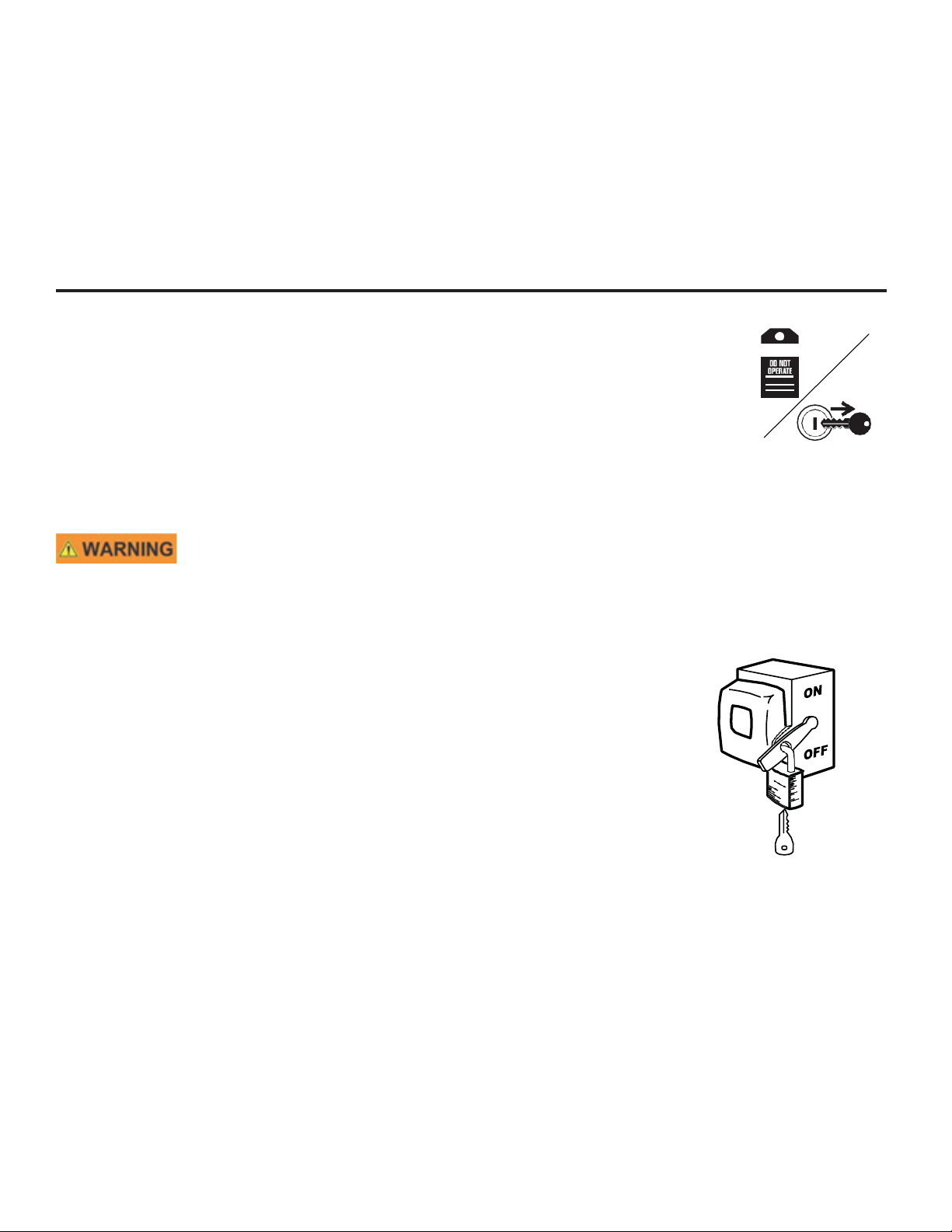

2.12. Drives and Lockout Safety

Inspect the power source(s) before using and know how to shut down in an emer-

gency. Whenever you service or adjust your equipment, make sure you shut down the

power source and follow lockout and tagout procedures to prevent inadvertent start-up

and hazardous energy release. Know the procedure(s) that applies to your equipment

from the following power source(s). Ensure that only 1 key exists for each assigned

lock, and that you are the only one that holds that key. Ensure that all personnel are

clear before turning on power to equipment.

WARNING

2.12.1 Electric Motor Safety

Power Source

• Electric motors and controls shall be installed and serviced by a qualied

electrician and must meet all local codes and standards.

• A magnetic starter should be used to protect your motor.

• You must have a manual reset button.

• Reset and motor starting controls must be located so that the operator has

full view of the entire operation.

• Locate main power disconnect switch within reach from ground level to

permit ready access in case of an emergency.

• Motor must be properly grounded.

• Guards must be in place and secure.

• Ensure electrical wiring and cords remain in good condition; replace if

necessary.

• Use a totally enclosed electric motor if operating in extremely dusty condi-

tions.

Lockout

• The main power disconnect switch should be in the locked position during

shutdown or whenever maintenance is performed.

• If reset is required, disconnect all power before resetting motor.

11

2.12.1 Hydraulic Motor Safety

Power Source

• Refer to the rules and regulations applicable to the power source operating your hydraulic

drive.

• Do not connect or disconnect hydraulic lines while system is under pressure.

• Keep all hydraulic lines away from moving parts and pinch points.

• Escaping hydraulic uid under pressure will cause serious injury if it penetrates the skin

surface (serious infection or toxic reaction can develop). See a doctor immediately if injured.

• Use metal or wood as a backstop when searching for hydraulic leaks and wear proper

hand and eye protection.

• Check all hydraulic components are tight and in good condition. Replace any worn, cut,

abraded, attened, or crimped hoses.

• Clean the connections before connecting to equipment.

• Do not attempt any makeshift repairs to the hydraulic ttings or hoses with tape, clamps,

or adhesive. The hydraulic system operates under extremely high pressure; such repairs

will fail suddenly and create a hazardous and unsafe condition.

Lockout

• Always place all hydraulic controls in neutral and relieve system pressure before discon-

necting or working on hydraulic system.

2.13. Personal Protective Equipment

The following Personal Protective Equipment (PPE) should be worn when operating or maintaining the

equipment.

Safety Glasses

• Wear safety glasses at all times to protect eyes from debris.

Work Gloves

• Wear work gloves to protect your hands from sharp and rough edges.

Steel-Toe Boots

• Wear steel-toe boots to protect feet from falling debris.

Coveralls

• Wear coveralls to protect skin.

Hard Hat

• Wear a hard hat to help protect your head.

12

Hearing Protection

• Wear ear protection to prevent hearing damage.

2.14. Safety Equipment

The following safety equipment should be kept on site:

Fire Extinguisher

• Provide a re extinguisher for use in case of an accident. Store in a highly visible and

accessible place.

First-Aid Kit

• Have a properly-stocked rst-aid kit available for use should the need arise, and know

how to use it.

Eyewash Kit

• Keep a portable eye wash kit available or make sure a permanent eyewash station is

available should the need arise to ush materials from the eyes. Review instructions for

use before working with the bin unload.

Salvage Container

• Keep a sealable salvage container on site, such as a spill containment pallet.

Absorbent Materials

• Keep granular absorbent materials on hand to clean up any chemical spills.

Aluminum Shovel and Broom

• Keep an aluminum shovel and broom for cleanup of spilled materials.

13

2.15. Safety Decals

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible.

• Replaced parts must display the same decal(s) as the original part.

• Replacement safety decals are available free of charge from your distributor, dealer, or factory as applicable.

2.15.1 Decal Installation/Replacement

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specied area and carefully press the small portion with the exposed sticky backing

in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign backing paper.

Replicas of the safety decals that are attached to the bin unload and their messages are shown in the gure(s)

that follow. Safe operation and use of the bin unload requires that you familiarize yourself with the various

safety decals and the areas or particular functions that the decals apply to, as well as the safety precautions

that must be taken to avoid serious injury, death, or damage.

2.15.2 Safety Decal Locations and Details

14

Note:

Decal location same in incline discharge

Part Number Discription

PS-002

15

Part Number Discription

PS-001

PS-006

16

Part Number Discription

PS-003

PS-004

PS-005

17

3. Installation

Your Grain Saver™ Power Sweep System is completely assembled and is ready for in-

stallation in your new concrete foundation, or in your new existing conventional drying,

natural air drying or other style aeration / drying system.

To install Power Sweep System in a concrete foundation:

A. The Splined Gearbox Sweep output shaft is to be the center of the concrete foundation.

B. Set the concrete forms, “stake” the tube in place using the leveling brackets provided on

the Center Hopper to prevent “slip” and “oat”.

C. Check control rod sleeves to be certain that they were not bent in shipping or handling.

This could cause diculty in opening the wells. Straighten if necessary with a pry bar.

D. The discharge end of the tube must be installed at least 1” lower than the intake end to

prevent water build-up in the tube.

E. Pour the concrete foundations to the bin manufacturer’s specications and let “cure”.

F. Install the sweep assembly with the one bolt “keeper” over the splined shaft.

G. Adjust the sweep backboard to the length by loosening the 4 bolts and rotating the wheel

so the sweep telescopes in or out to the desired location. Tighten the bolts. Sweep should

also be adjusted on both the center and wheel end to ensure proper movement and opera-

tion. Make sure the sweep is not touching the bin oor at any point around the bin.

H. Install Powerhead drive by inserting powerhead drive screw into unload screw and fasten

them with the 2 provided bolts and tighten them. Then tighten the ange clamps on pow-

erhead drive to ange on unload tube or u-trough. Adjust the unload screw on the spline of

the center gearbox by loosening the insert bearing on the powerhead and sliding the unload

screw and connected powerhead screw in or out so it is connected securely on the spline of

the center gearbox. When properly set, There should be approximitely 7/8” to 1” of spline

showing from the gearbox plate to the unload screw spine.

I. Install sweep safety stop on the inside of the bin wall right behind where the sweep will be

parked when lling the bin, the sweep should be parked right over the sumps.

18

To Install Power Sweep System in Drying, Aeration or Full Floor Systems:

A. Locate the area where the tube is to exit the bin wall. Using the rodent cover as a tem-

plate cut the hole just large enough to allow for the tube and ange to pass through with mini-

mal clearance. Be sure to allow for the handles and handle cover as well.

B. Align the splined gearbox output shaft with the center of the bin.

C. Check control rod sleeves to be certain that they were not bent in shipping or handling.

This could cause diculty in opening the wells. Straighten if necessary with a pry bar.

D. Level the tube using the leveling brackets provided. Make sure that there is a 1” decline

in the tube towards the discharge end or drill a 1/8” diameter hole in the center intake hopper

bottom to allow for drainage.

E. Install the Drying / Aeration oor to the manufacturer’s specications. Seal the area in the

oor that was cut to t around the hoppers with Grain Saver™ Hopper Flanges. Use self-drill-

ing screws to attach this to the hopper

F. Install the Grain Saver™ Bin Wall Plate over the tube and opening in the bin wall and at-

tach with bolts or screws. The top half overlaps the bottom half by 1/2” to allow for proper

watershed. Caulk any cracks or openings and ll corrugations with a good quality silicone or

butyl based sealant.

G. Install the sweep assembly with the one bolt “keeper” over the splined shaft.

H. Adjust the sweep backboard to the desired length by loosening the 4 bolts and rotating the

wheel so the sweep telescopes in or out to the desired length. Tighten the bolts. Sweep

should also be adjusted on both the center and wheel end to ensure proper movement and

operation. Make sure the sweep is not touching the bin oor at any point around the bin.

I. Install Powerhead drive by inserting powerhead drive screw into unload screw and fasten

them with the 2 provided bolts and tighten them. Then tighten the ange clamps on pow-

erhead drive to ange on unload tube or u-trough. Adjust the unload screw on the spline of

the center gearbox by loosening the insert bearing on the powerhead and sliding the unload

screw and connected powerhead screw in or out so it is connected securely on the spline of

the center gearbox. When properly set, There should be approximitely 7/8” to 1” of spline

showing from the gearbox plate to the unload screw spine.

J. Install sweep safety stop on the inside of the bin wall right behind where the sweep will be

parked when lling the bin, the sweep should be parked right over the sumps.

Note: If any warning or safety decals become lost or damaged in any manner, please contact

us for free replacements. and the perforated oor. Caulk any cracks or openings with a good

quality silicone or butyl based sealant.

19

4. Operation

Before continuing, ensure you have completely read and understood this manual’s Safety

section, in addition to the safety information in the section(s) below.

4.1. Operation Safety

• Keep away from rotating and moving parts, including the auger ighting, drive components,

shafts, and bearings.

• Do not enter the grain bin while the bin unload is operating.

• Always operate with guards, covers, and shields in place.

• Have another trained person nearby who can shut down the equipment in case of accident.

• Keep the work area clear of bystanders.

• Keep the work area clean and free of debris.

• Ensure maintenance has been performed and is up to date.

Refer to your bin operation manual for specic operating and safety information for your bin.

4.2. Bin Unload Overview

The bin unload system operates by rst opening the center sump to remove 70-80% of grain by gravity (see

step 1 below). Next, the intermediate sumps are opened when the center sump runs empty to free the sweep

(see step 2 below). Next, the bin sweep is operated to remove the remaining 20-30% of grain (see step 3 be-

low). Lastly, the sweep is parked over the sumps for the bin to be relled again.

Open center hop-

per. Unload until

gravity ow stops.

Open intermediate

hopper and unload

until gravity ow

stops.

Stop equipment

and engage clutch

on bin sweep.

Remove remaining

grain.

Return sweep to

position over inter-

mediate hoppers

and bin is ready to

be relled.

To prevent serious injury or death from bin collapse,

the center sump must be open rst to empty bin.

Make certain there are adequate vents installed on the bin to prevent a vacuum from

forming in the upper portion of the bin during unloading. The pressures on the roof

caused by such a vacuum could damage or cause structural failure to the bin roof.

20

This manual suits for next models

4

Table of contents