Fervi 0630/2200 User manual

OPERATION AND

MAINTENANCE MANUAL

12 V Electric winch

-

direct current

Art. 0630/2200

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

fervi.com

MACHINES

AND

ACCESSORIES

Page

2

of

35

FOREWORD

Read this manual before operation

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

It is compulsory to read this

instruction manual before starting operation. The assurance of

smooth operation and full compliance of machine performance is strictly dependent on the

rigorous application of all the instructions contained in this manual.

Operator Qualifications

Th

e workers responsible for using this machine must have all necessary information,

education and receive adequate training regarding safety, including:

a)

Conditions of use for the equipment;

b)

Foreseeable, abnormal situations;

c)

pursuant to art. 73 of Legislative

Decree no. 81/08.

We guarantee the Machine's conformity to the specifications and technical instructions

described in the Manual on the date of issuance and listed herein; On the other hand,

the machine may also be subject to important technical change

s in the future, without

the manual being updated.

Therefore, contact FERVI for information about modifications that may have been

implemented.

REV. 0

March 2013

fervi.com

MACHINES AND

ACCESSORIES

Page

3

of

35

TABLE OF CONTENTS

1

INTRODUCTION

................................

................................

........................

4

2

GENERAL SAFETY PRECA

UTIONS

................................

..............................

6

2.1

S

AFETY REGULATIONS FO

R THE

E

LECTRIC

W

INCH

................................

................................

..

7

2.2

S

AFETY REGULATIONS FO

R ELECTRICAL MACHINE

S

................................

................................

.

9

2.3

T

ECHNICAL

S

UPPORT

................................

................................

................................

.......

9

2.4

O

THER

P

ROVISIONS

................................

................................

................................

........

9

3

INTENDED USE AND DES

CRIPTION OF THE MACH

INE

.............................

10

3.1

I

DENTIFICATION PLATE

................................

................................

................................

..

12

3.2

B

UTTON MARKINGS

................................

................................

................................

.......

12

3.3

P

ICTOGRAMS AND WARNIN

GS

................................

................................

..........................

12

3.4

S

AFETY DEVICES ON THE

MACHINE

................................

................................

....................

13

4

TECHNICAL SPECIFICAT

IONS

................................

................................

.

15

5

MISUSE AND CONTRAIND

ICATIONS

................................

.......................

16

6

TRANSPORT

, LIFTING AND MOVING

................................

.......................

16

7

COMMISSIONING

................................

................................

....................

17

7.1

G

ENERAL

W

ARNINGS

................................

................................

................................

.....

17

7.2

I

NSTRUCTIONS TO REMOV

E PACKAGING

................................

................................

.............

17

7.3

I

NSTALLING THE CABLE

-

GUIDE

................................

................................

........................

17

7.4

E

LECTRIC WIRING

................................

................................

................................

.........

18

7.5

C

ONNECTING THE WINCH

TO THE SUPPORTING SU

RFACE

................................

........................

19

7.6

C

ONNECTING THE PUSH

-

BUTTON CONTROL PANEL

TO THE WINCH

................................

.............

20

7.7

C

ONNECTING THE PULLIN

G HOOK

................................

................................

.....................

21

7.8

P

RELIMINARY TESTING

................................

................................

................................

..

22

8

MACHINE OPERATION

................................

................................

.............

23

8.1

D

ANGERS WHEN USING TH

E MACHINE

................................

................................

................

23

8.2

C

HECKS BEFORE USE

................................

................................

................................

......

23

8.3

H

OOKING THE LOAD

................................

................................

................................

......

23

8.4

P

ULLING AND RELEASING

THE LOAD

................................

................................

..................

25

8.5

O

PERATING THE

W

INCH

:

................................

................................

................................

26

8.6

R

ELEASING THE LOAD

/

LOOSENING THE CABLE

................................

................................

...

27

9

MAINTENANCE

................................

................................

........................

28

9.1

R

OUTINE MAINTENANCE

................................

................................

................................

.

28

9.2

R

EPLACING THE STEEL C

ABLE

................................

................................

...........................

29

10

TROUBLESHOOTING

................................

................................

.............

30

11

CHECKS AND VERIFICAT

ION REGISTER

................................

...............

31

12

DECOMMISSIONING

................................

................................

.............

33

12.1

M

ACHINE DOWNTIME

................................

................................

................................

..

33

12.2

D

ISPOSAL OF

P

ARTS AND

M

ATERIALS

................................

................................

............

33

13

REPLACEMENT PARTS

................................

................................

...........

34

fervi.com

MACHINES

AND

ACCESSORIES

Page

4

of

35

1

INTRODUCTION

This manual is considered an integral part of the machine to which it is attached at the time

of pu

rchase.

The manufacturer holds the material and intellectual property of this publication and prohibits

its disclosure and copying, even partially, without prior written consent.

The purpose of this manual is to provide the knowledge necessary for the use

and

maintenance of the

Electric Winch (Art. 0630/2200)

, and create a sense of responsibility

and knowledge of the capabilities and limitations of the device entrusted to the operator.

Operators must be properly trained and prepared, so make sure that this

manual is read and

consulted by the staff responsible for commissioning, operation and maintenance of the

machine. This is to make all operations the safest and most effective possible for those who

carry out these tasks. Therefore, it is imperative to str

ictly comply with the requirements in

this manual, a necessary condition for safe and satisfactory operation of the machine.

Prior to the installation and use of the machine, authorised personnel shall:

read this technical documentation carefully;

know whi

ch protections and safety devices are available on the Winch, their location and

how they work.

The buyer is responsible for ensuring that users are properly trained, that they are aware of

all the information and instructions in this document and that th

ey are aware of the potential

risks of operating the Winch.

The manufacturer declines all responsibility for any damage to people and/or things

caused by non

-

observance of the instructions in this manual.

Users will be held fully responsible for any chan

ges made to the machine and the

manufacturer will not, therefore, be held responsible for any damage caused to

persons and/or property resulting from maintenance performed by unqualified

personnel and in a manner that differs from the operating procedures

shown below.

The

Electric Winch (Art. 0630/2200)

was designed and built with mechanical guards and

safety devices designed to protect the operator/user from possible injury.

It is strictly forbidden to modify or remove guards, safety devices and caution l

abels. If this

must be done (for example, for cleaning or repair), make sure that no one can use the

machine.

fervi.com

MACHINES AND

ACCESSORIES

Page

5

of

35

G

RAPHIC FORM OF THE A

LERTS RELATED TO SAF

ETY

,

OPERATION

,

RISK WARNINGS

The following boxes are designed to attract the attention of the reader /

user for the

proper

and

safe

use of the machine:

Pay Attention

This emphasizes behavioural rules to avoid damaging the machine and/or the occurrence of

hazardous situations.

Residual Risks

This emphasizes the presence of hazards causing residual r

isks which the operator must

watch for to avoid personal injury or material damage.

fervi.com

MACHINES

AND

ACCESSORIES

Page

6

of

35

2

GENERAL SAFETY PRECA

UTIONS

Even if you are already familiar with

Electric winches

you must read this manual carefully to

acquire full knowledge of the machine and genera

l precautions to be observed during

operation.

Pulling loads

Pulling loads

ALWAYS

entails a risk related to the possibility of the cable disconnecting,

even if it is managed properly.

An “intrinsically” safe device does

NOT

exist, in the same way tha

t a worker does

NO

t

exist who, with the proper care can “always” avoid accidents. Therefore, DO NOT

underestimate the risks associated with the use of the machine and concentrate on the

work at hand.

Risks associated with using the machine

Despite the

implementation of all the safety devices for safe use of the machine, it is

necessary to take note of all the requirements for the prevention of accidents reported in

various parts of this manual.

Risks associated with using the machine

Each person

who is responsible for the use and maintenance of the machine should have first

read the instruction manual and in particular the chapter on safety.

Use of PPE

Before starting any type of work with the Winch, the operator must wear appropriate persona

l

protective equipment (PPE) such as crush resistant safety gloves and shoes.

1.

Do not try to operate the machine at higher performance levels than those for which it

was designed,

in particular regarding the size of the load to be pulled.

In other

words,

do not make demands of the Winch in excess of its maximum pulling capacity.

2.

Use the Winch exclusively for pulling, and only in the manner and intended use described

in this instruction manual.

3.

Before starting pulling operations, always check:

the efficienc

y and integrity of the machine, and in particular the hooks, the steel cable

and brake;

the strength and integrity of the support structure to which the machine is attached

(truss, means of transport, etc);

the perfect state of the electrical wiring, the f

unctioning of the pull and release buttons.

4.

Keep the work area tidy and free of clutter; untidiness causes accidents.

5.

Make sure that children, unauthorized persons and animals are not allowed in the work

area.

6.

Only work with good lighting.

fervi.com

MACHINES AND

ACCESSORIES

Page

7

of

35

7.

Do not use the w

inch in humid environments. Do not expose the winch to rain.

8.

Do not use the winch in environments with potentially explosive atmospheres. Do not use

the winch in the presence of flammable liquids or gases.

9.

Disconnect the machine power cords from the batter

y when:

the machine is not being used for a long time;

the machine is left unattended;

performing maintenance or registration, because the machine does not work properly;

a power cord is damaged;

moving or transporting;

cleaning the machine.

10.

Wear appropria

te clothing. In particular, loose

-

fitting clothing and/or jewellery should not

be worn. It is a good idea to wear anti

-

slip shoes and electrically non

-

conductive clothing.

Tie up long hair.

11.

Do not step over the cable or winch when the cable is under tensio

n.

12.

Pay close attention to what you are doing! Do not use the winch if your psycho

-

physical

condition does not allow it.

13.

Do not leave any tools in the vicinity of the winch.

14.

It is recommended that users of this publication, for maintenance and repair, have

a basic

knowledge of the mechanical principles and procedures inherent in repair technique.

15.

Replace worn and/or damaged parts, check that protective devices work correctly before

operation. If necessary, have the machine checked by the Service Support pers

onnel.

Use only original spare parts !

16.

The staff responsible for using the machine must have read and understood this

manual in its entirety.

2.1

Safety regulations for the Electric Winch

Precautions for use

The electric winch is designed for intermitten

t use, and should not be used continuously in

harsh working conditions. The duration of work must be as short as possible. If the motor

shows signs of overheating (check the temperature by touch) stop the winch and wait a few

minutes for the machine to coo

l. Do not prolong use over 1 minute, when operating close to

the rated maximum load. Stop use if the motor show signs of fatigue.

1.

Never lift people or things above people.

Never lift things vertically. The Winch is NOT a lifting device, and is only

desi

gned for horizontal "pulling" of vehicles or other objects.

2.

Do not overload the Winch, beyond its maximum pulling capacity (2200 kg).

3.

The winch is not designed for continuous use. Do not use the electric winch for more than

one minute when pulling a load c

lose to the rated maximum load capacity.

4.

In the event of the motor overheating, wait for a few minutes for the machine to cool.

5.

Do not operate the Winch with the cable wound less than five times around the drum,

never unwind the cable to the end.

6.

Only wind

the cable with the load positioned in front of the winch. If the load is positioned

laterally, the winding of the cable is not optimal, causing wear and damage to the cable

or Winch.

7.

To achieve the maximum pulling capacity of the Winch it is necessary to

ensure that the

voltage between the poles of the motor is always 12 V DC.

fervi.com

MACHINES

AND

ACCESSORIES

Page

8

of

35

8.

Do not hook the cable to itself to pull a load, but use a harness.

9.

Do not use unsuitable extension cables to extend the length of the cable.

10.

Before using the Electric Winch, make sur

e it is securely fastened to a support or the

vehicle on which it is mounted.

11.

Before starting to pull the load, tighten the cable slowly until it is perfectly under tension.

Check that the load is securely hooked, especially if using a harness.

12.

It is good

practice to place a heavy rag on the cable (blanket, jacket, etc.) when pulling

heavy loads. In the event of the cable breaking the rag reduces whiplash.

13.

When operating the winch, do not move the vehicle on which it is mounted to increase

the pulling capac

ity: the sum of the two actions only causes the overloading of the cable

and the winch which damages them!

14.

Never stand near the Winch or the cable when pulling a load, or attempt to climb over the

cable. Stand at a distance of least 1.5 m.

15.

When operating t

he Winch, put the gearbox of the vehicle into neutral, apply the

handbrake and block the wheels with chocks. Keep the motor running to avoid draining

the battery.

16.

Do not attempt to unlock the Winch drum during operation.

17.

Loosen the cable immediately after

having finished pulling the load.

18.

Keep the cable, hook and Winch well cleaned.

19.

Frequently inspect the cable and Winch. If the cable is worn replace it immediately. Use

only original accessories.

20.

Always wear protective gloves and never let the the cable run

through your hands when

pulling loads.

21.

Do not insert your fingers into the hook to prevent them from becoming trapped: you

could lose your finger! To unwind the cable from the drum use the appropriate safety

pull

-

cable belt.

22.

Do not put your hands or cloth

ing near the cable guide when using the winch.

23.

Wind up the cable in such a way that the turns are tight and compact on the drum.

24.

Do not operate the Winch when under the influence of drugs, alcohol or medication.

During operation maximum attention is requir

ed.

25.

Do not make any changes and do not perform welding on the Winch. Any interventions of

this kind may affect the structural integrity of the Winch and its proper functioning, and

will render the warranty null and void.

26.

Perform routine maintenance in acco

rdance with the plan provided by the manufacturer.

Frequently check the condition of your Winch.

fervi.com

MACHINES AND

ACCESSORIES

Page

9

of

35

2.2

Safety regulations for electrical machines

Modifications to the electrical system

Do not modify the electrical system in any way. Any attempt in this regar

d may

jeopardise the operation of electrical devices, causing malfunction or accident.

Work carried out in the electrical system of the machine must, therefore, be carried out

only by qualified and authorized personnel.

If you hear unusual noises, or notic

e anything unusual, stop the machine immediately.

Then, carry out an inspection and, if necessary, perform any repairs as required.

1.

The supply voltage must correspond to that stated on the label and in the technical

specifications (12 V

DC

).

Never use any

other type of power supply.

2.

Extension cable diameters must be equal to or greater than the machine's power cable

diameter. In any event, the end of the cable must be provided with a terminal for

connection to the battery.

3.

Make sure that the power cords an

d extension cords do not come into contact with hot

objects, wet or oiled surfaces, and/or sharp edges.

4.

The power cords and extension cords should be checked regularly and before each use to

check for signs of damage or wear. If these are not in good condi

tion, do not use the

machine, and replace the damaged cable.

5.

Do not use the power cords to lift the machine.

2.3

Technical Support

For any problems or concerns, please contact, without hesitation, the Customer Service

Department of your dealer, who has compet

ent and specialised staff, specific equipment and

spare parts.

2.4

Other Provisions

A

LTERING

S

AFETY

D

EVICES IS

P

ROHIBITED

The first thing to do when starting work is to check the presence and integrity of the guards

and the operation of safety devices.

If any

defect is detected, do not use the Electric Winch!

fervi.com

MACHINES

AND

ACCESSORIES

Page

10

of

35

3

INTENDED USE AND DES

CRIPTION OF THE

MACHINE

The

Electric Winch (Art. 0630 / 2200)

is a device to be used for the horizontal "pulling" of

vehicles or other loads that move on a horizontal flat surface (or

slightly tilted). It can be

mounted on vehicles such as agricultural tractors, cars, trucks, three

-

wheeled vans, means

for roadside assistance, boats, etc.

Prohibited Use

The Winch is NOT a lifting device.

It is absolutely forbidden to lift objects v

ertically.

The winch is not designed for continuous use, nor to be used in an industrial environment. To

use the machine, it must be fixed to a stable and sufficiently resistant support structure.

To unlock the drum it is necessary to move the lever, so

that the drum is no longer

integrated with the transmission, allowing the cable to be freely pulled manually. The cable

-

guide device is positioned in front of the drum. This device reduces the slack and the curling

of the cable.

The machine can operate out

doors, provided it is protected from the weather and, in

particular, from rain and strong wind. Protect the machine from frost, especially if it is

not in use. Moreover, the environment of use must be sufficiently illuminated, so as

to ensure safe operatio

n.

Intended use and maximum pulling capacity

The machine was designed for a specific use, different uses and non

-

compliance with

the technical parameters established by the Manufacturer may constitute dangerous

conditions for the operator. In the event

of said different uses, the manufacturer cannot

accept any responsibility for any resulting damages.

Pulled loads must NOT exceed the envisaged maximum pulling capacity.

fervi.com

MACHINES AND

ACCESSORIES

Page

11

of

35

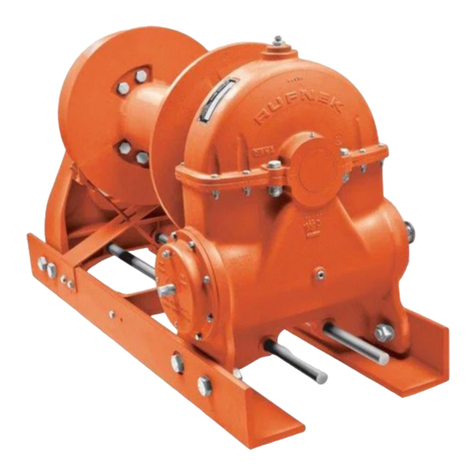

The

Electric Winch (Art. 0630 / 2200)

is composed of (

Figure

1

):

1

-

Push

-

button cable socket;

2

-

Coils box;

3

-

Coupling eyelet;

4

-

Steel cable;

5

-

Running rollers / cable

-

guide;

6

-

Drum;

7

-

Frame;

8

-

Warning plate;

9

-

Transmission activation lever;

10

-

Electric motor;

11

-

Power cord connection terminals.

Figure

1

Close

-

up of the main parts of the electric winch.

fervi.com

MACHINES

AND

ACCESSORIES

Page

12

of

35

3.1

Identification plate

An identification plate with CE marking is attached to the machine (

Figure

2

)

:

Figure

2

CE Plate.

M

AX

IMUM

P

ULLING

C

APACITY

V

ALUE

Indicated on the CE plate is the

Maximum Pulling Capacity.

This “maximum pulling capacity” value must not be exceeded under any

circumstance!!

3.2

Button markings

On the portable push

-

button panel, there are symbols indicating th

e machine's direction of

movement.

The arrows indicate the direction of the cable when winding up and/or winding out.

3.3

Pictograms and warnings

There is a warning label on the cable

-

guide, as shown

here at the side.

On the motor body, near the transmi

ssion lever, there is

a warning label, as shown here at the side.

Lift to unlock the drum!

WARNING

Disconnect the power supply

ATTENTION!

Avoid damage to

the cable

fervi.com

MACHINES AND

ACCESSORIES

Page

13

of

35

3.4

Safety devices on the machine

The main safety devices present on the machine are:

the

pawl device

, when the cable is under tension;

the

cable

-

guide device and upper line stop

, to allo

w the correct winding of the cable

on the drum and to prevent the hook from knocking against the drum, at the end of the

winding phase (

Figure

3

);

The

hook closure safety device

is there to prevent the load from accidentally becom

ing

disconnected during normal use (

Figure

4

).

The

pawl device

acts by exploiting the characteristic of the

gears with a high reduction ratio which prevents the

retrograde motion. This phenomenon is guaranteed up t

o

the maximum pulling capacity: this load must not be

exceeded, as it can result in the unwinding of the cable!!!!

The

cable

-

guide and line stop

device is a mechanical

stop which allows the winding of the cable on the drum in a

correct and orderly way and

, above all prevents the hook

from wrapping onto the drum at the end of the stroke and

damaging it (

Figure

3

).

Figure

3

Close

-

up of the

cable

-

guide / line stop.

Overheat

ing and damage to the motor

It is good practice to avoid keeping the pull button pressed down, once the hook reaches its

line end, as the motor could suffer irreversible damage.

The

hook closure safety device

(

Figure

4

)

safeguards against the dangers due to the uncoupling /

disconnection of the load during pulling.

Figure

4

-

Closure device.

Use of PPE

In any case, ALWAYS use appropriate PPE (

Figure

5

) such as:

Gloves;

Safety shoes.

fervi.com

MACHINES

AND

ACCESSORIES

Page

14

of

35

Figure

5

-

Personal Protective Equipment PPE.

fervi.com

MACHINES AND

ACCESSORIES

Page

15

of

35

4

TECHNICAL SPECIFICAT

IONS

Description (unit of measurement)

Art. 0630 / 2200

Rate

d load capacity (kg)

2000

Reduction ratio of the transmission

172:1

Motor type

A permanent magnet

Motor power (kW)

2.4

Voltage (V)

12 DC

Drum dimensions D x L (mm)

45 x 97 mm

Cable length (m)

14.5

Diameter of the steel cable (mm)

6.4

Weight (kg)

1

3

Overall dimensions L x W x H (mm)

364 x 126 x 141

Pulling force and speed as a function of absorbed current (1

st

winding)

Pulling Force (kN)

0

4.5

9

13.3

17.8

Pulling Speed (m/min.)

2.1

1.9

1.7

1.6

1.5

Current absorption (A)

30

50

70

100

130

Pull

ing force and capacity of the drum as a function of the windings.

No. of Windings

1

2

3

4

5

6

Pulling Force (kN)

17.8

15

12.5

11

9.8

/

Drum capacity (m)

2.2

4.7

7.5

10.5

13.5

16

fervi.com

MACHINES

AND

ACCESSORIES

Page

16

of

35

5

MISUSE AND CONTRAIND

ICATIONS

The following actions described, which obvi

ously can not cover the entire range of potential

"misuse" of the machine, are to be considered

strictly prohibited

.

IT IS STRICTLY FORBIDDEN !!

To use the winch for lifting loads (vertical pull). The Winch is not a lifting device.

To lift people, anim

als or things;

To pull loads weighing more than the

MAXIMUM

PULLING CAPACITY of the Winch

indicated on the rating plate.

To repeat the PULL command if the load is greater than that allowed, the motor is not

equipped with thermal protection and over

-

current

s can cause overheating and burn

the windings;

To pull loads placed laterally and not frontally;

To operate without having verified that the hooks are properly closed;

To attach the Winch to a fixed structure or a vehicle with insufficient strength;

To lea

ve the Winch unattended with the cable in tension;

To introduce objects or body parts between the steel cable while winding and the drum;

To operate the Winch with less than five turns wound on the drum;

To move the vehicle on which the Winch is mounted to

increase the pulling force;

To stand less than 1.5 m from the winch or cable, when the cable is under tension;

To allow untrained personnel to use the Winch;

To use the Winch when not psycho

-

physically fit to do so;

To use the Winch without due care and a

ttention;

To use the Winch for purposes other than those for which it was designed;

To use the Winch in adverse and/or unexpected environmental conditions (strong wind,

rain, high humidity, low light etc.);

To attempt to unlock the drum while pulling a loa

d;

To use the Winch in potentially explosive environments.

6

TRANSPORT, LIFTING A

ND MOVING

Moving the Winch for transport purposes can be done manually by a single operator (machine

weight about 18 kg).

Before moving the

Electric Winch

, completely wind up t

he pulling cable around the drum

and collect all power cords and the push

-

button panel.

fervi.com

MACHINES AND

ACCESSORIES

Page

17

of

35

7

COMMISSIONING

7.1

General Warnings

The following chapters are the core of the manual, and contain the actual operational

instructions on how to install, operate and mainta

in the

Electric Winch

(Art. 0630 /

2200).

The installation and commissioning of the machine, due to the delicacy and importance

involved, may lead, if poorly executed, to serious risks to the safety of people exposed at this

stage or with subsequent use of

the machine.

7.2

Instructions to remove packaging

The

Electric Winch

is supplied partially assembled in a cardboard box. The following parts

are supplied

Connection plate;

Cable

-

guide device;

Pulling hook;

Portable push

-

button control panel with power cord;

Bolts and relative safety washers for connection.

Before disposing of the packing cardboard, check that no parts of the machine, the user's

manual or other documentation are thrown away. Check that all the parts supplied as

standard are present.

Standar

d packaging

Packing materials (plastic bags, polystyrene foam, etc.) must not be left within reach of

children as it would constitute a source of potential danger.

7.3

Installing the cable

-

guide

First of all, the cable

-

guide device must be attached to the w

inch, in front of the drum. The

fastening screws must be inserted in holes “A” and “B”

(

Figure

6

) of the cable

-

guide.

Figure

6

Cable

-

guide / mounting the cable

-

guide.

Installing the cable

-

guide

Care should be taken to install the Winch with the cable coming out of the lower position of

the drum (

Figure

6

) !!

A

B

fervi.com

MACHINES

AND

ACCESSORIES

Page

18

of

35

7.4

Electric wiring

After checking that the power supply voltag

e corresponds to that indicated on the rating plate

(12 V

DC

), the Winch can be connected to the battery.

To make the connections it is necessary to use two pairs of

wires which come out of the coils box "C" (see figure 8).

The pair that exits from the rea

r is formed by two long

wires, one is red and the other is black. The red wire should

be connected to the positive (+) battery terminal, and the

black wire should be connected to the negative terminal (

-

).

Figure

7

Coils box and wires.

The coils box acts as a support for the winch motor.

Once the winch has been positioned on the box,

connect the two short wires protruding behind to the

respective motor terminals "D" and "E", as shown in

Figure

8

.

Figure

8

Connecting the

winch.

Connecting the motor

Check that the direction of rotation of the drum corresponds to that indicated on the

command buttons!

In the event the dire

ction of rotation is not correct, reverse the connection of the

electrical terminals of the Winch motor.

D

E

C

fervi.com

MACHINES AND

ACCESSORIES

Page

19

of

35

7.5

Connecting the winch to the supporting surface

The Winch must be mounted on a suitable support structure, with adequate resistance

characteristics.

This structure must be able to withstand the stresses resulting from operating

the Winch (max pulling capacity 2200 kg).

In this regard it would be possible for example to use the most robust parts or sections of the

chassis of the motor vehicles.

The winc

h is supplied already assembled to the connecting plate, which is fixed by four bolts

and the relative safety washers.

Mounting the Winch

It is necessary to remember that the winch is designed to operate on a horizontal plane, not

vertical.

In order

to fix the winch properly it is necessary to use the two shims, the bolts and the

relative washers supplied (

Figure

9

).

Figure

9

Shims, bolts and washers.

Not

e how the hole “F” on the shim is not centred, as

shown in

Figure

9

.

First insert the screws into the two holes on the

connecting plate with the screw head at the top.

Insert the two shims in the part below, making

sure to

position them in such a way that the holes are facing

inwards, as shown in

Figure

10

.

Figure

10

Shims, bolts and

washers.

F

F

fervi.com

MACHINES

AND

ACCESSORIES

Page

20

of

35

To secure the winch to t

he support surface it is necessary to drill two holes with a

diameter that will allow the screws to pass through, spaced apart by 94 mm (distance

between the respective centres).

Place the winch on the support surface, so that the holes line up. Fit the w

asher and

safety washer on the screw and tighten the nut.

Mounting the Winch

ALWAYS check that the connection screws of the Winch are fully tightened, before operating

with loads.

7.6

Connecting the push

-

button control panel to the winch

To connect the p

ush

-

button control panel to the electric winch just insert the plug "G" of the

cable into the socket "H", located at the front on the coils box (

Figure

11

).

Figure

11

Connecting the push

-

button panel to the winch.

G

H

fervi.com

Table of contents

Other Fervi Winch manuals