Sheet entry angle

must be at least 8°.

Mount the Winch

7Determine Winch Location

Make sure there is clearance for Motor and Reduction Gearbox.

Drill an 127 mm hole through the deck.

8Position Drive Gear/Secure Mounting Base

Make sure Mounting Base sits flat on deck.

Position so Drive Gear aligns to sheet load (see Step 13)

Mark the six (6) mounting holes, drill deck.

Use bedding compound/sealant to prevent leakage.

Secure Mounting Base using five (5) 8 mm (B56) or 10 mm (B64

and up) countersunk screws.

9

Attach Motor/Gearbox Assembly to Mounting Base

Have another person below deck to position gearbox underneath winch.

12 IMPORTANT - Test Winch Operation

After winch is assembled, test operation in manual mode only,

before sailing. Important - use a lock-in winch handle.

Using a locking winch handle, check winch operation.

Disconnect rod must disconnect gearbox when lock-in

winch handle is inserted in Handle Socket.

11 Assemble Winch

Use steps 1 - 9 in reverse order to assemble winch.

10

Attach Winch

Tighten the six (6) bolts securing Winch to Mounting Base.

Use blue Loctite®on threads.

Use brush to lightly lubricate gear with grease

Position drive gear

where sheet enters

winch drum.

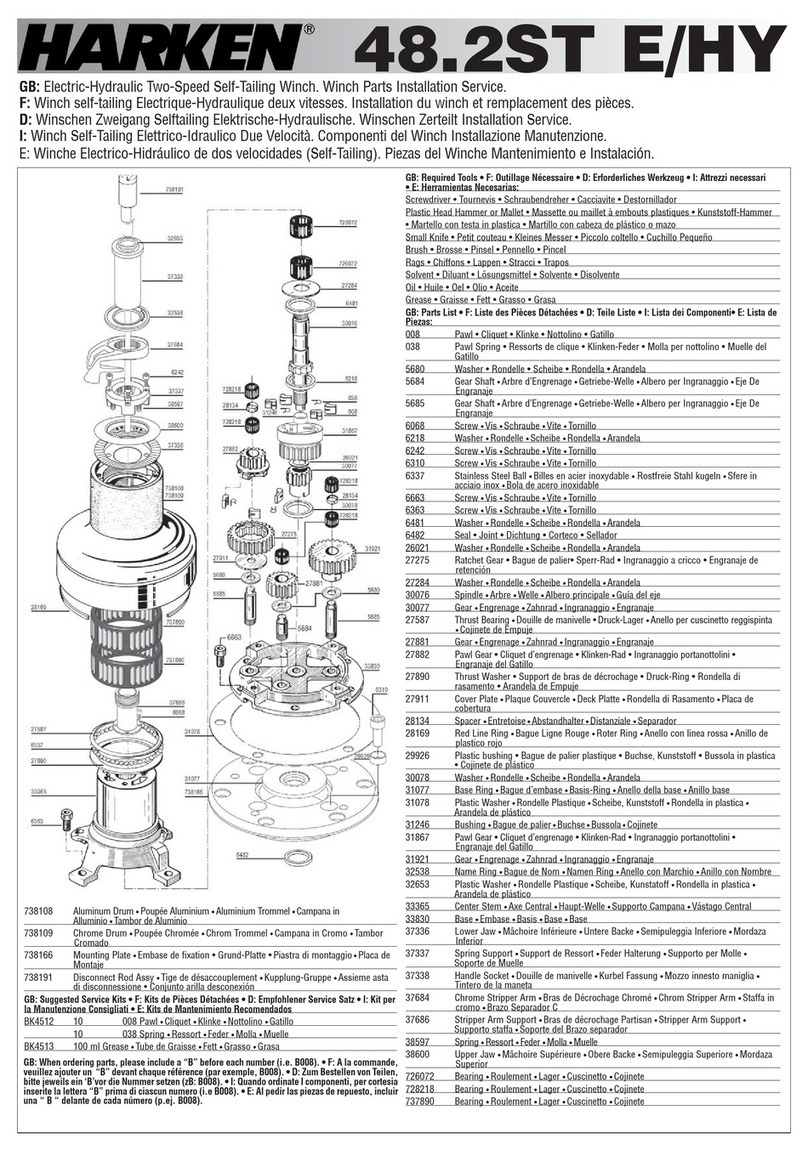

■Minimum/Maximum Line Diameter

Harken winches feature spring-loaded self-tailing jaws

which adjust automatically to the following line sizes:

Minimum

5

/

16

" (8 mm)

Maximum

1

/

2

" (12 mm)

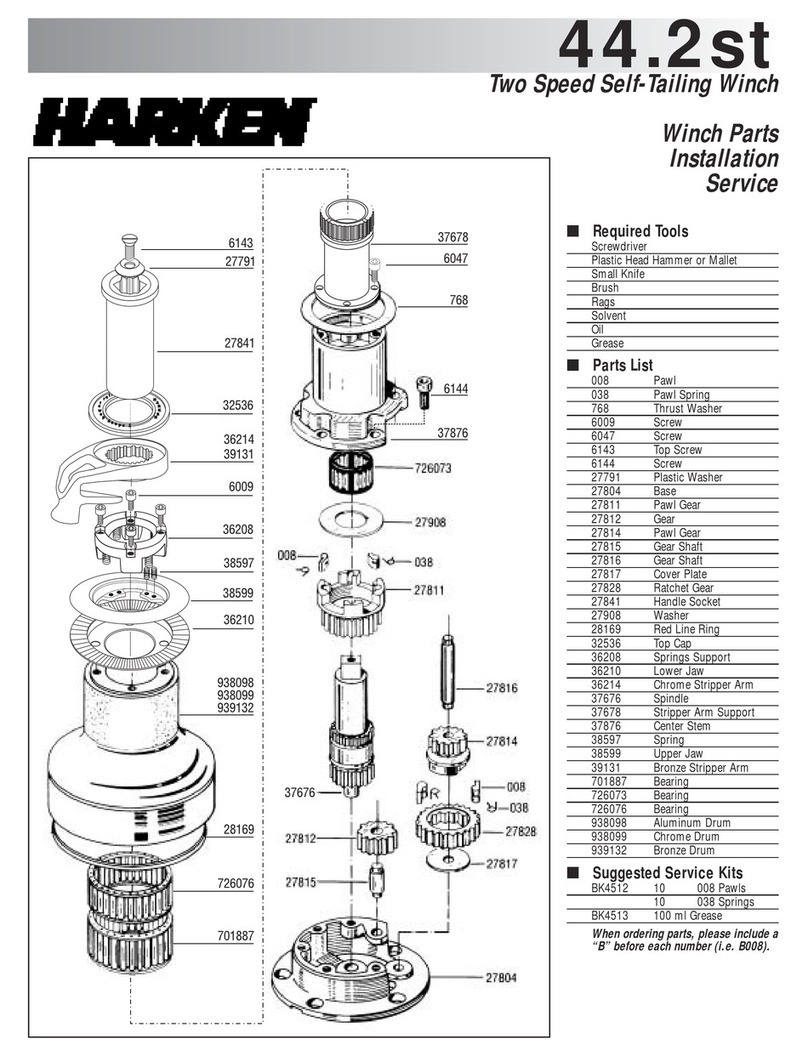

■Positioning Stripper Arm

Loosen top Screw.

Remove Handle Socket.

Lift Stripper Arm and position as desired.

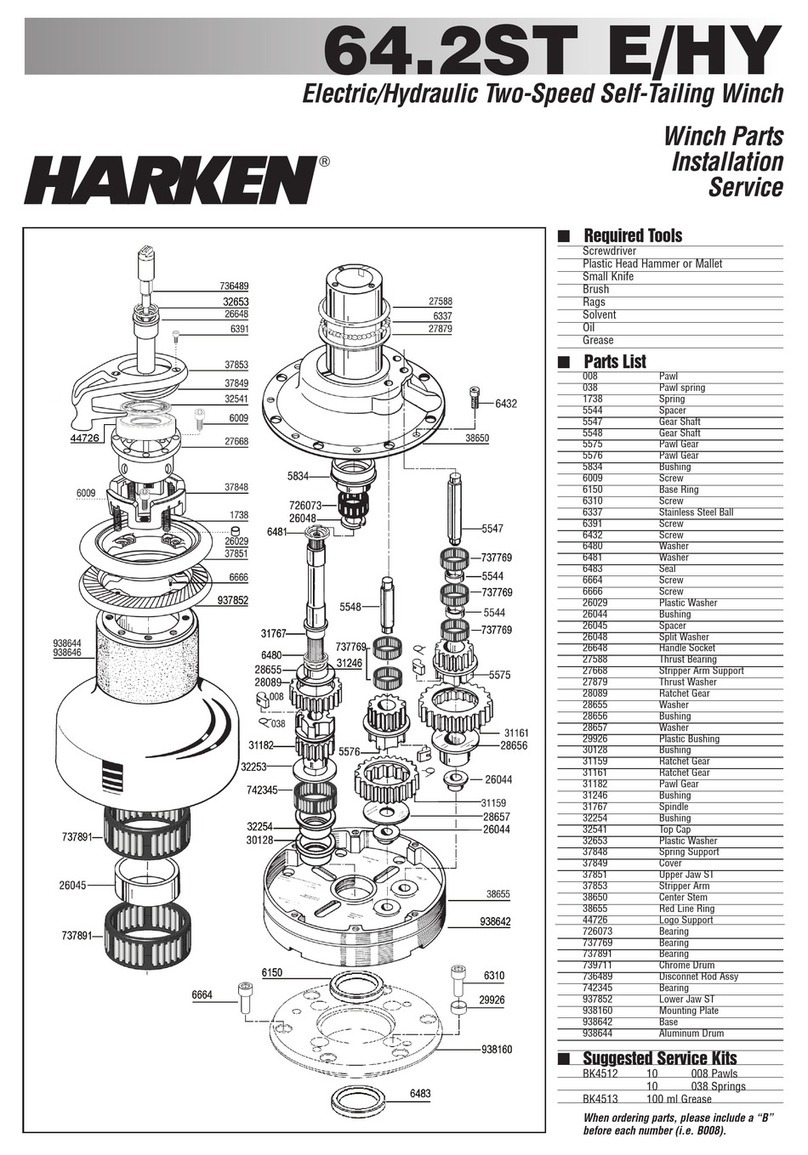

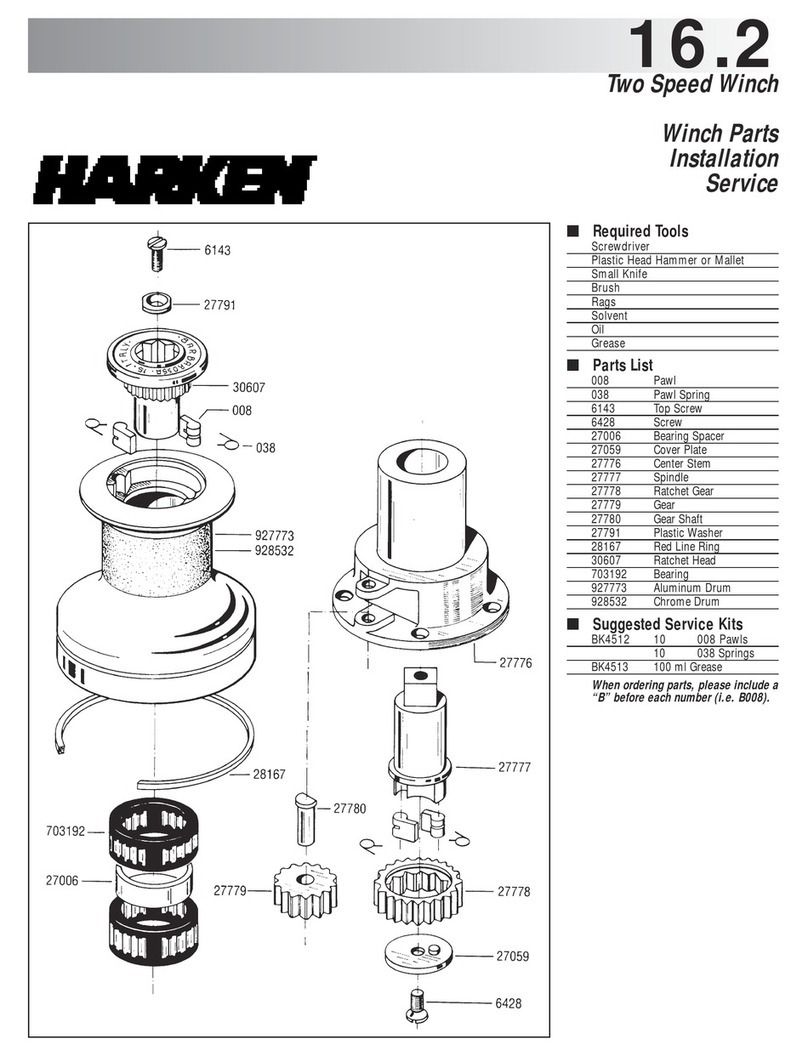

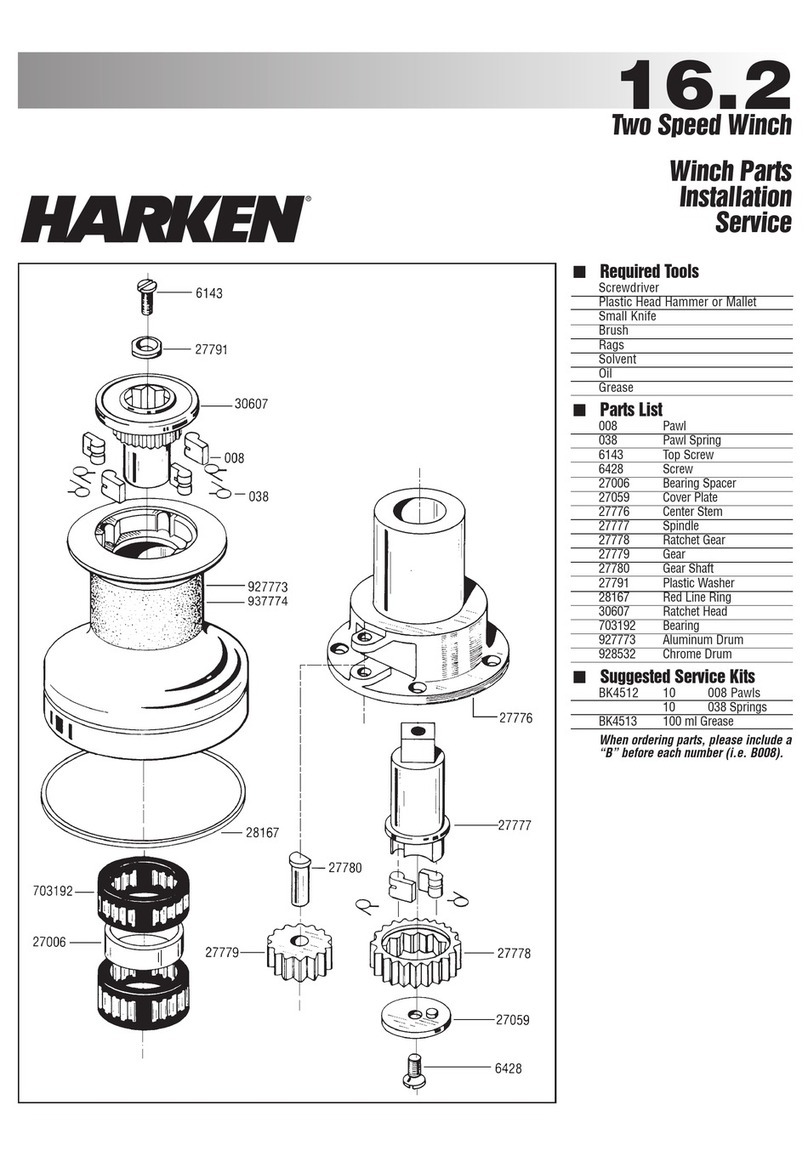

■Opening Winch

Remove top Screw.

Lift off Drum and Stripper Arm.

■Servicing Winch

Remove Pawls and Springs - service as below.

Remove Bearing, Gear Shaft and Gears.

Clean all parts except 37383 and 38598 with rag and solvent.

Important: Use freshwater only on parts 37383 and 38598

Use brush to lubricate all moving parts lightly with grease.

Replace Pawls and Springs and lubricate lightly with oil.

Assemble and close winch.

■Servicing Pawls

Catch Spring with knife and hold against Pawl.

Lift out Pawl. Clean and check for wear.

Place “straight leg” of Pawl Spring against Pawl.

Hold Spring closed and slip Pawl into Pawl Socket.

Lubricate Pawls using oil.

Service winch before the sailing season begins and once during

Clean all parts, except 37383

and 38598, with solvent.

Correct Incorrect

If ratchet gear is mounted

backwards, winch will slip.

Use a brush to spread a light,

even coat of grease.

Use knife to free captive Pawl

Spring. Insert Pawl Spring with straight leg

against Pawl. Use oil for lubrication.

Servicing Winch

Servicing Pawls

Pawl

Socket

13

127 mm