3Festo — EGSC-BS-KF — 2018-11c

1 About this document................................................................................................... 4

2 Safety........................................................................................................................... 4

2.1 Safety instructions........................................................................................................ 4

2.2 Intended use................................................................................................................ 4

2.3 Training of qualified personnel..................................................................................... 4

3 Additional information................................................................................................ 4

4 Service..........................................................................................................................4

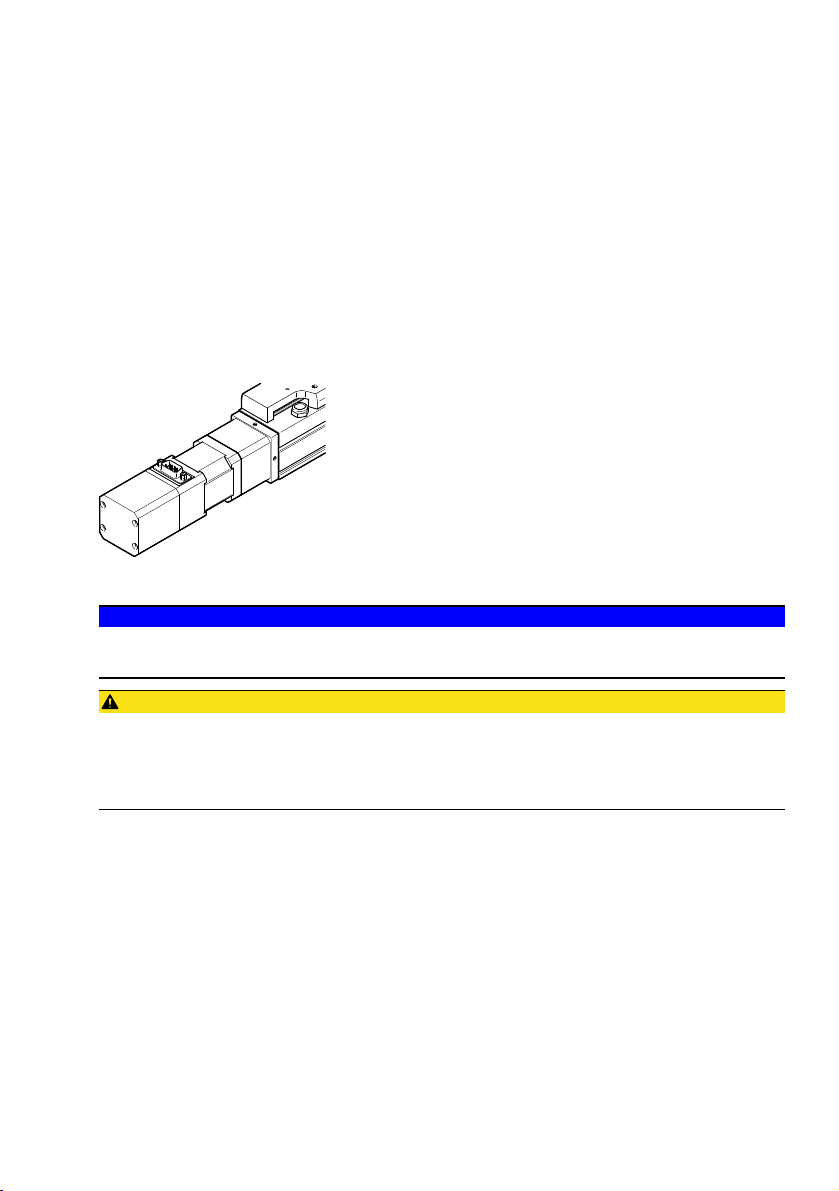

5 Product overview......................................................................................................... 5

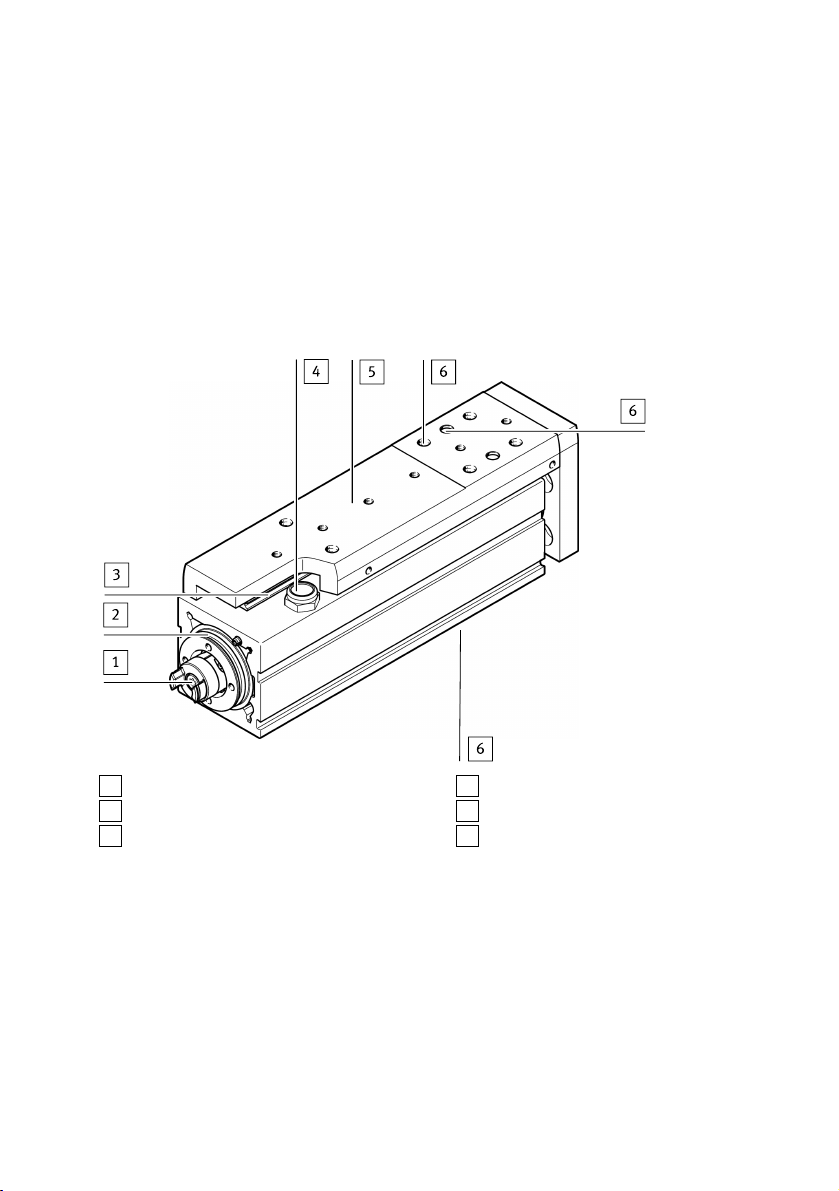

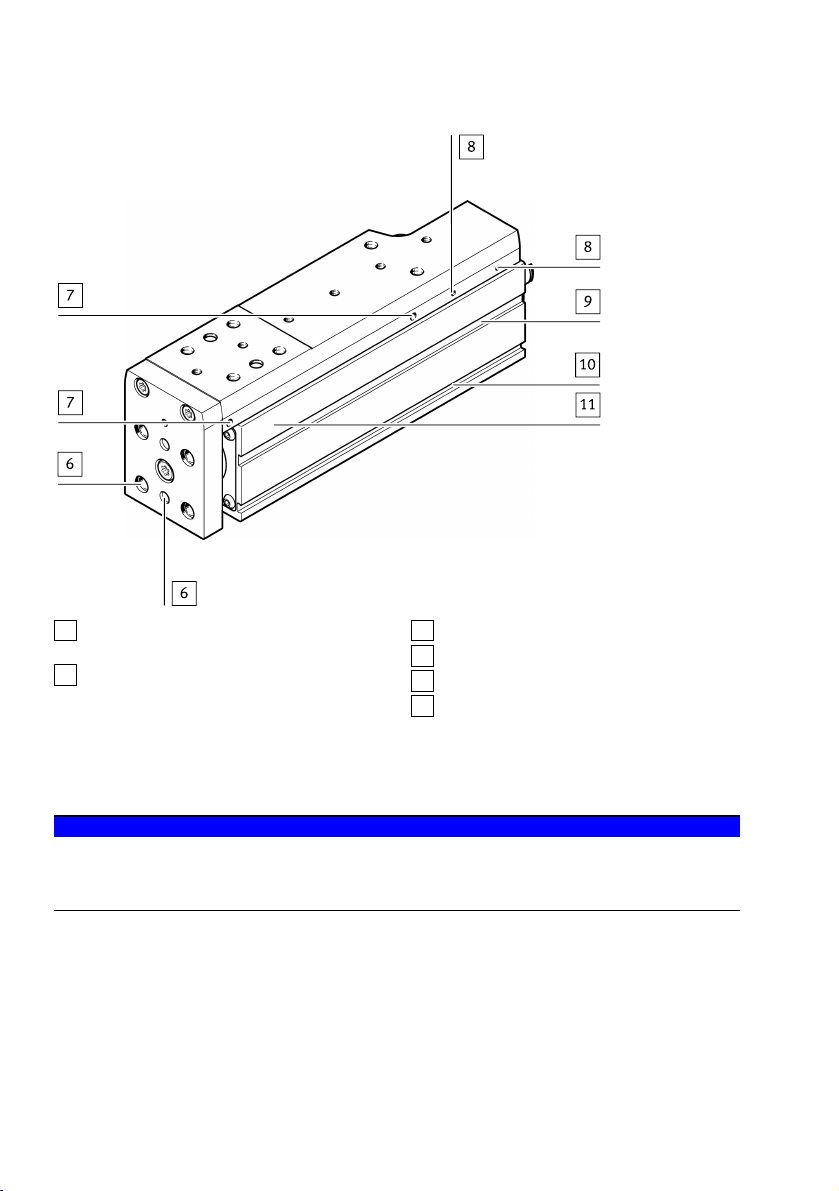

5.1 Function....................................................................................................................... 5

5.2 Design........................................................................................................................... 5

6 Transport..................................................................................................................... 6

7 Assembly..................................................................................................................... 7

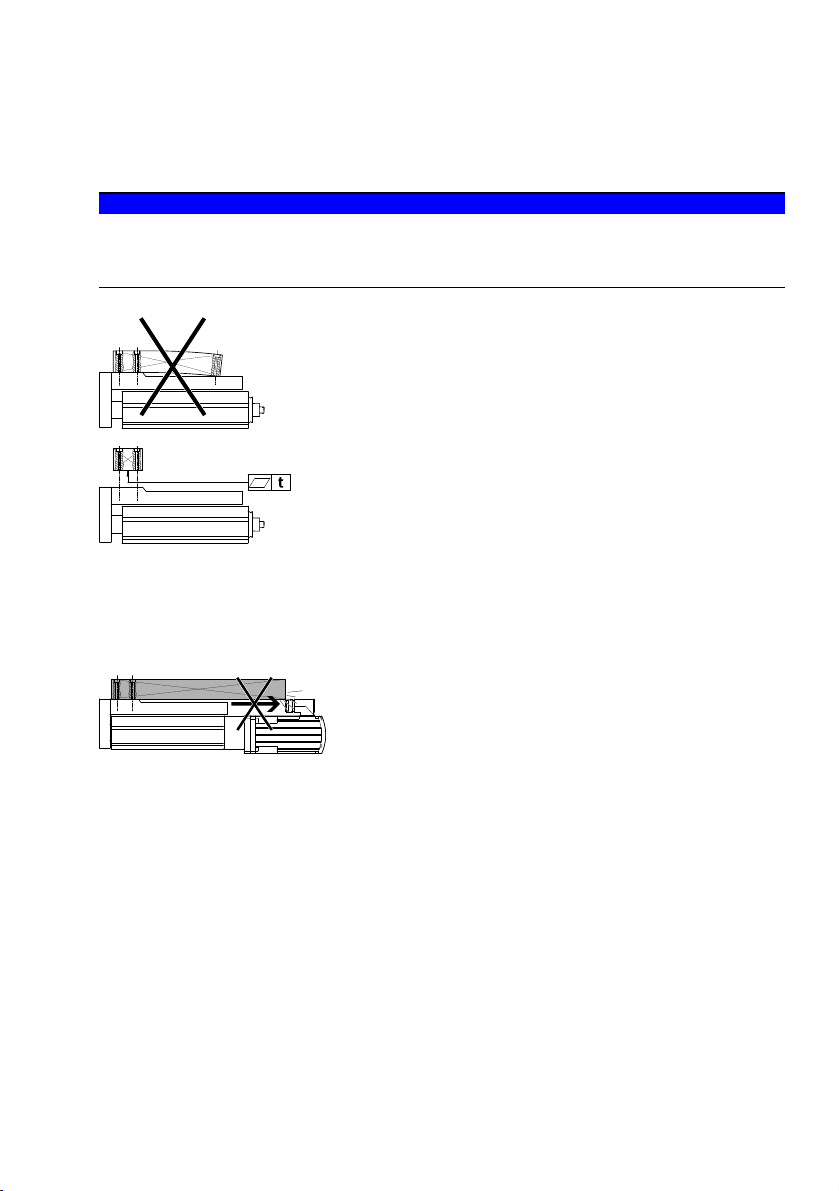

7.1 Preparation................................................................................................................... 7

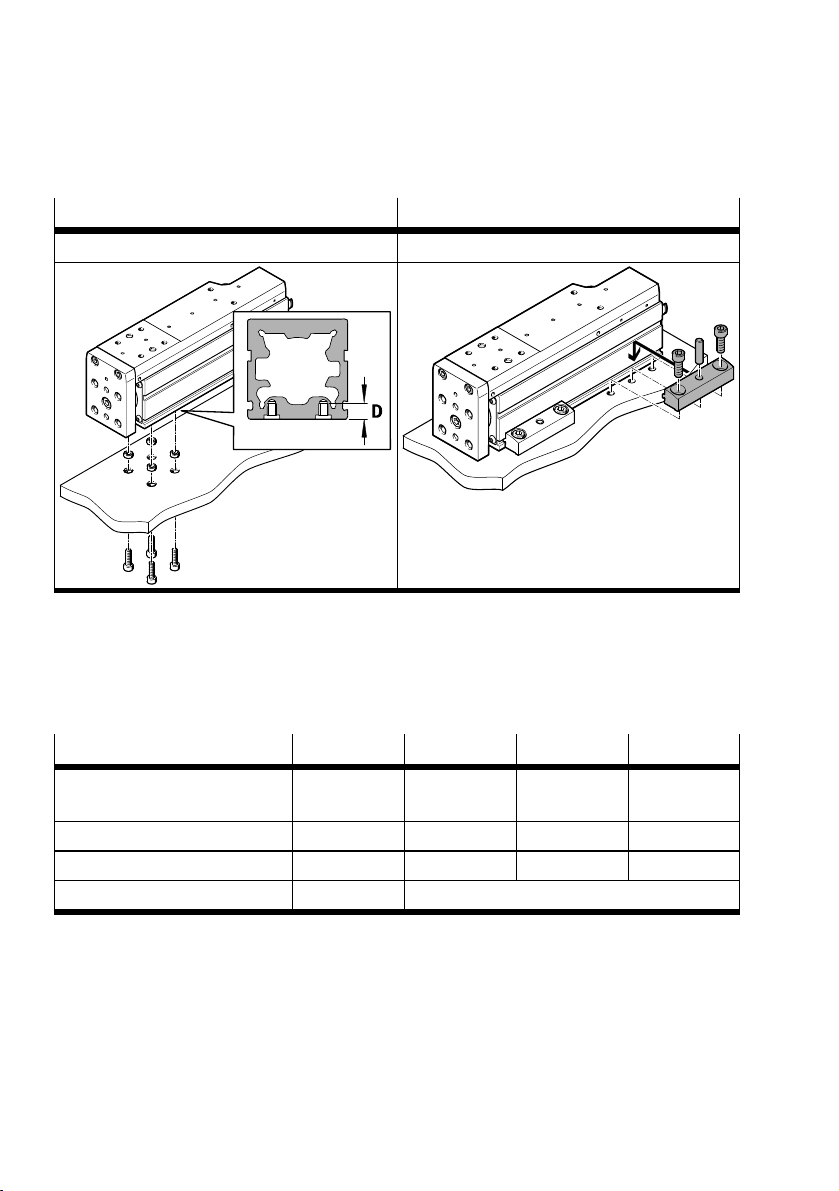

7.2 Mounting...................................................................................................................... 8

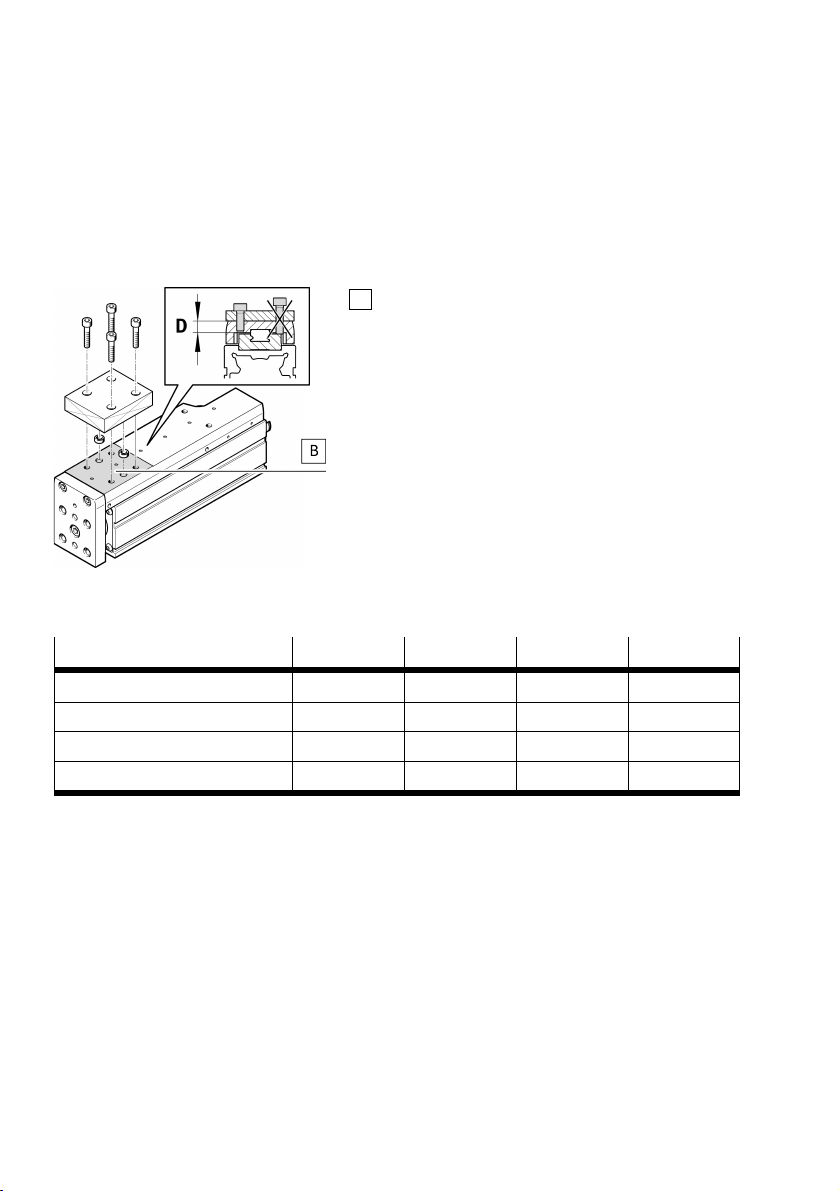

7.3 Attachment................................................................................................................... 9

7.4 Mounting accessories................................................................................................... 10

8 Commissioning............................................................................................................ 12

9 Service..........................................................................................................................13

10 Disassembly................................................................................................................ 14

11 Disposal........................................................................................................................14

12 Fault clearance............................................................................................................ 15

13 Technical data............................................................................................................. 16

Table of contents