Festo PDAD 1701g English | 3

Table of contents

1. Introduction .................................................................................................................. 4

2. Safety............................................................................................................................ 5

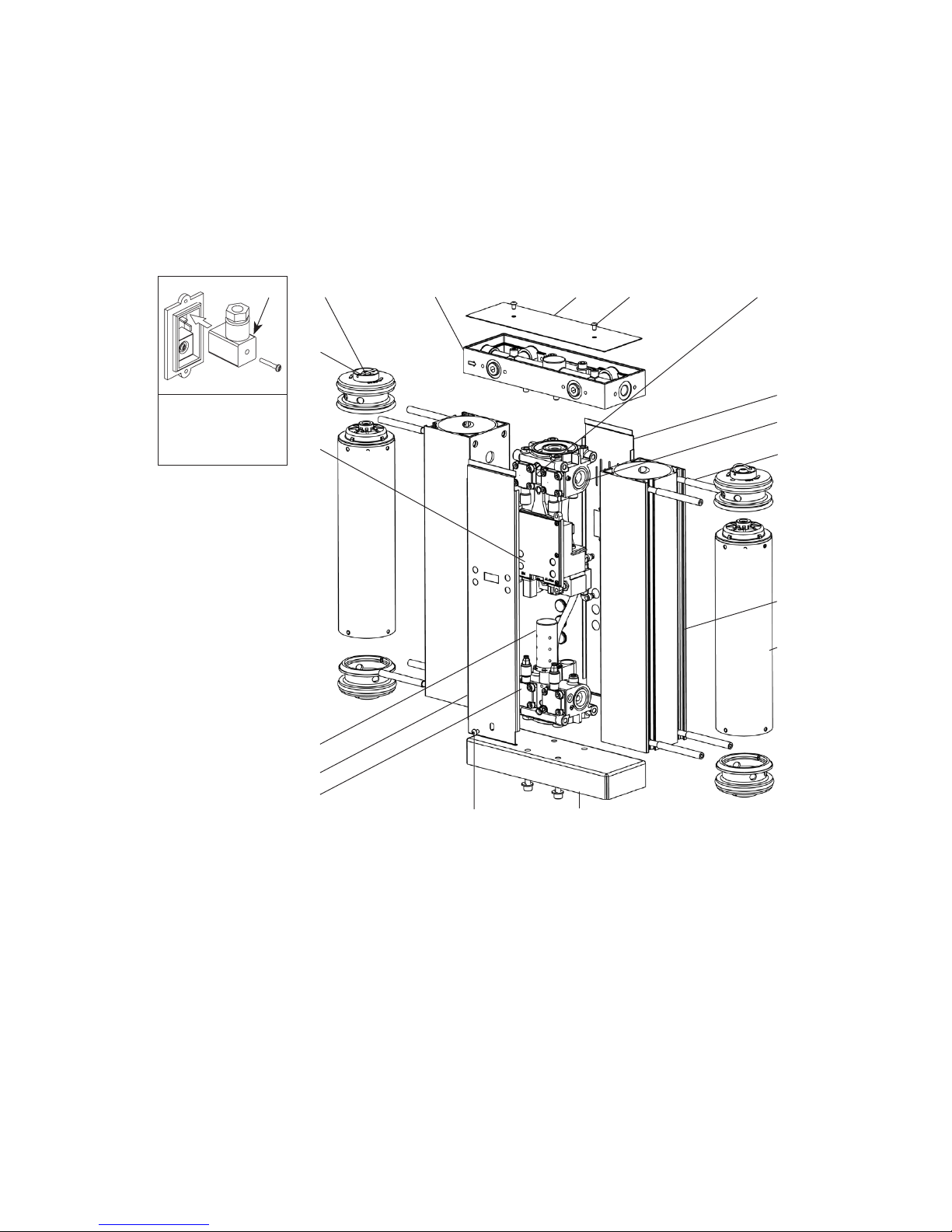

3. Component designation................................................................................................ 7

3.1 Overview....................................................................................................................... 7

3.2 Electronic controller 2................................................................................................ 9

3.3 Multiple distributor aJ ................................................................................................ 9

3.4 Desiccant cartridge with integrated dust filter 9........................................................ 9

3.5 Reservoir 7................................................................................................................. 9

4. Function ...................................................................................................................... 10

5. Installation.................................................................................................................. 11

5.1 Mounting the micro filter on the dryer ........................................................................ 11

5.2 Pneumatic connection................................................................................................. 13

5.3 Assembling the mounting accessories on the dryer.................................................... 14

5.4 Changing the connections for the inlet and outlet ...................................................... 15

5.5 Installation conditions ................................................................................................ 16

6. Power supply .............................................................................................................. 17

6.1 Voltage connection ..................................................................................................... 17

6.2 Power supply socket connection................................................................................. 18

6.3 Alarm connection ........................................................................................................ 19

7. Commissioning ........................................................................................................... 20

8. Maintenance and care................................................................................................. 22

8.1 LED displays................................................................................................................ 22

8.2 Decommissioning for maintenance purposes ............................................................. 24

8.3 Maintenance and service ............................................................................................ 24

8.4 Removing/installing the front or rear cover ................................................................ 25

8.5 Replacing or cleaning the air nozzle............................................................................ 26

8.6 Cleaning the silencer................................................................................................... 27

8.7 Resetting the controller .............................................................................................. 28

9. Troubleshooting.......................................................................................................... 29

9.1 General fault finding ................................................................................................... 29

9.2 Electrical troubleshooting ........................................................................................... 30

10. Accessories................................................................................................................. 31

11. Technical data............................................................................................................. 32