3Festo — PDAD — 2020-05h

1 About this document................................................................................................... 5

1.1 Applicable documents.................................................................................................. 5

1.2 Product labelling.......................................................................................................... 5

2 Safety........................................................................................................................... 5

2.1 Safety instructions........................................................................................................ 5

2.2 Intended use................................................................................................................ 5

2.3 Training of qualified personnel..................................................................................... 5

2.4 Approvals..................................................................................................................... 6

3 Further information..................................................................................................... 6

4 Service..........................................................................................................................6

5 Product overview......................................................................................................... 6

5.1 Product range overview................................................................................................ 6

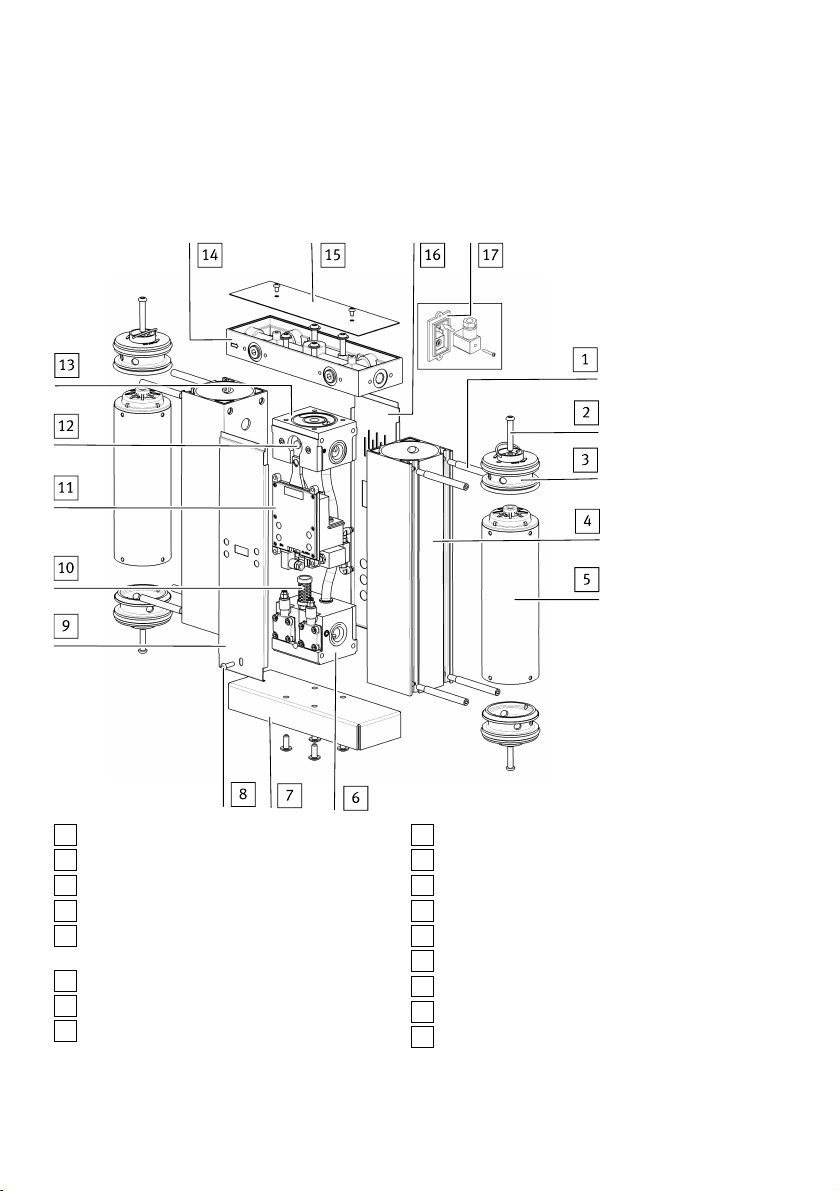

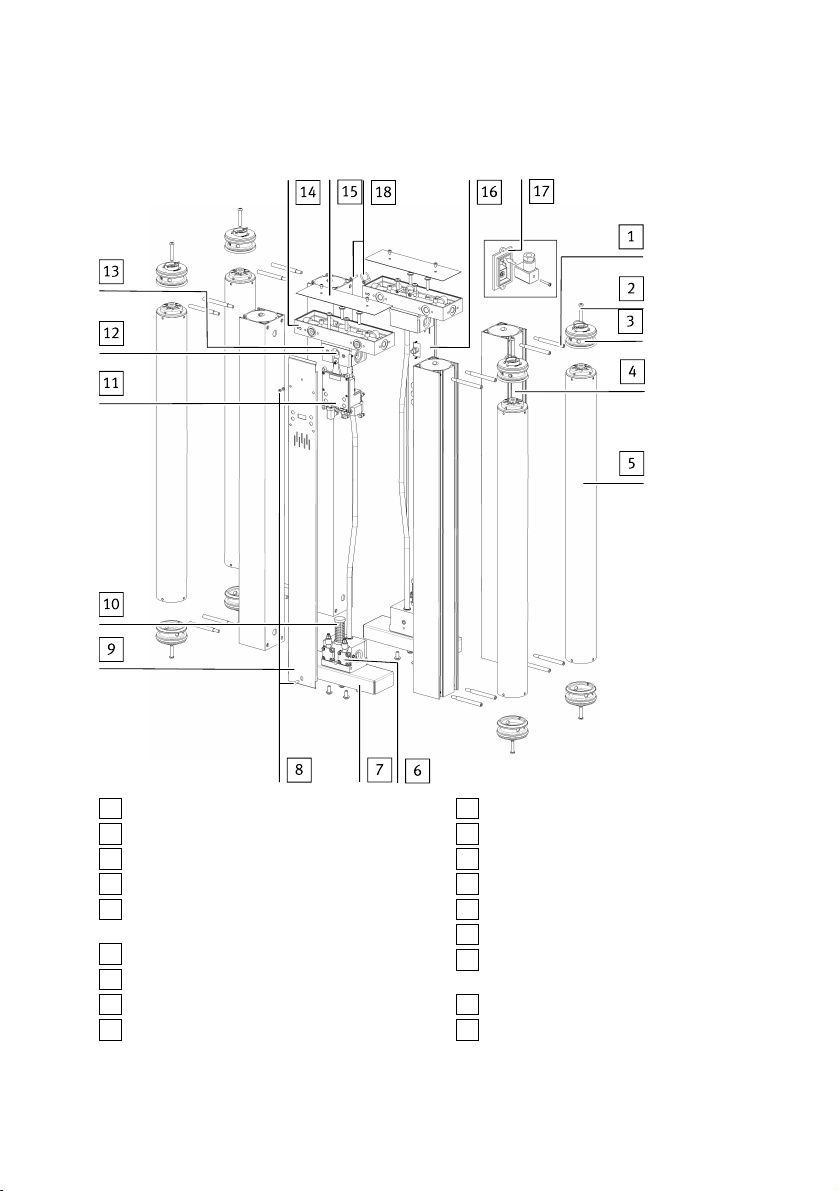

5.2 Design........................................................................................................................... 8

5.2.1 Overview.................................................................................................................8

5.2.2 Electronic controller................................................................................................10

5.2.3 Multi-way distributors.............................................................................................10

5.2.4 Drying agent cartridge with integrated dust filter................................................... 10

5.2.5 Air reservoirs.......................................................................................................... 10

5.2.6 Alarm relay..............................................................................................................10

5.2.7 Air gun nozzles........................................................................................................10

5.3 Control and display elements....................................................................................... 11

6 Function........................................................................................................................12

7 Assembly..................................................................................................................... 13

7.1 Mount micro filter......................................................................................................... 13

7.2 Installing mounting accessories................................................................................... 15

7.3 Exchange connections for inlet and outlet.................................................................... 16

8 Installation.................................................................................................................. 18

8.1 Pneumatic installation.................................................................................................. 18

8.2 Electrical installation.................................................................................................... 19

8.2.1 Connecting supply voltage......................................................................................19

8.2.2 Connecting alarm relay........................................................................................... 21

9 Commissioning............................................................................................................ 21

9.1 Setting device for the pressure range........................................................................... 21

9.2 Commissioning device.................................................................................................. 22

10 Maintenance................................................................................................................ 23

10.1 Overview of maintenance work..................................................................................... 23

10.2 Shut down the device................................................................................................... 23

10.3 Remove covering and mount........................................................................................ 23

10.4 Replace or clean the air gun nozzle.............................................................................. 25

10.5 Cleaning the silencer.................................................................................................... 26

Table of contents