FFC LAF5412 User manual

800-747-2132 I www.paladinbrands.com 100 East Lee Road, Lee, IL 60530, United States of America

SERIAL NUMBER: ___________________ Manual Number: MR15650

Models: LAF5412 & LAF5413

MODEL NUMBER: ___________________ Release Date: January 30, 2006

STANDARD FLOW

COLD PLANER

1

TABLE OF CONTENTS

Introduction, General Information, Serial Number ……………………………………………..1

Definitions of Safety Terms and Symbols ……………………………………………………… 2

Accident Prevention, Safety Instructions……………………………………………………3-4

Safety Signs…………………………………………………………………………………….5-6

Power Unit Specifications …………………………………………………………………………7

Mounting …………………………………………………………………………………………… 7

Hydraulic Connection………………………………………………………………………………7

Setup ………………………………………………………………………………………………. 8

Operation ……………………………………………………………………………………………9

Maintenance………………………………………………………………………………………..10

Service ……………………………………………………………………………………………...11

Parts Illustration……………………….……………………………………………………………12

Parts List ………………………………..……………………………………………………..….. 13-14

Cylinder Illustration & Parts List ………………………………………………………………….15

Specifications & Requirements……………………………………………………………………15

Warranty ……………………………………………………………………………………………. i

INTRODUCTION

Congratulations on your purchase of a new FFC Attachments Cold Planer. This product has been designed and built for

planing & milling asphalt. This product may also be used for roughing concrete. You or any other person who will be

assembling, operating, maintaining, or working with this product are required to read and completely understand the

information and instructions contained in this manual. If anyone does not fully understand every part of this manual,

please obtain further assistance by contacting the dealer from which this product was purchased or by contacting FFC

Attachments at the telephone number or address listed on the cover of this manual. Keep this manual available for

reference whenever this product is being handled or used. Provide this manual to any new owners and/or operators.

This manual covers model(s): LAF5412 & LAF5413

GENERAL INFORMATION

The purpose of this manual is to assist in assembling, mounting, operating, and maintaining your Planer: read this manual

carefully to obtain valuable information and instructions that will help you achieve years of safe and dependable service.

The illustrations and data used in this manual were current at the time of printing, but due to possible engineering and/or

production changes, this product may vary slightly in detail. FFC Attachments reserves the right to redesign and/or

change components as necessary without notification to anyone.

Throughout this manual, references may be made to:

Power Unit The engine-driven machine to which this product must be attached.

Right, Left, Front, Rear Directions that are determined in relation to the operator of the equipment when

seated in the normal operating position.

IMPORTANT Precautions that must be followed to prevent damage to equipment.

NOTICE Precautions that must be followed to prevent substandard performance.

SERIAL NUMBER LOCATION

Always refer to the model and serial number when ordering parts or requesting information from your dealer. The serial

number plate for this product is located on the upper left of your Planer.

Reference Information

Model Number Loader Make

Serial Number Loader Model

Date Purchased Loader Serial #

2

DEFINITION OF SAFETY TERMS AND SYMBOLS

Throughout this manual, the terms DANGER,WARNING, and CAUTION are used to indicate the degree of

hazard to personnel if proper safety procedures are not followed. These words will be used in conjunction with

the Safety Alert Symbol: a dark triangle containing a white exclamation mark.

The Safety Alert Symbol means:

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury;

OR

May also be used to alert against unsafe practices which may result in personal injury.

ACCIDENTS CAN BE PREVENTED WITH

YOUR HELP!

No accident prevention program can be successful

without the wholehearted cooperation of the person

who is directly responsible for the operation of the

equipment.

To read equipment accident reports from all over

the country is to be convinced that a large number

of accidents can be prevented only by operators

who consistently anticipate the results of their

actions and thus prevent accidents from ever

occurring. No power-driven equipment, whether it

is on the highway, in a farm field, or in an industrial

plant, can be any safer than the person who is at

the controls.

If accidents are to be prevented (and accidents can

be prevented), that prevention will come from

equipment operators who accept their complete

responsibility.

The designer, the manufacturer, and the safety

engineer all help create a safe product, but their

combined efforts can be wiped out with a single

careless act by the operator of that product.

The best safety device is a careful operator. FFC

Attachments and your dealer ask that YOU be that

careful, responsible equipment operator.

YOU ARE THE KEY TO SAFETY BECAUSE:

YOU are responsible for the SAFE operation and

maintenance of YOUR Planer.

YOU are responsible to familiarize yourself, and

anyone else who will assemble, operate, maintain,

or work around this product, with the safety

information contained in this manual.

YOU are responsible to read ALL information

contained in this manual to any operators or

maintenance personnel who are not fully able to

read the written English language. Whether YOU

read the manual as written or translate it into

another language, YOU must make certain that all

operators and maintenance personnel have a

complete understanding of the full and exact

contents of this manual. Translations of this

manual into other languages are available by

submitting a written request to FFC Attachments.

YOU can reduce the risk of injury or death by

following all safety precautions and by using good

safety practices.

3

SAFETY INSTRUCTIONS

WORK SAFELY - A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST ACCIDENTS !!

SECTION 1

WARNING SECTION

WARNING

Obey all the safety instructions listed in

this section and throughout this manual.

Failure to obey instructions in this

section could result in death or serious

injury.

BEFORE ATTEMPTING ANY TYPE OF ASSEMBLY,

OPERATION, MAINTENANCE, OR OTHER WORK ON

OR NEAR THIS PRODUCT:

xREAD AND COMPLETELY UNDERSTAND THIS

MANUAL.

xREAD AND COMPLETELY UNDERSTAND THE

MANUALS PROVIDED WITH YOUR POWER

UNIT,LOADER AND QUICK-ATTACH.

xRead and understand all safety signs on this

product and on your power unit, loader, and quick-

attach.

xKnow all your controls and know how to quickly stop

all power unit movement, the planer movement, and

the engine in case of an emergency.

xKnow and obey all applicable government rules,

O.S.H.A. regulations, local laws and other

professional guidelines for your operation.

xMake sure that anyone who will be assembling,

mounting, maintaining, repairing, removing, and/or

storing this product:

xhas been instructed in the safe operation of this

product and of the power unit and quick-attach

to which this product is attached.

xis physically and mentally capable of the safe

operation of this type of equipment.

xis not under the influence of drugs or alcohol.

xis carefully supervised from a safe distance,

especially if such person is inexperienced.

xwears appropriate protective equipment (i.e.

hardhat, safety glasses, work gloves, protective

shoes, respirator, ear protection, etc.).

xdoes not wear loose fitting clothing, loose or

uncovered hair, or any accessories (jewelry,

necktie, scarf, wrist watch, etc.) that can catch in

moving parts.

xhas annually reviewed all safety instructions.

xKnow and follow good work practices when

assembling, mounting, maintaining, repairing,

removing, and storing this product:

xWork on a level surface in a well lit area.

xKeep the area clean and dry.

xUse properly grounded electrical outlets & tools.

xUse the right tool for the job at hand.

xMake sure that your tools are in good condition for

performing the desired function.

xWhen using tools, wear the protective equipment

specified by the tool manufacturer. (i.e. hardhat,

safety glasses, work gloves, protective shoes, etc.)

WHEN YOUR POWER UNIT IS USED DURING ANY

TYPE OF ASSEMBLY, OPERATION, MAINTENANCE,

OR OTHER WORK ON OR NEAR THIS PRODUCT:

xBefore leaving the operator’s station or before

beginning any type of work on this product, lower

this product to the ground, apply your power unit’s

parking brake, stop the engine, remove the starter

key, wait for all moving parts to stop, and then

relieve all pressure in the hydraulic lines. Refer to

your power unit’s operator’s manual for instructions

on how to relieve hydraulic pressure in lines.

xKnow your loader’s safe lifting and operating

capacity and the weight of this product. See the

specifications in this manual for the weight of this

product and refer to your power unit’s and loader’s

operator’s manuals for safe operating limits. Lift

capacity may be reduced if using a quick-attach.

xNever allow anyone, except the operator, to be

around the power unit or this product when either is

in motion. Do not startup unless others are clear of

the work area.

xDo not allow riders on this product or the power unit.

xDo not stand or climb on this product when raised.

xDo not place any part of your body under any part of

this product unless this product is securely resting

on adequate blocking or on the ground.

xDo not use blocking made of concrete blocks, logs,

buckets, barrels or any other material that could

suddenly collapse or shift positions. Do not use

wood or steel blocking that shows any signs of

material decay. Do not use blocking that is warped,

twisted, or tapered.

xNever operate controls from the ground. Operate

the controls only from the operator’s station.

xNever leave equipment unattended with the engine

running or with this product raised on the loader.

xBe aware of the added weight and width of this

product. Reduce travel speeds accordingly,

especially when traveling over rough ground.

xKeep this product close to the ground and under

control when transporting.

4

SAFETY INSTRUCTIONS

WORK SAFELY - A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST ACCIDENTS !!

WARNING SECTION [CONTINUED]

WARNING

Obey all the safety instructions

listed in this section and throughout

this manual. Failure to obey

instructions in this section could

result in death or serious injury.

WHEN DEALING WITH HYDRAULICS DURING ANY

TYPE OF ASSEMBLY, OPERATION, MAINTENANCE,

OR OTHER WORK ON OR NEAR THIS PRODUCT:

xHydraulic fluid under pressure can penetrate the

skin and cause serious injury or death. Hydraulic

leaks under pressure may not be visible!

xIf any fluid penetrates the skin, GET IMMEDIATE

MEDICAL ATTENTION!!

xWear safety glasses, protective clothing, and use a

sound piece of cardboard or wood when searching

for hydraulic leaks. DO NOT USE YOUR HANDS!

xBefore connecting or disconnecting hydraulic hoses,

read your tractor or power unit’s operator’s manual

for detailed instructions on connecting and

disconnecting hydraulic attachments.

xMake certain that all parts meet the specifications for

this product when installing or replacing hydraulic

hoses or fittings.

xAfter connecting hydraulic lines:

xSlowly and carefully raise the loader and cycle

the rollback / dump cylinders to check hose

clearances and to check for any interference.

xOperate the hydraulics on this product to check

hose clearances and to check for any

interference.

xMake certain that the hoses cannot interfere with

or actuate the quick-attach mechanism.

xMake certain that hoses will not be pinched, or get

tangled, in any equipment.

xDo not lock the auxiliary hydraulics of your power

unit in the “ON” position.

xRefer to your power unit’s operator’s manual and

this manual for procedures and intervals, then

inspect and maintain the entire hydraulic system to

insure that the fluid remains clean, that all devices

function properly, and that there are no fluid leaks.

WHEN MOUNTING THIS PRODUCT TO YOUR

POWER UNIT:

xRefer to the operator’s manuals of your power unit,

your loader, and your quick-attach for special or

detailed mounting instructions.

xThis product should fit onto the quick-attach or

loader arms of your power unit the same as the

original products that were designed by your loader /

quick-attach manufacturer.

xIf this product does not fit properly, contact FFC

Attachments before operating.

xNever place your finger into the mounting plate or 3-

point hitch or loader holes. A slight movement of the

power unit or this product could cause serious injury.

BEFORE EACH USE, THOROUGHLY INSPECT THIS

PRODUCT AND:

xMake certain that all safety signs are in place and

legible. Refer to the safety sign page in this manual

for the placement of safety signs for this product.

xReplace all damaged or excessively worn parts and

hardware only with genuine FFC Attachments parts

or with properly rated fasteners, hydraulic hoses, or

fittings.

xMake certain that all locking pins, latches, and

connection devices are properly installed and

secured.

xMake certain that all protective guards, canopies,

doors, etc., are in place and secure.

WHEN OPERATING THIS PRODUCT IN

ACCORDANCE WITH DESIGN INTENTIONS:

xKeep everyone at least nine feet away from the unit

when operating.

xNever operate your planer with the cover open.

WHEN ADJUSTING, SERVICING OR REPAIRING THIS

PRODUCT:

xMake no modifications to your planer.

xWhen making repairs, use only genuine FFC

Attachments parts or, for fasteners, hydraulic hoses,

or hydraulic fittings, use only properly rated parts.

xReplacement parts, for parts with safety signs

attached, must also have safety signs attached.

5

SAFETY SIGN LOCATIONS

INSTRUCTIONS

xKeep all safety signs clean and legible.

xReplace all missing, illegible, or damaged safety signs.

xReplacement parts for parts with safety signs attached must also have safety signs attached.

xSafety signs are available, free of charge, from your dealer or from FFC Attachments.

PLACEMENT OR REPLACEMENT OF SAFETY SIGNS

1. Clean the area of application with non-flammable solvent, then wash the same area with soap and water.

2. Allow the surface to fully dry.

3. Remove the backing from the safety sign, exposing the adhesive surface.

4. Apply the safety sign to the position shown in the diagram above and smooth out any bubbles.

ITEM QTY. PART # DESCRIPTION

1 1 50-0723 READ MANUAL

2 1 50-0724 HYDRAULIC

3 1 50-0721 CRUSH HAZARD

4 2 RDL3159 FLYING DEBRIS

5 2 RDL3100 STAND CLEAR

ITEM # 3

ITEM # 1

ITEM # 2

ITEM # 4

ITEM # 5

6

SAFETY SIGN LOCATIONS (CONTINUED)

DECAL PARTS LIST

ITEM QTY. PART # DESCRIPTION

1 1 LAF8231 NON-SKID TAPE

2 2 RDL3100 DECAL, WARNING ROTATING CUTTER

3 1 50-0724 DECAL, WARNING OIL INJ. HAZARD

4 1 50-0723 DECAL, WARNING READ MANUAL

5 1 RDL3159 DECAL, WARNING FLYING OBJECTS

6 1 50-0721 DECAL, WARNING CRUSHING HAZARD

7 2 RDL3179 DECAL, LIFT POINT

8 1 RDL3301 DECAL, DEPTH INDICATOR

9 1 RDL3302 DECAL, TILT INDICATOR

7

POWER UNIT SPECIFICATIONS

IMPORTANT Exceeding any of the maximum recommended tractor or power unit specifications

CAN result in damage to this product and

WILL

void all FFC Attachments warranties.

DESCRIPTION SPECIFICATIONS

Weight of Power Unit without Planer 11,000 lbs. maximum

Operating Capacity of Power Unit’s loader 4,500 lbs. maximum

Lift Capacity of Power Unit’s loader 9,000 lbs. maximum

Hydraulic Pressure Output 3,400 psi. maximum

Front or Rear Ballast As required to maintain full power unit stability. (Note

the shipping weight on page 15, then see the operator’s

manual(s) for your power unit, loader, and quick-attach for

ballasting needs.)

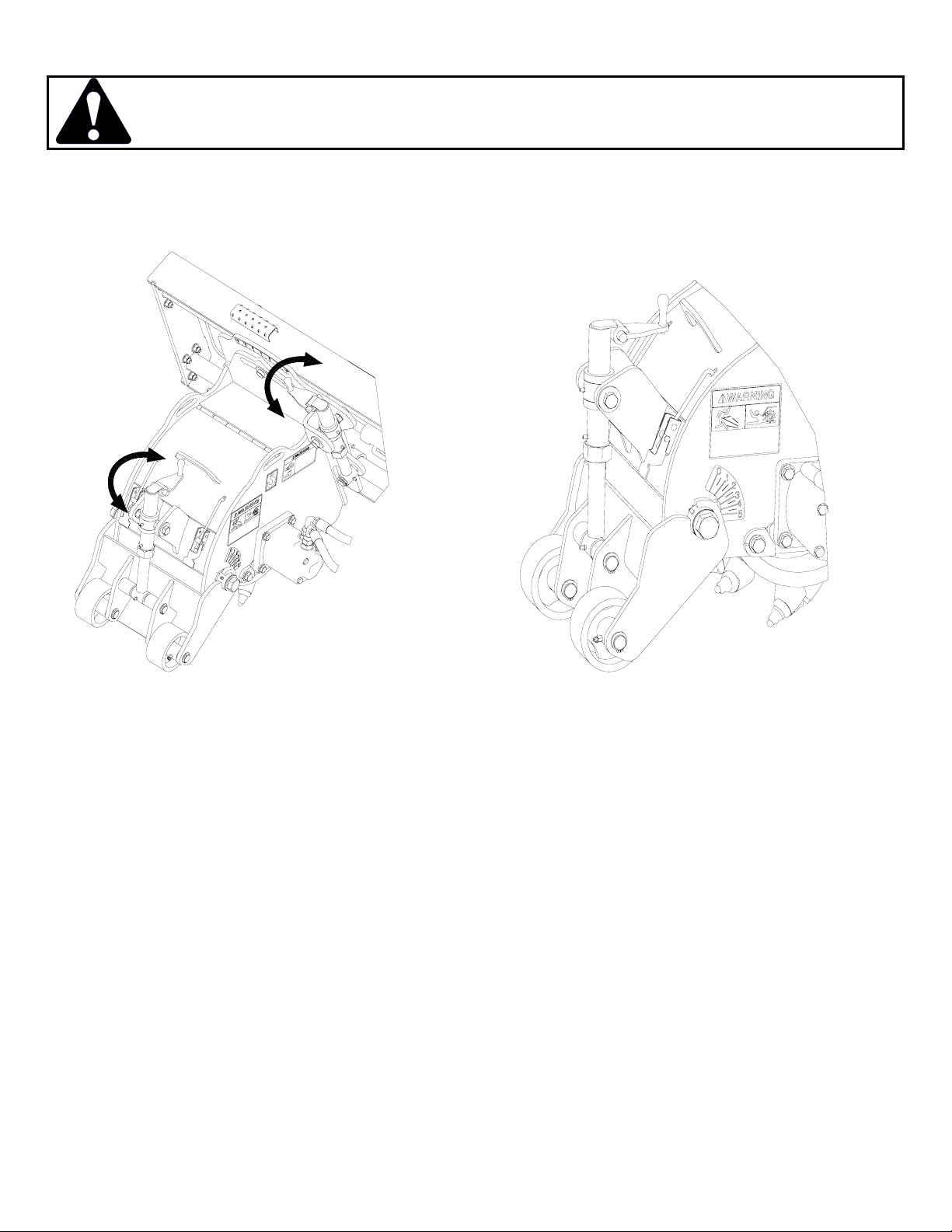

PLANER MOUNTING

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER MOUNTING

1. Place this product on a firm, level surface that is large enough to safely accommodate this product, your

power unit and all workers involved in the mounting process.

2. Refer to the operator’s manual(s) for your power unit, loader, and quick-attach and follow the mounting

instructions contained therein.

3. Carefully raise the loader and cycle the tilt cylinders to check clearances and to verify that all mounting

procedures have been successfully completed.

IMPORTANT Lubricate all grease fittings before connecting this product to your power unit’s hydraulic

system. Refer to PLANER MAINTENANCE on page 10 and follow the instructions.

PLANER HYDRAULIC CONNECTION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER HYDRAULIC CONNECTION

1. Disconnect the hydraulic hose quick couplers from one another and attach the quick couplers to your

power unit as per the instructions in your power unit’s operator’s manual.

2. Carefully raise the loader and cycle the tilt cylinders to check hose clearances and to check for any

interference.

3. Cycle the hydraulic cylinder(s) on this product several times from fully retracted to fully extended until all air

has been completely removed from the cylinder.

NOTICE: When shipped, the hydraulic cylinder on this product contained air or an air-fluid mixture.

Failure to remove all the air from the hydraulic cylinder can cause uneven, jerky cylinder movement

when the hydraulic controls are being operated and unwanted cylinder movement when those controls

are not being operated.

WARNING

Do not lock the auxiliary hydraulics of your tractor or power unit in the “ON”

position. Failure to obey this warning could result in death or serious injury.

8

PLANER SETUP

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER SETUP

Setting planer depth:

iTurn the depth jack (located on the front of the planer) to adjust planing depth.

iA depth indicator decal is located on the left side of the chassis.

Setting planer sideshift:

iTo sideshift the planer, actuate the diverter valve (LAF4699). The diverter valve is bi-directional.

iActuate the hydraulic system of the power unit and the planer will sideshift.

iReturn the diverter valve to its original position after sideshift operation is completed.

Setting planer Tilt:

iThe planer tilt can be adjusted using the tilt jack located on the left side of the chassis.

iAn indicator decal is provided to set the tilt at an approximate angle.

9

PLANER OPERATION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER OPERATION

Starting a Cut:

1. To begin a cut, adjust the tilt and depth jacks to

the desired tilt depth with the planer slightly

above the ground. Engage the hydraulic system

to start the drum.

2. Lower the planer, bringing the rear planer

wheels onto the ground

3. Roll the planer into the cut, until the front

wheels of the planer are on the ground.

4. Slightly lift the front loader wheels to create a

downward force on the planer. Slowly move

forward, planing in a straight line.

NOTE: Materials can vary greatly: it is recommended that cutting depth be limited to 1 inch when roughing

concrete.

WARNING

Failure to obey the following procedures could result in death or serious injury:

xNever lift this product above (a.) the operator’s eye level or (b.) to a height where

visibility is obstructed, whichever is lower.

xNever operate your Planer with the Cover open.

10

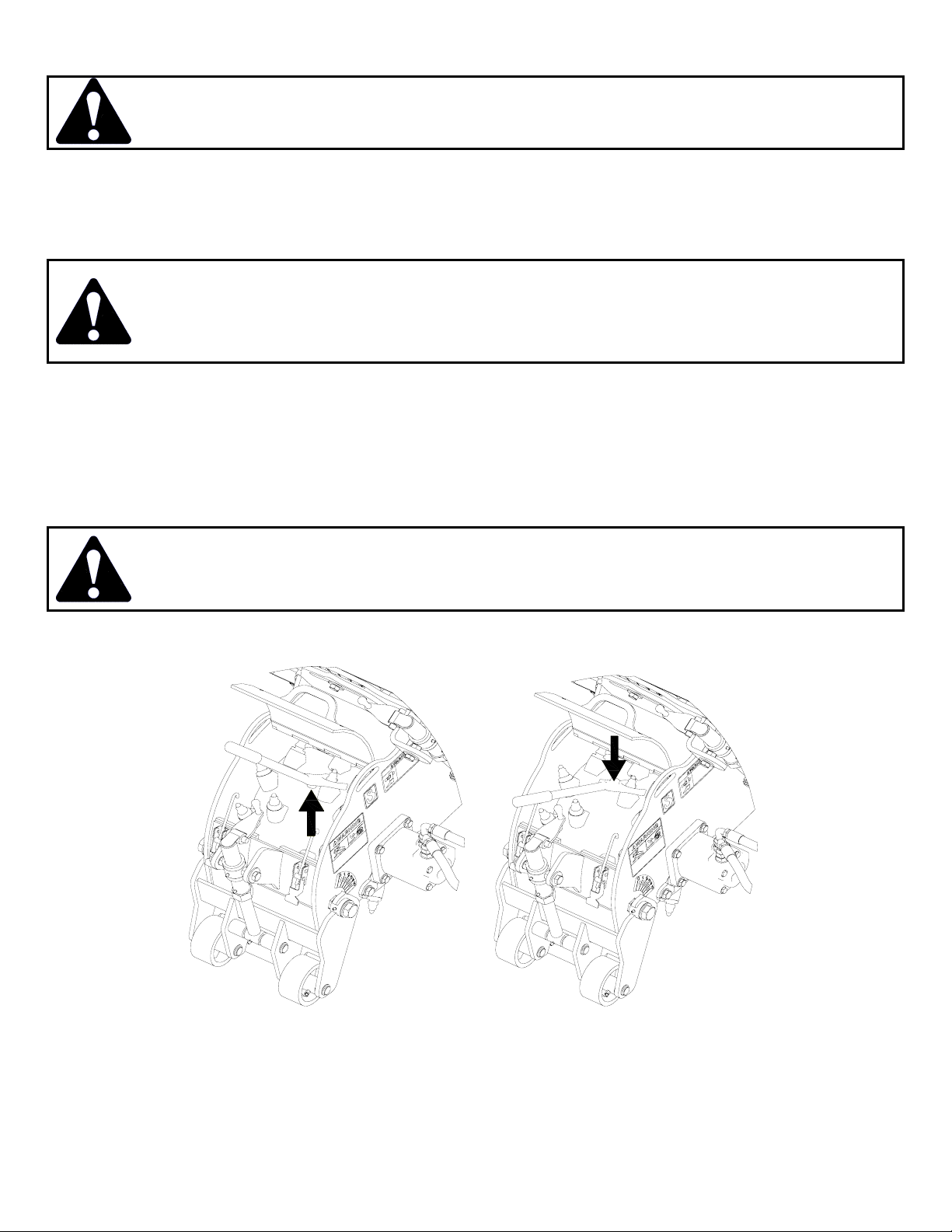

PLANER MAINTENANCE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER MAINTENANCE

WARNING

Failure to obey the following procedures could result in death or serious injury.

xNever walk under or climb on raised liftarms or a raised attachment.

xIf the attachment must be raised, block the machine with blocks or jackstands, NOT lift

jacks or hoists.

WARNING

Failure to obey the following procedures could result in death or serious injury.

xAlways wear protective equipment including a HARD HAT and EYE PROTECTION when

operating, performing maintenance, or working near this product.

BEFORE EACH USE

xMake sure that all nuts and bolts are in place and properly tightened.

xMake sure that all other fasteners are in place and are performing their specified function.

xMake sure that all hydraulic fittings are tightened to specifications and that there are no leaks in any fittings

or hoses. (see the hydraulic connection section on page 7.)

xMake sure that all safety signs are in place, are clean, and are legible.

(see the safety sign section on pages 5-6)

xReplace any damaged parts and excessively worn parts.

DAILY

xGrease [9] fittings: [1] on the drum shaft bearing / [4] on the wheels / and [4] on the slider bar bosses (see

parts illustration on page 12).

NOTE: Lubricate all grease fittings with a NLGI #1 or 2 multipurpose grease.

WEEKLY

xGrease [8] fittings: [2] on the depth jack / [1] on the depth pin / [2] on the depth weldment / [2] on the tilt

jack / and [1] on the tilt pin (see parts illustration on page 12).

NOTE: Lubricate all grease fittings with a NLGI #1 or 2 multipurpose grease.

11

PLANER SERVICE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER SERVICE

1. Park your power unit on a level surface with this product properly attached.

2. Place your power unit’s transmission in “Park” and engage the parking brake.

3. Lower this product onto preplaced blocking.

4. Shut off your power unit’s engine, remove the starter key, wait for all moving parts to come to a stop, and relieve all

pressure in the hydraulic lines.

WARNING

Do not use blocking made of concrete blocks, logs, buckets, barrels or any other material

that could suddenly collapse or shift positions. Do not use wood or steel blocking that

shows any signs of material decay. Do not use blocking that is warped, twisted, or tapered.

Failure to obey this warning could result in death or serious injury.

Pick Removal/Replacement:

Proper pick maintenance is essential to the productive use of your planer. Failure to perform regular pick maintenance

can result in severely decreased performance and expensive repairs to your planer drum.

A missing pick must be replaced immediately, as a missing pick will cause the surrounding picks to wear faster.

Picks must be replaced when their carbide tips become excessively blunt.

Picks must rotate freely in their holders. If picks do not rotate freely, they will develop flat spots. Picks should be removed

and retaining rings cleaned as necessary.

NOTE: the edge picks wear faster and require more frequent replacement.

CAUTION

Picks become hot during operation: Wait for picks to cool before replacing.

Do not hammer on carbide point when replacing picks. The carbide can break and cause

injury.

Remove and replace picks using the pick removal tool (LAF9326) and a hammer as shown below.

NOTE: the edge picks wear faster and require more frequent replacement.

NOTE: do not hammer on carbide point of the pick. The carbide can break and cause injury.

12

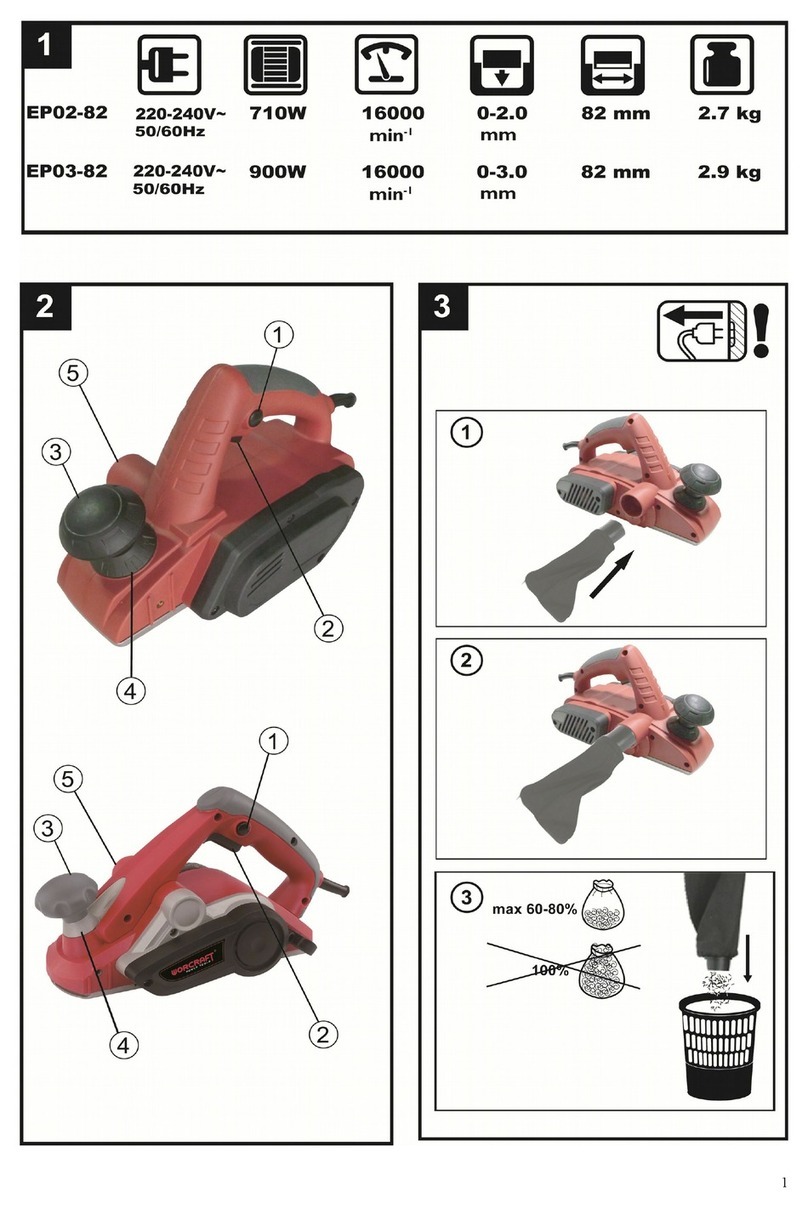

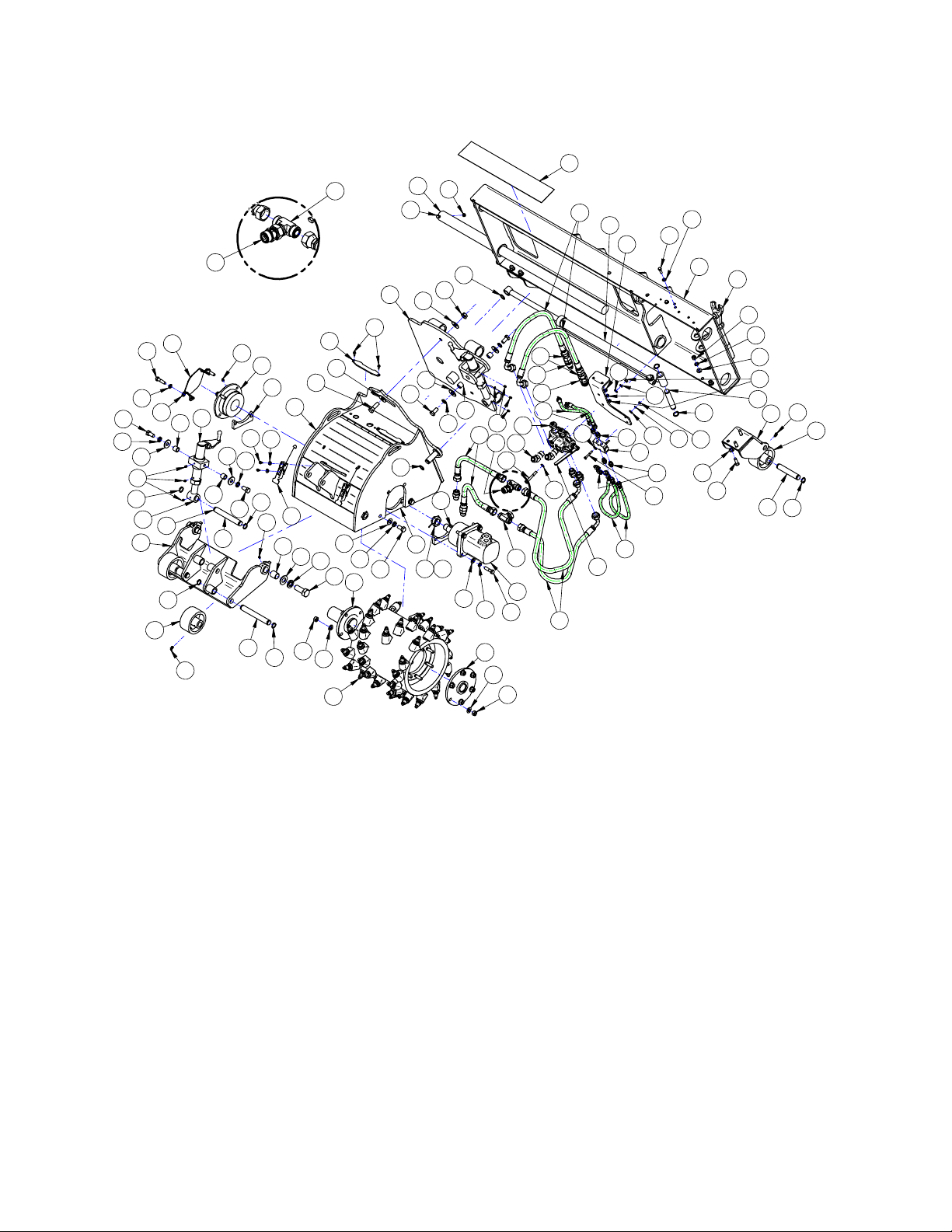

STANDARD FLOW COLD PLANER PARTS ILLUSTRATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

20

21

23

24

25

26

27

28

29

30

31

32

33

22

35

36

37

38

76

40

41

44

45

46

47

48

49

50

51

52

54

55

56

57

58

59

61

62

63

64 66

67

68

70

71

72

73

74

75

76

77

59

76

59

73

53

65

60

43

73

77

76

26

76

51

64

59

24

39 76 57

70

64 51

56 63 50

A

DETAIL A

14

6

33

56

74

17

55

76

54

3

12

76

51

64

59

24

73 54

69

56

63

55

34

42

13

STANDARD FLOW COLD PLANER PARTS LIST

ITEM

No. QTY.

LAF5412

12"

LAF5413

16" DESCRIPTION

1 2 13-50392 13-50392 Rod, 2 x 47.25" w/ 0.406 Cross Hole

2 6 LAF4076 LAF4076 Hydraulic Fitting 12MFS 12MB Straight

3 6 LAF4229 LAF4229 Hydraulic Fitting 6MFS 6MB Straight

4 1 Hydraulic Quick Coupler, Female

5 1 Hydraulic Quick Coupler, Male

6 2 LAF4694 LAF4694 Hydraulic Tee 12MFS 12FFS 12MFS

7 1 LAF4697 LAF4697 Motor, 24 Cu. In.

8 1 LAF4698 LAF4698 Sideshift Cylinde

r

9 1 LAF4699 LAF4699 Two Position Diverter Valve

10 1 LAF4700 LAF4700 Cylinder Lock Valve

11 2 LAF4701 LAF4701 Hydraulic Hose, 5/8” dia., 12FFS-12FFS90, 36" Length

12 4 LAF4702 LAF4702 Hydraulic Hose, 1/4” dia., 6FFS-6FFS90, 22" Length

13 2 LAF4703 LAF4703 Hydraulic Hose, 5/8” dia., 12FFS-12FFS90, 60" Length

14 1 LAF4707 LAF4707 Check Valve

15 1 LAF4717 LAF4717 Key, Char Lynn 4K Moto

r

16 2 LAF4720 LAF4720 Hydraulic Fitting 12MB 6MFS Straight

17 2 LAF4721 LAF4721 Hydraulic Fitting 12MB 12MFS 45q

18 2 LAF4722 LAF4722 Hydraulic Hose, 5/8” dia., 12FFS-12FFS, 12" Length

19 1 LAF8231 LAF8231 Non-Skid Tape 4" x 24"

20 1 LAF9300 LAF9301 Chassis Weldment

21 1 LAF9302 LAF9303 Depth Arm Weldment

22 2 LAF9304 LAF9304 Jack Body Weldment

23 2 LAF9307 LAF9307 Lid Latch

24 4 LAF9309 LAF9309 Boss Pivot Bolt Space

r

25 1 LAF9310 LAF9310 Deadshaft Bearing

26 1 LAF9311 LAF9311 1” x 7.4” Dual Snap Ring Pin

27 1 LAF9313 LAF9313 Hub Weldment

28 1 LAF9314 LAF9315 Drum Assembly

29 1 LAF9316 LAF9316 Deadshaft Weldment

30 1 LAF9317 LAF9318 Sideshift Weldment

31 1 LAF9319 LAF9319 Mainframe Weldment

32 2 LAF9321 LAF9321 Wheel Bracket Weldment

33 4 LAF9322 LAF9322 Planer Wheel Weldment

34 2 LAF9323 LAF9323 Jack Screw Weldment

35 2 LAF9324 LAF9324 Dual Snap Ring Pin 1” x 5-29/32”

36 1 LAF9325 LAF9325 Dual Snap Ring Pin 1” x 5-17/32”

37 1 LAF9326 LAF9326 Pick Removal Tool

38 1 LAF9335 LAF9335 Valve Mounting Bracket

39 2 LAF9324 (5-29/32") LAF9347 (7-29/32") Dual Snap Ring Pin 1” x Length Noted

40 1 LAF9348 LAF9348 Bearing Guard

41 2 LAF9362 LAF9362 Bearing Mount Space

r

42 2 LAF9363 LAF9363 Bearing Mount Plate

43 2 LAF9386 LAF9386 Pivot Bushing

44 2 LAF9399 LAF9399 Water Kit Hole Cove

r

45 2 RHW1011 RHW1011 Grade 5 Hex Head Cap Screw, ¼” x 2”

46 2 RHW1207 RHW1207 Grade 5 Hex Head Cap Screw, 3/8” x 1-1/4””

47 2 RHW1215 RHW1215 Grade 5 Hex Head Cap Screw, 3/8” x 3”

48 2 RHW1217 RHW1217 Grade 5 Hex Head Cap Screw, 3/8” x 3-1/2”

49 6 RHW1406 RHW1406 Grade 5 Hex Head Cap Screw, ½” x 1-3/4”

50 8 RHW1407 RHW1407 Grade 5 Hex Head Cap Screw, ½” x 2”

51 8 RHW1601 RHW1601 Grade 5 Hex Head Cap Screw, 5/8” x 1-1/4”

STANDARD FLOW COLD PLANER PARTS LIST

Contact FFC to obtain the correct item

Contact FFC to obtain the correct item

14

STANDARD FLOW COLD PLANER PARTS LIST (cont.)

ITEM

No. QTY.

LAF5412

12"

LAF5413

16" DESCRIPTION

52 3 RHW1604 RHW1604 Grade 5 Hex Head Cap Screw, 5/8” x 2”

53 2 RHW1908 RHW1908 Grade 5 Hex Head Cap Screw, 1” x 2-1/2”

54 8 RHW5062 RHW5062 Grade 5 Flat Washer USS, ¼”

55 8 RHW5232 RHW5232 Grade 5 Flat Washer SAE, 3/8”

56 20 RHW5432 RHW5432 Grade 5 Flat Washer SAE, ½”

57 10 RHW5532 RHW5532 Grade 5 Flat Washer SAE, 9/16”

58 4 RHW5632 RHW5632 Grade 5 Flat Washer SAE, 5/8”

59 10 RHW5662 RHW5662 Grade 5 Flat Washer USS, 5/8”

60 2 RHW5932 RHW5932 Grade 5 Flat Washer SAE, 1”

61 2 RHW6002 RHW6002 Grade 5 Lockwasher, 1/4”

62 4 RHW6202 RHW6202 Grade 5 Lockwasher, 3/8”

63 14 RHW6402 RHW6402 Grade 5 Lockwasher, 1/2”

64 8 RHW6602 RHW6602 Grade 5 Lockwasher, 5/8”

65 2 RHW6902 RHW6902 Grade 5 Lockwasher, 1”

66 2 RHW7001 RHW7001 Grade 5 Hex Nut, ¼”

67 4 RHW7201 RHW7201 Grade 5 Hex Nut, 3/8”

68 2 RHW7203 RHW7203 Grade 5 Lock Nut Center Dent, 3/8”

69 6 RHW7451 RHW7451 Grade 8 Hex Nut, 1/2”

70 10 RHW7502 RHW7502 Grade 8 Hex Nut, 9/16”

71 3 RHW7607 RHW7607 Grade 8 Top Lock Flange Nut, 5/8"

72 1 RHW7906 RHW7906 Castle Nut, 1-1/4” 18 tpi

73 13 RHW8090 RHW8090 Grease Zerk, ¼”–28 tpi, Straight

74 4 RHW8107 RHW8107 Grease Zerk, ¼”–28 tpi, 45 q

75 1 RHW8138 RHW8138 Cotter Pin, 5/32” x 2-3/4”

76 14 RHW8146 RHW8146 Retaining Ring, 1”, Heavy Duty

77 8 RHW9004 RHW9004 Self Tapping Screw, ¼” x ¾”

15

CYLINDER ILLUSTRATION & PARTS LIST

ITEM # Qty Part # DESCRIPTION

1 1 LAF4723 NUT, ¾-16 GRADE C ANTIVIBRATION

2 1 LAF4724 HEAD, 1.0” I.D. NOMINAL

3 1 LAF4725 PISTON 1.5” O.D. X 1” I.D. NOMINAL

4 1 LAF4726 SEAL KIT 1.5” BORE 1.0” ROD

5 1 LAF4727 COLLAR, 1.0 I.D. NOMINAL

6 1 LAF4728 SHAFT, 1” DIAMETER 24” STROKE

7 1 LAF4729 BARREL, 1.5” I.D. 24” STROKE

PLANER SPECIFICATIONS

Model

Number

Cutting

Width

Cutting

Depth

Tilt Sideshift Overall

Width

Overall

Height

Overall

Depth

Shipping

Weight

LAF5412

SSP12 LF

12” 0 – 5” +15q24” 66” 33” 60” 1033 lbs

LAF5413

SSP16 LF

16 0 – 5” +15q24” 66” 33” 60” 1116 lbs

PLANER REQUIREMENTS

Model Number Required Pressure Required Flow

LAF5412 SSP12 LF 2200 psi 13 gpm

LAF5413 SSP16 LF 2200 psi 16 gpm

TORQUE SPECIFICATIONS FOR STANDARD MACHINE HARDWARE

Bolt Size SAE Grade Bolt Torque Ft./Lbs Bolt Size SAE Grade Bolt Torque Ft./Lbs

0.31 - 18 5 17 0.56 - 11 5 120

0.38 - 16 5 30 0.63 - 11 5 150

0.50 - 13 5 75 1.00 - 8 5 580

Warranty Registration Form and Delivery Inspection Report

IMPORTANT! Warranty Void if card is not returned with 10 days.

All Applicable sections must be filled in.

This section to be filled out and signed by Dealer at time of delivery.

Warranty Registration

Customer’s Name Dealer’s Name

Address Address

City State Zip City State Zip

Phone CHECK ONE:

Loader / Tractor Model Construction Use

Delivery Date Agricultural Use

Model or Part # Landscape Use

Serial # Other:

Dealer Inspection (check items applicable)

All Decals installed (see operator’s manual) Review Operating and Safety Instructions

Hydraulic fittings tight and free of leaks Guards and covers in place and secure

Fasteners tight Does Product Function Properly

I have thoroughly instructed the buyer on the above described equipment. This review included: The Operator’s manual content,

equipment care, adjustments, safe operation and applicable warranty policy.

Date Dealer’s Rep. signature

This section to be completed and signed by the customer

QUALITY ASSURANCE RATING

Question: FFC Local Dealer

Quality of Product: Appearance . . . . . . . . . . . . . . . . . . . . . . . . .

Construction . . . . . . . . . . . . . . . . . . . . . . . . .

Quality of Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Value (Priced Fairly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Does it perform as claimed . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The above described equipment and Operator’s Manual have been received by me and I have been thoroughly instructed

as to care, adjustments, safe operation and applicable warranty policy.

Date: Owner’s signature

NOTE! Make one copy each for the dealer’s and owner’s records. Mail original to FFC Attachments.

Form MR00000-000 Rev. 09/04

FFC Attachments • 100 E. Lee Road • PO Box 122 • Lee, IL 60530 • 800-747-2132 • Fax 815-824-2071

www.ffcattachments.com

123 4 5

Excellent Good Average Unsatisfactory Poor

PLEASE TRI-FOLD AND AFFIX TAPE HERE

FFC LIMITED 12 MONTH WARRANTY

Thank you for purchasing a FFC product. Warranty protection is valid only when this Warranty

Registration is completed and signed by the customer and dealer, and mailed to FFC. I hereby

acknowledge that I have received a copy of the owners Limited Warranty and I accept the terms

therein.

For a period of 12 months from date of delivery of product to the original user, FFC, warrants

each product to be free from manufacturing defects, subject to the limitations contained in this

policy.

This warranty does not apply to defect caused, in whole or in part, by unreasonable use while in

the possession of the user, including, but not limited to: failure to properly set up product; failure

to provide reasonable and necessary maintenance; normal wear; routine tune ups or

adjustments; improper handling or accidents; operation at speed or load conditions contrary to

published specification; improper or insufficient lubrication; improper storage. This warranty is

also not a guarantee that the performance of each product will meet the expectations of the

purchaser.

FFC shall not be liable for consequential damages of any kind, including, but not limited to:

consequential labor costs or transportation charges in connection with the replacement or repair

of defective parts; lost time or expense which may have accrued because of said defects. In no

event shall FFC, Inc.’s total liability hereunder exceed the product purchase price.

FFC makes no warranty with respect to trade accessories or any component or accessory of the

product which was not manufactured by FFC, including any purchased components on any kind.

These are subject to the warranties of their respective manufacturers. The warranty will be

considered void if the product or any part of the product is modified or repaired in any way not

expressly authorized by FFC, or if closed components are disassembled prior to return. Closed

components include, but are not limited to: gearboxes, hydraulic pumps, motors, cylinders, and

actuators.

Our obligation under the warranty is expressly limited, at our option, to the replacement or repair

at FFC, of Lee, Illinois, or at a service facility designated by us, or such part or parts as inspection

shall disclosed to have been defective. We are not responsible for unauthorized repairs or

replacements. Any implied or statutory warranties, including any warranty of merchantability or

fitness for a particular purpose, are expressly limited to the duration of this written warranty. We

make no other express or implied warranty, nor is anyone authorized to make any in our behalf.

This warranty cannot be extended, broadened, or changed except in writing by an authorized

officer of FFC.

This manual suits for next models

1

Table of contents

Other FFC Planer manuals