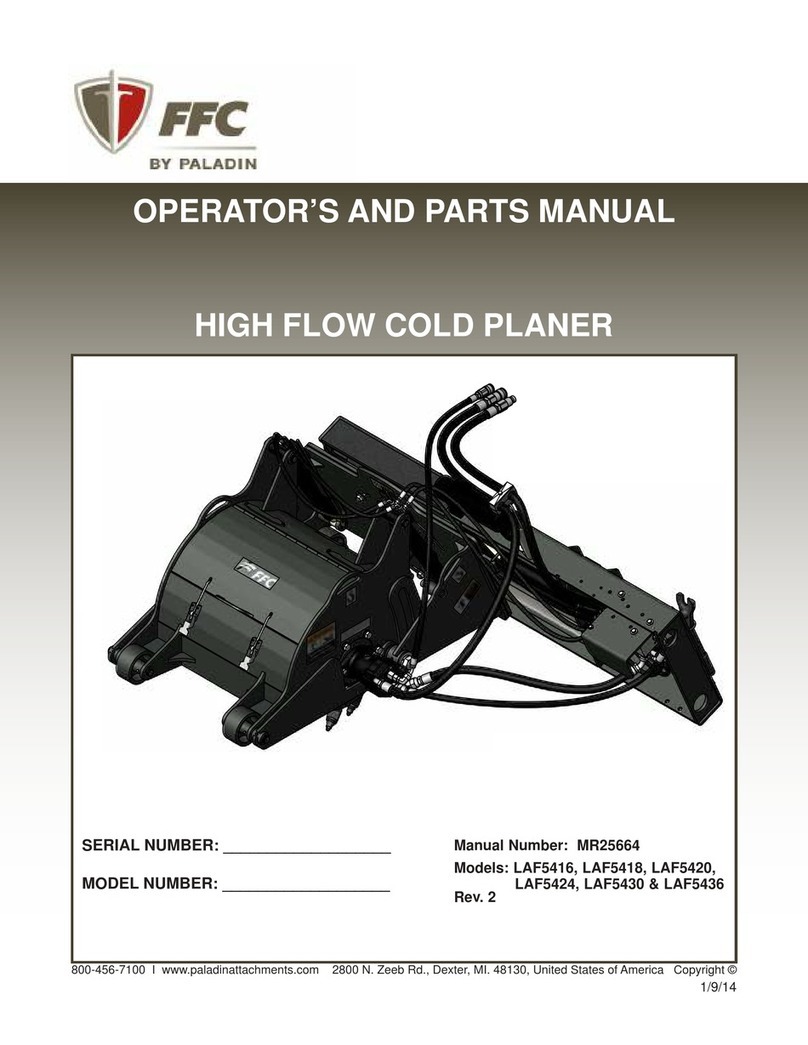

FFC LAF5416 User manual

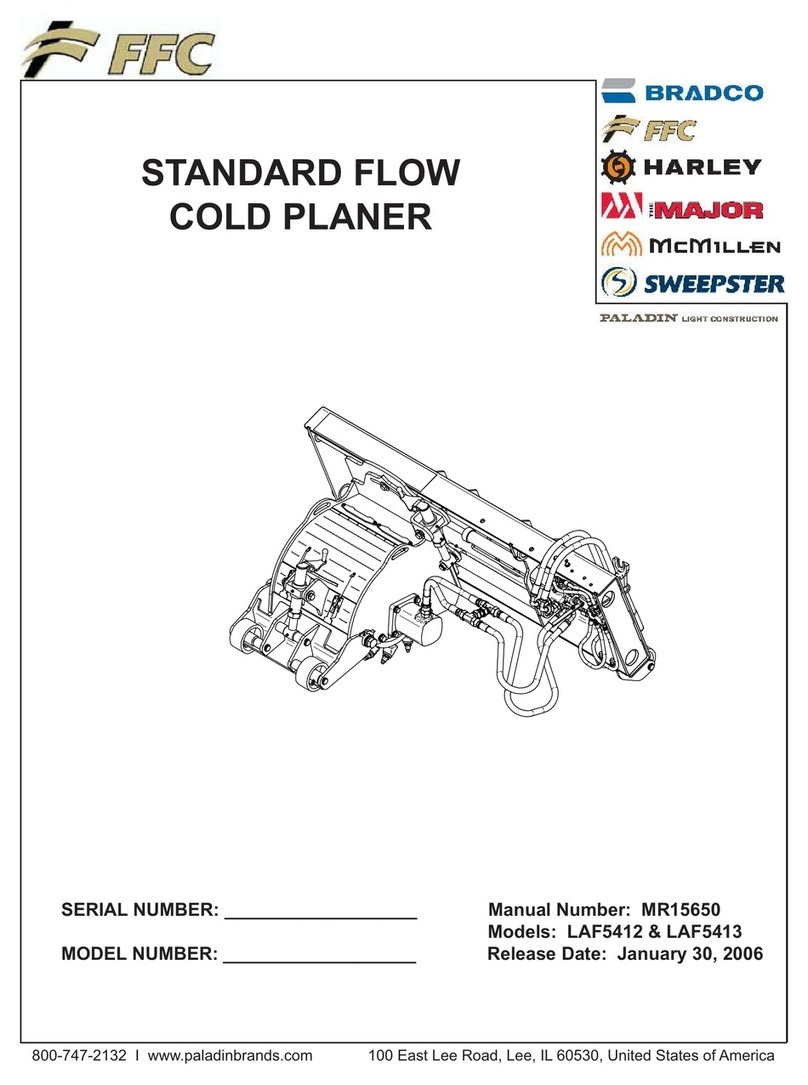

800-747-2132 I www.paladinbrands.com 100 East Lee Road, Lee, IL 60530, United States of America

SERIAL NUMBER: ___________________ Manual Number: MR25664

Models: LAF5416, LAF5418,

MODEL NUMBER: ___________________ LAF5420, LAF5424,

LAF5430 & LAF5436

Release Date: January 30, 2006

HIGH FLOW

COLD PLANER

1

TABLE OF CONTENTS

Introduction, General Information, Serial Number ……………………………………… 1

Definitions of Safety Terms and Symbols ………………………….………………….… 2

Accident Prevention, Safety Instructions……………………………………….. 2-4

Safety Signs…………………………………………………………………..……… 5-6

Power Unit Specifications …………………………………………………………………… 7

Mounting ………………………………………………………………………………………... 7

Wiring Harness & Actuator Installation…………………………………………………….. 7

Hydraulic Connection………………………………………………………………………… 8

Setup ………………………………………………………………………………………….. 8

Operation ……………………………………………………………………………………… 9

Maintenance…………………………………………………………………………………… 10-11

Service ………………………………………………………………………………………… 12

Parts Illustration & Parts List…………………………….…………………………………… 13-16

Hydraulics Group Illustration & Parts List………………………………………………….. 17-18

Decal Group Illustration & Parts List……………………………………………………….. 19

Cylinder Illustrations & Parts Lists………………………………………………………….. 20

Specifications & Requirements……………………………………………………………… 21

Warranty ………………………………………………………………………………………. i

INTRODUCTION

Congratulations on your purchase of a new FFC Attachments Cold Planer. This product has been designed and built for

planing & milling asphalt. This product may also be used for roughing concrete. You or any other person who will be

assembling, operating, maintaining, or working with this product are required to read and completely understand the

information and instructions contained in this manual. If anyone does not fully understand every part of this manual,

please obtain further assistance by contacting the dealer from which this product was purchased or by contacting FFC

Attachments at the telephone number or address listed on the cover of this manual. Keep this manual available for

reference whenever this product is being handled or used. Provide this manual to any new owners and/or operators.

This manual covers model[s] : LAF5416, LAF5418, LAF5420, LAF5424, LAF5430, & LAF5436.

GENERAL INFORMATION

The purpose of this manual is to assist in assembling, mounting, operating, and maintaining your Planer: read this manual

carefully to obtain valuable information and instructions that will help you achieve years of safe and dependable service.

The illustrations and data used in this manual were current at the time of printing, but due to possible engineering and/or

production changes, this product may vary slightly in detail. FFC Attachments reserves the right to redesign and/or

change components as necessary without notification to anyone.

Throughout this manual, references may be made to:

Power Unit The engine-driven machine to which this product must be attached.

Right, Left, Front, Rear Directions that are determined in relation to the operator of the equipment when

seated in the normal operating position.

IMPORTANT Precautions that must be followed to prevent damage to equipment.

NOTICE Precautions that must be followed to prevent substandard performance.

SERIAL NUMBER LOCATION

Always refer to the model and serial number when ordering parts or requesting information from your dealer. The serial

number plate for this product is located on the upper rear left of your Planer.

Reference Information

Model Number Loader Make

Serial Number Loader Model

Date Purchased Loader Serial #

DEFINITION OF SAFETY TERMS AND SYMBOLS

Throughout this manual, the terms DANGER,WARNING, and CAUTION are used to indicate the degree of

hazard to personnel if proper safety procedures are not followed. These words will be used in conjunction with

the Safety Alert Symbol: a dark triangle containing a white exclamation mark.

The Safety Alert Symbol means:

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury;

OR

may also be used to alert against unsafe practices which may result in personal injury.

ACCIDENTS CAN BE PREVENTED WITH

YOUR HELP!

No accident prevention program can be successful

without the wholehearted cooperation of the person

who is directly responsible for the operation of the

equipment.

To read equipment accident reports from all over

the country is to be convinced that a large number

of accidents can be prevented only by operators

who consistently anticipate the results of their

actions and thus prevent accidents from ever

occurring. No power-driven equipment, whether it

is on the highway, in a farm field, or in an industrial

plant, can be any safer than the person who is at

the controls.

If accidents are to be prevented (and accidents can

be prevented), that prevention will come from

equipment operators who accept their complete

responsibility.

The designer, the manufacturer, and the safety

engineer all help create a safe product, but their

combined efforts can be wiped out with a single

careless act by the operator of that product.

The best safety device is a careful operator. FFC

Attachments and your dealer ask that YOU be that

careful, responsible equipment operator.

YOU ARE THE KEY TO SAFETY BECAUSE:

YOU are responsible for the SAFE operation and

maintenance of YOUR Planer.

YOU are responsible to familiarize yourself, and

anyone else who will assemble, operate, maintain,

or work around this product, with the safety

information contained in this manual.

YOU are responsible to read ALL information

contained in this manual to any operators or

maintenance personnel who are not fully able to

read the written English language. Whether YOU

read the manual as written or translate it into

another language, YOU must make certain that all

operators and maintenance personnel have a

complete understanding of the full and exact

contents of this manual. Translations of this

manual into other languages are available by

submitting a written request to FFC Attachments.

YOU can reduce the risk of injury or death by

following all safety precautions and by using good

safety practices.

2

SAFETY INSTRUCTIONS

WORK SAFELY - A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST ACCIDENTS !!

SECTION 1

3

WARNING SECTION

WARNING

Obey all the safety instructions listed in

this section and throughout this manual.

Failure to obey instructions in this

section could result in death or serious

injury.

BEFORE ATTEMPTING ANY TYPE OF ASSEMBLY,

OPERATION, MAINTENANCE, OR OTHER WORK ON

OR NEAR THIS PRODUCT:

xREAD AND COMPLETELY UNDERSTAND THIS

MANUAL.

xREAD AND COMPLETELY UNDERSTAND THE

MANUALS PROVIDED WITH YOUR POWER

UNIT,LOADER AND QUICK-ATTACH.

xRead and understand all safety signs on this

product and on your power unit, loader, and quick-

attach.

xKnow all your controls and know how to quickly stop

all power unit movement, the planer movement, and

the engine in case of an emergency.

xKnow and obey all applicable government rules,

O.S.H.A. regulations, local laws and other

professional guidelines for your operation.

xMake sure that anyone who will be assembling,

mounting, maintaining, repairing, removing, and/or

storing this product:

xhas been instructed in the safe operation of this

product and of the power unit and quick-attach

to which this product is attached.

xis physically and mentally capable of the safe

operation of this type of equipment.

xis not under the influence of drugs or alcohol.

xis carefully supervised from a safe distance,

especially if such person is inexperienced.

xwears appropriate protective equipment (i.e.

hardhat, safety glasses, work gloves, protective

shoes, respirator, ear protection, etc.).

xdoes not wear loose fitting clothing, loose or

uncovered hair, or any accessories (jewelry,

necktie, scarf, wrist watch, etc.) that can catch in

moving parts.

xhas annually reviewed all safety instructions.

xKnow and follow good work practices when

assembling, mounting, maintaining, repairing,

removing, and storing this product:

xWork on a level surface in a well lit area.

xKeep the area clean and dry.

xUse properly grounded electrical outlets & tools.

xUse the right tool for the job at hand.

xMake sure that your tools are in good condition for

performing the desired function.

xWhen using tools, wear the protective equipment

specified by the tool manufacturer. (i.e. hardhat,

safety glasses, work gloves, protective shoes, etc.)

WHEN YOUR POWER UNIT IS USED DURING ANY

TYPE OF ASSEMBLY, OPERATION, MAINTENANCE,

OR OTHER WORK ON OR NEAR THIS PRODUCT:

xBefore leaving the operator’s station or before

beginning any type of work on this product, lower

this product to the ground, apply your power unit’s

parking brake, stop the engine, remove the starter

key, wait for all moving parts to stop, and then

relieve all pressure in the hydraulic lines. Refer to

your power unit’s operator’s manual for instructions

on how to relieve hydraulic pressure in lines.

xKnow your loader’s safe lifting and operating

capacity and the weight of this product. See the

specifications in this manual for the weight of this

product and refer to your power unit’s and loader’s

operator’s manuals for safe operating limits. Lift

capacity may be reduced if using a quick-attach.

xNever allow anyone, except the operator, to be

around the power unit or this product when either is

in motion. Do not startup unless others are clear of

the work area.

xDo not allow riders on this product or the power unit.

xDo not stand or climb on this product when raised.

xDo not place any part of your body under any part of

this product unless this product is securely resting

on adequate blocking or on the ground.

xDo not use blocking made of concrete blocks, logs,

buckets, barrels or any other material that could

suddenly collapse or shift positions. Do not use

wood or steel blocking that shows any signs of

material decay. Do not use blocking that is warped,

twisted, or tapered.

xAlways block the rear wheels of the Planer in a

manner that stabilizes the chassis.

xNever operate controls from the ground. Operate

the controls only from the operator’s station.

xNever leave equipment unattended with the engine

running or with this product raised on the loader.

xBe aware of the added weight and width of this

product. Reduce travel speeds accordingly,

especially when traveling over rough ground.

xKeep this product close to the ground and under

control when transporting.

SAFETY INSTRUCTIONS

WORK SAFELY - A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST ACCIDENTS !!

WARNING SECTION

4

[CONTINUED]

WARNING

Obey all the safety instructions

listed in this section and throughout

this manual. Failure to obey

instructions in this section could

result in death or serious injury.

WHEN DEALING WITH HYDRAULICS DURING ANY

TYPE OF ASSEMBLY, OPERATION, MAINTENANCE,

OR OTHER WORK ON OR NEAR THIS PRODUCT:

xHydraulic fluid under pressure can penetrate the

skin and cause serious injury or death. Hydraulic

leaks under pressure may not be visible!

xIf any fluid penetrates the skin, GET IMMEDIATE

MEDICAL ATTENTION!!

xWear safety glasses, protective clothing, and use a

sound piece of cardboard or wood when searching

for hydraulic leaks. DO NOT USE YOUR HANDS!

xBefore connecting or disconnecting hydraulic hoses,

read your tractor or power unit’s operator’s manual

for detailed instructions on connecting and

disconnecting hydraulic attachments.

xMake certain that all parts meet the specifications for

this product when installing or replacing hydraulic

hoses or fittings.

xAfter connecting hydraulic lines:

xSlowly and carefully raise the loader and cycle

the rollback / dump cylinders to check hose

clearances and to check for any interference.

xOperate the hydraulics on this product to check

hose clearances and to check for any

interference.

xMake certain that the hoses cannot interfere with

or actuate the quick-attach mechanism.

xMake certain that hoses will not be pinched, or get

tangled, in any equipment.

xDo not lock the auxiliary hydraulics of your power

unit in the “ON” position.

xRefer to your power unit’s operator’s manual and

this manual for procedures and intervals, then

inspect and maintain the entire hydraulic system to

insure that the fluid remains clean, that all devices

function properly, and that there are no fluid leaks.

WHEN MOUNTING THIS PRODUCT TO YOUR

POWER UNIT:

xRefer to the operator’s manuals of your power unit,

your loader, and your quick-attach for special or

detailed mounting instructions.

xThis product should fit onto the quick-attach or

loader arms of your power unit the same as the

original products that were designed by your loader /

quick-attach manufacturer.

xIf this product does not fit properly, contact FFC

Attachments before operating.

xNever place your finger into the mounting plate or

loader holes. A slight movement of the power unit or

this product could cause serious injury.

BEFORE EACH USE, THOROUGHLY INSPECT THIS

PRODUCT AND:

xMake certain that all safety signs are in place and

legible. Refer to the safety sign page in this manual

for the placement of safety signs for this product.

xReplace all damaged or excessively worn parts and

hardware only with genuine FFC Attachments parts

or with properly rated fasteners, hydraulic hoses, or

fittings.

xMake certain that all locking pins, latches, and

connection devices are properly installed and

secured.

xMake certain that all protective guards, canopies,

doors, etc., are in place and secure.

WHEN OPERATING THIS PRODUCT IN

ACCORDANCE WITH DESIGN INTENTIONS:

xKeep everyone at least nine feet away from the unit

when operating.

xNever operate your planer with the cover open.

WHEN ADJUSTING, SERVICING OR REPAIRING THIS

PRODUCT:

xMake no modifications to your planer.

xWhen making repairs, use only genuine FFC

Attachments parts or, for fasteners, hydraulic hoses,

or hydraulic fittings, use only properly rated parts.

xReplacement parts, for parts with safety signs

attached, must also have safety signs attached.

xThe Attachment Part group and the Chassis Part

group pivot freely. Do not place any part of your

body between these areas or under this product

without stabilizing this pivot point. Always block

the rear wheels of your Planer in a manner that

stabilizes the chassis.

SAFETY SIGN LOCATIONS

INSTRUCTIONS

xKeep all safety signs clean and legible.

xReplace all missing, illegible, or damaged safety signs.

xReplacement parts for parts with safety signs attached must also have safety signs attached.

xSafety signs are available, free of charge, from your dealer or from FFC Attachments.

PLACEMENT OR REPLACEMENT OF SAFETY SIGNS

1. Clean the area of application with non-flammable solvent, then wash the same area with soap and water.

2. Allow the surface to fully dry.

3. Remove the backing from the safety sign, exposing the adhesive surface.

4. Apply the safety sign to the position shown in the diagram above and smooth out any bubbles.

ITEM #3

ITEM #1

5

ITEM #2

ITEM#4

ITEM #5 ITEM #6

SAFETY SIGN LOCATIONS (CONTINUED)

6

2

1

6

3

4

5

ITEM QTY. PART # DESCRIPTION

1 2 RDL3100 STAND CLEAR

2 2 RDL3127 PINCH POINT

3 1 50-0724 HYDRAULIC

4 1 50-0723 READ MANUAL

5 1 RDL3159 FLYING DEBRIS

6 2 50-0721 CRUSH HAZARD

NOTE: items with quantity (2) are located directly opposite the item shown.

6

POWER UNIT SPECIFICATIONS

IMPORTANT Exceeding any of the maximum recommended tractor or power unit specifications

CAN result in damage to this product and

WILL

void all FFC Attachments warranties.

DESCRIPTION SPECIFICATIONS

Weight of Power Unit without Planer 11000 lbs. maximum

Operating Capacity of Power Unit’s loader 3750 lbs. maximum

Lift Capacity of Power Unit’s loader 7500 lbs. maximum

Hydraulic Pressure Output 5,000 psi. maximum

Front or Rear Ballast As required to maintain full power unit stability.

(see the shipping weight on page 22, then see the

operator’s manual(s) for you power unit, loader, and quick-

attach for your ballasting needs.)

PLANER MOUNTING

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER MOUNTING

1. Place this product on a firm, level surface that is large enough to safely accommodate this product, your power unit

and all workers involved in the mounting process.

2. Refer to the operator’s manual(s) for your power unit, loader, and quick-attach and follow the mounting instructions

contained therein.

3. Carefully raise the loader and cycle the tilt cylinders to check clearances and to verify that all mounting procedures

have been successfully completed.

4. IMPORTANT: Lubricate all grease fittings before connecting this product to your power unit’s hydraulic system.

Refer to PLANER MAINTENANCE on page 10 and follow the instructions.

ELECTRIC HARNESS AND ACTUATOR INSTALLATION

MATERIALS NEEDED: Nylon cable ties.

1. Attach the control box to a location convenient for the operator to control the planer without hindering operation of the

power unit. Use the magnet on the back of the control box to secure the control box with the toggle switches on top.

CAUTION

Failure to obey the following procedures may result in personal injury.

xTo avoid electric shock during the wiring harness installation, remove the ground cable

from the battery of your power unit.

2. Remove the ground cable from the negative (-) post of your power unit’s battery.

3. Remove the nut from the POSITIVE (+) cable clamp on the battery and slide the RED wire ring terminal from the 9’

wiring harness cable over the positive (+) cable clamp bolt. Secure the ring terminal with the nut.

4. Remove the nut from the NEGATIVE (-) cable clamp on the ground cable and slide the BLACK wire ring terminal

from the 6’ wiring harness cable over the negative (-) cable clamp bolt.

5. Reinstall the ground cable on the negative (-) post of the battery and secure the ring terminal and the ground cable

with the nut removed in the previous step.

6. Secure the 9’ wiring harness cable from the battery to the control box with your nylon cable ties.

7. Feed the 16’ wiring harness cable:

a) back to the left-rear area of your power unit,

b) past the loader arm’s rear hinge point by following the hydraulic hoses where possible, and

c) down the loader arm following the hydraulic lines.

8. Use your nylon cable ties to secure the 16’ cable’s female connector to the hydraulic lines next to the auxiliary

hydraulic quick couplers.

9. Straighten the 16’ cable and use your nylon cable ties to secure the cable to the hydraulic lines back to the loader arm

hinge point.

10. Allow sufficient slack in the cable at the hinge point to provide for a full range of motion of the loader arms. Use your

nylon cable ties to secure the cable to the loader frame below the hinge point and back to the control box.

11. Connect the male connector on the actuator cable to the female connector on the loader arm.

7

PLANER HYDRAULIC CONNECTION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER HYDRAULIC CONNECTION

1. Disconnect the hydraulic hose quick couplers from one another and attach the quick couplers to your power unit as

per the instructions in your power unit’s operator’s manual.

2. Carefully raise the loader and cycle the tilt cylinders to check hose clearances and to check for any interference.

3. Cycle the hydraulic cylinder(s) on this product several times from fully retracted to fully extended until all air has been

completely removed from the cylinder.

WARNING

Do not lock the auxiliary hydraulics of your power unit in the “ON” position.

Failure to obey this warning could result in death or serious injury.

PLANER SETUP

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER SETUP

From the operator’s position:

xThe left switch controls the Planer Tilt.

xThe middle switch controls the Planer Sideshift.

xThe right switch controls the Planer Depth.

.

8

PLANER OPERATION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER OPERATION

Starting a Cut:

1. To begin a cut, adjust the depth cylinders to the

desired depth with the planer slightly above the

ground. Engage the hydraulic system to start the

drum. Lower the planer bringing the front wheels

onto the ground.

9

2. Continue lowering the planer until the rear wheels

are on the ground and the drum is milling the

material.

3. Slightly lift the front loader wheels to create a

downward force on the planer. Slowly move forward,

planing in a straight line.

NOTE: Materials can vary greatly: it is recommended that cutting depth be limited to 1 inch when roughing concrete.

Deeper cuts in concrete should be made in multiple passes.

WARNING

Failure to obey the following procedures could result in death or serious injury:

xNever lift this product above (a.) the operator’s eye level or (b.) to a height where

visibility is obstructed, whichever is lower.

xNever operate your Planer with the Cover open.

PLANER MAINTENANCE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER MAINTENANCE

WARNING

Failure to obey the following procedures could result in death or serious injury.

xNever walk under or climb on raised liftarms or a raised attachment.

xDo not use blocking made of concrete blocks, logs, buckets, barrels or any other

material that could suddenly collapse or shift positions. Do not use wood or steel

blocking that shows any signs of material decay. Do not use blocking that is warped,

twisted, or tapered.

xIf the attachment must be raised, block the machine with blocks or jackstands, NOT lift

jacks or hoists. Always block the rear wheels of the Planer in a manner that stabilizes

the chassis.

xAlways wear protective equipment including a HARD HAT and EYE PROTECTION when

operating, performing maintenance, or working near this product.

xThe Attachment Part group and the Chassis Part group pivot freely. Do not place any

part of your body between these areas or under this product without stabilizing this

pivot point.

BEFORE EACH USE

xMake sure that all nuts and bolts are in place and properly tightened.

xMake sure that all other fasteners are in place and are performing their specified function.

xMake sure that all hydraulic fittings are tightened to specifications and that there are no leaks in any fittings or hoses

(see the hydraulic connection section on page 8.)

xMake sure that all safety signs are in place, are clean, and are legible (see the safety sign section on pages 5-6).

xReplace any damaged parts and excessively worn parts.

DAILY

xGrease (13) fittings: (1) on the drum bearing / (4) on the wheels / (4) on the slider frame bosses / (2) on the depth skids /

and (2) on the pivot bosses (see illustrations on page 13).

NOTE: Lubricate all grease fittings with a NLGI #1 or 2 multipurpose grease.

WEEKLY

IMPORTANT Prior to performing the following operation, make sure the cylinders are positioned as follows:

Tilt cylinder must be centered (head level).

Sideshift cylinder must be fully retracted (left side maximum).

Depth cylinder must be fully extended (shallowest cut position).

Failure to do so CAN result in damage to this product and

WILL void all FFC Attachments warranties.

10

PLANER MAINTENANCE (continued)

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER MAINTENANCE

WARNING

Failure to obey the following procedures could result in death or serious injury.

xNever walk under or climb on raised liftarms or a raised attachment.

xDo not use blocking made of concrete blocks, logs, buckets, barrels or any other

material that could suddenly collapse or shift positions. Do not use wood or steel

blocking that shows any signs of material decay. Do not use blocking that is warped,

twisted, or tapered.

xIf the attachment must be raised, block the machine with blocks or jackstands, NOT lift

jacks or hoists. Always block the rear wheels of the Planer in a manner that stabilizes

the chassis.

xAlways wear protective equipment including a HARD HAT and EYE PROTECTION when

operating, performing maintenance, or working near this product.

xThe Attachment Part group and the Chassis Part group pivot freely. Do not place any

part of your body between these areas or under this product without stabilizing this

pivot point.

ANNUALLY

NOTE: initial oil change should be after 50 hours of operation. Subsequent oil change should be every 1000 hours of

operation or annually, whichever comes first.

Planetary gearbox is to be half full of oil when the unit is mounted level and horizontal. Use mild extreme pressure lubricant

API-GL-5, No. 80 or 90. The capacity of the gearbox is 30 oz.

Refer to Parts Illustrations to disassemble and reassemble your Planer.

To change the oil in the Planetary Gearbox:

1. Remove motor. NOTE: motor shaft adapter is loose and can fall from planetary.

2. Remove pivot weldment with attach weldment. Keep attach weldment close and do not stretch hoses.

3. Remove depth cylinders. Hydraulic lines can be left attached.

4. Remove two depth skids.

5. Remove the right and left support plates from the chassis.

6. Using the lift point on the chassis, raise the chassis off of the drum.

7. Remove the planetary.

8. Remove drain plug from the planetary.

9. Drain oil from planetary.

10. Fill planetary with oil. The oil level must be at the bottom of the threads with the hole level. Do not tip the

planetary, as the oil can run out of the planetary before the motor is installed.

11. Clean any debris from the drain plug and apply pipe thread sealant to the threads.

12. Install the planetary in the drum.

13. Install the drum in the chassis. Install the depth skids, pivot weldment, and depth cylinders.

14. Complete the reassembly of your Planer. (See Parts Illustrations & Parts Lists and Torque Specifications for

reference during reassembly.)

11

PLANER SERVICE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-4 of this

manual) BEFORE BEGINNING ANY PLANER SERVICE

WARNING

Failure to obey the following procedures could result in death or serious injury.

xNever walk under or climb on raised liftarms or a raised attachment.

xDo not use blocking made of concrete blocks, logs, buckets, barrels or any other

material that could suddenly collapse or shift positions. Do not use wood or steel

blocking that shows any signs of material decay. Do not use blocking that is warped,

twisted, or tapered.

xIf the attachment must be raised, block the machine with blocks or jackstands, NOT lift

jacks or hoists. Always block the rear wheels of the Planer in a manner that stabilizes

the chassis.

xAlways wear protective equipment including a HARD HAT and EYE PROTECTION when

operating, performing maintenance, or working near this product.

xThe Attachment Part group and the Chassis Part group pivot freely. Do not place any

part of your body between these areas or under this product without stabilizing this

pivot point.

1. Park your power unit on a level surface with this product properly attached.

2. Place your power unit’s transmission in “Park” and engage the parking brake.

3. Lower this product onto preplaced blocking.

4. Shut off your power unit’s engine, remove the starter key, wait for all moving parts to come to a stop, and relieve all

pressure in the hydraulic lines.

CAUTION

Picks become hot during operation: Wait for picks to cool before replacing.

Do not hammer on carbide point when replacing picks. The carbide can break and cause

injury.

Pick Removal/Replacement:

xProper pick maintenance is essential to the productive use of your Planer. Failure to perform regular pick

maintenance can result in severely decreased performance and expensive repairs to your Planer drum.

xA missing pick must be replaced immediately, as a missing pick will cause the surrounding picks to wear faster.

xPicks must be replaced when their carbide tips become excessively blunt. NOTE: the edge picks wear faster and

require more frequent replacement.

xPicks must rotate freely in their holders. If picks do not rotate freely, they will develop flat spots. Picks should be

removed and retaining rings cleaned as necessary.

xRemove and replace picks using the pick removal tool (LAF9326) and a hammer as shown below.

12

13

PARTS ILLUSTRATION

53

71

11 81

82

83

60

66

52

4

1

50

5-LINE MANIFOLD

79

3

84

70

85

51

86

59

65

2

52

15

ITEM

No.

QTY. LAF5416

16"

LAF5418

18"

LAF5420

20"

LAF5424

24"

LAF5430

30"

LAF5436

36" Description

1 2 07-10017 Grade 5 Hex Head Cap Screw 3/8"-

16tpi x 6-1/2" f/ 3-Line

2 2 07-10050 Grade 5 Hex Head Cap Screw 5/16"-

18tpi x 4-1/2" f/ 5-Line

3 2 13-50392 Rod 2" x 47-1/4" w/ 13/32" Cross

Hole

4 1 13-50811 Manifold Guard Plate

51 LAF4537 O-Ring, #155 3/32” x 4” ID x 4-

3/16” OD

61 LAF4698 Sideshift C

y

linder

7 2 LAF4704 Depth Cylinder

81 LAF4705 Tilt C

y

linder

91 LAF4706 Motor

10 1 LAF8231 Non-Skid Ta

p

e 4" x 24"

11 2 LAF9307 Latch Lid

12 2 LAF9308 Pivot Bushin

g

13 1 LAF9310 Deadshaft Bearing

14 1 LAF9316 Deadshaft

15 1 LAF9319 LAF9319 LAF9319 LAF9319 13-50434 13-50434 Mainf rame Weldment

16 4 LAF9322 Planer Wheel Weldment

17 2 LAF9324 Dual Snap Ring Pin, 1” x 5-29/32”

18 3 LAF9325 Dual Snap Ring Pin, 1” x 5-17/32”

19 1 LAF9326 Pick Removal Tool

20 1 LAF9336 LAF9337 LAF9338 LAF9339 LAF9340 LAF9341 Chassis Weldment

21 1 LAF9342 Planetary Side Depth Skid

22 1 LAF9343 Deadshaft Side Depth Skid

23 1 LAF9344 Planetary Support

24 2 LAF9347 Dual Snap Ring Pin, 1” x 7-3/8”

25 1 LAF9348 Bearing Guard

26 2 LAF9350 Depth Indicator Receiver

27 2 LAF9351 Depth Indicator Weldment

28 1 LAF9352 LAF9353 LAF9354 LAF9355 LAF9356 LAF9357 Drum Assembl

y

29 1 LAF9358 Tilt Retainer

30 1 LAF9362 Bearing Mount Spacer

31 1 LAF9364 Planetar

y

Gearbox

32 1 LAF9365 Deadshaft Support

33 1 LAF9366 LAF9367 LAF9368 LAF9369 LAF9370 LAF9371 Pivot Weldment

34 1 LAF9377 LAF9378 LAF9379 LAF9380 LAF9381 LAF9382 Sideshift Weldment

35 varies

(

48

)

(

52

)

(

56

)

(

64

)

(

76

)

LAF9389

(

88

)

Pick Holder

(q

uantit

y

noted

)

36 varies

(

48

)

(

52

)

(

56

)

(

64

)

(

76

)

LAF9390

(

88

)

As

p

halt Pick

(q

uantit

y

noted

)

37 2 LAF9396 Depth Skid Retainer Plate

38 4 LAF9397 Depth Skid Retainer Boss

39 2 LAF9399 Water Nozzle Hole Cover

PLANER: PARTS LIST

NOTE 1: All

p

arts are the same as LAF5436 unless otherwise noted.

14

15

ITEM

No.

QTY. LAF5416

16"

LAF5418

18"

LAF5420

20"

LAF5424

24"

LAF5430

30"

LAF5436

36" Description

40 1 RHW1004 Grade 5 Hex Head Cap Screw 1/4"-

20tpi x 3/4"

41 1

2

f/ 3-Line

f/ 5-Line

RHW1108 Grade 5 Hex Head Cap Screw 5/16"-

18tpi x 1-1/2"

42 1

2

f/ 3-Line

f/ 5-Line

RHW1112 Grade 5 Hex Head Cap Screw 5/16"-

18tpi x 2-1/2"

43 1

0

f/ 3-Line

f/ 5-Line

RHW1207 Grade 5 Hex Head Cap Screw 3/8"-

16tpi x 1-1/4"

44 2 RHW1217 Grade 5 Hex Head Cap Screw

3/8” -16t

p

i x 3-1/2”

45 2 RHW1404 Grade 5 Hex Head Cap Screw

1/2” -13t

p

i x 1-1/4”

46 2 RHW1405 Grade 5 Hex Head Cap Screw

1/2” -13t

p

i x 1-1/2”

47 4 RHW1407 Grade 5 Hex Head Cap Screw

1/2” -13t

p

i x 2”

48 14 RHW1603 Grade 5 Hex Head Cap Screw 5/8”-

11tpi x 1-3/4”

49 2 RHW1971 Grade 5 Hex Head Cap Screw

1-1/8” -7t

p

i x 4”

50 3 RHW2601 Grade 8 Carriage Bolt

5/8"-11t

p

i x 2"

51 1

5

f/ 3-Line

f/ 5-Line

RHW5062 Grade 5 Flat Washer USS 1/4"

52 1

6

f/ 3-Line

f/ 5-Line

RHW5162 Grade 5 Flat Washer USS 5/16"

53 6

4

f/ 3-Line

f/ 5-Line

RHW5262 Grade 5 Flat Washer USS 3/8"

54 8 RHW5432 Grade 5 Flat Washer SAE 1/2"

55 13 RHW5532 Grade 5 Flat Washer SAE 9/16"

56 14 RHW5632 Grade 5 Flat Washer SAE 5/8"

57 3RHW5662 Grade 5 Flat Washer USS 5/8"

58 4 RHW5971 Machine Bushin

g

2" ID x 3" OD

59 1

3

f/ 3-Line

f/ 5-Line

RHW6002 Grade 5 Split Lock Washer 1/4"

60 1

4

f/ 3-Line

f/ 5-Line

RHW6102 Grade 5 Lock Washer 5/16"

61 3

0

f/ 3-Line

f/ 5-Line

RHW6202 Grade 5 Lock Washer 3/8"

62 6 RHW6402 Grade 5 Lock Washer 1/2”

63 14 RHW6602 Grade 5 Lock Washer 5/8"

64 2 RHW6903 Grade 5 Lock Washer 1-1/8"

NOTE 2: Quantity of item 58 may vary. Use as required to minimize gap.

PLANER: PARTS LIST (Continued)

NOTE 1: All

p

arts are the same as LAF5436 unless otherwise noted.

ITEM

No.

QTY. LAF5416

16"

LAF5418

18"

LAF5420

20"

LAF5424

24"

LAF5430

30"

LAF5436

36" Description

65 1

3

f/ 3-Line

f/ 5-Line

RHW7001 Grade 5 Hex Nut 1/4"

66 1

4

f/ 3-Line

f/ 5-Line

RHW7101 Grade 5 Hex Nut 5/16"

67 3

0

f/ 3-Line

f/ 5-Line

RHW7201 Grade 5 Hex Nut 3/8"

68 2 RHW7203 Grade 5 Lock Nut 3/8”

69 13 RHW7502 Grade 8 Hex Nut 9/16”

70 3 RHW7607 Grade 8 Top Lock Flange Nut 5/8”

71 7 RHW8090 Grease Zerk, ¼”-28tpi, Straight

72 1

2

f/ 3-Line

f/ 5-Line

RHW8098 Grade 2 Fender Washer 5/64" x

5/16" x 1-1/2"

73 6 RHW8107 Grease Zerk, ¼”-28tpi, 45°

74 19 RHW8146 Retaining Ring, 1”, Heavy Duty

75 4 RHW8181 Grade 5 USS Flat Washer 1-1/8"

YDC

76 1 RHW8314 Loop Clamp 1/2" Rubber/Steel

Combo

77 1 RHW8610 Cover Plate f/ 1-21/64" Cradle

78 1

2

f/ 3-Line

f/ 5-Line

RHW8613 Weld Plate f/ 7/8" OD

79 1

2

f/ 3-Line

f/ 5-Line

RHW8618 Hose Spring

80 1 RHW8619 Hose Cradle f/ 1-21/64" Pipe

81 8 RHW9004 Self Tapping Screw, 1/4" x 3/4"

82 1 f/ 5-Line only RHW8616 Hose Cradle f/ 7/8" Clamp

83 1 f/ 5-Line only RHW8614 Cover Plate f/ 7/8" Cradle

84 2 not used not used not used not used not used 13-50445 Spacer Tube

85 2 f/ 5-Line only RHW1011 Grade 5 Hex Head Cap Screw 1/4"-

20tpi x 2"

86 1 f/ 5-Line only LAF4700 Cylinder Lock Valve

PLANER: PARTS LIST (Continued)

NOTE 1: All parts are the same as LAF5436 unless otherwise noted.

16

17

HYDRAULIC & ELECTRICAL GROUP ILLUSTRATION 3-LINE

HYDRAULIC & ELECTRIC GROUP ILLUSTRATION 5-LINE

18

Other manuals for LAF5416

1

This manual suits for next models

5

Table of contents

Other FFC Planer manuals