FFS VIZU VI014HHC User manual

Page 1of 20

VIZU®Holder

VI014(S)HHC

Thermostatically controlled internal environment with digital display

Fan assisted air convection to improve consistency

Removable internal parts for easy cleaning

Two sizes available in 6 or 8 pan configurations

Mounted on non-marking heavy duty castors

Sealed door to improve internal humidity

Humidity control via water pan venting system

Page 2of 20

Contents

VIZU® Holder ..............................................................................................................1

VI014HHC SPECIFICATION PAGE................................................................................3

Model VI014HHC.......................................................................................................3

VI014SHHC SPECIFICATION PAGE ..............................................................................4

Model VI014SHHC .....................................................................................................4

General Description ...................................................................................................5

Assembly and Installation Instructions.........................................................................5

Switch Controls .........................................................................................................5

Instructions for use ...................................................................................................6

Description of Vizu Humidified Holding Cabinets ...........................................................6

Cleaning instructions - Daily .......................................................................................7

Cleaning of Auto Fill Pass-Thru machines .....................................................................8

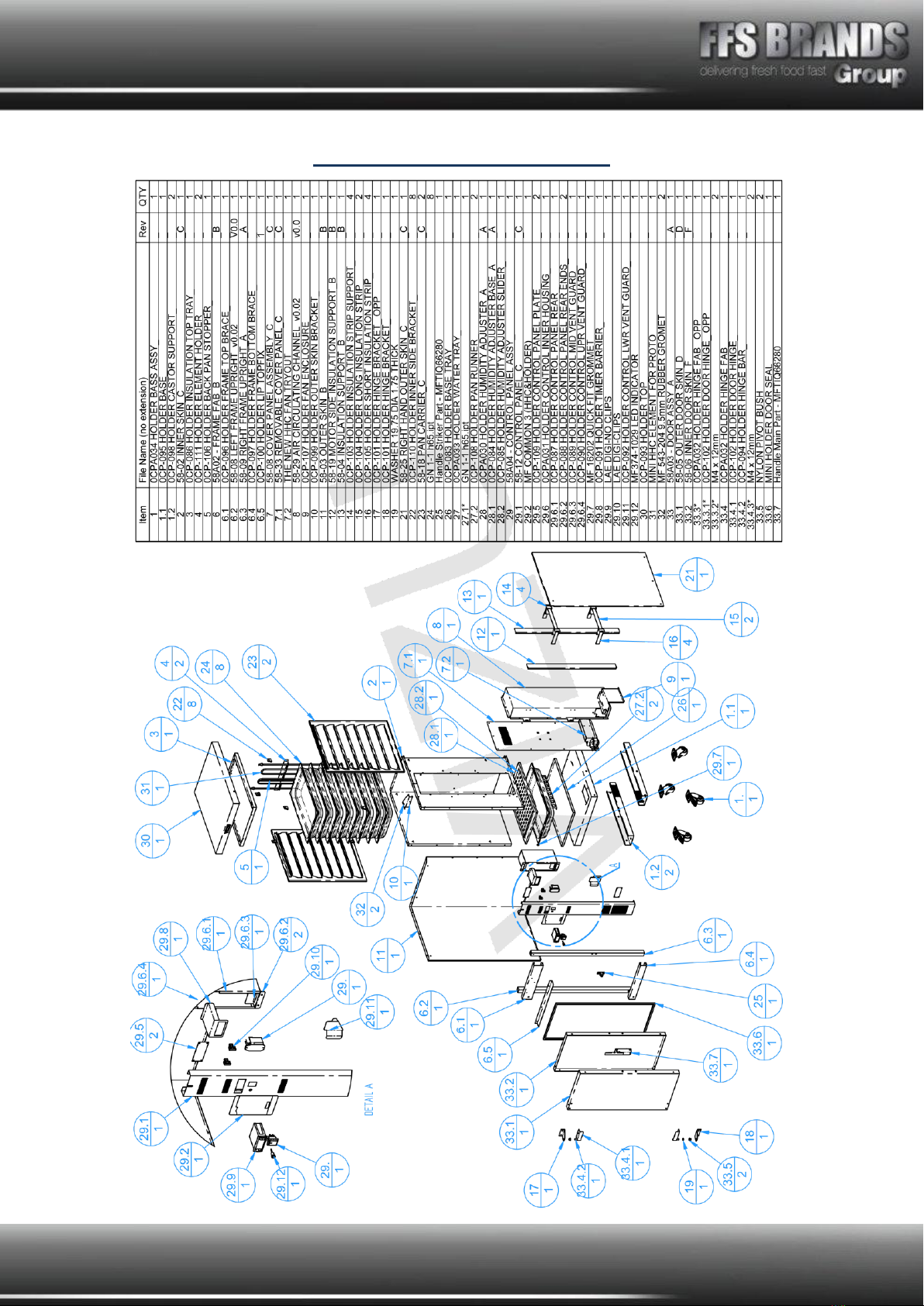

Exploded View - VI014HHC ......................................................................................10

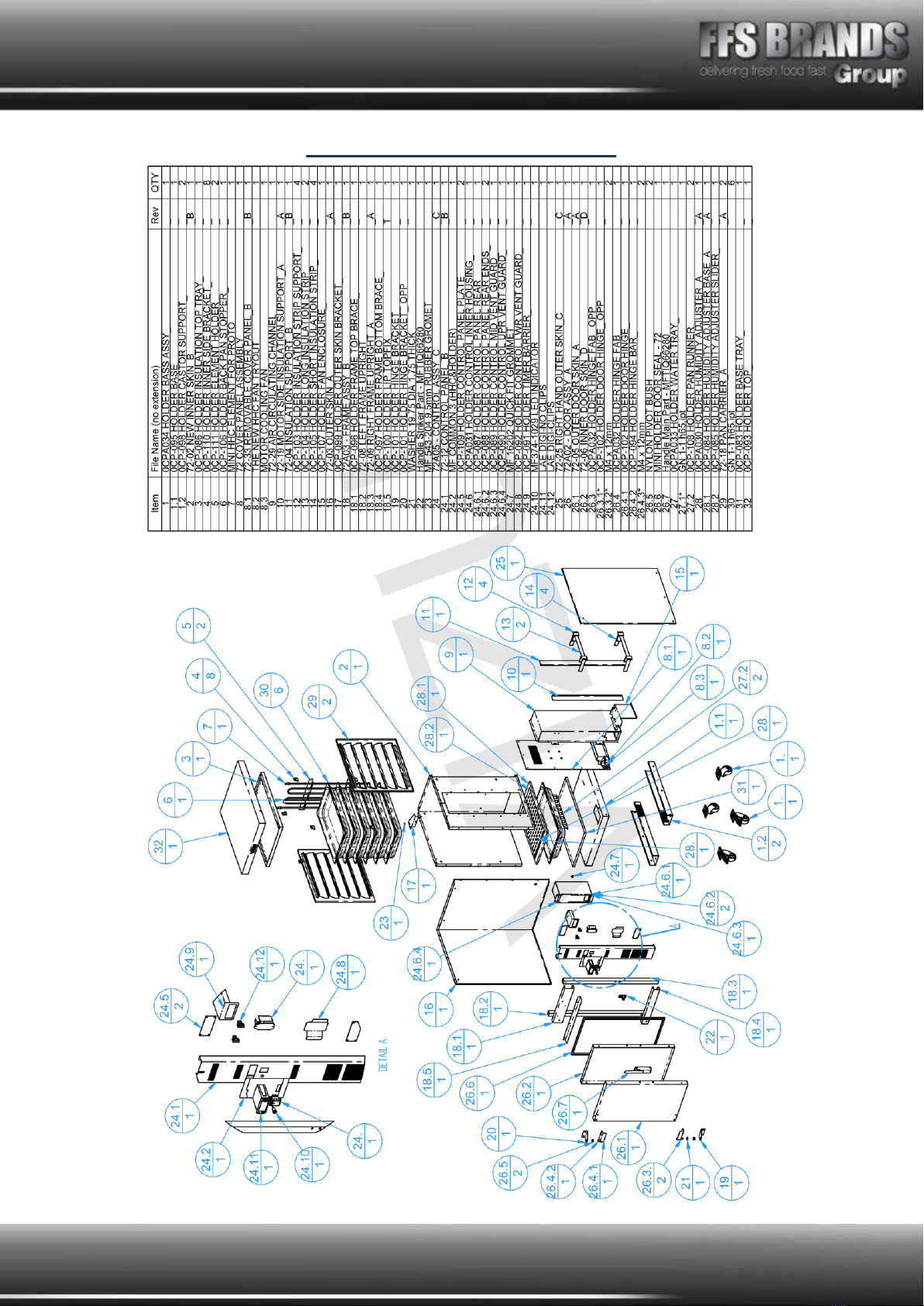

Exploded View - VI014SHHC.....................................................................................11

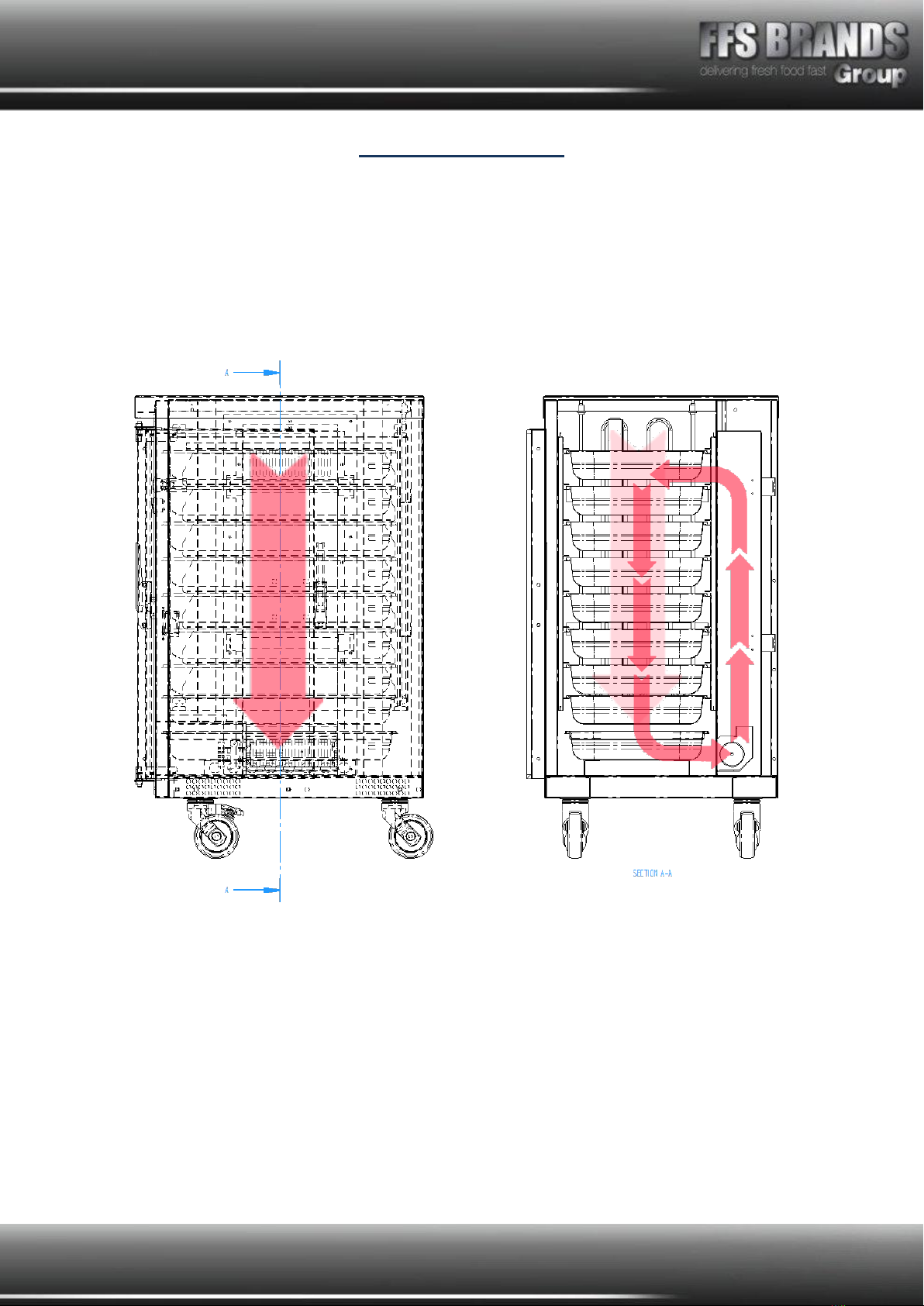

Air Flow Reference ..................................................................................................12

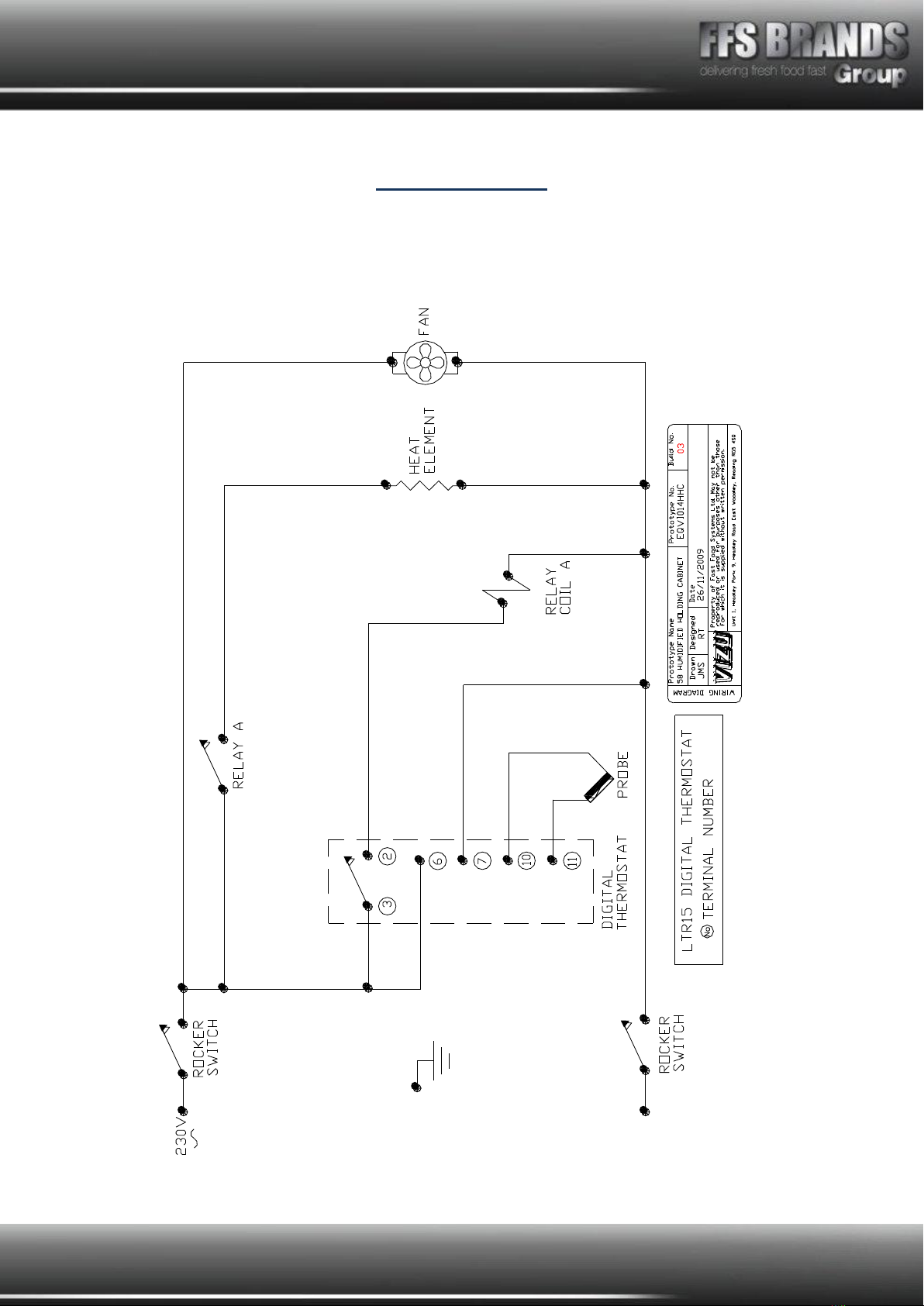

Wiring Diagram .......................................................................................................13

Spare Parts List.......................................................................................................14

FAULT FINDING ......................................................................................................16

Terms and Conditions .................................................................................................17

Claims....................................................................................................................17

Returns ..................................................................................................................17

Damage Claim Form ...................................................................................................18

Warranty ...................................................................................................................19

Page 3of 20

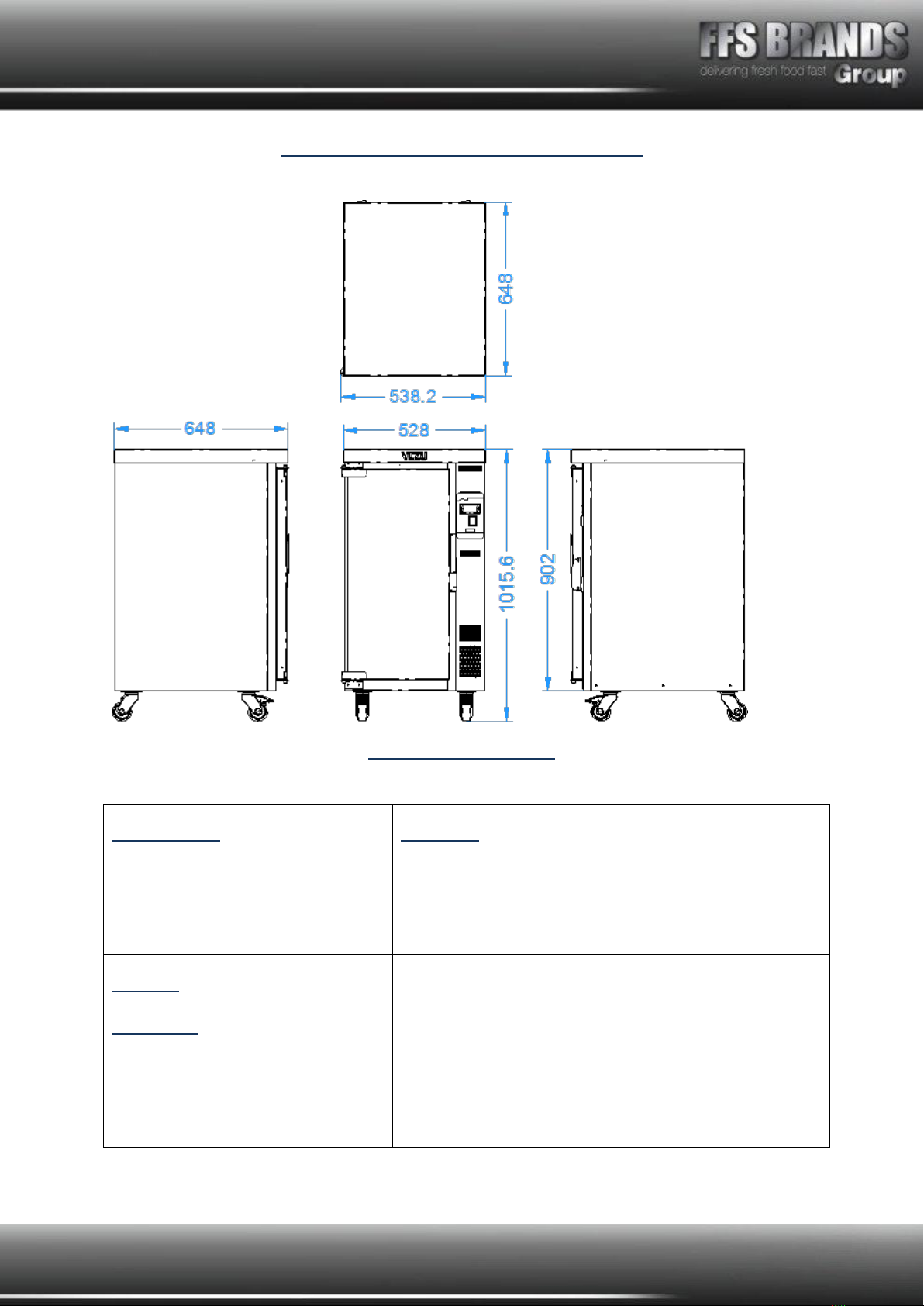

VI014HHC SPECIFICATION PAGE

Model VI014HHC

Dimensions

Height

Width

Depth

Machine

1020mm

540mm

650mm

Weight

66kg

Electrical

Running Amps

Connection Type

International Option

1 phase, 50HZ AC, 2030v, 0.9Kw

3.9 Amps

BSCHUKO 2/3 PIN PLUG

MFEUROCONVERT Plug adapter

Page 4of 20

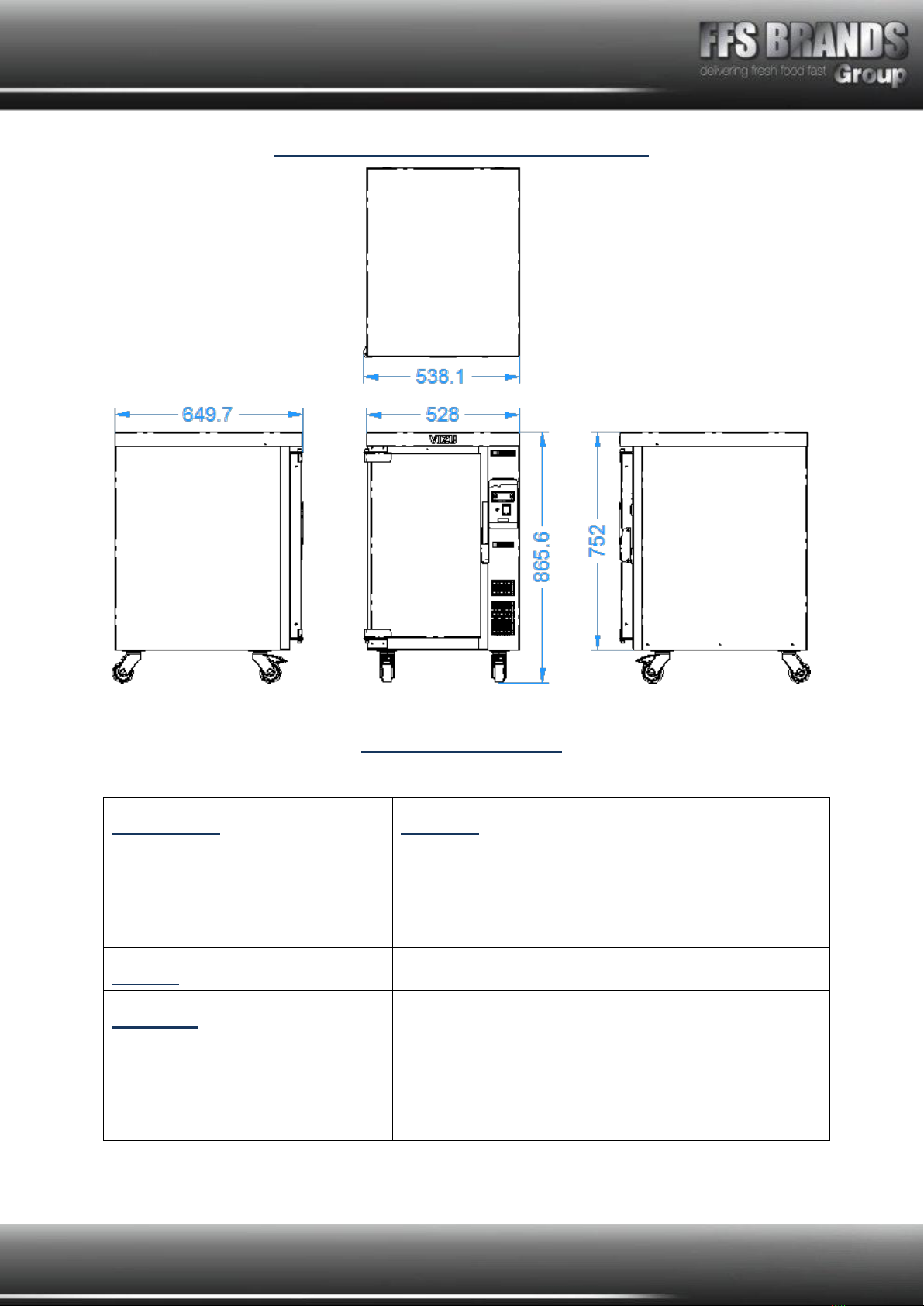

VI014SHHC SPECIFICATION PAGE

Model VI014SHHC

Dimensions

Height

Width

Depth

Machine

870mm

540mm

650mm

Weight

59kg

Electrical

Running Amps

Connection Type

International Option

1 phase, 50HZ AC, 2030v, 0.9Kw

3.9 Amps

BSCHUKO 2/3 PIN PLUG

MFEUROCONVERT Plug adapter

Page 5of 20

All

Vizu Humidified Holding Cabinets

have been tested and checked for proper

operation before leaving the factory.

Upon delivery please check the unit for damage. If the unit is damaged, contact the carrier,

or Fast Food Systems, immediately and file a damage claim (found in the back of the

manual) Please retain all packing materials.

Damage must be reported within 7 days of delivery

General Description

The unit has been designed to hold cooked food products in a controller humidity and

temperature helping to reduce drying and shrinking of the cooked products.

Assembly and Installation Instructions

1. Remove all packing from the unit.

2. Peel off all protective plastic covering from metal

3. Wash all removable parts in warm, soapy water and dry them thoroughly.

4. Check runners are hooked internally in the unit.

5. Slide gastronorm pans into their positions on the horizontal runners.

6. Fit water tray and water tray lid.

Switch Controls

Red Switch –‘ON/OFF’

-Power to the unit

LED Indicator - ‘LED LIGHT’

-Shows the unit has power

Digital Stat –‘Digital display with controls’

-Controls temperature in the cabinet, will be set in the factory to provide the best

possible interior environment. If you need to adjust the settings, please let us

know and we will provide instructions.

Page 6of 20

Instructions for use

1. Ensure Mains power is on –The LED Indicator ‘LED LIGHT’ light should be lit

2. Ensure the water tray has water in it (or empty if you want to hold in dry heat)

3. Turn red ‘ON/OFF’ switch to ‘ON’

4. Leave the machine for 30 minutes to heat (and humidify)

5. Adjust the humidity vents to the desired opening

Description of Vizu Humidified Holding Cabinets

The Vizu Humidified Holding unit must only be used to keep cooked food hot and moist; it

must not be used to re-heat cooked foods.

The machine is suitable for holding cooked meats and fish, and other items.

This unit has a few removable parts, these should be handled with care when using or

cleaning as damage may affect the machines ability to work correctly.

The machine is factory set to 70C. This is adequate to hold cooked food at a safe

and legal temperature (i.e. above 63C)

The red switch light should always remain on as long as the cabinet is plugged in. For

uncovered foods, fill the water tray (situated in the base of the cabinet) with 1 inch (2.5cm)

of hot water. This will allow the heating system to add humidity to the cabinet. Continue to

pre-heat the cabinet for 30 minutes before use. The Vizu Mini/Standard Humidified Holding

Cabinet is now ready to be loaded with hot foods.

Keep the Vizu Humidified Holding Cabinet plugged in while loading and keep the door closed

as much as possible. After loading do not open door again until ready to serve. Before

moving cabinet ensure that cabinet is up to selected temperature, then quickly wheel the

Vizu Humidified Holding Cabinet to the serving area and immediately re-connect to electrical

supply so that the thermostat will automatically 'hold' at the temperature selected.

Do not load or continue to hold food if the thermostat indicates less than 65°C

Page 7of 20

Cleaning instructions - Daily

1. Disconnect the machine from the power supply before cleaning and allow to cool.

2. Remove food gastronorme pans, wire insets, water tray assembly, lower tray and

pan side racks wash thoroughly in warm soapy water, rinse and dry.

3. Doors may be wiped with a soft damp cloth, dry thoroughly taking care not to

damage the seal.

4. Wipe down the inside of the machine with a damp warm soapy cloth, and then dry

thoroughly.

5. Take care not to let any water get into the vents and through to the electrics, you do

not want to soak the machine in water, just use enough water to make the cloth

damp for cleaning.

NEVER use wire wool, scourers, abrasive cleaners, acids or bleach.

DO NOT flood or allow electrical parts to become wet.

DO Dry all surfaces thoroughly removing all moisture.

A stainless steel cleaner/polish may be applied to the exterior.

N.B - For Hard Water Areas

To avoid the risk of scale build up, we advise to use a water softener or de-ionised water for

the water you put into the pan.

Please be aware of these guidelines as scale is not covered by our warranty.

Page 8of 20

Cleaning of Auto Fill Pass-Thru machines

Keep the unit clean by simply wiping the interior and exterior as necessary with a damp

cloth or sponge and a mild soapy solution. NEVER use abrasives, acids or strong cleaners.

DO NOT flood or allow electrical parts to become wet. The interior racks, water tray and

element cover are removable for ease of cleaning. A stainless steel cleaner/polish may be

applied to the exterior to maintain an as-new appearance. Do not use wax or powerful

cleaners on door gasket.

NEVER USE WIRE WOOL –THIS WILL MARK THE STAINLESS STEEL SURFACES

CARE MUST BE TAKEN WHEN CLEANING THE INTERIOR OF THE MACHINE

BECAUSE ELEMENTS, PANELS ETC. MAY REMAIN HOT FOR SOMETIME AFTER THE

HEATING HAS BEEN SWITCHED OFF.

NOTE: - DO NOT USE ABRASIVE CLEANERS OR PADS.

DO NOT USE BLEACH.

Dry all surfaces thoroughly removing all moisture.

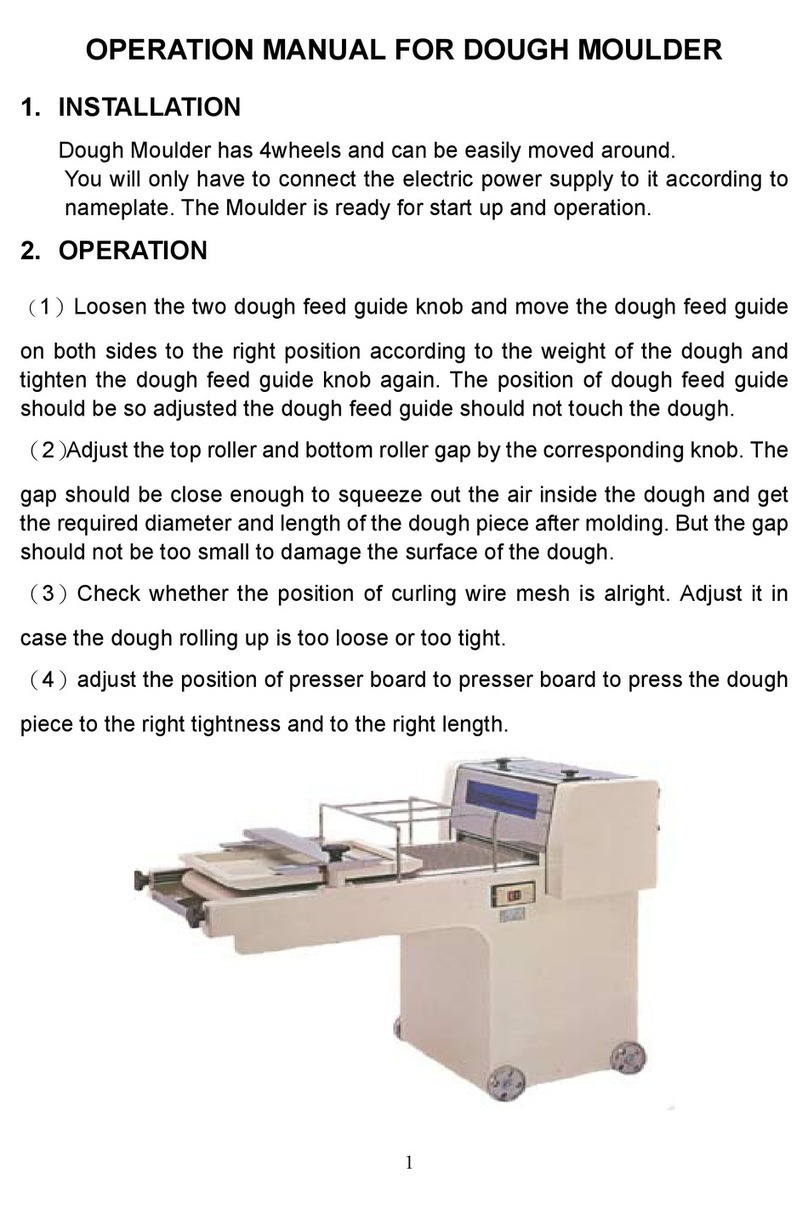

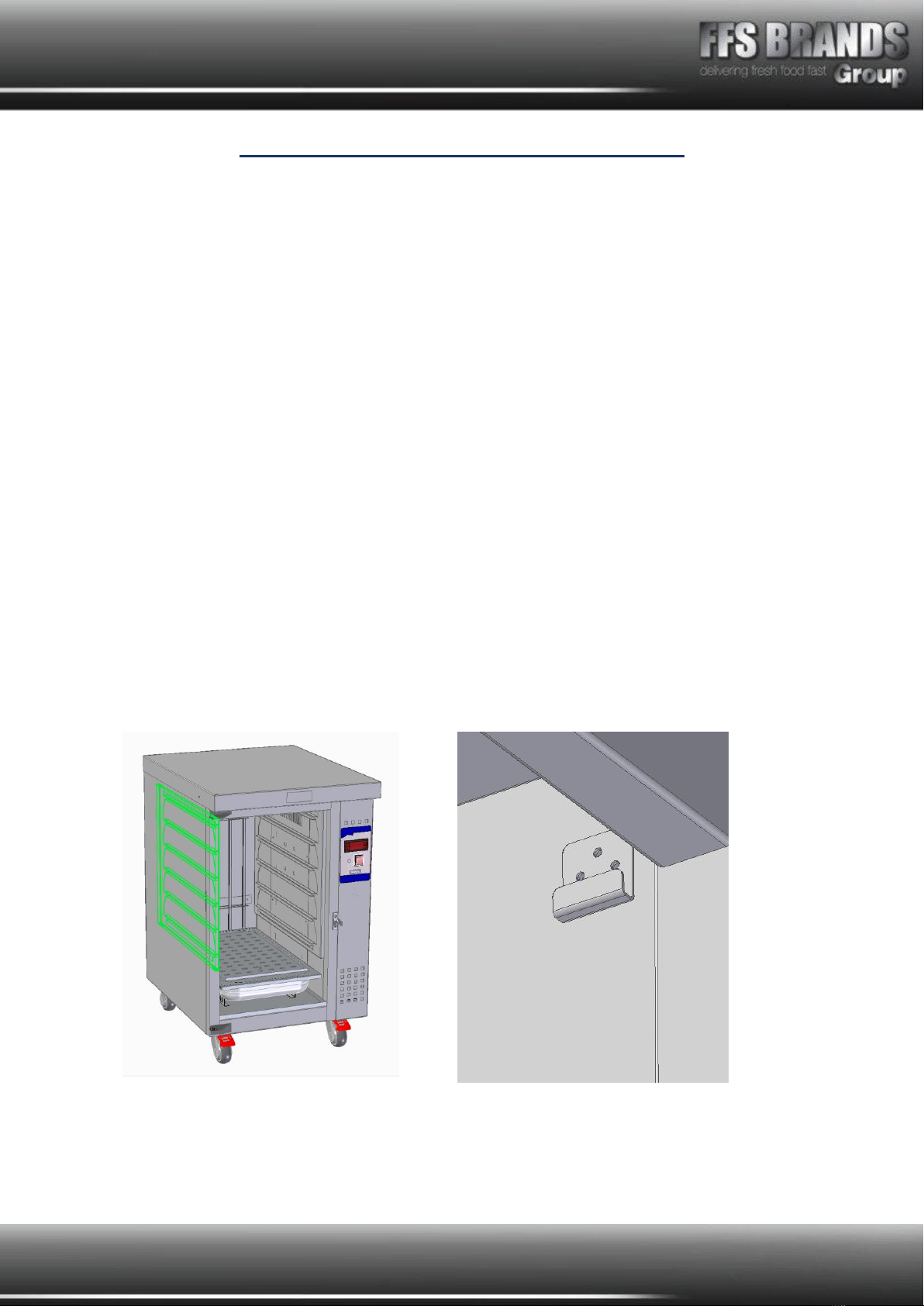

Removal of the tray runners from the inside of the unit

As part of the cleaning procedure the tray runners must be removed to allow cleaning to be

carried out. Fig 1 shows the runners in position.

By lifting the runners frame upwards and inwards it can be moved off the locating hooks,

Fig 2.

Fig. 1 Fig. 2

Page 9of 20

The runner assembly can now be lifted away from the inner side of the machine, Fig 3.

Fig.4 shows the inside of the machine with the runner assembly removed.

The water tray used in the humidified holding cabinets consists of a tray with a cover plate.

Fig. 3 Fig. 4

Fig. 5

The cover plate has a sliding adjustable vent to control the amount of water evaporation.

See Fig. 5. Set to the middle position, and slide open or closed of more or less moisture is

required.

For normal operation the factory setting of the holder is 75C

Temperature / Humidity characteristics

If the temperature of the holder is changed then the characteristics of the unit will change

too. Typically the humidity will be affected by changes to the temperature.

If the temperature is altered then experimentation will be required to see what water levels

(if any) are required, as well as the position of how open or closed the vents are.

Page 10 of 20

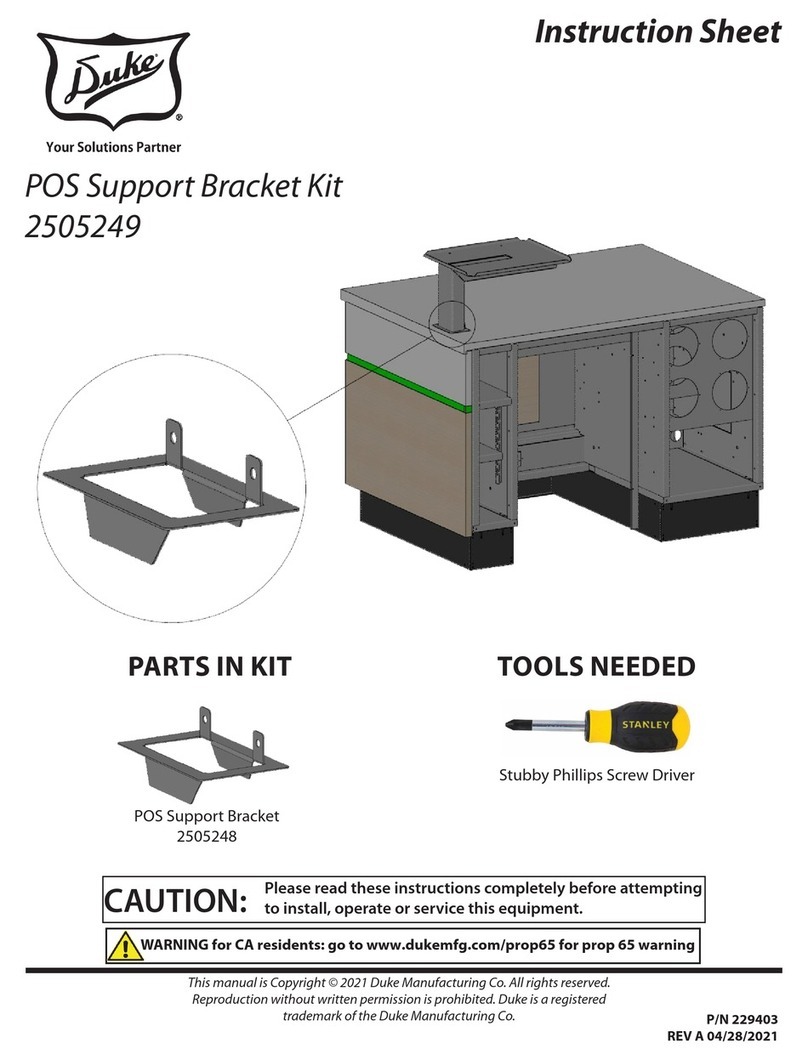

Exploded View - VI014HHC

Page 11 of 20

Exploded View - VI014SHHC

Page 12 of 20

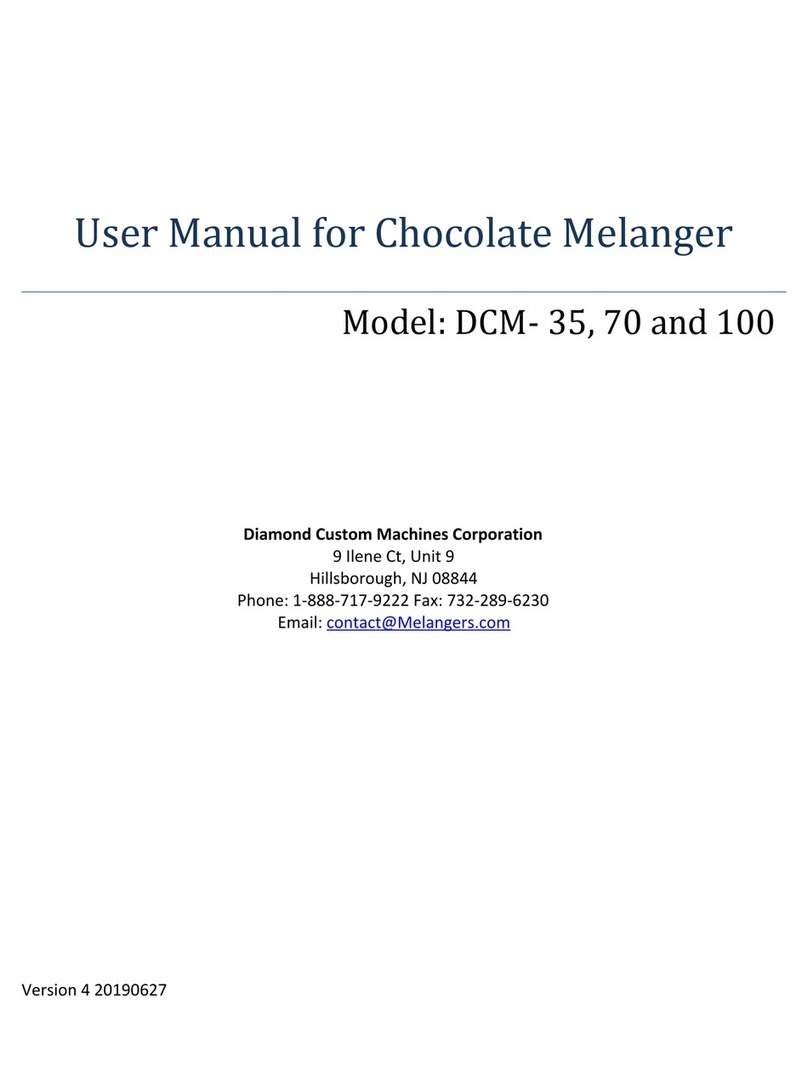

Air Flow Reference

Internal Air flow is controlled by a centrifugal fan mounted at the bottom of the machine.

Diagram shows correct air flow for MF2701060286A Fan.

Page 13 of 20

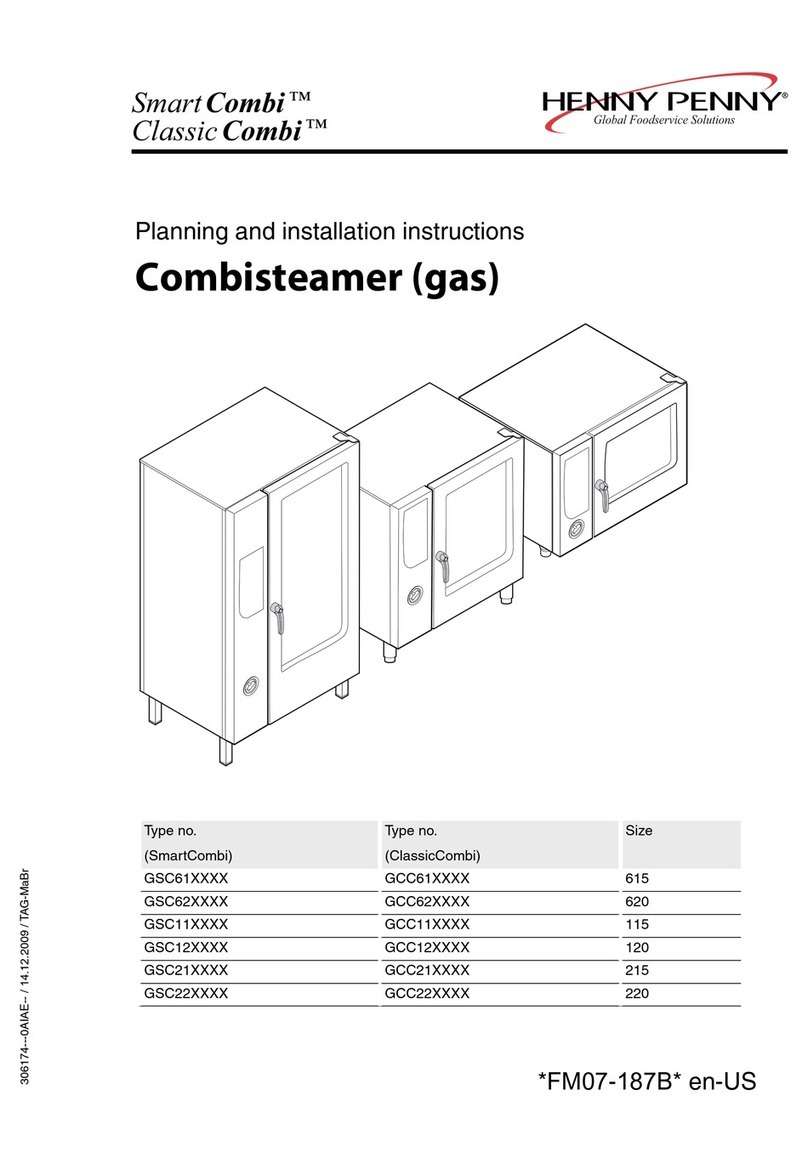

Wiring Diagram

Page 14 of 20

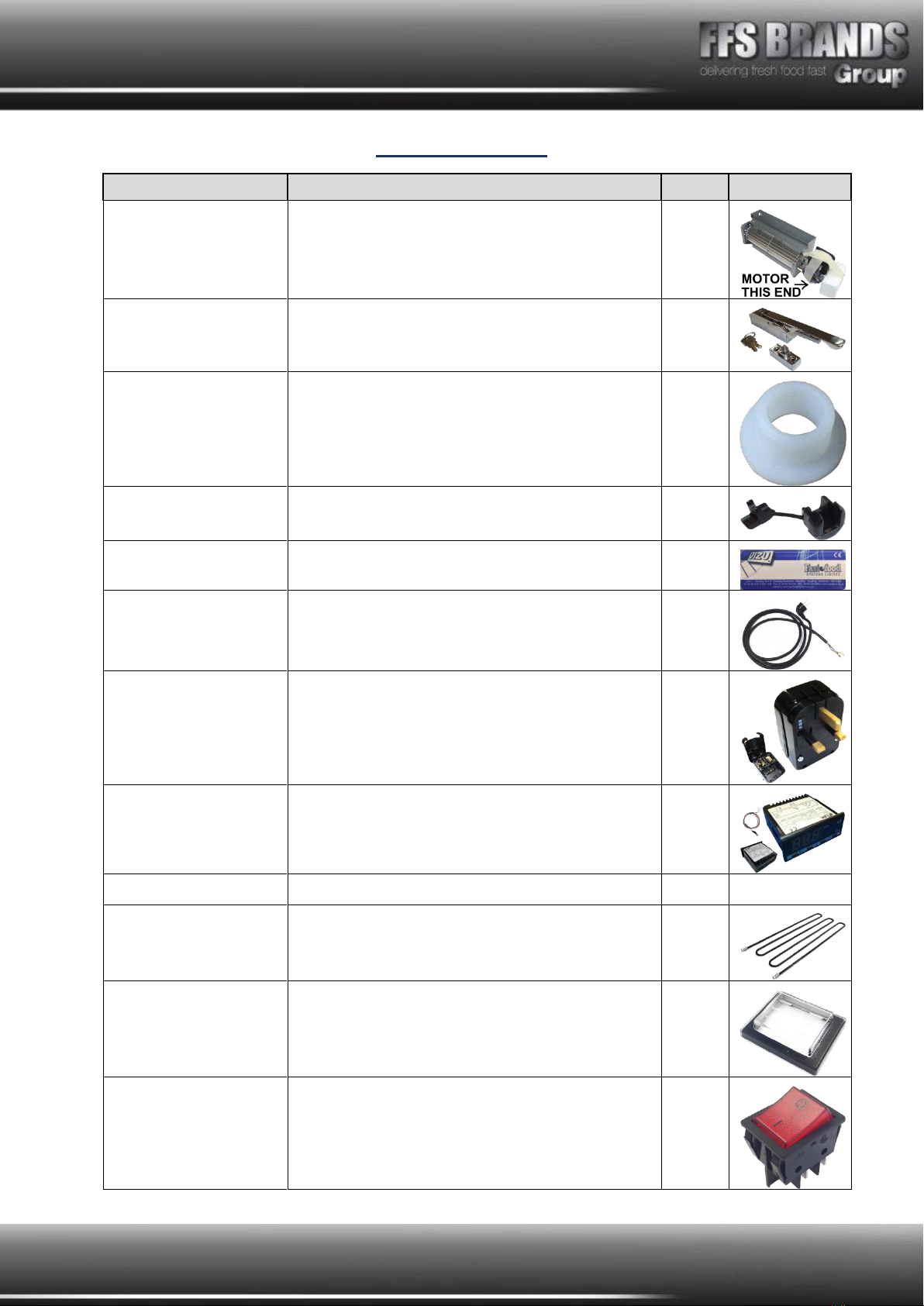

Spare Parts List

PART NO.

DESCRIPTION

QTY.

IMAGE

MF2701060286A

Electric Motor And Scroll Fan

1

MFDP2074-13

Latch And Strike Complete Set

1

MF08-10-11

Nylon Pivot Bushes 1092540000Vr

2

MF817-8877

Black Nylon 66, strain relief cable bush

1

MFCOMMON1

Label 5 140mm x 53mm

1

BESCHUKO

H05Rr-F 2Mtr. Rubber C032

1

MFEUROCONVERT

Euro to UK converter plug In black 19-1032

1

MFMTR11TIRES

Ltr-5Tsre-A(P) Digit Therm. With Probe

1

MFVI014SHHCINS

Mini Holda Insulation

1

Ztbc –oos

MFMINIHHCELEMENT

800W 230V Humidified Holda Element

1

VILE14

Switch cover / bezel HD2/HD4 MFF1025 /

MF1026

1

VISW17

Rocker switch HD2 Revolva HD4 MFC1553ALR

1

Page 15 of 20

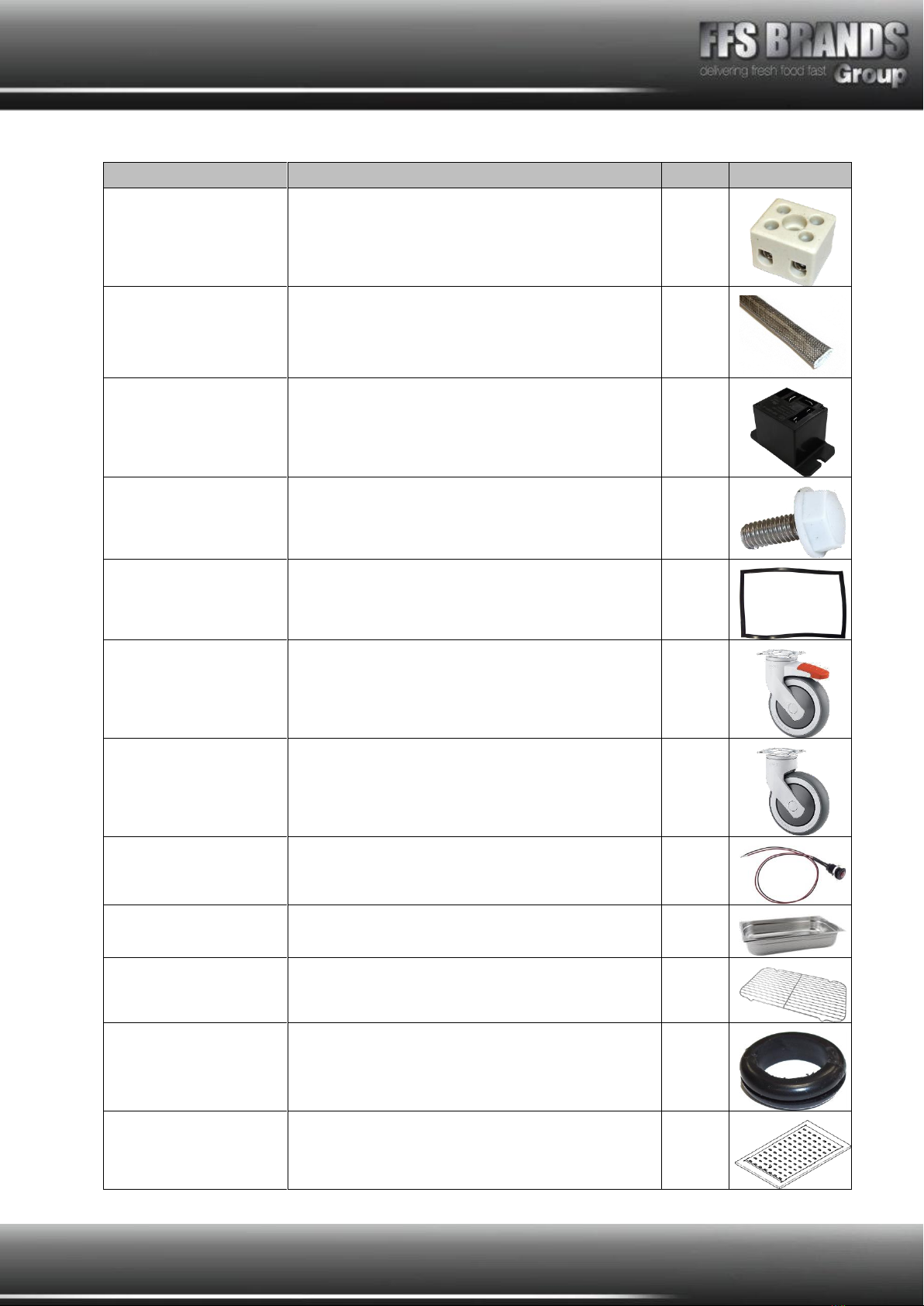

PART NO.

DESCRIPTION

QTY.

IMAGE

MF354Z

2 Pole 5amp term block TB06

2

MFOHSL01

High temperature sleeving

1

MF376-925

Relay 65-31 Holda / HD4 691-2124 Zsp-No

1

MFVC-14

Socket drive Sh/MSM4GY1011SS0100

1

VI06-378

Door Seal Vizu Holda

1

MFMKLJS75PTEK80

Swivel Castor With Break 75mm

2

MFMKLS75PTEK80

Swivel Castor No Break 75mm

2

MF374-1029

10mm low profile lens indicator 230VAC

1

GSGAST90022

1/1GN pan 65mm deep

7

GSGAST160

Stainless steel wire inserts for gast/pans

6

MF543-204

9.5mm Grommet

2

MF0CPA030

ADJUSTABLE HUMIDITY ADJUSTER

1

Page 16 of 20

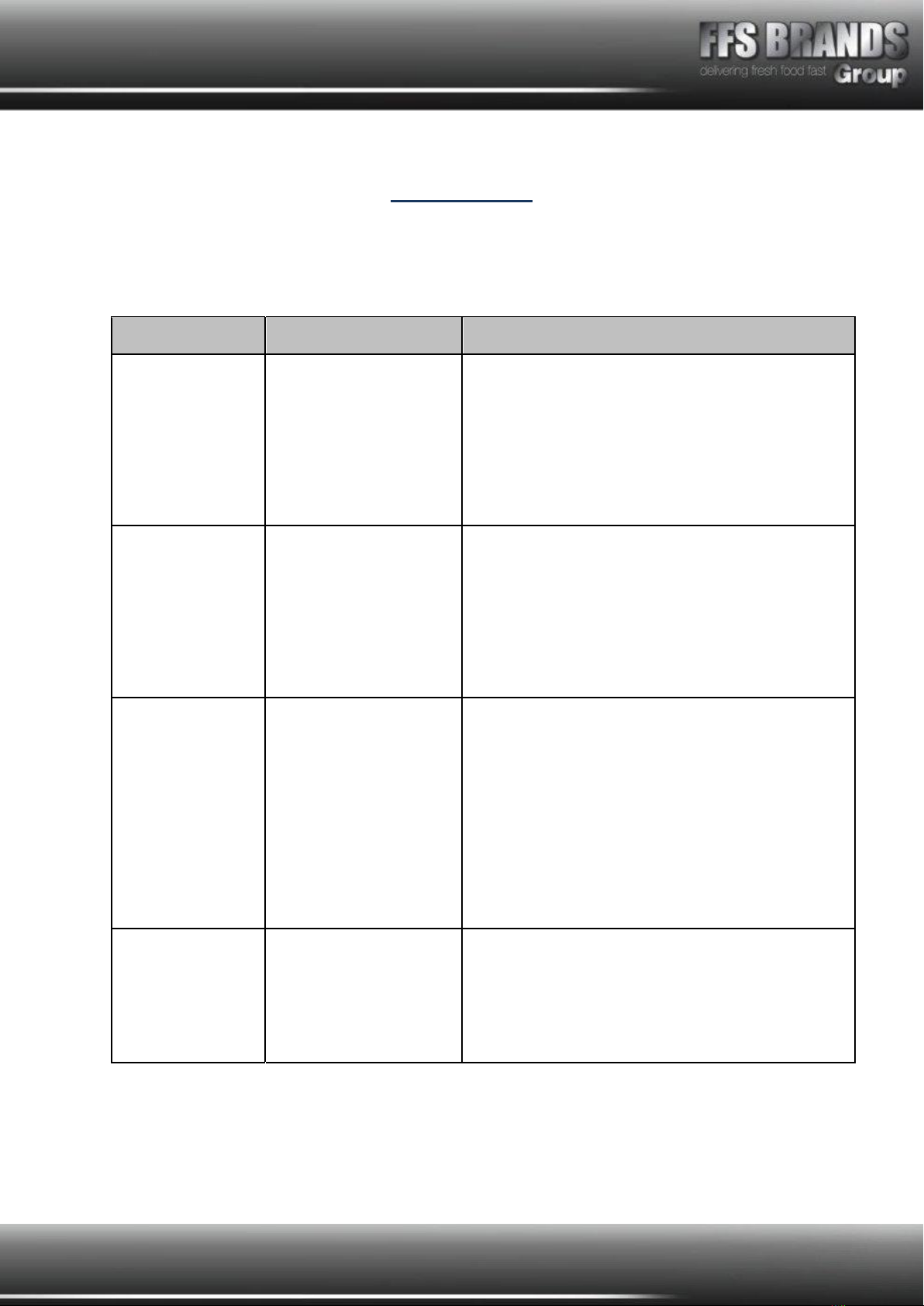

Fault Finding

Any servicing must only be carried out by qualified personnel.

Unit must be removed from electrical supply before servicing.

Problem

Probable Cause

Solution

1. Indicated

ON/OFF switch

does not light up

No power to machine.

ON/OFF switch faulty

Check machine is plugged in and switched on.

Check fuse in 13a plug.

Check circuit breaker at main supply board is in

(ON).

Check Switch

Replace switch.

2. Digital

thermostat does

not indicate

temperature

reading.

ON/Off switch OFF

ON/OFF switch faulty

Digital thermostat

faulty

Switch ON

Replace switch

Unit has overheated, allow to cool

Replace if thermostat

3. Unit does not

heat up.

No power to machine

ON / OFF switch off

ON / OFF switch faulty

Digital thermostat

faulty

Switching relay faulty

Heat element faulty

See section 1.

Switch ON

Replace Switch

Replace thermostat

Replace relay

Replace element

4.Machine does

not heat up,

alarm shown in

digital

thermostat

As indicated

Identify and correct

Page 17 of 20

Terms and Conditions

Claims

No claim shall be entertained by the Company unless made in writing. Claims arising from

damage or partial loss in transit must reach the Company within 7 days from the date of

delivery. Claims for non-delivery must reach the Company within 10 days from the date of

dispatch. All other claims must reach the Company within 7 days. Damaged goods must be

retained for inspection/collection.

Returns

The Company does not operate a returns policy unless the goods are defective:

In circumstances where the Company agrees to accept return of goods, a charge of 25% of

the invoice value will be made.

Page 18 of 20

Damage Claim Form

Machine: MINI/STANDARD HUMIDIFIED HOLDING CABINETS

Product code: VI014SHHC & VI014HHC

Customer name……………………………………………………………

Date of delivery……………………………………………………………

Machine serial number…………………………………………………

Damage comments………………………………………………………

……………………………………………………………………………………………………………

……………………………………………………………………………………………………………

……………………………………………………………………………………………………………

……………………………………………………………………………………………………………

………………………

Please indicate on the picture where the unit is damaged

Courier name…………………………………………………………………

Please cut this page out and post to Fast Food Systems

(The address is on the back of this manual)

Page 19 of 20

Warranty

UNITED KINGDOM AND REPUBLIC OF IRELAND

Excepting where otherwise specified all products are subject to 12 months parts and labour

warranty Goods found defective will be repaired, credited or replaced without charge

according to the terms of the Company’s standard warranty, provided written notice is given

within the guarantee period. In no case will the company be liable for repairs made without

its knowledge or sanction, or for indirect damage, or any consequential loss or expense

incurred by purchasers.

Fast Food Systems Ltd, warrants to the original purchaser that the equipment supplied to be

free from defective materials or workmanship for a period of 12 (twelve) months.

The following are NOT covered by warranty:

1. Failure or breakdown caused by incorrect installation.

2. Glass parts, electric lamps or door seals.

3. Adjustment or calibration of controls - this is a routine maintenance function.

4. Abuse or misuse, including cleaning.

5. Warranty labour is only carried out during normal working hours; calls attended to out

of hours may be subject to surcharges.

6. The warranty will commence either on installation or 1 (one) month from date of

dispatch - whichever is the sooner.

7. Warranty on spare parts purchased for equipment outside of the warranty period is 3

(three) months from date of sale.

8. Any faulty spare parts replaced under warranty must be returned with 7 days of

supply.

9. Warranty is non-transferable.

Fast-Food-Systems Ltd will not be held responsible, financially or otherwise, for any loss of

business as a result of equipment breakdown.

Page 20 of 20

Fast Food Systems Limited

Manufacturer & Distributor of Catering Equipment

Unit 1 Headley Park 9 Headley Road East

Woodley Reading Berkshire RG5 4SQ

Tel: 0118 944 1100 Fax: 0118 944 0350

Website: www.fast-food-systems.com

ISSUE 13 : 15.08.19

Model Number………………………………

Order ID/Job No……………………………

Machine serial number……………………

Date of Manufacture ……/………/………

Date of delivery……/………/……

Date of Commissioning……/………/……

This manual suits for next models

1

Table of contents