FIBER FOX MINI3S User manual

Rev.0.01

This User Manual explains the use, performance characteristics, and cautions about MINI3S fusion splicer

and how to install and operate it. The primary goal of this manual is to make the user as familiar with the

splicer as possible.

01

Preface

Thank you for choosing MIN3S Arc Fusion Splicer. This product delivers ultra fast

splicing time and has an incredibly short shrinking time. It uses the prole alignment

technique and extremely accurate alignment process to ensure precise splice

loss estimation. A new shrinking technology makes that the shrink time is greatly

reduced, thus resulting in an extremely fast total cycle time. The splicer is designed

to withstand harsh environmental conditions. Its lightweight, yet robust, compact and

ergonomic design allows users to easily carry or move. MINI3S has a menu-driven

user interface with dynamic function buttons and a fully automatic splice process.

For more information of MINI3S, please contact local agent or visit our ocial

website.

Important!

We recommend all users to read this manual before operating MINI3S fusion splicer.

0302

3.6 Preparing the Fiber 15

3.7 How to Splice 16

3.8 Inspecting the Fiber 17

3.9 Splicing 18

3.10 How to Protect Splice 19

Chapter 4 Splice Mode

4.1 Displaying the Active Splice Program 20

4.2 Selecting a Splice Program 20

4.3 General Splicing Steps 21

4.4 Parameters for Normal Splicing Process 23

Chapter 5 Splice Option 25

Chapter6 Heater Mode

6.1 Heater Template 26

6.2 Select Heat Mode 26

6.3 Edit Heat Mode 27

6.4 Deleting Heat Mode 27

6.5 Heat Mode Parameters 28

Chapter 7 Maintenance Menu

7.1 Replace Electrodes 29

7.2 Stabilize Electrodes 30

7.3 Diagnostic Test 30

7.4 Dust Check 31

7.5 Motor Calibration 31

7.6 Arc Calibration 32

7.7 Electrode Setting 32

7.8 Quick Optimize 33

7.9 Motor Drive 34

Contents Contents

Chapter1 Technical Parameters

1.1 Applicable Fiber Type 05

1.2 Splice Loss 05

1.3 Splice Mode 05

1.4 Heater 05

1.5 Power Supply 06

1.6 Size and Weight 06

1.7 Environmental Conditions 06

1.8 Others 06

Chapter 2 Installation

2.1 Safety Warning and Precautions 07

2.2 Operational Safety Warnings 07

2.3 Maintenance and External Care Precautions 08

2.4 Transport and Storage Precautions 08

2.5 Installation 09

2.6 Splice Overview 09

2.7 Power Supply Method 10

2.8 Charging Process 11

2.9 Charging Methods 11

2.10 Battery Status 11

2.11 Battery Refresh Cycle 12

2.12 Heater 12

Chapter 3 Basic Operation

3.1 Power Connection 13

3.2 Battery Check 13

3.3 Turn On the Splicer 14

3.4 Adjust Monitor Position 14

3.5 Adjust LCD Backlight Brightness 14

0504

Chapter 1 Technical Parameters

1.1 Applicable Fiber Type

1.2 Splice Loss

1.3 Splice Mode

SM(ITU-TG.652&G.657)/MM(ITU-TG.651)/DS(ITU-TG.653)/NZDS(ITU-TG.655)

/ITU-TG.657A/ITU-TG.657B

Fiber count: Single

Applicable ber / cable diameter: 0.25mm/0.9mm/2.0mm/2.4mm/3.0mm/ Indoor

Cable

Applicable ber diameter: Cladding diameter: 150μm / Coating diameter:100μm ~

3000μm

Same ber is spliced, measured by insertion method relevant to ITU-T standard.

The typical values of splice loss are:

SM:0.03dB

MM:0.02dB

DS:0.05dB

NZDS:0.05dB

G.657:0.03dB

128 kinds of splice modes; 11 kinds of preset splice mode

Up to 10,000 redords and 2,000 splice image

Splice time: SM Quick Mode:7s.

1.4 Heat Oven

kinds of applicable protection sleeve

Heating time: 8 to 900s optional.

Typical heating time: 18s.

Heating mode: Factory Installed Mode: 5, User Installable Mode: 32

Heater: Specic heater for MINI3S fusion splicer.

7.10 Update Software 34

Chapter 8 Other Functions & Utilities

8.1 Data Storage 35

8.2 Display Splice Record 35

8.3 Delete Splice Record 35

8.4 Cancel Data Storage 35

8.5 System Setting 35

8.6 Auto rotate screen 36

8.7 Power Save Option 37

8.8 System Information 38

Appendix A 39

Appendix B 41

Appendix C 44

Battery precautions 46

Contents

0706

Chapter 2 Installation

2.1 Safety Warning and Precautions

2.2 Operational Safety Warnings

1.6 Size and Weight

Size:124(L)mm x 123(W)mm x 138(H)mm

weight:1.1kg (with battery : 1.3kg)

1.7 Environmental Conditions

Operating conditions: Altitude: 0 to 5000m, relative humidity: 0 to 95%,

temperature: -10 to 50 ℃ , the maximum wind speed: 15m / s;

Storage conditions: relative humidity: 0 to 95%, temperature: -20 to 60 ℃ ,

battery: -20 to 30 ℃ for long-term storage

1.8 Others

Observation and display: Two cameras (orthogonally view), 4.3-inch color LCD

touch screen

Fiber Display (Magnification) : X/Y (Single image): 260x, X&Y (Dual image): 130x

Tension test:1.96 to 2.25N.

Terminals:

Port Descriptions

SD card Inside the inner device, SD card drive, program for storage

MINI USB External outside the device, data encryption function and image save

As MINI3S is designed for fusion splicing silica glass optical bers, it is very

important that the splicer should not be used for any other purposes. The splicer is

a precision instrument and must be handled with caution. Therefore, you must read

the following safety rules and general precautions in this manual regarding the use

and handling of MINI3S at any time. Any behaviors that do not follow the warnings

and cautions will break the safety standard about design, manufacture, and usage

of the fusion splicer. The users will be liable for any consequences incurred from

violation of the related requirements!

① Never operate the splicer in an environment where flammable liquids or vapors

exist.

② DO NOT touch the electrodes when the splicer is on.

Note: Only use specied electrodes for the fusion splicer. Select [Replace electrode]

in maintenance menu to replace electrodes, or turn o the splicer and disconnect

the AC power source or remove battery before replacing electrodes. Discharging is

prohibited before the electrodes are placed as a pair.

③ DO NOT disassemble or modify any components of the splicer without approval,

except for the permitted-to-disassemble / modify components or parts by users

stated in this manual. Component replacement and its internal adjustment must be

implemented by authorized technicians or engineers.

④ Handle the main supply cable carefully. Pull out the cable from the electrical

socket by holding only the wall plug and not by pulling the cable. Always ensure this

cable to be in good condition. Otherwise, there is a risk of re or electrical shock.

⑤ To prevent any re or electrical shock, do not expose the splicer to rain or damp

conditions.

⑥ Safety glasses should always be worn during ber preparation and splicing

operation. Fiber fragments can be extremely dangerous if they come into contact

with the eye, skin, or are ingested.

⑦ Turn o the fusion splicer immediately, and disconnect the adapter from the port

of power supply input on the splicer if user observes the following the following

faults, to avoid malfunction or beyond repair:

1.5 Power Supply

AC 100-240 input or DC 12.6V

Out put 11.1V, 3,000mAh, Typical 200cycles (Splice & Heat)

0908

2.4 Transport and Storage Precautions

2.5 Installation

Hold the handle upwards, and then lift the splicer out of the carrying case. As shown

below.

Unpacking the Splicer

① Always avoid using hard objects to clean V-grooves and electrodes.

② Always avoid using acetone, thinner, benzol or alcohol when cleaning any part of

the splicer, except for the places advised.

③ Use a dry cloth to remove dust and dirt from the splicer.

④ If the outside of the splicer is dirty, plunge a soft cloth into diluted neutral

washing up liquid, wring out the cloth and clean. Dry the splicer with a dry cloth but

DO NOT use furniture polish or other cleaning agents.

⑤ Always follow the maintenance instructions in this manual.

2.3 Maintenance and External Care Precautions

① When the splicer is moved from cold to warm environment, you should allow the

splicer to warm up gradually. Otherwise, the condensation generated inside will

bring harmful eects to the splicer.

② Pack the fusion splicer well for long time storage.

③ Keep the splicer clean and dry.

④ The splicer is precision adjusted and aligned. Always keep the splicer in its

carrying case to protect from damage and dirt. Put cushion package outside the

carrying case for long distance transportation.

⑤ Always avoid leaving the splicer in direct sunlight or expose to excessive heat.

⑥ Keep the humidity to a minimum level where the splicer is stored. The humidity

must not exceed 95%.

Important! Follow these instructions carefully.

Fumes, bad smell, abnormal noise or over heat.

Liquid or other matter falls into cabinet

The splicer is damaged or dropped.

If any of these faults occurs, please contact our service center immediately. Leaving

the splicer in a damaged state without any prompt measures may cause equipment

failure, electric shock, or re and may result in injury or death.

⑧ Do not use compressed gas or canned air to clean the splicer. They may contain

flammable materials that could ignite during the electrical discharge.

⑨ Please use MINI3S specic standard AC adapter only. Using an improper AC

power source may cause fuming, electric shock or equipment damage and may even

result in re, injury or death.

⑩ Please use MINI3S specic AC power cord only. Do not place any heavy objects

on the AC power cord. Keep the power cord away from heat source. Do not modify

the power cord. Using an improper cord or a damaged cord may cause fuming,

electric shock or equipment damage and may even result in re, injury or death.

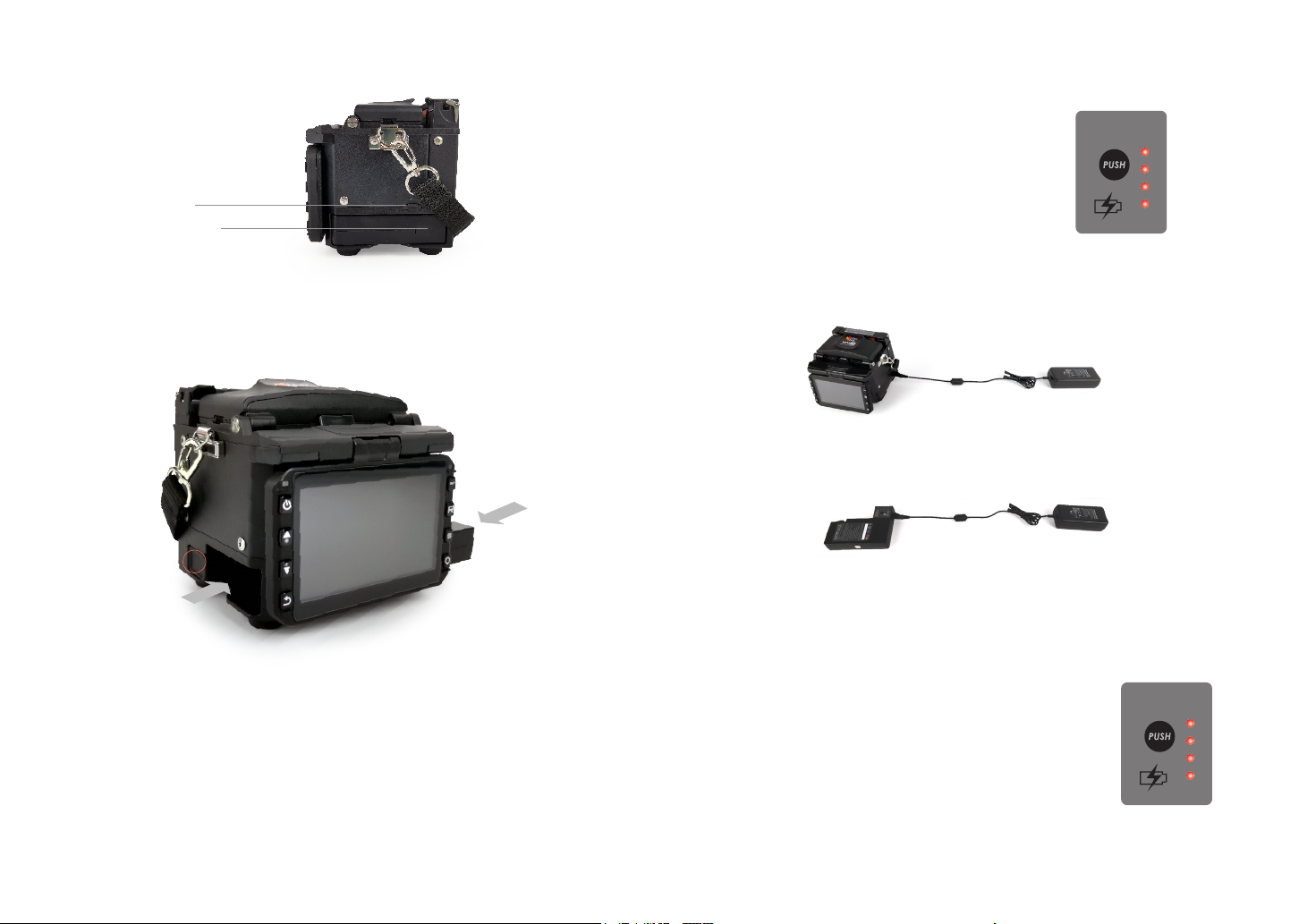

2.6 Splice Overview

Heater

Display

Battery

Handle

On/o button

Indicator

1110

Port of battery charge

MINI USB 2.0 Port

2.7 Power Supply Method

2.8 Charging Process

Following is the way of installing a battery.

Take out the battery

Insert the battery

Shut o fusion splicer.

Press on release button

at lateral, drawing power

supply unit out of the

fusion splicer.

Insert the battery into

the power unit dock until

it clicks into place.

The battery indicator will be illuminated one by one

along with increasing electric quality until battery is

fully charged upto 100%.

2.9 Charging Methods

When battery is connected with fusion splicer, charging method is as follows:

When battery is separated from fusion splicer, charging method is as follows:

Note: Try your best not to charge battery when the battery is working for the

running fusion splicer which is splicing or heating bers for fear of shortening the

battery’s life.

2.10 Battery Status

There are 2 ways for viewing battery level.

① If the battery is connected to the slicer, then its level will be

displayed on the upper right side of the screen.

② Battery level is indicated by Battery LED indicator. As shown

below:

BATTERY

INDICATOR

BATTERY

INDICATOR

1312

2.11 Battery Refresh Cycle

The battery should be refreshed or activated periodically for fear of aging caused

by battery memory eect. The method is as follows:

Keep the splicer in power-on status to discharge until the splicer switched o

automatically due to completely discharging. Then go on to charge until fully

charging completes. Battery refreshing process completes.

2.12 Heat Oven

Heat oven lid open

cooling tray

Chapter 3 Basic Operation

3.1 Power Connection

Follows are 2 ways of power supply for the fusion splicer, of which the inner slot

for power supply unit is able to support:

1. AC adapter, if external power source supply adopted;

2. Removable battery, if battery power supply adopted.

3.2 Battery Check

Before fusion splicer operation, Please check and ensure the residual electric quality

of the battery, which should be equal to 20% or more. Otherwise the battery is not

able to support fusion splicing and heating operations of the fusion splicer.( As to

the ways of electric quality check for battery, please refer to chapter2 for battery

status in detail)

1514

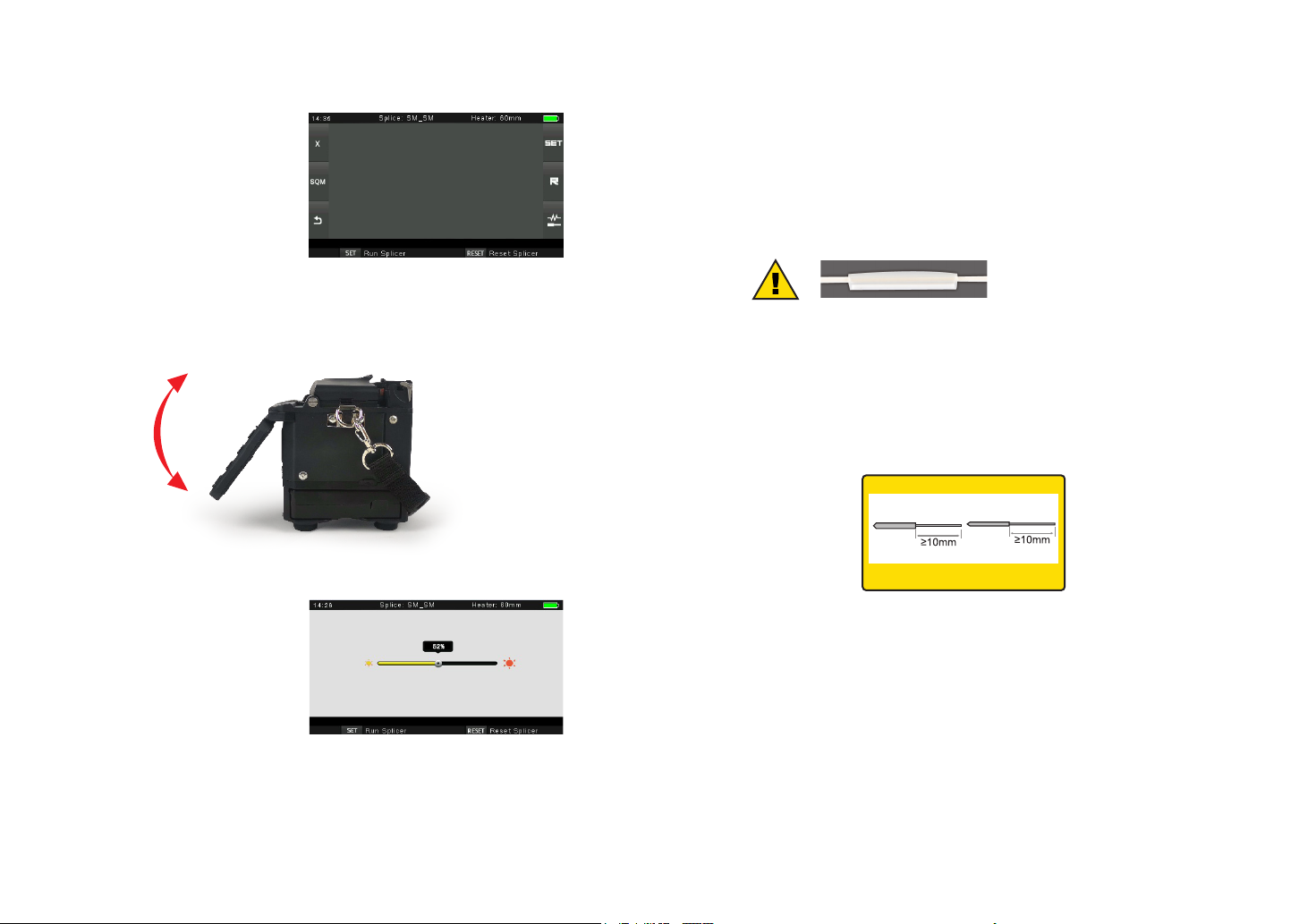

3.4 Adjust Monitor Position

Users can adjust the monitor position by moving it with a desired angle for the

clearest display.

3.5 Adjust LCD Backlight Brightness

Enter into Power save option

interface, and select LCD

Brightness option to adjust LCD

backlight brightness until you

nd the clearest position.

Note: The LCD monitor is a precise component produced by manufacturing factory

under strict quality control. However, some tiny dots in dierent colors may still

remain on the screen. Meanwhile, the screen brightness may not appear uniform,

depending on its viewing angles. Note that these symptoms are not defects, but are

natural phenomenon.

3.6 Preparing the Fiber

3 steps should be carried out before splicing:.

1.Stripping

Remove at least 50mm of secondary coating (valid for both tight and loose tube

secondary coating) and approximately 30~40mm of primary coating with an

appropriate stripper.

Note: always remember to slip a

heat-shrinkable sleeve onto either

end of the bers at the beginning

of each ber preparations.

2. Clean bare bers with pure alcohol-soaked gauze or lint-free tissue.

3. Cleave the ber

In order to ensure the best splicing result, cleave the bers with high quality cleaver

such as DC-09 ber cleaver, and strictly control the cleaving lengths shown as

below.

Important!

From this moment, you must be very careful with the bers to ensure that they do

not become dirty again.(For example, avoid putting them down on a dusty working

surface, or even waving them around in the air). Also check if the V-grooves are

clean, if not, wipe them clean.

3.3 Turn On the Splicer

Press [Power] key on the operation

panel, and wait the splicer to be

turned on and move to Workbench

page.

Examples of cleaving lengths

primary coating

use blue V-grooves

(Clamping on bare ber)

tight secondary

coating

1716

② Open the ber holder. Position

the bers into V-grooves. Make

sure the ber ends are between

the V-groove edges and the

electrode tip.

Note: Make sure to avoid sliding the

bers along V-grooves, but rather

position them over V-grooves and tilt

them down into place (as shown in the

picture).

③ Close the ber holder.

④ Close the wind proof cover

3.8 Inspecting the Fibers

① Before continuing with splicing, inspect the bers whether they are clean and

well-cleaved.

3.7 How to Make a Splice

① Open the safety shield.

a. b. c.

imaging area

ber ends visible

on the monitor

Fiber ends outside

monitor

Fiber ends

above and

below monitor,

not possible

to nd

automatically.

imaging area imaging area

② To change between Front View and Back View, adjust Monitor position.

1918

③ If you nd any defects as shown in the following pictures, remove the ber and

prepare again.

Note:The bers are checked

automatically when you press

Splice button. The splicer

automatically focuses the bers

and checks for damage or dust

particles.

3.9 Splicing

① Select any appropriate splice

mode.

Note: If the splicer is set as

“Auto mode”, splicing will start

automatically once the wind proof

cover is closed.

② Start splicing by pressing

button.

3.10 How to Protect the Splice

After splicing, protect the joint by using a heat-shrink sleeve and the heat oven

which is mounted onto the splicer. “Shrink” process can be activated via pressing

the “HEAT” key.

① Open the heat oven lid

② Raise left and right ber holders on the splicer. Hold the heat-shrink tube, lift the

spliced bers and hold them move the heat-shrink tube so that it is centered over

the splice point.

③ Move both the bers and the heat-shrink tube over to the heat oven and place

them in the oven clamps.

④ Press the “HEAT” key to begin heating, when the heating process is nished, the

heating indicator will be turned o automatically and companied by prompt sound of

the buzzer.

Open the heat oven lid Position of splices

Moving the ber into heat oven

dust on ber

chip large cleave angle

lip

Heating Indicator

Heat Button

2120

Chapter 4 Splice Mode

4.1 Displaying the Active Splice Program

MINI3S has an intuitive and simple but very powerful program structure to operate.

Splice programs dene arc currents, splice times as well as various parameters

used when performing a splice. Therefore, it is essential to select the correct splice

program.

There are a number of “Preset” splice programs for common ber combinations.

Therefore, it is much easier to modify and further optimize the parameters for more

unusual ber combinations.

The active splice program is

always displayed at the top of the

screen (see below).

4.2 Selecting a Splice Program

To select another splice program

other than the active one, you

must enter Select splice mode

menu.

① Enter main menu

② Select Splice Mode

③ Highlight the program you

want to select.

④ Back to initial interface

4.3 General Splicing Steps

This section explains the steps involved in automatic splicing process and describes

how various program parameters are related to this process. The normal splicing

process can be divided into two sections: pre-fusion and fusion.

Pre-Fusion

During pre-fusion, the splicer performs automatic alignment and focusing, where

the bers are subjected to a low pre-fusion current for cleaning purposes; a pre-

fusion image is also taken. At this point, the user is informed of any problems

recognized in the pre-fusion image, such as a poorly prepared ber. The splicer will

then issue a warning before the bers are fused together.

2322

Fusion

Splicing Process

During fusion, the bers are joined together and subjected to ve dierent currents

as illustrated below. An important parameter, which changes during splicing, is

the distance between the bers. During Pre-fusion, the bers are apart. With the

current phase changing, bers are spliced gradually.

The most important splicing parameters are the time and current, each current

phase is shown below, that the name and function and other parameters are

important to the splice process are described under “Parameters for Normal

Splicing Process” on the next page.

The following gure shows the discharge conditions (The relationship between the

“discharge intensity" and "motor move"). We can change the splicing parameters

listed below to change the discharge conditions.

A: Pre-fuse power B: Arc power C: Cleaning Arc

D: Pre-fuse time E: Arc time F: Overlap

G: Taper wait time H: Taper time related to taper length I: Taper speed

Diagram of ARC discharge condition

4.4 Parameters for Normal Splicing Process

Parameter Description

Template

A list of splice modes stored in the splicer database is displayed.

Upon inputting the appropriate mode, the selected splice mode

stored in database area is copied to a selected splice mode in user-

programmable area.

Name Title for a splice mode expressed in up to seven characters.

Note Detailed explanation for a splice mode expressed in up to 15

characters. It is displayed at “Select splice mode” menu.

Focus-L Set the focus parameter for lens X.

Focus-R Set the focus parameter for lens Y.

Arc adjust Set to adjust arc power according to the bers’ conditions.

Pull test If “Proof test” is set to “ON”, a pull-test is performed upon opening

the windproof cover or by pressing the SET button after splicing.

Loss

estimate

Loss estimate should be regarded as a reference. Since the loss is

calculated upon the ber image, there is certain dierence with the

real value. The estimate method is based on a single mode ber and

calculates at the wavelength of 1.31μm. The estimated value can be a

valuable reference, but cannot be used as the basis of acceptance.

Minimum

loss

This amount is added to the estimate splice loss originally calculated.

When splicing specially or dissimilar bers, a high actual splice loss

may occur even with optimized arc conditions. To make the actual

splice loss concur with the estimated splice loss, set the actual splice

loss to minimum value (minimum loss).

Loss Limit An error message is displayed if the estimated splice loss exceeds

the selected threshold (loss limit).

Core angle

limit

An error message is displayed if the bend angle of the two bers

spliced exceeds the selected threshold (Core angle limit).

Cleave angle

limit

An error message is displayed if the cleave angle of either the left or

right ber ends exceed the selected threshold (cleave limit).

Gap position

Set the relative position of the splicing location to the center of

electrodes. Splice loss may be improved in the case of dissimilar

ber splicing by shifting [Gap position] towards a ber whose MFD is

bigger than the other ber MFD.

Gap Set the end-face gap between the left and right bers at the time of

aligning and pre-fusion discharge.

2524

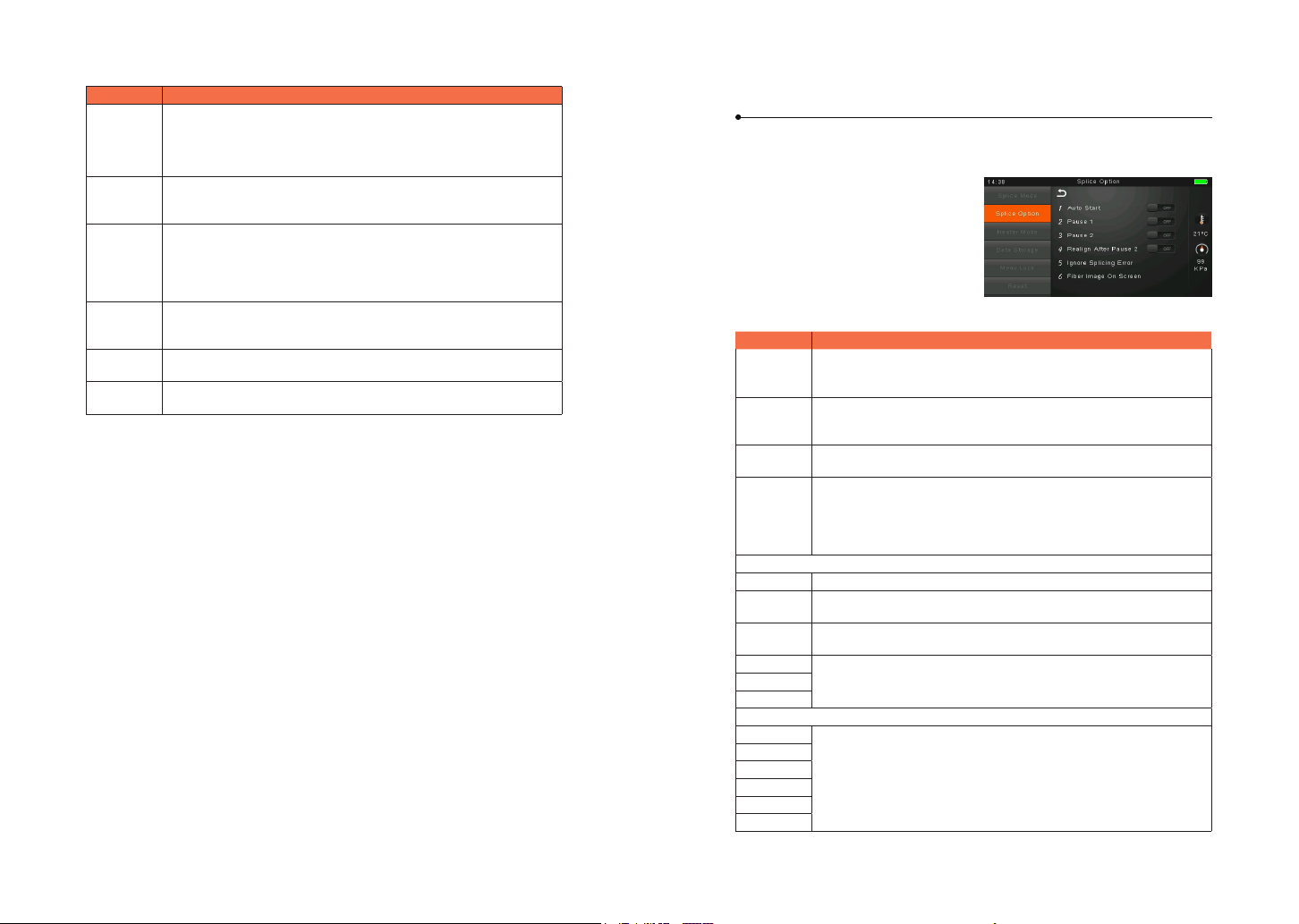

Chapter 5 Splice Option

As to the Splice Mode setting.

① Select [Splice option] in menu from

main menu.

② Select a parameter to be changed.

Parameter Description

Auto start

If “Auto start” is set to ON, splicing starts automatically as soon as

the wind protector is closed. Fibers should be prepared and placed

into the splicer in advance.

Pause 1

If “Pause 1” is set to ON, splicing operation pauses when bers are

forwarded to gap-set position. Cleave angles are displayed during

the pause.

Pause 2 If “Pause 2” is set to ON, splicing operation pauses after ber

alignment is completed.

Realign after

pause 2

Alignment failure may appear after “Pause2” for a long period.

Therefore, realign after “Pause2” is needed. Setting to “OFF” will

prevent the implementation of realign function. Manual splicing,

rather than setting the realign to “OFF”, is recommended when there

is an axial displacement of the splicer

Ignore splice error

Cleave end

Cleave

angle

Setting to “OFF” ignores the faults and continues to complete the

splicing even if the message “Cleave Angle Error” appears.

Core angle Setting to “OFF” ignores the faults and continues to complete the

splicing even if the message “Core Angle Error” appears.

Loss Setting to “OFF” ignores the faults and continues to complete the

splicing even if the message “Loss Error”, “Cleave Shape Error”, “Fat

Error”, or “Thin Error” appears.

Fat

Thin

Fiber immage on screen

Paulse 1 Set the displaying method of the ber image on the screen during

splicing operation.

X : Enlarged display of X-axis image

Y : Enlarged display of Y-axis image

X/Y : Composite display vertically of X-axis and Y-axis images

Align

Paulse 2

Arc

Estimate

Gap set

Parameter Description

Overlape

Set the overlap amount of bers at the ber propelling stage.

Relatively small [Overlap] is recommended if [Preheat Arc Value] is

low, while relatively large [Overlap] is recommended if [Preheat Arc

Value] is high.

Cleaning Arc

time

A cleaning arc burns out micro dust on the surface of the ber with

an arc discharge for a short period of time. The duration of the

cleaning arc can be changed by this parameter.

Preheat Arc

value

Set the pre-fuse arc power from the beginning of arc discharging

to the beginning of bers propelling. If “Preheat Arc Value” is set

too low, axial oset may occur if cleaved angles are relatively poor.

If “Preheat Arc Value” is set too high, ber end faces are fused

excessively and splice loss gets worse.

Preheat Arc

time

Set the pre-fuse arc time from the beginning of arc discharging to

the beginning of bers propelling. Long [Preheat Arc Time] and high

[Preheat Arc Value] lead to the same results.

Fuse Arc

value

Set Arc power.

Fuse Arc

time

Set Arc time.

2726

Parameter Description

60mm For standard protection sleeve of 60mm

40mm For standard protection sleeve of 40mm.

33mm For standard protection sleeve of 33mm

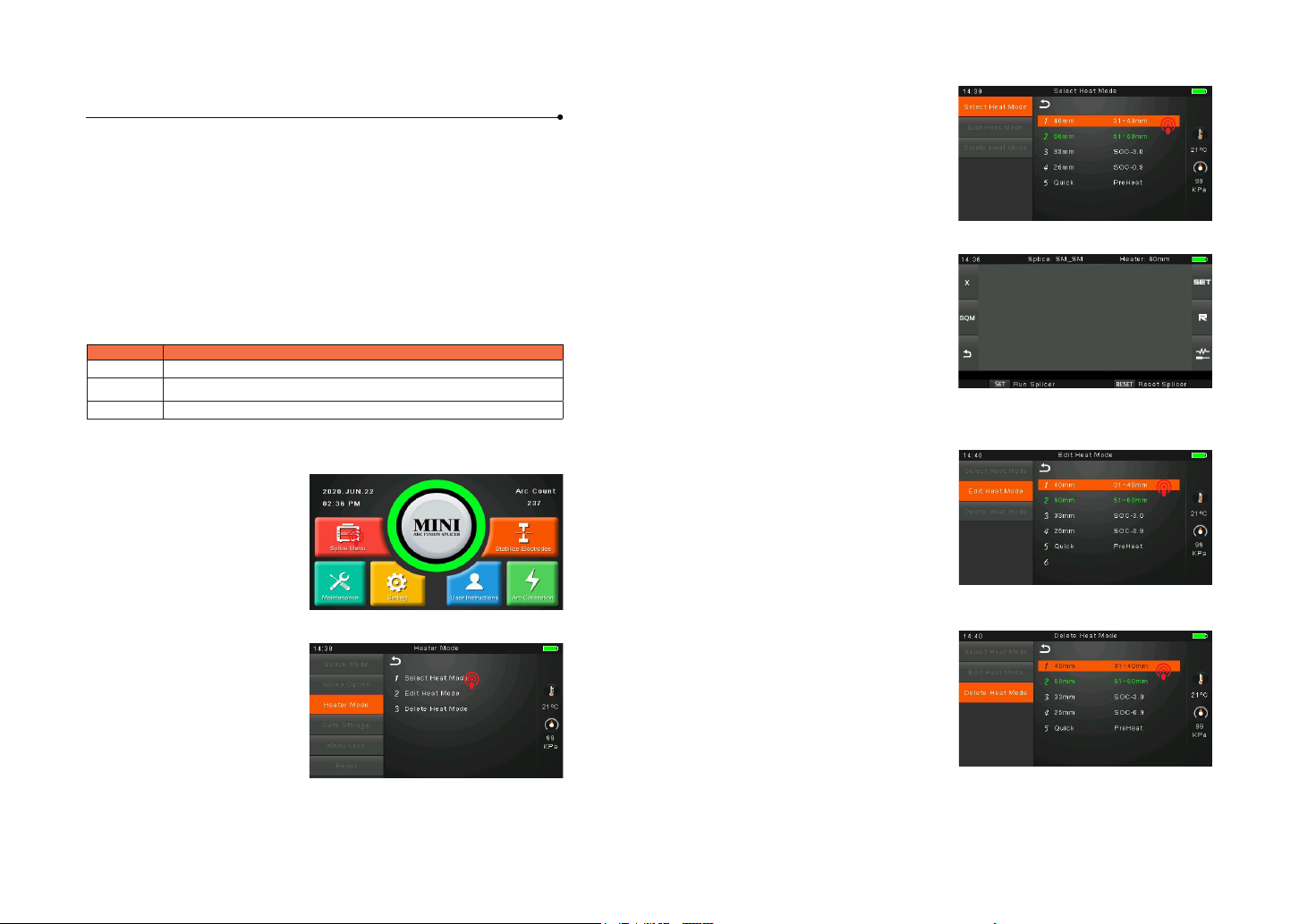

Chapter 6 Heater Mode

The splicer provides max 32 heat modes including 5 heat modes preset by factory

and the rest that can be dened by users. Select a heating mode that best matches

with the protection sleeve used.

For each type of protection sleeve, MINI3S has its optimum heating mode. These

modes can be found in the database area for reference. Copy the appropriate mode

and paste it to the user–programmable area. Users can edit those parameters.

To select another heating mode

other than the active one, you must

enter Select heat mode menu.

① Enter main menu

6.1 Heater Template

6.2 Select Heat Mode

② Select Heater Mode

③ Touch on Select Heat mode

④ Back to original interface

Tube-heating conditions stored

in heating mode can be edited or

changed.

① Enter edit heat mode menu via

touching on heater mode menu.

6.3 Edit Heat Mode

① Select Heater mode menu.

② Select Delete Heat Mode.

③ Select the heat mode to be

deleted

6.4 Deleting Heat Mode

Note: The gray mode (40mm,

60mm) is the system preset

initial heat modes which cannot

be deleted.

2928

6.5 Heat Mode Parameters

Parameter Description

Template Set sleeve type. List of all heat modes are displayed. Selected mode

will be copied to a user-programmable area.

Name Title for a heat mode.

Note

Title of the heat mode displayed in the bottom right corner of

the monitor during splicing or heating process. Max number of

characters used is 15.

Heater

control

Set the length of heat-shrink sleeve.

Long: protection sleeves over 30mm.

Short: 30mm protection sleeves or below.

Heater

temperature Sets heating temperature.

Heater time Sets heating time from the beginning to the heating completed.

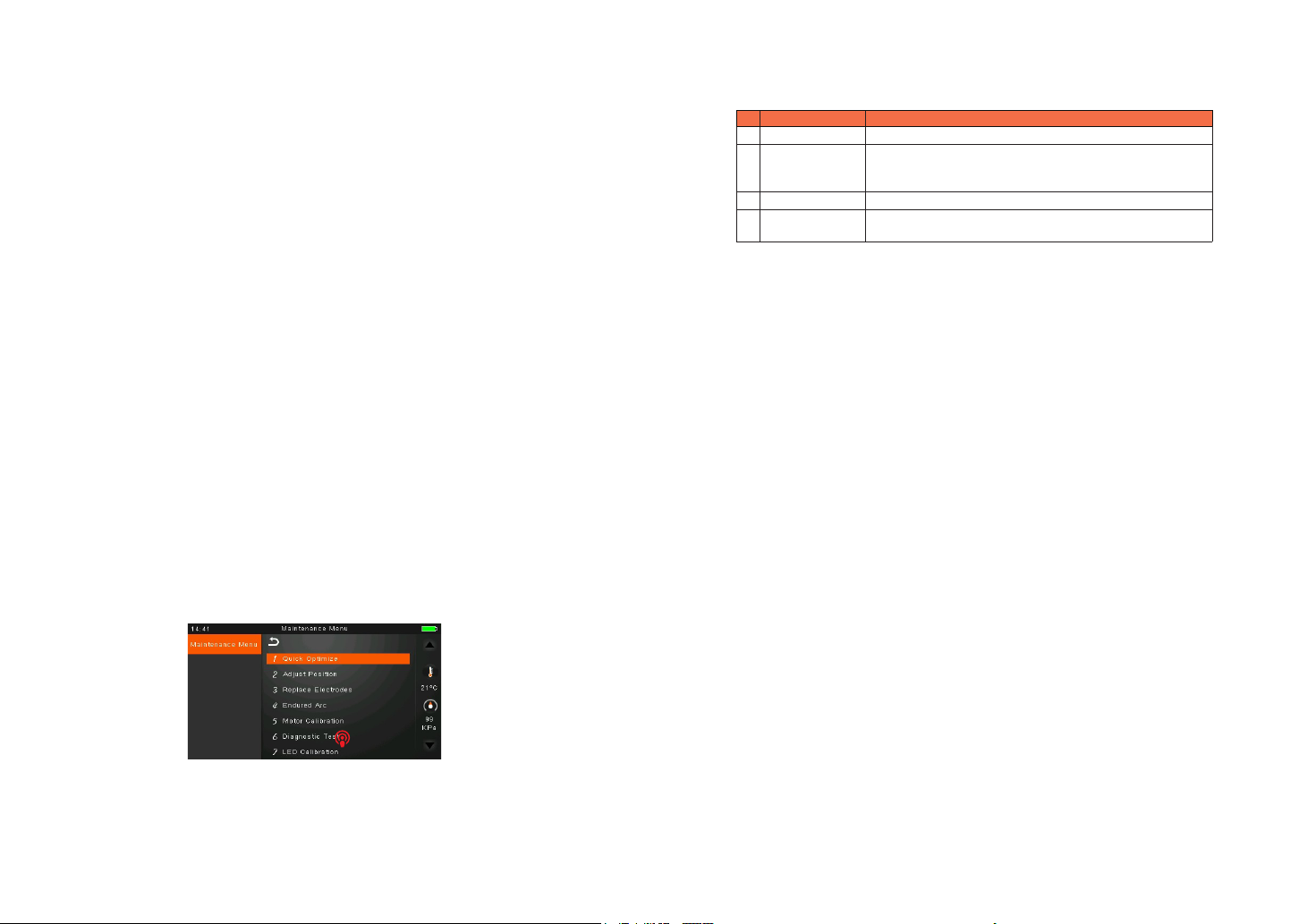

Chapter 7 Maintenance Menu

The splicer has a function to perform routine maintenance. This section describes

how to use the maintenance menu.

① Press Menu button, and select [Maintenance menu].

② Select a function to perform.

7.1 Replace Electrodes

As electrodes are worn out during the splicing process, oxide generated on the tips

of electrodes should be regularly eliminated. It is recommended that the electrodes

should be replaced after 2500 arc discharges. When the number of arc discharges

reaches a count of 2500, a message prompting to replace the electrodes is

displayed immediately after turning on the power. Using the electrodes without a

replacement will result in greater splice loss and reduced splice strength.

Replacement Procedure

① Select [Replace electrodes] in [Maintenance Menu].

② Instruction messages will appear on the screen to turn o the power. Click on OK

until LCD shuts down to continue.

③ Remove the old electrodes.

ⅰ ) Loosen screw located on electrode cover.

ⅱ ) Take electrodes out of the electrode covers. (Electrodes are xed in electrode

cover)

④ Clean the new electrodes with alcohol-impregnated clean gauze or lint-free

tissue, and install them in the splicer.

ⅰ)Insert the electrodes in the electrode covers.

ⅱ)Place the electrode covers on the splicer, and tighten the screws.

loosen screw

electrode cover

Tighten screw

Remove old electrode

Install new electrode

3130

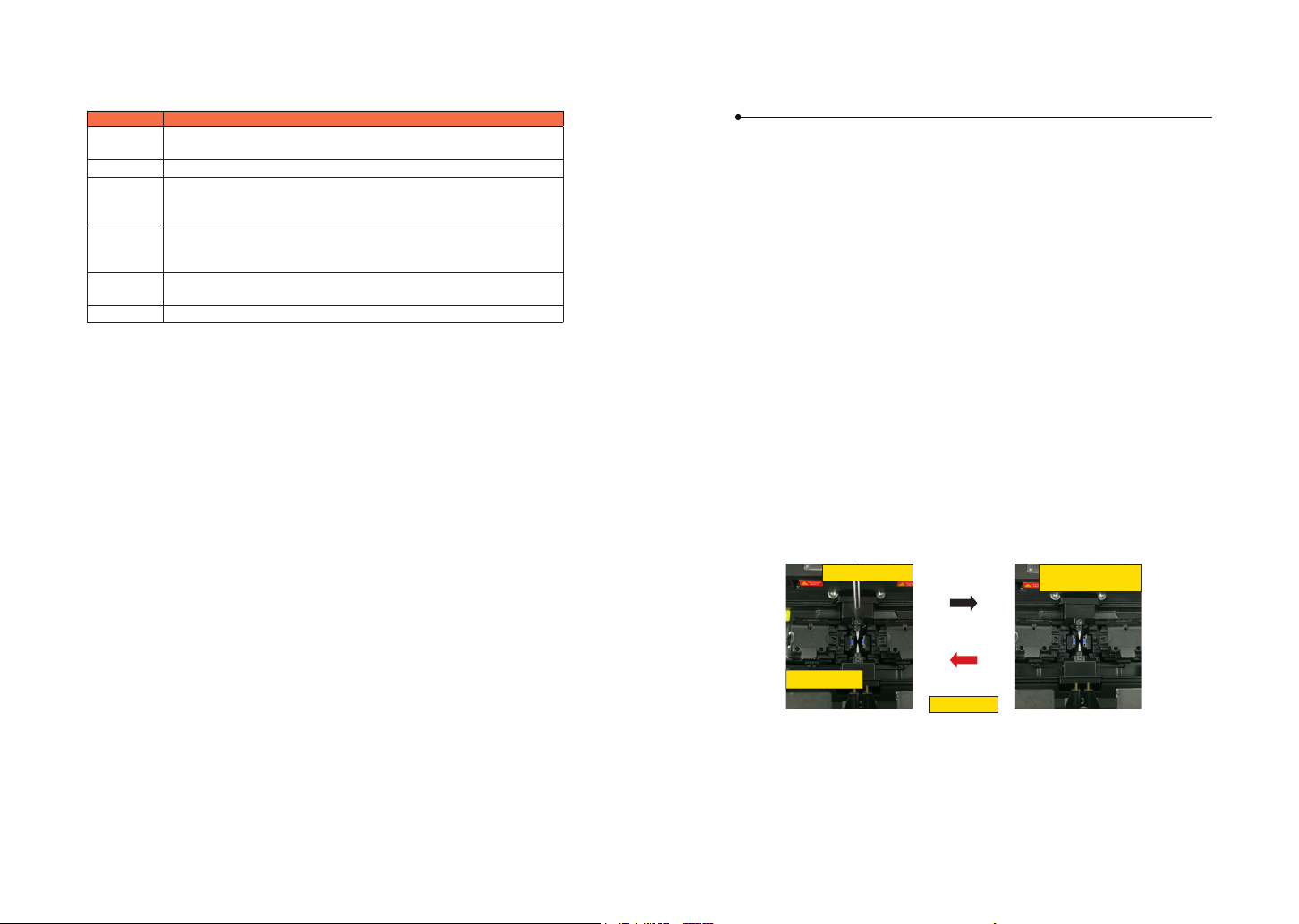

7.2 Stabilize Electrodes

In the event of sudden change in environmental conditions, especially when the

splicer is moved from lower altitudes to higher altitudes, the arc power may become

unstable, resulting in higher splice loss. In such case, it takes time for arc power to

be stabilized. In this case, stabilizing electrodes will expedite the process to set the

arc power stable. If many tests are needed until the “Operation Complete” message

appears in [Arc calibration], use this function as well.

Operation Procedure

① Select [Stabilize electrodes].

② Place prepared bers into the splicer for splicing.

③ Press [SET] button, and the splicer will begin to stabilize the electrodes

automatically in the following procedures:

• Repeat arc discharge ve times to measure the arc position.

• Perform splicing rapidly.

•Perform stabilizing electrodes 20 times consecutively to precisely locate the

electrodes position.

7.3 Diagnostic Test

MINI3S has a built-in diagnostic test function that allows the user to evaluate

several critical variable parameters with only one simple step. Perform this function

in case of splicer operation fault.

Operation Procedure

① Select [Diagnostic Test] in [Maintenance Menu]

② Execute [Diagnostic test], then the following checks will be made.

Parameter Description

1 LED calibration Measure and adjust the brightness of the LED.

2 Dust check

Check the optical path for dust or dirt and judges whether

they disturb ber observation. If contamination exists, press

the return button twice to display the location.

3 Motor Calibration Automatically calibrate the speed of 4 motors.

4 Arc Calibration Automatically calibrate the arc power factor and ber

splicing position.

7.4 Dust Check

Through image acquisition, the splicer detects dust and contaminants on the splicer,

camera, and objective lenses that may disturb normal observation of bers and

result in improper splicing. This function checks the optical path for the presence

or absence of contaminants, and judges whether they will aect the quality of ber

splicing.

Operation Procedure

① Select [Dust check] in [Maintenance menu].

② If bers are set in the splicer, remove them and press [SET] again to start the

dust check.

③ If no dust exists, splicer will prompt out message for operation completion. If

dust is detected during the dust check process, the message “Found Dust On The

Lens” will be displayed on screen. Press the return button twice, and the location of

contamination will be shown on the screen. Then clean the objective lenses, and [Dust

check] until the message “Operation Complete” is shown on screen.

Note:

If contamination still exists after cleaning the objective lenses, please contact your

nearest sales agent

7.5 Motor Calibration

Motors are adjusted at the factory before shipping. However, settings may be

changed in various reasons. This function automatically calibrates the speed of 4

motors.

Operation Procedure

① Select “Motor Calibration” in “Maintenance Menu”.

② Load prepared bers in the splicer and press “SET” button.

③ Speeds for all motors are automatically calibrated. Upon completion, message

will be displayed.

Note:

Perform this function when "Fat " or "Thin" error occurs, or ber aligning or focusing

takes too much time.

⑤ We recommend all users to do stabilizing electrodes and arc calibration after

electrodes replacing to keep good splice results and splice strength (Details are

described below).

3332

Operation procedure

① Select [Arc Calibration] in [Maintenance Menu] to display arc calibration on the

screen.

② Place prepared bers into the splicer, and press [SET] to perform arc calibration.

③ The splicer will show up two values on the screen after each arc calibration. If the

value shown on the right-hand side meets 11±2, the message “Operation Complete”

will be shown on screen. Otherwise, set prepared bers on the splicer again and

redo arc calibration until the message “Operation Complete” is displayed.

Note :

* Use standard SM、DS or MM ber for arc calibration.

* Ensure clean bers for arc calibration. Dust on the ber surface aects arc

calibration.

7.7 Electrode Setting

Set the electrode change warnings. We recommend replacing the electrodes every

4500 discharge to ensure the best splice results.

① Select [Electrode Setting] in [Maintenance Menu].

② Set the electrode caution and electrode warning.

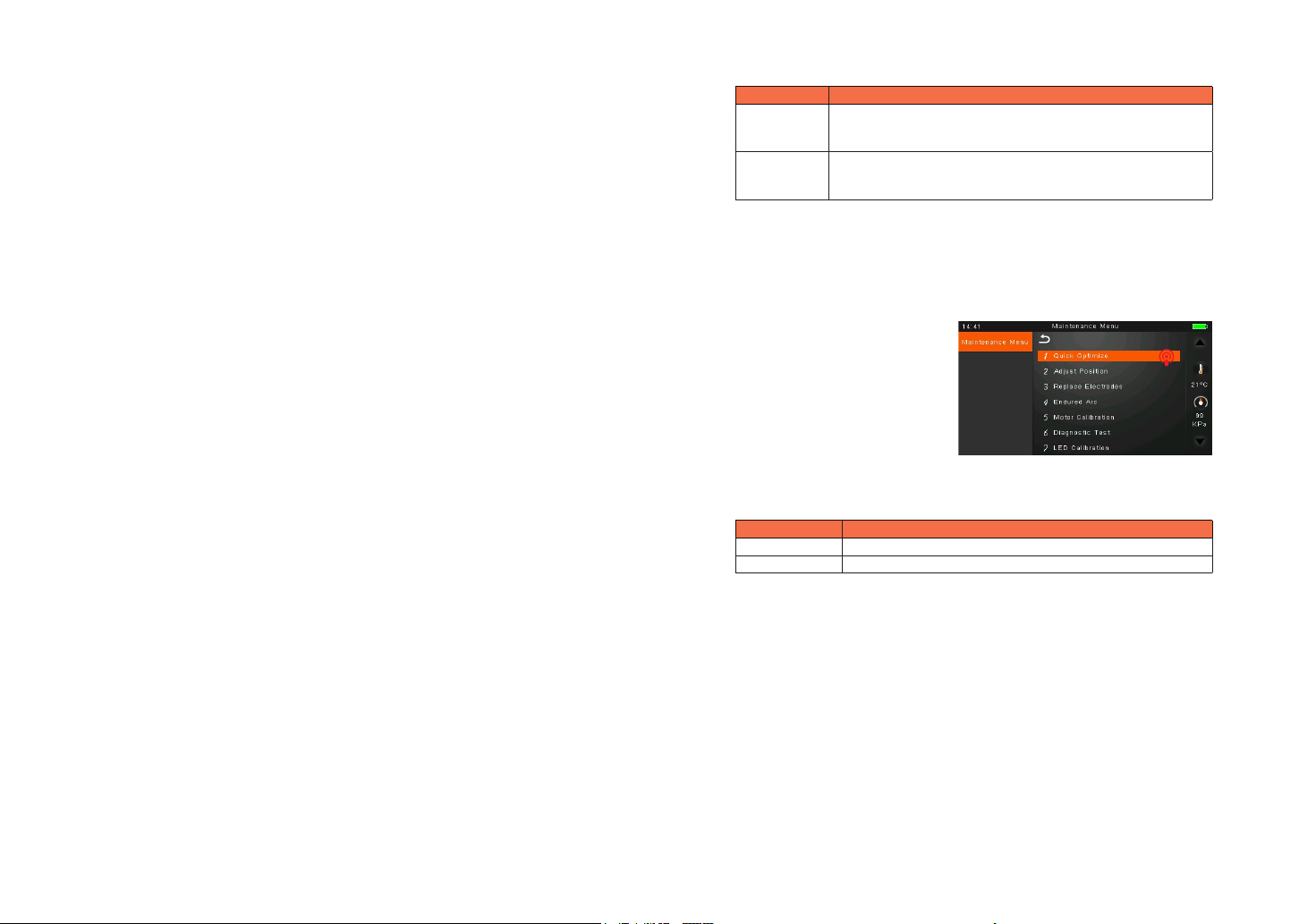

7.8 Quick Optimize

MINI3S fusion splicer bares optimizing function inside. The operator just need carry

out simple operation for adjusting 4 motors’ calibration of fusion splicer.

1 Select quick optimize in maintenance menu.

Parameter Description

Electrode

caution

If actual arc discharge exceeds the set value, a message “Caution!

Replace Electrodes” is displayed when turning on the splicer.

Fiber Fox recommends that this parameter should be set to “2500”

Electrode

warning

If actual arc discharge exceeds the set value, a message “Warning!

Replace Electrodes” is displayed when turning on the splicer.

Fiber Fox recommends that this parameter should be set to “3500”.

Parameter Description

Adjust position Adjust the motor’s position automatically.

Motor calibration Adjust 4 motor speeds automatically.

2 Follows are the optimizing functions in Quick optimize.

7.6 Arc Calibration

Atmospheric conditions such as temperature, humidity and pressure are constantly

changing, which creates variability in the arc temperature. MINI3S is equipped with

temperature and pressure sensors that are used in a constant feedback monitoring

control system to maintain the arc power at a stable level. However, changes in arc

power due to electrode wear and glass adhesion cannot be calibrated automatically.

Also, the center position of arc discharge sometimes shifts to the left or to the

right. In this case, the ber splicing position has to be shifted in relation to the arc

discharge center. It is necessary to perform an arc power calibration to eliminate

those problems.

Note :

* Arc calibration is performed automatically in SM mode only. So, arc calibration

does not have to be performed when splicing in SM mode.

* Performing Arc Calibration function changes the arc power value. The arc power

value is used in the algorithm program for all splicing. The arc power value will not

be changed in the splice modes.

3534

Chapter 8 Other Functions & Utilities

8.1 Data Storage

This splicer stores up to 10,000 splicing results. Contents of data stored are

dierent depending on splicing mode.

8.2 Display Splice Record

Splicing results stored in the splicer can be displayed.

Select Data Storage Menu and Select Display Splice Record to view.

8.3 Delete Splice Record

Splicing results can be cleared by part or whole.

① Select “Delete Splice Record”, and then input specic number (Start Splice

Record and End Splicer Record) of splicing results to be cleared.

② Select Delete Splice Record and press conrm key to conform. Selected

splicing results are cleared and replaced with following splicing results.

8.4 Cancel Data Storage

If you don’t want to store the records, press the "OFF" button in the "Splice Data

Save" Menu.

8.5 System Setting

This menu is used to change settings in detail, or for an administrator to limit

functions for operator to select or change.

7.9 Motor Drive

This function is used to test if 4 motors of the fusion splicer operate normally.

① Select “Motor drive”.

② Touch screen to select motor.

7.10 Update Software

① Select “update software” in “system setting”.

② Connect the USB driver with the copy of upgrade les to the USB port

③ Press “OK”, and then the splicer will process the update automatically. Upon

completion, the splicer will restart automatically.

③ Touch the icons of L press and R

press to drive motor, observing if the

motor can be driven normally.

3736

Parameter Description

Buzzer Sets the sound volume of the buzzer

Automatic

heating

If select “On”, when the ber is placed into heat oven, which will

automatically execute heating.

Language Sets a language to be displayed on the screen.

Auto Rotate

Screen

When you press "ON" in the system setting menu, the screen can

auto rotate the screen.

Power Save

Option

Sets the time of Monitor Shut Down, time of Splicer Shut Down

and LCD brightness.

Set Calendar Sets the system time.

Password

Changes the password to access some menus as “Power on

Option” and “Menu Lock”.

At the time of shipment from the factory, the password is set as

“0000”.

If you have forgotten your password after you changed another

one,

contact the nearest sales agency.

Pull test If you select “ON”, pull test will be performed after fusion splicing

completion.

Dust check

Dust check: check dust and contaminants in optical path to avoid

optical ber inspection disturbance. If contaminants exist, press

conrm key to display the contaminants’ position.

Password lock

“On”: passwords are needed to input for entering into the fusion

splicing window when power on. “OFF”: No passwords are

needed when power on.

System

information

Display fusion splicer’s basic information: Machine serial NO.,

Software version, FPGA version, total Arc count, current Arc

count, Last maintenance, Production date, Sales Region, Product

OEM.

8.6 Auto Rotate Screen

When you press "ON" in the system setting menu, the screen can auto rotate the

screen.

8.7 Power Save Option

This function is important for power conservation. If the power saving function is

not set during battery pack use, the number of splice cycles will be reduced.

(1) Insert a power unit and turn on the splicer.

(2) Select “Power Save Option” in “System Setting” menu.

(3) Change values of “Monitor Shut Down” and “Splicer Shut Down”.

Parameter Description

Monitor Shut Down

To avoid power loss when battery is used, setting this function turns o

the power supply to the LCD monitor if the splicer does not operate after

a certain period of time. When the power supply for monitor turns o, the

LED near the power key blinks. Press any key to turn on the LCD monitor.

Splicer Shut Down

Automatically turns o the power supply of the splicer if it performs no

operation for a certain period of time. The function serves to prevent the

battery capacity from running low if the splicer is left on for an extended

period of time.

LCD Brightness Adjust LED backlight brightness.

Table of contents

Other FIBER FOX Welding System manuals

Popular Welding System manuals by other brands

Leister

Leister TWINNY T7 Repair instructions

Hobart Welding Products

Hobart Welding Products Hobart 150 STi owner's manual

CIGWELD

CIGWELD weldskill 100 operating manual

Ritmo

Ritmo ELEKTRA 400 Operator's manual

Chicago Electric

Chicago Electric 61792 Owner's manual & safety instructions

ESAB

ESAB LTH 161 Service manual