FIBRO 2486.22 Series Technical specifications

WE LOVE TECHNOLOGY

MEMBER OF THE LAEPPLE GROUP

MAINTENANCE INSTRUCTIONS

GAS SPRING DS

2486.22.

Maintenance instructions Gas spring DS

Document: Maintenance instructions

Document number: 2.7539.00.0915.0100000

Revision: R04-2020

Version: V01

Language:

In the German language, this document is the original version in the EU language of the manufacturer and is labelled

with the German national flag.

In the language of a country of use, this document is a translation of the original version and labelled with the national

flag of the country of use.

This document is referred to as "instructions" in the following text.

Number of pages in this manual including the title page: 30

These instructions are valid for the product

2486.22.

Gas spring DS

This document was created by

FIBRO GMBH

August-Läpple-Weg

DE 74855 Hassmersheim

Phone: +49 (0) 62 66 73 0

Fax: +49 (0) 62 66 73 237

E-mail: [email protected]

Internet: www.fibro.de

© All rights to this document are subject to copyright of the author.

Without the prior written permission of FIBRO GMBH, this document must not be copied or

reproduced, either in full or in part.

The instructions are intended only for the operator of the described only

and must therefore not be made available to uninvolved third parties - in particular to competitors.

Maintenance instructions Gas spring DS 3/30

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Residual risks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.1 Check gas pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 Required spare parts, tools and tool kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Evacuating gas pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.3 Dismantle gas spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3.4 Clean and check components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.5 Assemble gas spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Fill with nitrogen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Third-party products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Index of figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 Personal notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4/30 Maintenance instructions Gas spring DS

Safety

1SAFETY

1.1 Safety information

The statements contained in this document only apply to the maintenance of the stated gas

springs and are only for the use by trained and authorised staff.

Staff has to have the necessary training, experience and product knowledge as well as specialist

tools in order to carry out maintenance work correctly.

Staff has to have fully read and understood this document prior to carrying out any maintenance

work.

Replacement of spare parts without special training or knowledge of the maintenance instruc-

tions and without the specialist tools can be dangerous and may lead to accidents causing se-

vere injuries or even death.

Most accidents during maintenance occur due to disregarding the basic safety regulation.

Noticing a potential danger can prevent accidents from happening. Safety information in this

document warn about potential risks. FIBRO GMBH can not foresee all situations which may

potentially cause risks. The warnings in this document are therefore not all encompassing.

If a work material, an act, a work method or work technique is used which has not been specif-

ically suggested by FIBRO GMBH, then the user has to ensure the safety for himself and other

persons.

The information, descriptions and illustrations in this documents are based on the information

on the basis of information which was available at the point of creation of this document.

Illustrations show examples of a potential gas spring and are not to scale.

Descriptions, tightening torques, operating pressures, measuring methods, illustrations and oth-

er points are subject to change at any time. The changes can have an influence on the compo-

nent's properties. Prior to starting any work, obtain the currently available information.

Maintenance instructions Gas spring DS 5/30

Safety

1.2 Safety instructions

These instructions contain safety notices intended to draw attention to possible dangers that

should be observed to prevent injury.

The pertinent text describes

• the type of danger

• the source of danger

• the options for preventing injuries

• the consequences in case of non-observance of the warning notices

The safety instructions are emphasised by a colour signal bar with warning triangle and signal

word.

The signal bars have the following meaning:

DANGER!

A safety notice on a red signal bar with the signal word DANGER designates a hazard

with a high risk level which, if not avoided, will result in death or severe injury.

WARNING!

A safety notice on an orange signal bar with the signal word WARNING designates a haz-

ard with a medium risk level which, if not avoided, might result in death or severe injury.

CAUTION!

A safety notice on a yellow signal bar with the signal word CAUTION designates a hazard

with a low risk level which, if not avoided, could result in minor or moderate injury.

1.3 General instructions

In addition to the safety notices, these instructions contain information that must be observed to

prevent property damage.

The pertinent text describes

• the possible reason for property damage

• the possibilities for preventing property damage

Notices of possible property damage are emphasised by a blue signal bar and the signal word

ATTENTION.

NOTICE

Notices for the prevention of property damage are not related to possible injuries.

Furthermore, these instructions contain general information on use.

General information on use and tips for certain applications are emphasised with a blue

information symbol.

6/30 Maintenance instructions Gas spring DS

Safety

For safe maintenance further, applicable documents are necessary. The information in these

documents have to be adhered to.

1.4 Residual risks

WARNING!

Filled gas springs are under high internal pressure.

Before repairing, drain the nitrogen completely.

To drain, open the valve carefully and only slightly

Wear safety glasses. Eye injuries due to nitrogen leaks

After removing the locking screw, never bend directly over the valve. Never direct the fill

opening towards persons

Only unscrew the valve when there is no more nitrogen flowing out and the piston rod can

be pushed in by hand. Injuries due to valve flying out.

If assembled incorrectly, parts may be propelled out after filling. Observe the precise instal-

lation position of the spare parts. Never direct the piston rod towards persons. Injuries pos-

sible due to parts flying out.

WARNING!

Use of incorrect spare parts

Installing the incorrect spare parts results in a loss of safety.

After filling with nitrogen, parts may be propelled out due to internal pressure.

Before repair, always ensure that the correct set of spare parts is being used.

Injuries possible due to parts flying parts.

NOTICE

Damages during repair

Always use protective jaws when clamping a gas spring into a vice. Ensure a clean environment.

Grooves, bumps or other damages can cause leakages.

Never exercise undue force to the gas spring during repair. Protect against damages.

Let nitrogen flow in slowly during the filling process. The valve of the gas spring can be dam-

aged.

For the filling process, only use pure nitrogen N2 of Grade 5.0 purity or higher.

Highest permissible filling pressure: 150 bar (2175 psi).

Gas spring operating instructions

Safety data sheet "Exchange of spare parts"

Operating instructions filling and control fitting.

Maintenance instructions Gas spring DS 7/30

Maintenance

2 MAINTENANCE

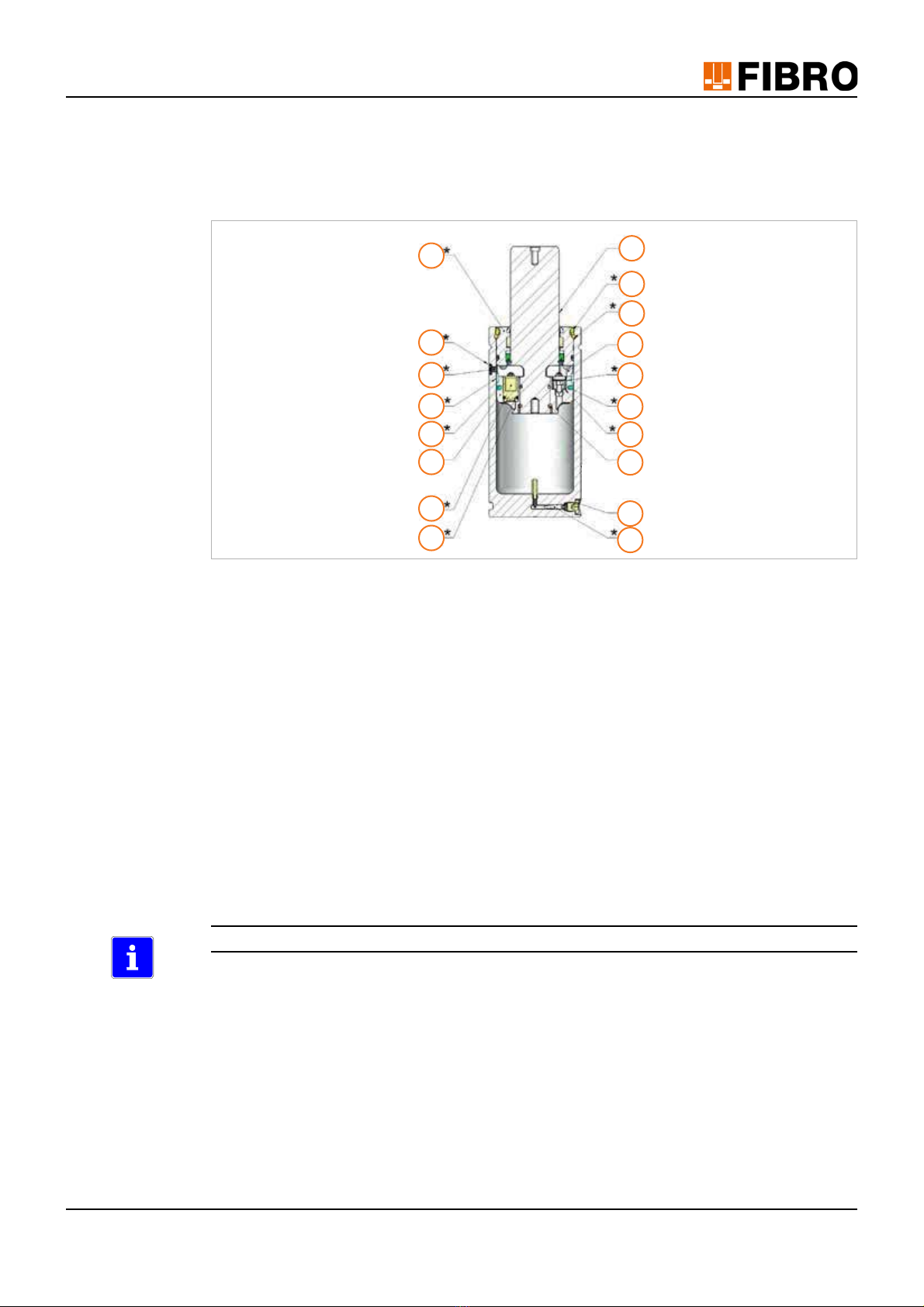

2.1 Components

Fig. 2-1 Components of the gas springs

1 Piston rod

2 Guide

3 Dirt ring guard

4 Circlip

5 Warning tape

6 Locking screw on service port

7 Separated piston disc

8 Guide ring

9 Filter screen

10 DS piston seal

11 Flow restrictor

12 DS piston

13 Sealing ring

14 Non-return valve

15 Circlip halves

16 DS piston O-ring

17 G 1/8 Fill opening locking screw

18 Valve

The components marked * are included in the spare parts set.

18

17

15

13

11

9

7

4

3

1

16

14

12

10

8

6

5

2

8/30 Maintenance instructions Gas spring DS

Maintenance

2.2 Inspection

2.2.1 Check gas pressure

NOTICE

Use the tools given below for the test. The tools are available from FIBRO GMBH. Damage to

the gas springs when using other tools.

Pos. Description Article number

[A] Filling and checking equipment 2480.00.32.21

[B] G1/8" filling adapter 2480.00.32.11

[C] Filling hose 2480.00.31.02

Cylinder pressure reducer (optional) 2480.00.32.07

Observe the operating instructions for the filling and checking equipment

2480.00.32.21.

G1/8“

A B C

Maintenance instructions Gas spring DS 9/30

Maintenance

1) Prepare filling and checking equipment.

– Turn the small knob (a) to the left as far as it will go. This will move the release pin (b)

into the retracted position.

– Close the outlet valve (c).

– Screw the filling adapter onto the M6 thread on the fittings. In the process, ensure that

the washer seal is located on the M6 thread.

2) Carefully unfasten the G1/8" locking screw via the fill opening of the gas spring using an

Allen wrench.

3) Unscrew and remove the locking screw.

4) Screw the filling and checking equipment into the fill opening of the gas spring by turning the

large knob.

5) Turn the small knob inwards. The release pin opens the valve. Caution! Do not turn the re-

lease pin inwards too far. Otherwise the valve may be damaged.

6) Read the filling pressure on the manometer display.

The permissible filling pressure is printed on the gas spring. If the filling pressure is too low, the

nitrogen must be topped up (see chapter 2.4 "Fill with nitrogen" on page 24).

a

c

1.

b

2. 5.

6.

4.

3.

10/30 Maintenance instructions Gas spring DS

Maintenance

7) After checking, turn the small knob to the left as far as it will go. The release pin moves into

the retracted position and closes the valve.

8) Slowly open the knob on the outlet valve and bleed the fittings.

9) Unscrew the fittings from the gas spring by turning the large knob.

10) Unscrew the filling adapter.

11) Screw the G1/8" locking screw into the fill opening of the gas spring.

– Tighten using a tightening torque of 15 - 18 Nm (11-13 lb-ft).

The locking screw has a sealing function and must always be fitted.

9. 11.

10.

8.

7.

Maintenance instructions Gas spring DS 11/30

Maintenance

2.3 Repairs

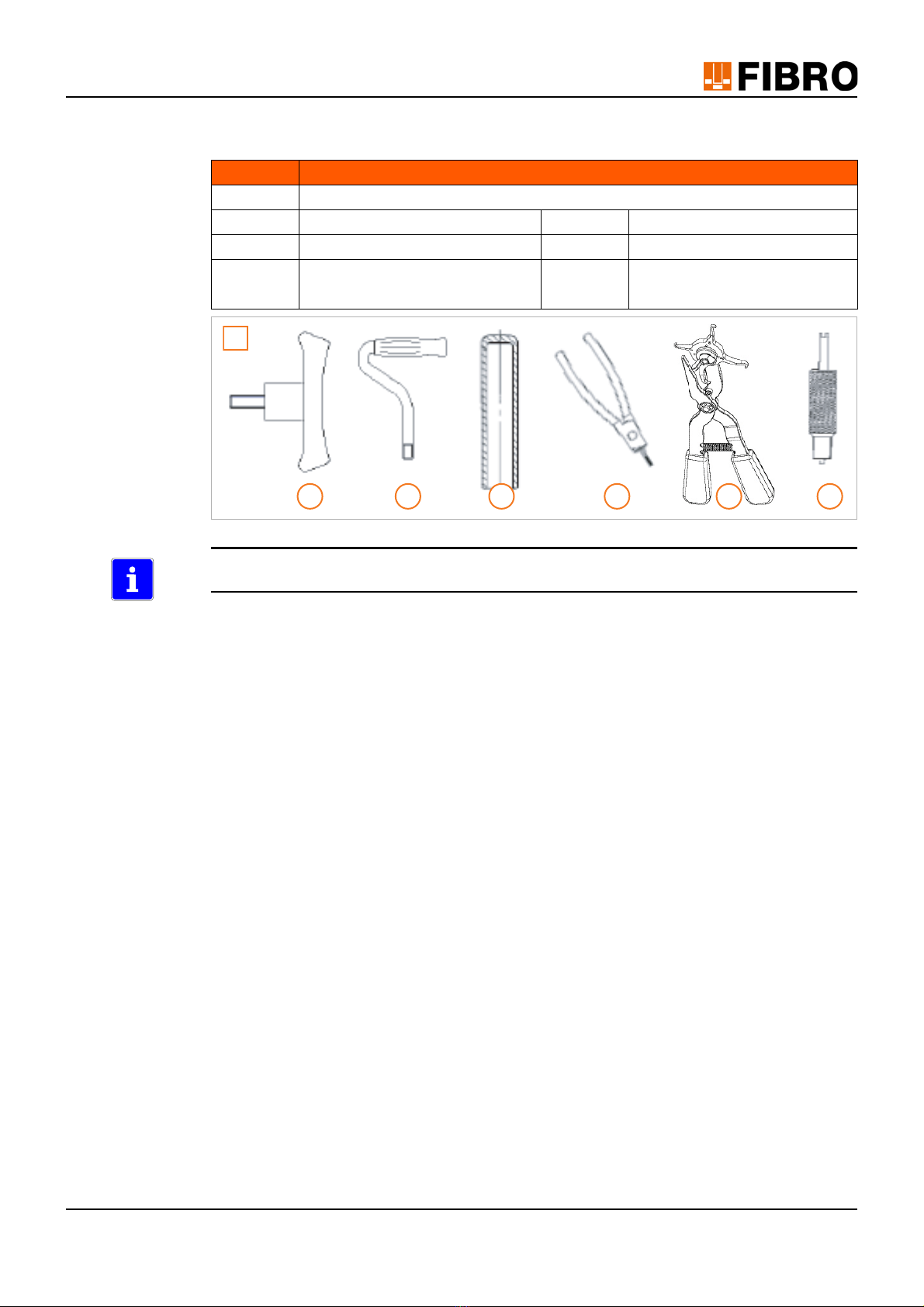

2.3.1 Required spare parts, tools and tool kits

NOTICE

Damage to the gas pressure spring if other spare parts are used

Only use genuine spare parts from FIBRO GMBH.

All spare parts included in the spare parts kit must always be replaced completely.

Spare parts set for gas spring 2486.22.

The spare parts set comprises:

Fig. 2-2 Spare parts set for gas spring 2486.22.

1 Guide 2 Circlip

3 Dirt ring guard 4 Guide ring

5 DS piston seal 6 DS piston O-ring

7 Flow restrictor 8 Filter screen

9 Valve 10 Locking screw on service port

11 Special oil 35 ml ( 248.00.50.) 12 O-ring on piston rod

13 Non-return valves 14 Warning tape

15 Sticker

6

7

8

9

11

5

4

3

1

15

14

10

12

13

2

12/30 Maintenance instructions Gas spring DS

Maintenance

NOTICE

Damage to the gas pressure spring if other resources and tools are used.

Use the resources and special tools listed below for repairs. The resources and tools can be

obtained from FIBRO GMBH.

Equipment and tools

Equipment:

Observe the operating instructions for the filling and checking equipment

2480.00.32.21.

Pos. Description Article number

[A] Filling and checking equipment 2480.00.32.21

[B] G1/8" filling adapter 2480.00.32.11

[C] Filling hose 2480.00.31.02

Cylinder pressure reducer (optional) 2480.00.32.07

G1/8“

A B C

Maintenance instructions Gas spring DS 13/30

Maintenance

Tools:

Fig. 2-3 Tool set 2480.00.50.11

To open the locking screw, an Allen wrench is required. To tighten the locking screw, a torque

wrench with a hexagon inset socket is required.

• 3 mm wrench size for M6 service port locking screw

• 5 mm wrench size for G1/8" locking screw

Pos. Description

[D] Required parts from tool set (2480.00.50.11)

(1) M8 T-lever (2) M16 T-lever

(3) Mounting sleeve (4) Valve tongs

(5) Circlip tongs (6) G1/8" valve tool

M6 valve tool

D

31 2 4 65

14/30 Maintenance instructions Gas spring DS

Maintenance

2.3.2 Evacuating gas pressure

WARNING!

High pressure

Serious injuries may result if the gas is not fully drained before removing the gas spring.

Only trained personnel with good product knowledge are permitted to carry out the activities

described.

Always wear safety glasses when working on a gas spring.

Never bend directly over a valve. Never direct connections towards yourself or other per-

sons.

Do not allow any extreme forces to be exerted on the gas spring.

When filled, the gas spring is under high internal pressure and must be protected against

damage.

To maintain the maximum service life of the gas spring, always protect it against dirt, caustic

liquids and abrasive dust.

When clamping in a vice, always use protective jaws.

NOTICE

The procedure given below for draining the gas must be followed with care.

Evacuation instructions for the safe draining of gas

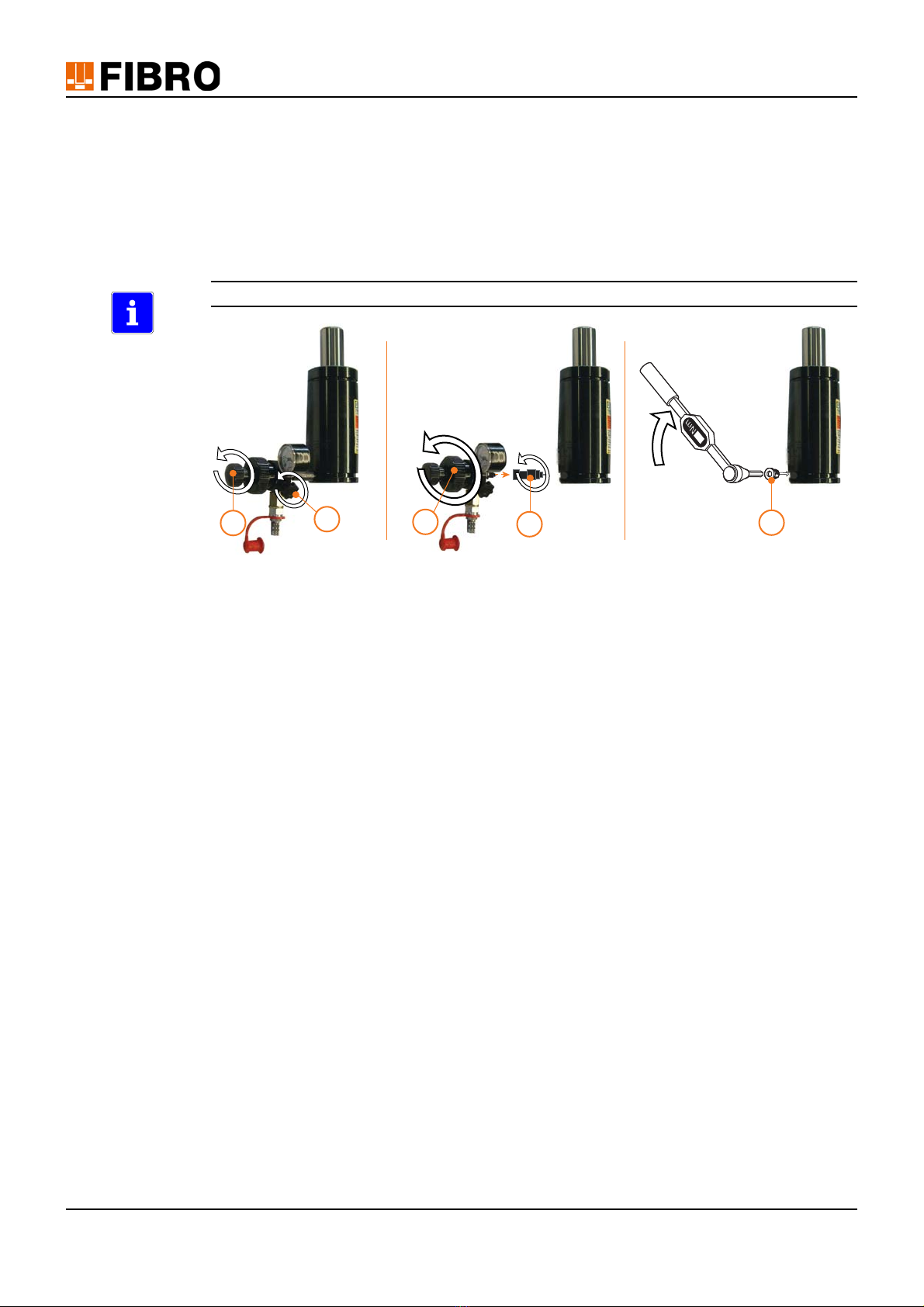

Fig. 2-4 Parts of the DS gas spring / Tools required

1 Locking screw on service port

2 Cylinder pipe

3 Locking screw on fill opening

4Valve

5 Warning tape

6 Maximum stroke

7 M8 T-Lever

8 G1/8“ Valve tool

9 Valve tongs

1

2

3

4

5

6

7

8

9

Maintenance instructions Gas spring DS 15/30

Maintenance

1) Remove warning tape underneath the top C-notch to make the locking screw of the service

port visible.

WARNING!

Escaping gas. High pressure.

The locking screw of the service port is under high internal pressure.

The locking screw is permitted to be opened by a maximum of one full rotation, and must

never be completely removed..

Wear safety glasses.

Leaking gas can cause eye injuries.

2) Use an Allen wrench (3 mm) to turn the locking screw on the service port counter-clockwise

by a maximum of one rotation to slightly open the service port and allow the gas to flow out.

NOTICE

After draining the gas from the service port, the piston rod can be extended.

3) Leave the service port open.

4) Clamp the gas spring in an inclined position (around 30°) in a vice. Piston rod points diago-

nally downwards.

5) Use an Allen key (5 mm) to detach and unscrew the locking screw via the fill opening of the

gas spring..

WARNING!

Escaping gas. High pressure.

Slowly actuate the valve by screwing in the valve tool.

Wear safety glasses.

Leaking gas can cause eye injuries.

6) Screw in the threaded end of the valve tool into the fill opening until the valve opens and the

gas escapes.

7) Allow gas to flow out slowly and completely.

NOTICE

The valve is not permitted to be removed until both pressure chambers of the gas spring are

completely empty.

8) Check the fill level.

– Screw the T-lever into the piston rod thread.

– When the piston rod can be moved up and down by hand, the gas spring can be regard-

ed as drained.

9) After draining with the other end of the G1/8" valve tool, unscrew the valve out of the thread

completely.

10) Remove the valve from the fill opening using the valve tongs and dispose of.

11) Unscrew and remove the locking screw of the service port.

The gas spring is now prepared for performing maintenance work.

16/30 Maintenance instructions Gas spring DS

Maintenance

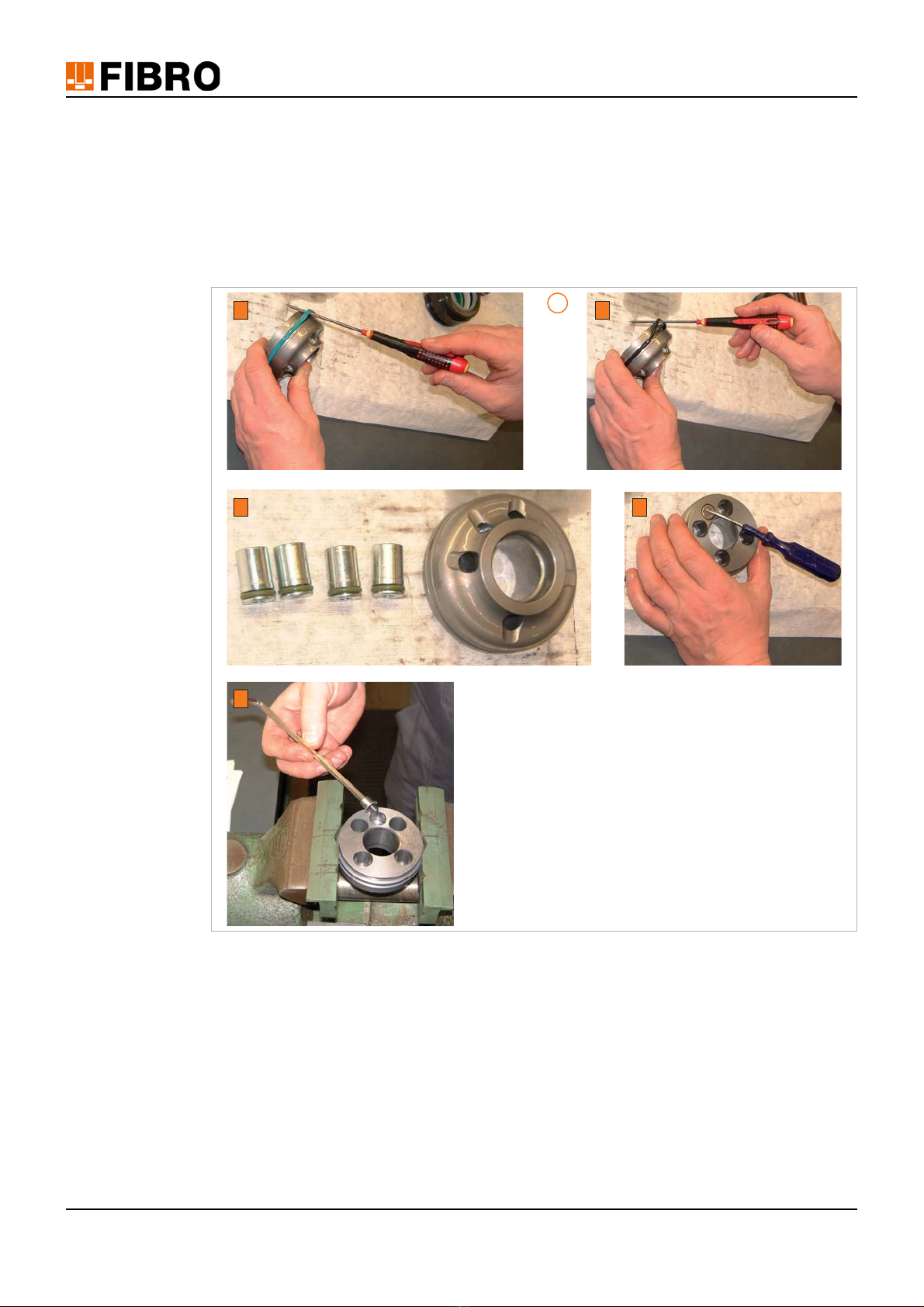

2.3.3 Dismantle gas spring

Position of the components, see chapter 2.1 "Components" on page 7.

The gas spring must be evacuated completely (see chapter 2.3.2 "Evacuating gas pressure"

on page 14).

Check: Screw the T-lever into the piston rod. When the piston rod can be moved up and

down by hand without resistance, there is no more gas in the gas spring.

The oil must be completely drained.

1. Remove the dirt ring guard.

2. Knock the guide into the pipe using the mounting sleeve and a hammer until the circlip is

exposed.

3. Lever out the circlip using the circlip tool.

CAUTION!

The circlip is tensioned like a spring and may spring out.

Wear safety glasses.

4. Clamp the gas spring in a vice.

5. Screw the T-lever into the piston rod and remove the piston rod including the guide and DS

piston.

2. 3. 5.

Maintenance instructions Gas spring DS 17/30

Maintenance

6. Remove the guide from the piston rod and dispose of.

7. Remove the blue guide ring from the piston rod.

8. Remove both piston disc halves from the piston rod.

9. Rotate the piston rod with DS piston.

10. Press the DS piston downwards to expose the circlip halves.

11. Remove the circlip halves.

12. Remove the DS piston from the piston rod to expose the O-ring on the end of the piston rod.

7. 8. 10.

18/30 Maintenance instructions Gas spring DS

Maintenance

13. Disassembling the DS piston.

a) Remove the piston seal from the DS piston.

b) Remove the O-ring from the DS piston. Ensure that the sealing groove in the DS piston

is not damaged.

c) Push the non-return valves out of the guides of the DS piston.

d) Lever out the filter screen from the flow restrictor.

e) Unscrew the flow restrictor.

13.

a b

c d

e

Maintenance instructions Gas spring DS 19/30

Maintenance

14. Remove the old O-ring from the piston rod.

15. Retain the cylinder pipe, piston rod, DS piston and piston disc halves. Dispose of the remain-

ing components.

2.3.4 Clean and check components

• Clean the cylinder pipe, piston rod, DS piston and piston disc halves.

• Check the interior of the cylinder pipe and piston rod.

– There must not be any scratches or dents on the interior of the cylinder pipe or piston

rod.

– If these parts are in any way scratched or damaged, they must be replaced.

14.

20/30 Maintenance instructions Gas spring DS

Maintenance

2.3.5 Assemble gas spring

NOTICE

Jamming, damage to equipment.

Make sure that the correct piston rod is installed. To check this, place the unmounted piston rod

in the cylinder. The upper end of the piston rod and the cylinder have to be in alignment.

1. Unpack the spare parts set and check for completeness. Spare parts in the spare parts set,

see chapter 2.3.1 "Required spare parts, tools and tool kits" on page 11.

2. Lubricate the piston rod.

3. Insert the O-ring into the second groove of the piston rod.

3.

Table of contents

Other FIBRO Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

TrueClean

TrueClean ToteTilter Installation, operation and maintenance manual

Nexen

Nexen AIR CHAMP 625 user manual

impro technologies

impro technologies XRH900-1-0-GB Series installation manual

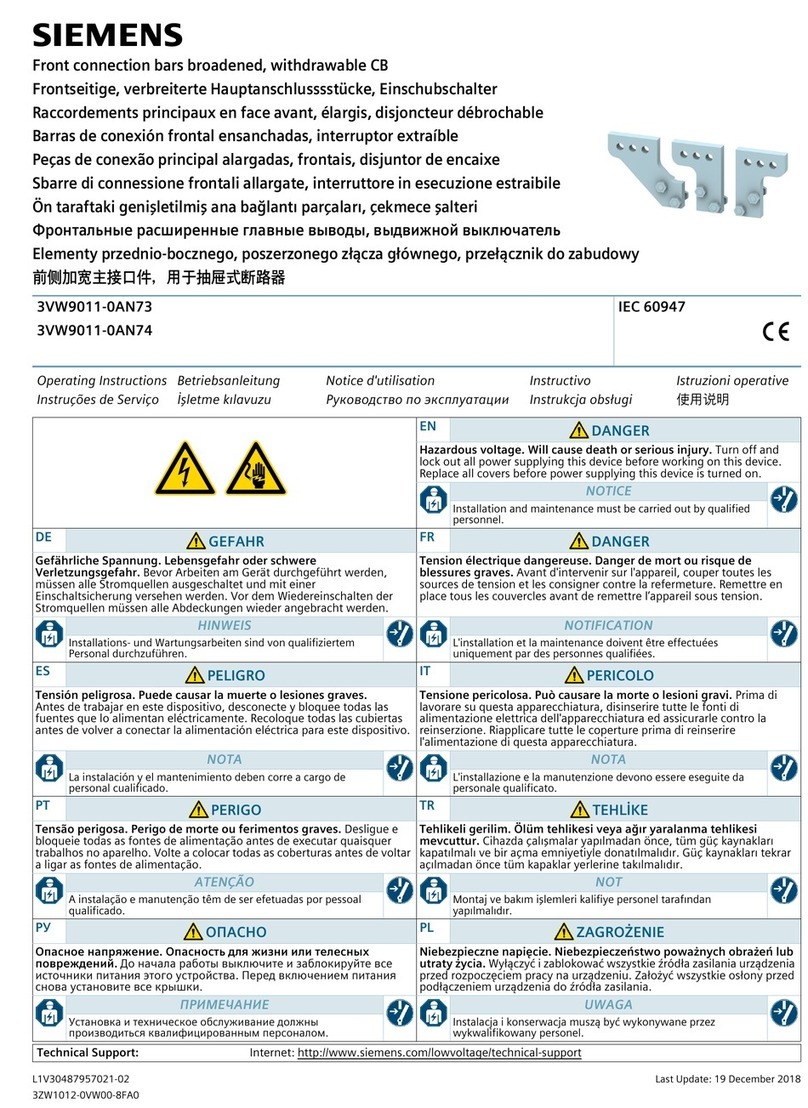

Siemens

Siemens SIRIUS 3RA Equipment manual

Festo

Festo EAMM-U-50-S38-40A Instructions & assembly

Teac

Teac TC-NSRSP-G3 Instructions for use

KSB

KSB 9972073510/200 Operating and maintenance instructions

Elgo

Elgo LIMAX2M Series operating manual

National Instruments

National Instruments NI SMD-7620 Getting started

Dover

Dover OPW 788 Series quick start guide

Siemens

Siemens 3VW9011-0AN73 operating instructions

RaycoWylie

RaycoWylie i4300 installation guide