5.5 Mounting the cover

Fig. 19 Attach the cover

• Fasten cover[7] to the housing[8] with the screws[1].

6 In operation

CAUTION!

Risk of injury from touching hot surfaces.

The motor connecting kit becomes hot due to the heat dissipation of the motor.

• Do not touch the motor connecting kit during operation or immediately after-

ward.

WARNING!

Risk of injury due to unexpected movement of components if toothed belt fails.

• Take supplemental safeguarding measures.

7 Maintenance

7.1 Check the toothed belt

The toothed belt[5] is a wearing part èwww.festo.com/spareparts.

1. Check toothed belt[5] regularly:

– during maintenance of the machine

– when replacing an axis

2. Replace the toothed belt[5] at the following indicators of wear:

– excessive accumulation of wear particles in the housing

– cracks on the back of the toothed belt

– visible glass fibre cords in the tooth base

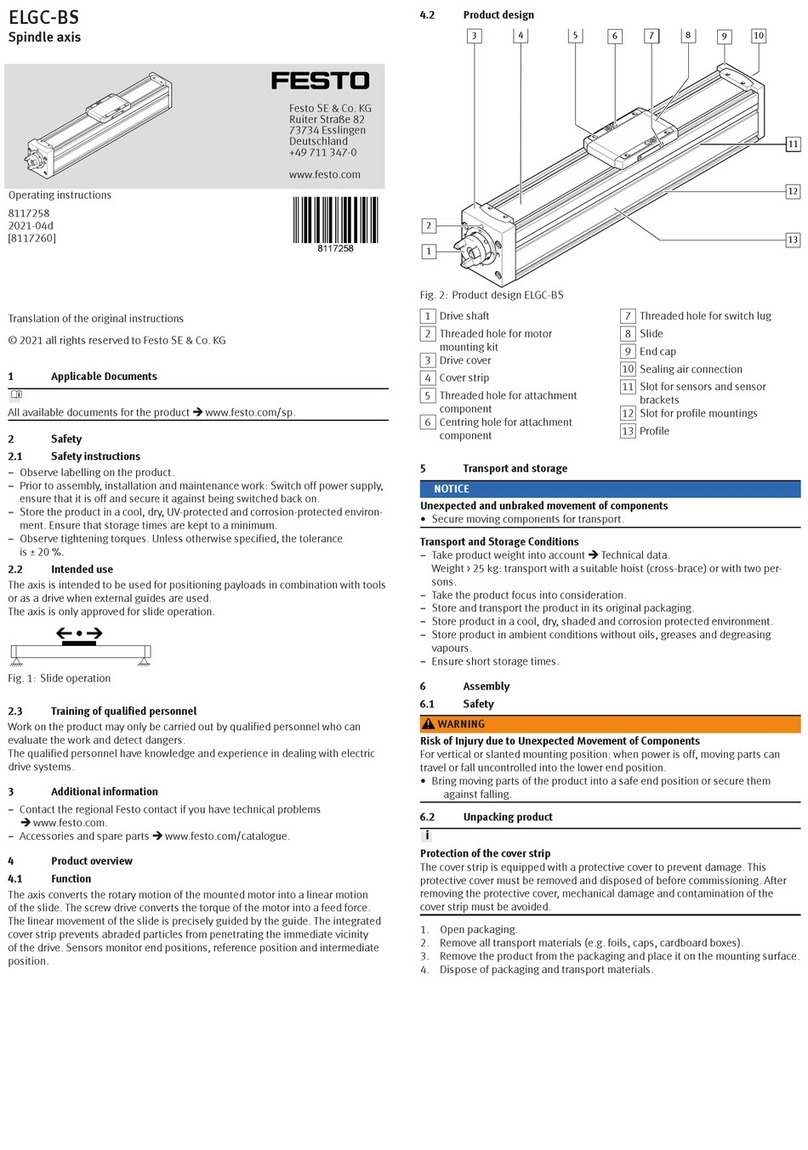

Fig. 20 Loosen toothed disc

1. Unscrew the screws[2] slightly.

ÄThe motor is movable and can be easily tilted.

2. Move the motor in the direction of the axis up to the stop and tilt it slightly.

3. Dismount the counter bearing.

4. Unscrew the toothed belt pulleys[6]. Apply counter pressure to the clamping

sleeves[3]/[4].

5. Rotate toothed belt pulleys[6] anti-clockwise.

ÄThe toothed belt pulleys[6] can be pulled from the cone of the clamping

sleeves[3]/[4].

7.2 Dismounting the toothed belt

Fig. 21 Loosen toothed disc

1. Unscrew the screws[2] slightly.

ÄThe motor is movable and can be easily tilted.

2. Move the motor in the direction of the axis up to the stop and tilt it slightly.

3. Dismount the counter bearing.

4. Unscrew the toothed belt pulleys[6]. Apply counter pressure to the clamping

sleeves[3]/[4].

5. Rotate toothed belt pulleys[6] anti-clockwise.

ÄThe toothed belt pulleys[6] can be pulled from the cone of the clamping

sleeves[3]/[4].

Fig. 22 Remove toothed belt

1. Pull the clamping sleeves[3]/[4] from the drive shaft.

2. Remove the toothed belt[5] from the toothed belt pulleys[6].

8 Technical data

8.1 Screw sizes and tightening torques

EAMM-U- [2] [Nm] [8] [Nm] [10] [Nm] [33] [Nm]

50-S38-40A M3x12 1.2 M4x25 3 M5x12 6 M5x20 6

50-S38-40P M3x10 1.2 M4x25 3 M5x12 6 M5x20 6

50-S38-42A M3x8 1.2 M4x25 3 M5x12 6 M5x20 6

60-S38-40R M4x12 3 M5x25 6 M5x12 6 M6x20 10

60-S38-55A M5x20 6 M5x25 6 M5x12 6 M6x20 10

60-S38-57A M5x30 6 M5x25 6 M5x12 6 M6x20 10

60-S38-67A M6x10 10 M5x25 6 M5x12 6 M6x20 10

60-S48-40R M4x12 3 M5x25 6 M5x12 6 M6x20 10

60-S48-55A M5x20 6 M5x25 6 M5x12 6 M6x20 10

60-S48-57A M5x35 6 M5x25 6 M5x12 6 M6x20 10

70-S48-60P M4x16 3 M5x35 6 M5x14 6 M8x30 18

70-S48-70A M5x18 6 M5x35 6 M5x14 6 M8x30 18

86-S48-60P M4x16 3 M6x40 10 M5x12 6 M8x30 18

86-S48-70A M5x18 6 M6x40 10 M5x12 6 M8x30 18

86-S48-87A M6x40 10 M6x40 10 M5x12 6 M8x30 18

86-S62-55A M5x20 6 M6x40 10 M6x18 10 M8x30 18

86-S62-70A M5x18 6 M6x40 10 M6x12 10 M8x30 18

86-S62-80P M5x20 6 M6x40 10 M6x12 10 M8x30 18

86-S62-87A M6x40 10 M6x40 10 M6x12 10 M8x30 18

110-S62-88A M6x20 10 M8x50 18 M6x12 10 M8x40 18

110-S62-100A M8x25 18 M8x50 18 M6x12 10 M8x40 18

110-S95-100A M8x25 18 M8x50 18 M8x16 18 M8x40 18

145-S62-140A M10x55 30 M8x50 18 M6x12 10 M8x40 18

145-S95-140A M10x55 30 M8x50 18 M8x16 18 M8x40 18

Tab. 6

EAMM-U- [41] [Nm]

60-S38-67A M5x8 6

Tab. 7

8.2 Tightening torques for the toothed belt pulleys

The transmittable torque depends on the tightening torque of the toothed belt

pulleys[6].

• Select the tightening torque of the toothed belt pulley[6] from the permiss-

ible range.

ÄCheck: The transferable torque is greater than the driving torque of the

motor èTechnical data of the motor.

EAMM-U- Toothed belt pulley[6] Parallel kit

Tightening torque [Nm] Transferable torque [Nm]

50 3 …5 0.5…1

60 10…15 1.5…3

70 22…35 3.5…7

86 25…40 4.8…9.5

110 65…80 12.5…25

145 120…180 25…50

Tab. 8

EAMM-U- Toothed belt[6] Clamping

sleeve[3]/[4]

Clamping

sleeve[31]

50 ß17 ß5 ß3

60 ß22 ß8 ß5

70/86 ß30 ß8 ß6

110/145 ß36 ß10 ß8

Tab. 9