Dover OPW 788 Series User manual

Other Dover Industrial Equipment manuals

Dover

Dover Universal 5588 Series User manual

Dover

Dover DESTACO ROBOHAND DPP Series User manual

Dover

Dover Automating Tomorrow DESTACO RA Series User manual

Dover

Dover WILDEN PSG Equalizer SD Series Instruction Manual

Dover

Dover DESTACO ROBOHAND RA-Toggle Series User manual

Dover

Dover Marathon V-4224 User manual

Dover

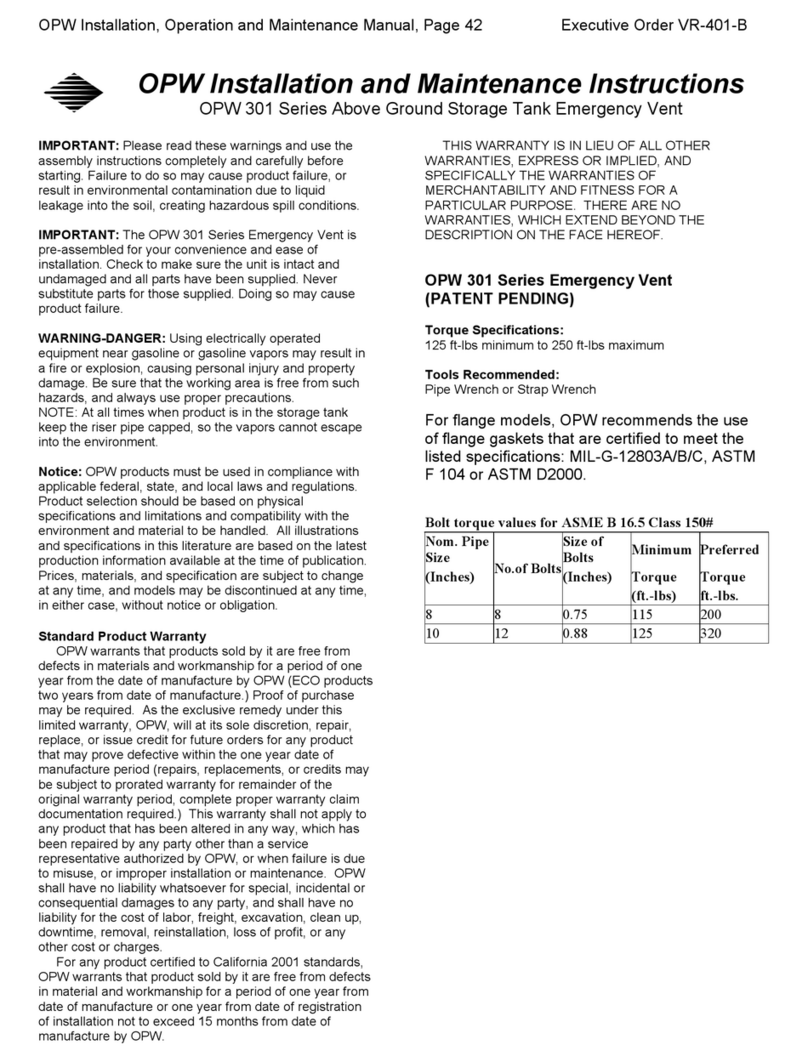

Dover OPW 301 Series User manual

Dover

Dover DESTACO RFE Series User manual

Dover

Dover Triton 96 Series User manual

Dover

Dover DESTACO ROBOHAND RPS Series User manual

Dover

Dover markem-image 9020 User manual

Dover

Dover OPW OT Series Technical specifications

Dover

Dover Vitronics Soltec DeltaWave 6622cc User manual

Dover

Dover DESTACO ROBOHAND RR Series User manual

Dover

Dover TWG PullMaster PM50 User manual

Dover

Dover TWG 250PR Operating instructions

Dover

Dover Blackmer DMX IV User manual

Dover

Dover DESTACO ROBOHAND RDH Series User manual

Dover

Dover Triton 9640 Manual

Dover

Dover Ravaglioli VSG J50HE User manual