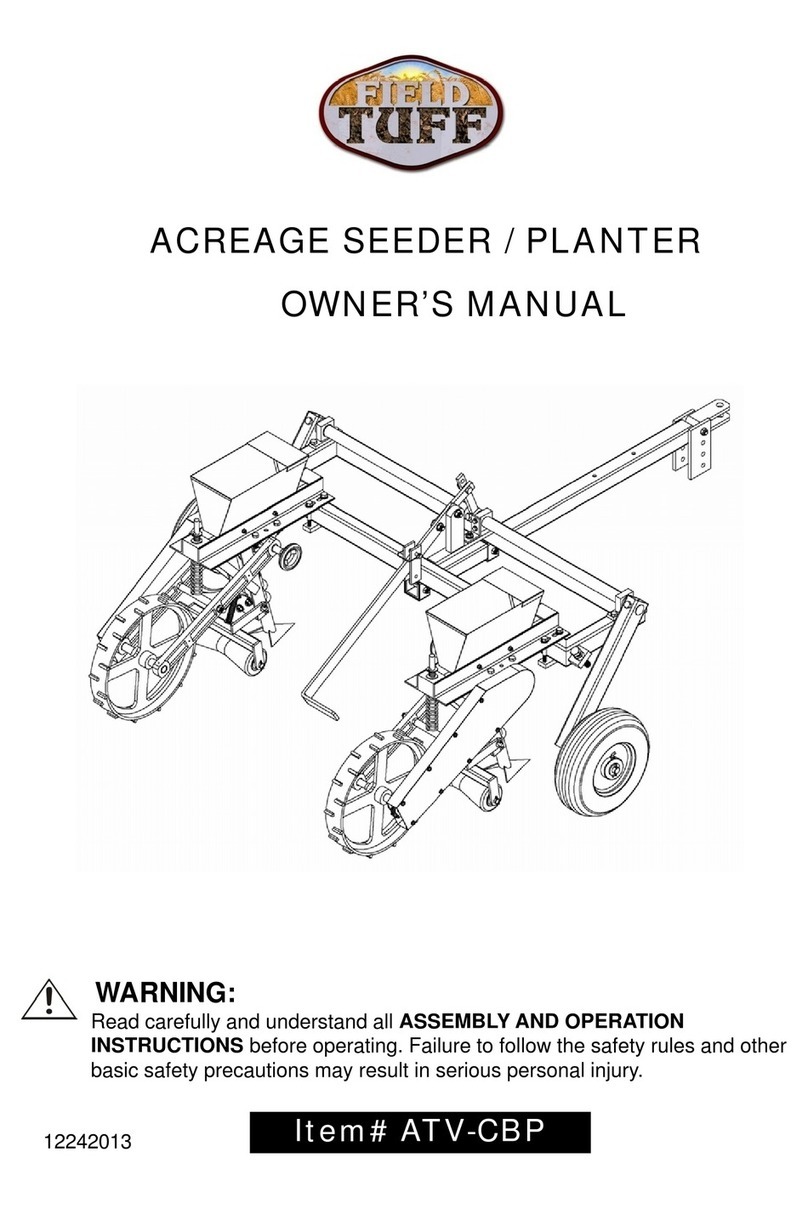

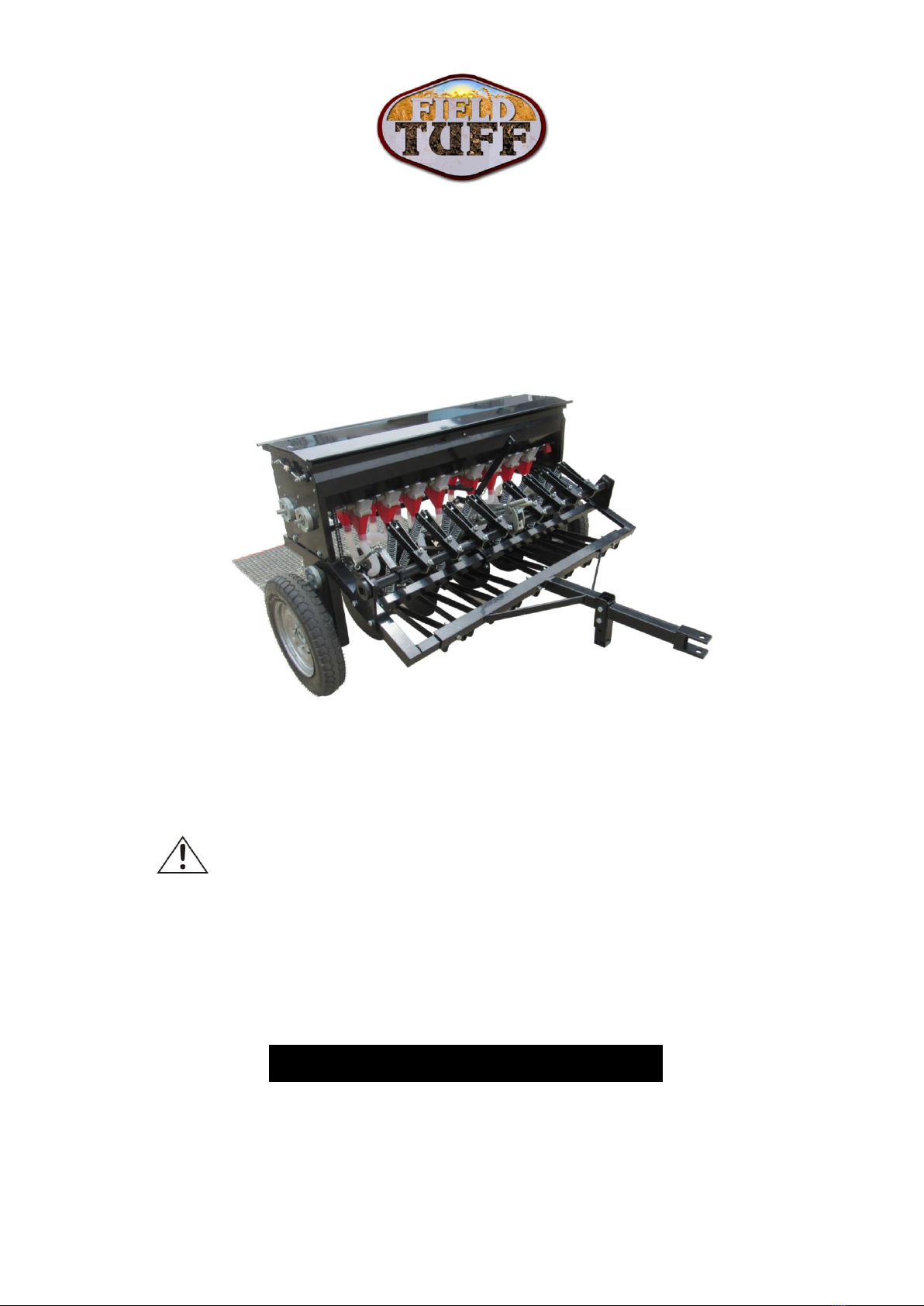

Field Tuff ATV-48ATVPS User manual

ATV Seeder

OWNER’S MANUAL

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

20180601

Model # ATV-48ATVPS

Page of 15

2

Thank you very much for choosing this product! For future reference, please complete the

owner’s record below:

Model: Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This product is designed for certain applications only. The manufacturer cannot be responsible

for issues arising from modification. We strongly recommend this product not be modified and/or

used for any application other than that for which it was designed. If you have any questions

relative to a particular application, DO NOT use the product until you have first contacted us to

determine if it can or should be performed on the product.

INTENDED USE

This ATV seeder has 8 rows to seed corn, beans, oats, etc. There are two boxes with closeable

slides for each row. The seeder has adjustable slots to use for different types of seed. This

seeder is also able to seed grain.

TECHNICAL SPECIFICATIONS

Weight

529 lbs

Rated Horse Power

Minimum 20 HP

Seeding Rows

8

Row Spacing

5.3 inches

Seed Rate

Each hole up to 20 lbs per acre

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this seeder until they have

read this manual and have developed a thorough understanding of how the seeder works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

Page of 15

3

SAVE THESE INSTRUCTIONS

WORK AREA

•Keep work area clean, free of clutter and well lit. Cluttered and dark work areas can cause

accidents.

•Keep children and bystanders away while operating a seeder. Distractions can cause you to

lose control, so visitors should remain at a safe distance from the work area.

•Be alert of your surroundings. Using a seeder in confined work areas may put you

dangerously close to cutting tools and rotating parts.

PERSONAL SAFETY

•Stay alert, watch what you are doing and use common sense when using a seeder. Do not use

a seeder while you are tired or under the influence of drugs, alcohol or medication. Amoment of

inattention while operating a seeder may result in serious personal injury.

•Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

•Use safety apparel and equipment. Use safety goggles or safety glasses with side shields

which comply with current national standards, or when needed, a face shield. Use a dust mask if

working in dusty work conditions. This applies to all persons in the work area.Also use non-skid

safety shoes, hardhat, gloves, dust collection systems, and hearing protection when

appropriate.

SEEDER USE AND CARE

•Do not modify the seeder in any way. Unauthorized modification may impair the function

and/or safety and could affect the life of the equipment. There are specific applications for which

the seeder was designed.

•Always check for damaged or worn out parts before using the seeder. Broken parts will

affect the seeder operation. Replace or repair damaged or worn parts immediately.

•Do not exceed the seeder load capacity.

•Distribute the load evenly. Uneven loads may cause the seeder to tip, resulting in personal

injury to the operator or others.

•Use the seeder on flat and level surfaces capable of supporting the seeder and its maximum

load. Pulling or pushing a load on a slanted or uneven surface can result in loss of control.

•Store idle seeder. When seeder is not in use, store it in a secure place indoors and out of the

reach of children. Inspect it for good working condition prior to storage and before re-use.

INTENDED USE

1. Suitable for drilling corn, beans, oats, small grains, etc. in level or gently rolling fields.

2. The double disc coulters create an opening to seed easily in tilled soil.

3. The depth of seeding can be adjusted. Seeding quantity can be adjusted.

4. The seeder can plant seeds, roll, and drag all at the same time.

Page of 15

4

SAFETY PRECAUTIONS AND OPERATION RULES

1. Note the following in order to avoid fertilizer burn:

a. The seed rate should be controlled according to your field condition.

2. Always inspect, maintain or adjust the seeder after each use.

3. While operating the seeder, keep area clean, free of clutter and well lit. Keep children and

bystanders away. Distractions can cause you to lose control, so bystanders should remain at a

safe distance from the work area.

4. The seeder should raise and lower smoothly.

5. The seeder should be inspected prior to each use. Carefully check all bolts, nuts, chains

sprockets etc. to make sure they are in good condition and properly tightened. Keep guards in

place at ALL times.

6. Keep the hopper clean and make sure there is no moisture inside before you fill with seed and

fertilizer.

7. Working speed can be 3 -5 miles/hr.

8. DO NOT stand/sit between the seeder and the tractor/ATV/UTV while operating.

9. DO NOT go in reverse or turn sharply while seeder is in the ground.

10. During planting, avoid unnecessary stopping in the field to maintain consistent seed spacing.

11. Driver should have experience and be familiar with using this type of equipment.

12. The tractor/ATV/UTV should be stopped when adding seed and performing maintenance.

13. DO NOT go under the seeder for inspecting or repairing while seeder is in the up position.

Page of 15

5

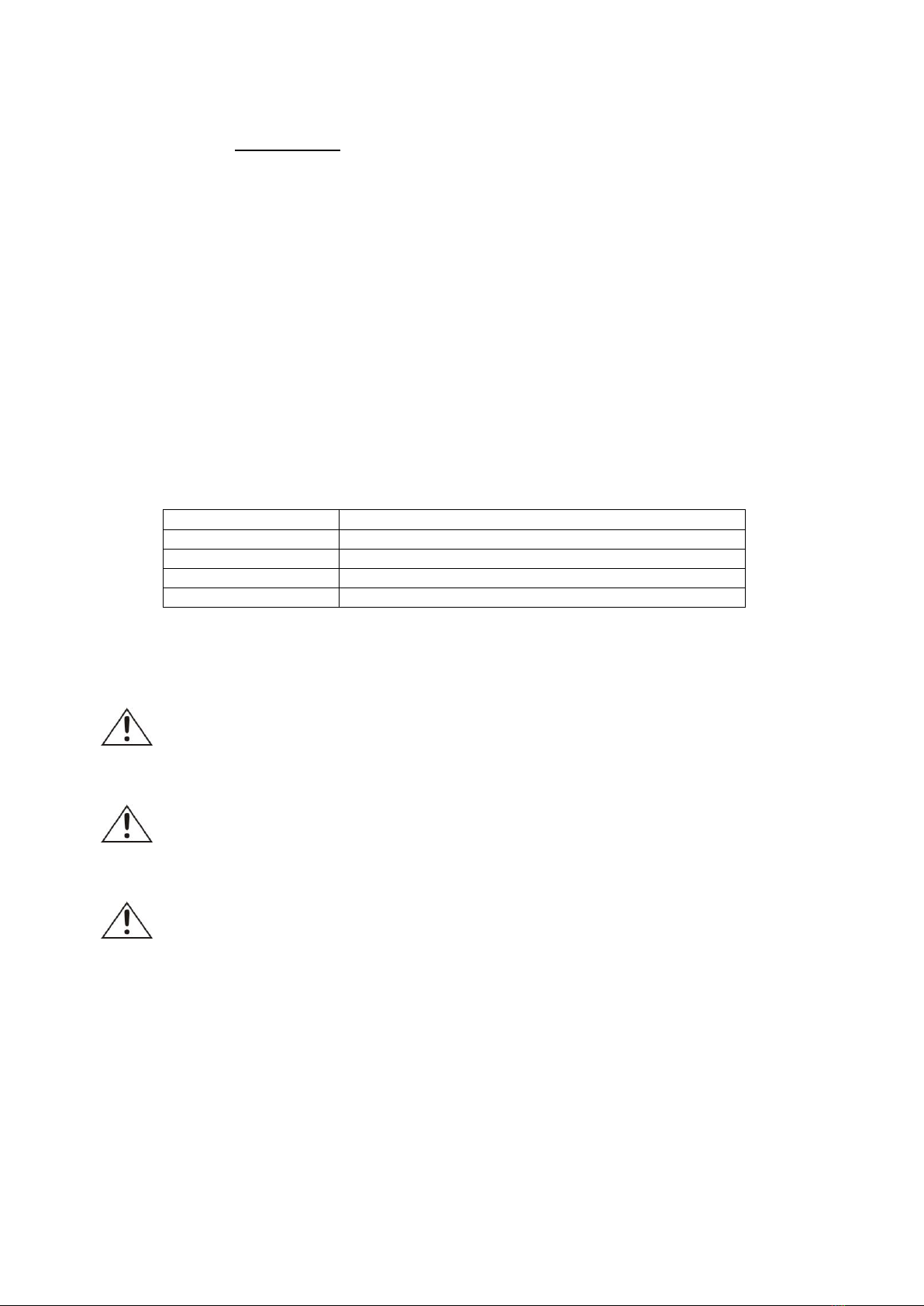

ASSEMBLY

Step #1:

Remove the seeder from the crate.

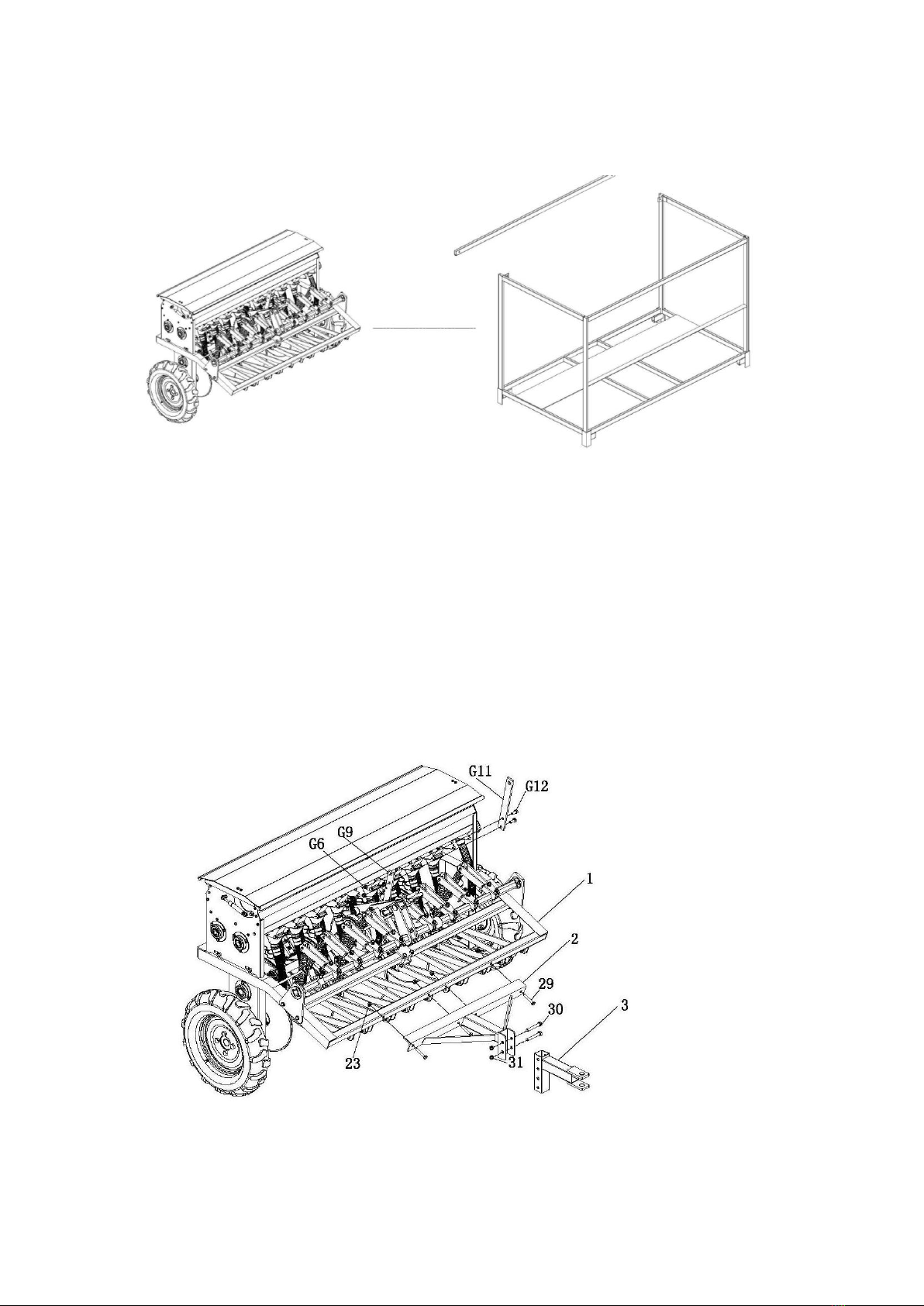

Step #2:

Connect the Support seat (#2) to the Seeder Rack (#1), using four Hex Bolts M10*60(#29) and four

Hex Lock Nuts M10 (#23);

Step #3:

Connect the Connecting base (#3) to the Support seat (#2),using two Hex Bolts M12*80(#30) and

two Hex Lock Nuts M12 (#31);

Step #4:

Connect the Handle component (#G11) to the Control handle component (#G9), using two Hex

Bolts M10*25(G12) and two Hex Lock Nuts M10 (G6);

Page of 15

6

Step #5:

Connect the Connecting base (#3) to theATV;

Step #6:

Pull the Handle component (#G11), to raise the seeder coulters (#12) off the ground, then drive ATV

to the destination.

Step #7:

Connect the Drag Mat (#46) to the Seeder Rack (#1).

Page of 15

7

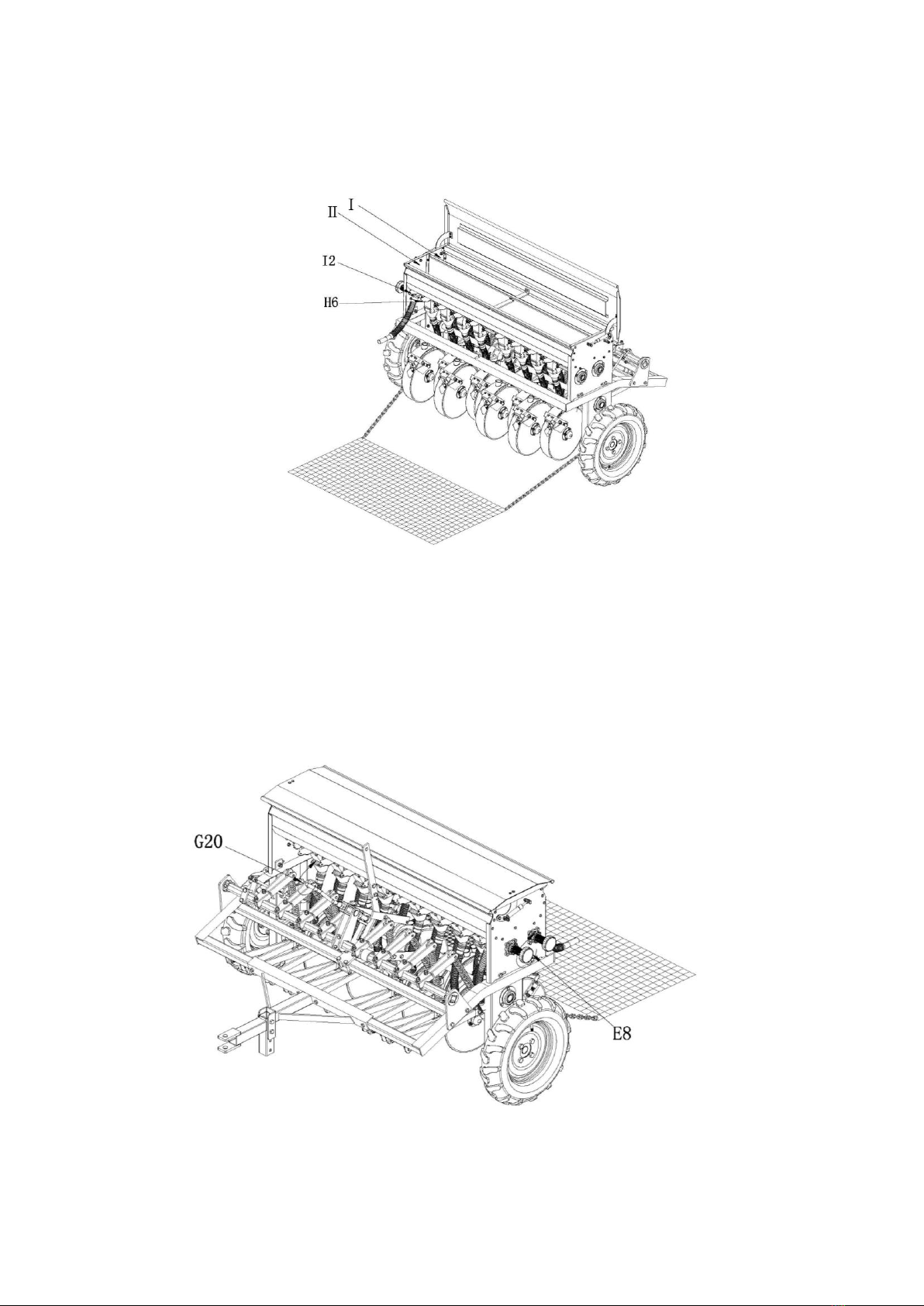

Step #8:

Open the material box ‘s cover plate, Close the two hose plate covers (#I2), then Close the front

eight plate covers (#H6), put the fertilizer into Hopper I, and close other eight plate covers (#H6), put

the seed into Hopper II. Close the material box.

Step #9:

Turn the Control hand wheel (#E8) to adjust the seed rate, turn clockwise to reduce the rate,

counter clockwise to increase the rate.

Step #10:

Turn the Transmission rod (#G20) to adjust the seed/fertilizer depth, turn clockwise for shallow

depths and counter clockwise for deeper depths.

Page of 15

8

Step #11:

Open the sixteen plate covers (#H6) to prepare to seed.

Step #12:

Drive the ATV, Pull the Handle component (#G11) to lower the seeder coulters (#12) into the ground.

Then begin to seed.

Step #13:

Close the sixteen plate covers (#H6), and open the two hose plate covers (#I2), to clear the seed

and fertilizer.

Step #14:

Take off the Drag Mat (#46), and pull the Handle component (#G11) to raise the coulter (#12) off the

ground, then pull ahead.

Page of 15

9

PART DIAGRAMS

Page of 15

10

Part List

Part #

Description

QTY

Part #

Description

QTY

1

Seeder Rack

1

29

Hex bolt M10*60

10

2

Support seat

1

30

Hex bolt M12*80

2

3

Connecting base

1

31

Hex Lock Nut M12

2

4

Hopper

1

32

Guiding pad

8

5

Adjustment for seeding

2

33

Block piece

8

6

Seeding component

16

34

Spring

8

7

Discharge component

2

35

Rod A for spring

4

8

Clutch component

1

36

Rod B for spring

4

9

Intermittent Component

1

37

Cotter Ø5*25

8

10

Right wheel component

1

38

U Bolt

8

11

Left wheel component

1

39

Adjusting plate A

8

12

Coulter

8

40

Adjusting plate B

8

13

Hexagon bearing

2

41

Hex bolt M8*35

8

14

Shaft ring Ø30

2

42

Hex bolt M10*40

8

15

Hex bolt M8*20

20

43

Hex bolt M10*25

8

16

Bearing housing

4

44

Hex bolt M10*65

6

17

Deep groove ball bearing

4

45

Fixed plate for

square shaft

2

18

Hexagonal shaft sprocket

part

2

46

Drag Mat

1

19

Hex Lock Nut M8

30

47

Pull plate

1

20

Circular shaft

1

48

Tension spring for handle

1

21

Circular shaft sprocket part

1

49

Tensioning wheel

2

22

Hexagon socket head cap

screw

1

50

Tensioning wheel bushing

2

23

Hex Lock Nut M10

38

51

ChainA

1

24

Square shaft sheath

2

52

Chain B

1

25

Hex bolt M10*30

6

53

Intermittent Transmission

components

1

26

Hex bolt M8*55

2

54

Lift arm

2

27

Screw support plate

1

55

Clutch lift component

1

28

Fixed plate

1

Left Wheel Component Diagram

Part #

Description

QTY

A1

Hex bolt M14*25

4

A2

Tire

1

A3

Hex Lock Nut M14

4

A4

Fixed base A for tire

1

A5

Hex bolt M10*55

3

A6

Bearing housing

2

A7

Deep groove ball bearing

2

A8

Shaft ring Ø35

2

A9

Hex Lock Nut M10

3

Page of 15

11

Right Wheel Component Diagram

Part #

Description

QTY

B1

Hex bolt M14*25

4

B2

Tire

1

B3

Fixed base B for tire

1

B4

Hex Lock Nut M14

4

B5

Hex bolt M10*55

3

B6

Bearing housing

2

B7

Deep groove ball bearing

2

B8

Shaft ring Ø35

2

B9

Hex Lock Nut M10

3

B10

Hex Lock Nut M8

1

B11

Chain wheel

1

B12

Hexagon socket head cap

screw

1

Coulter Diagram

Part #

Description

QTY

C1

Hex Lock Nut M6

8

C2

Dust cap

2

C3

Nut

4

C4

External hexagon nut

1

C5

Bearing housing

2

C6

Deep groove ball bearing

2

C7

Disc

2

C8

Sealing washer

2

C9

Hex bolt M6*16

8

C10

Coulter welding part

1

C11

Thin hexagon nut

1

C12

Outside scraping clay

plate

1

C13

Hex bolt M6*12

1

C14

Inside scraping clay plate

1

C15

Fixed base for the Inside

scraping clay plate

1

Page of 15

12

Clutch Component Diagram

Part #

Description

QTY

D1

Cotter Ø5*45

2

D2

Flat

2

D3

Chain wheel

1

D4

Round pin Ø10*30

1

D5

Master spoon

1

D6

Flat key

1

D7

Subordinate spoon

1

D8

Clutch

1

D9

Spring

1

D10

Cotter Ø2*16

2

D11

Threaded rod

1

D12

Hex Lock Nut M10

2

D13

Connecting Part

1

D14

Oil zerk

1

Adjustment For Seeding Diagram

Part #

Description

QTY

E1

Flat Ø16

2

E2

Cotter Ø4*35

2

E3

Hex Lock Nut M8

4

E4

Nut retainer

1

E5

Hex bolt M8*20

4

E6

Check ring

1

E7

Locknut

1

E8

Control hand wheel

1

E9

Handwheel cover

1

Page of 15

13

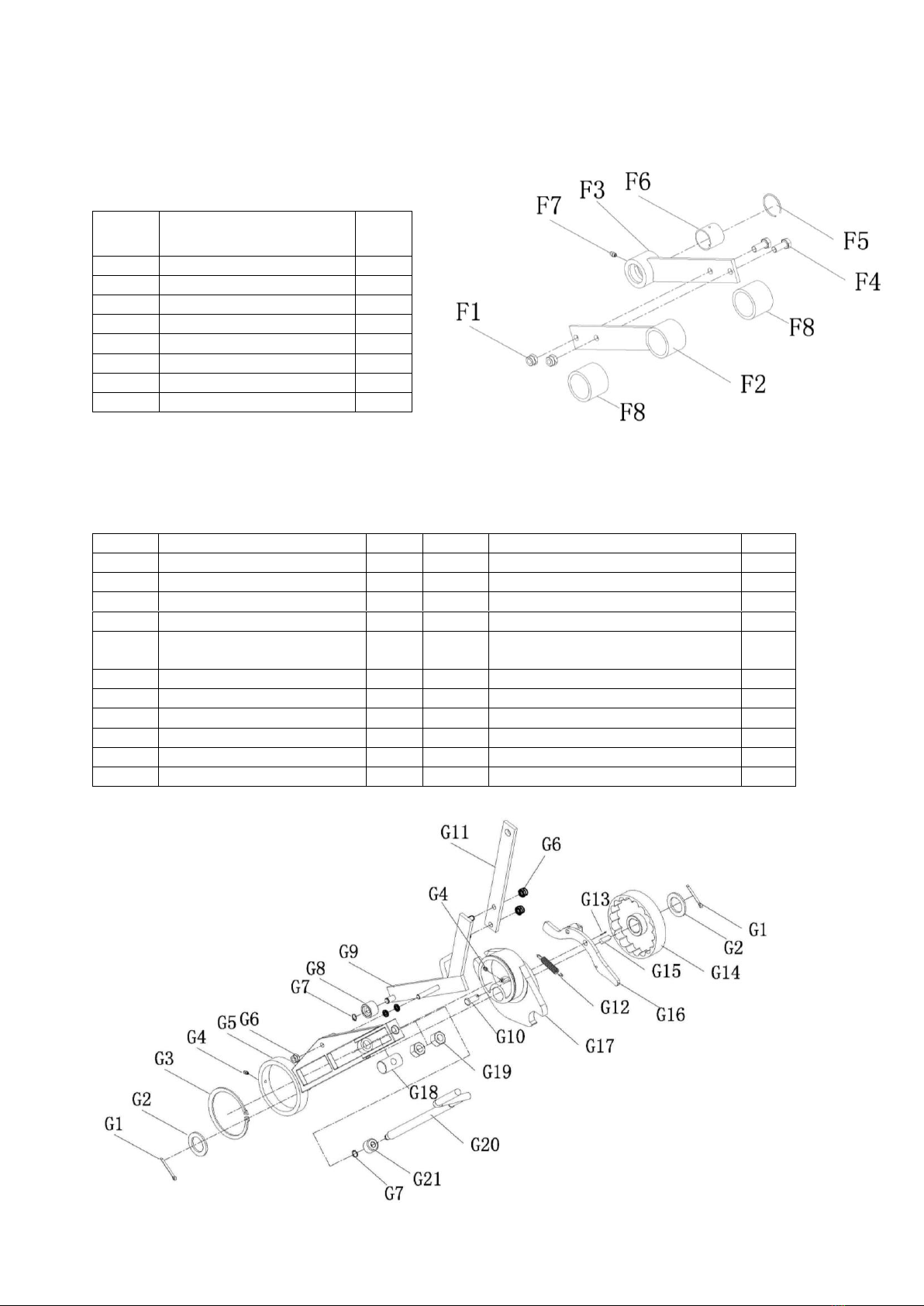

Pull Plate Diagram

Part #

Description

QTY

F1

Hex Lock Nut M10

2

F2

Sleeve A

1

F3

Sleeve B

1

F4

Hex bolt M10*25

2

F5

Steel Cable Baffle Ring

1

F6

Bush

1

F7

Oil zerk

1

F8

Pipe

2

Intermittent Components Diagram

Part #

Description

QTY

Part #

Description

QTY

G1

Cotter Ø5*45

2

G12

Tension spring

1

G2

Flat

2

G13

Cotter Ø2*16

1

G3

Shaft ring Ø110

1

G14

Intermittent driving components

1

G4

Oil zerk

2

G15

Flat key

1

G5

Intermittent transmission

component

1

G16

Hook

1

G6

Hex Lock Nut M10

2

G17

Eccentric component

1

G7

Shaft ring Ø12

1

G18

Round pin of transmission rod

1

G8

Wheel

1

G19

Hex Nut M18

2

G9

Control Handle

1

G20

Transmission rod

1

G10

Round pin Ø12*30

1

G21

Transmission rod base

1

G11

Handle component

1

Page of 15

14

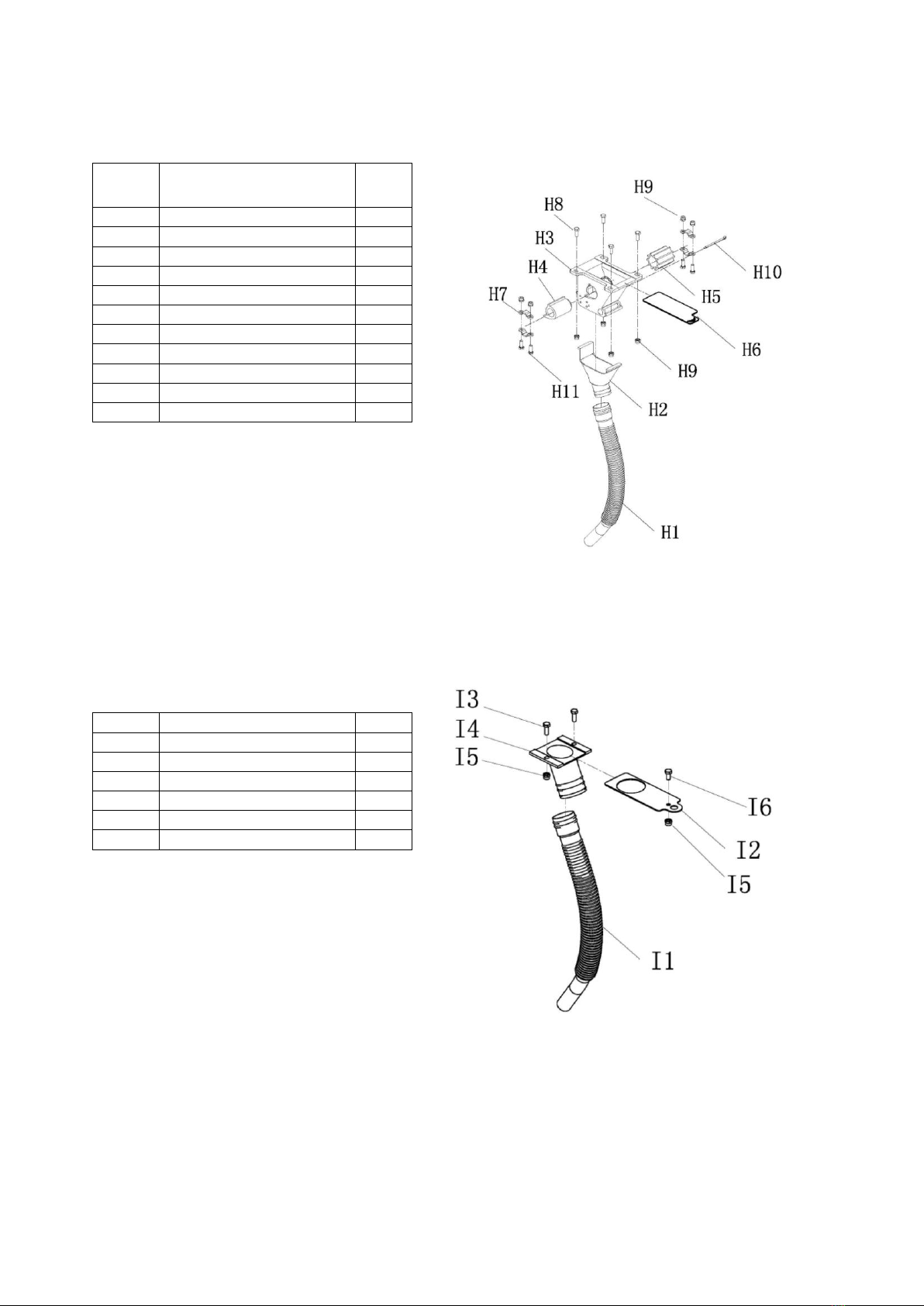

Seeding Component Diagram

Part #

Description

QTY

H1

Seeding pipe

1

H2

Seeding funnel

1

H3

Seeding component

1

H4

Blocking part

1

H5

Seeding wheel

1

H6

Plate Cover

1

H7

Hexagonal axis bolt

4

H8

Hex bolt M6*16

4

H9

Hex Lock Nut M6

8

H10

Cotter Ø3*55

1

H11

Hex bolt M6*20

4

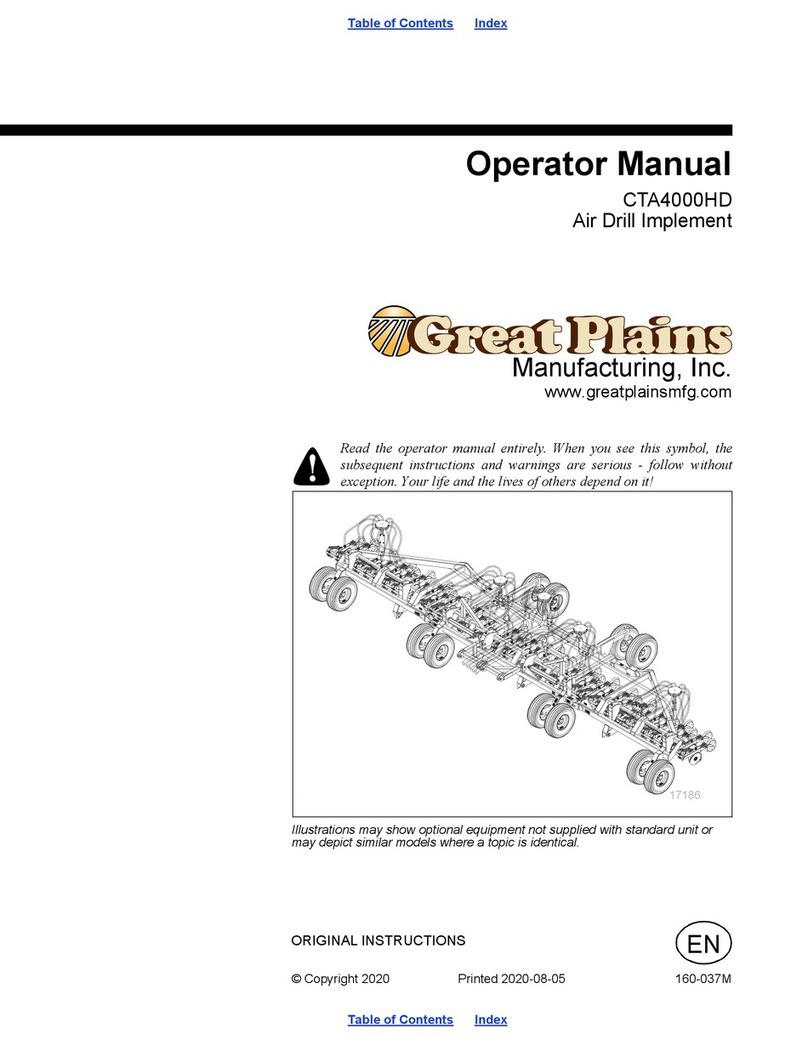

Discharge component Diagram

Part #

Description

QTY

I1

Hose

1

I2

Hose Plate Covers

1

I3

Hex bolt M6*16

2

I4

Hose opening

1

I5

Hex Lock Nut M6

2

I6

Hex bolt M6*12

1

Page of 15

15

Hopper Diagram

For technical questions, Please call 218-943-6296

WARRANTY

One-year limited parts warranty.

TG

PO BOX 203

Miltona, MN 56354

MADE IN CHINA

Part #

Description

QTY

Part #

Description

QTY

J1

Left side plate

1

J9

Left plate

1

J2

Right side plate

1

J10

Right plate

1

J3

Clapboard

1

J11

Hex bolt M8*25

4

J4

Hopper body

1

J12

Hex bolt M8*35

2

J5

Hopper Cover

1

J13

Hex nut M8

10

J6

Hex bolt M6*12

28

J14

Hex Lock Nut M8

6

J7

Hex Lock Nut M6

28

J15

Flat washer Ø8

6

J8

Gas spring

2

Table of contents

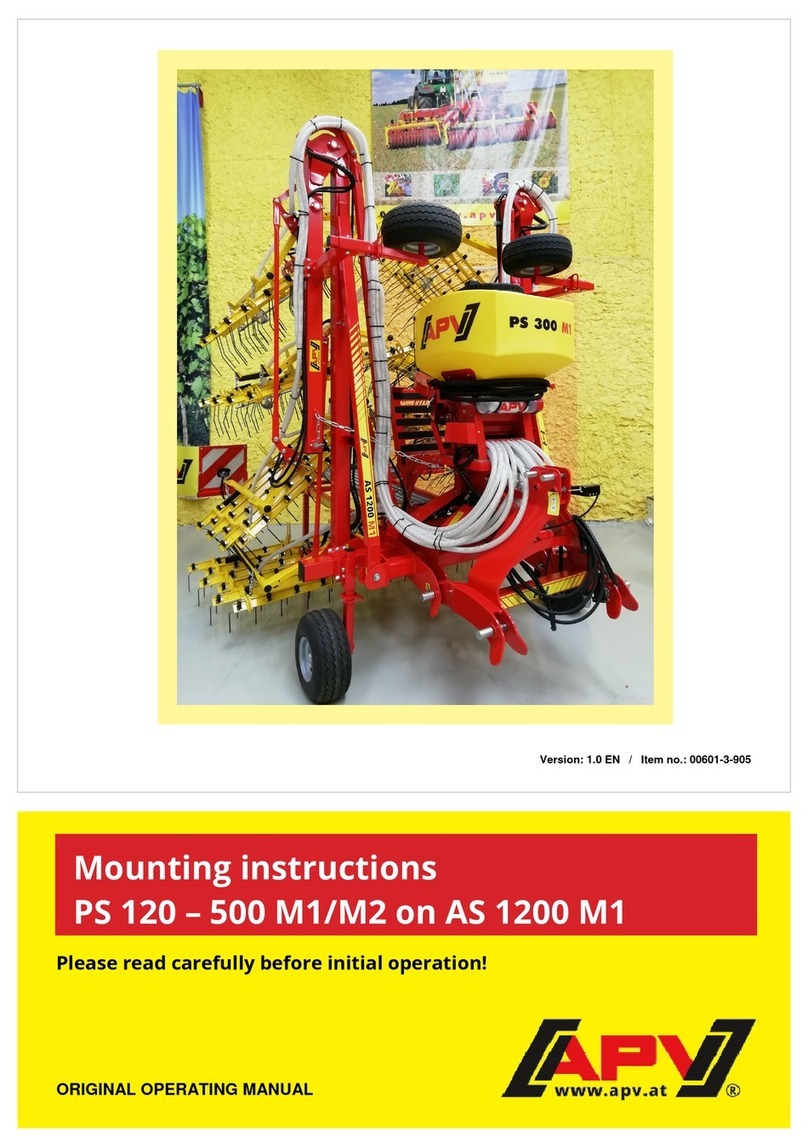

Other Field Tuff Seeder manuals

Popular Seeder manuals by other brands

John Shearer

John Shearer 6M Airdrill Operator's manual

Gaspardo

Gaspardo CHRONO 300 Use and maintenance

Prodana Seeds

Prodana Seeds Proseeder HP600 operating instructions

Finn

Finn HydroSeeder T30 Operator Instructions And Parts Manual

Earth Way

Earth Way 1001-B Assembly instructions

GREAT PLAINS

GREAT PLAINS CTA4000HD Operator's manual