2

Contents

chapter contents page

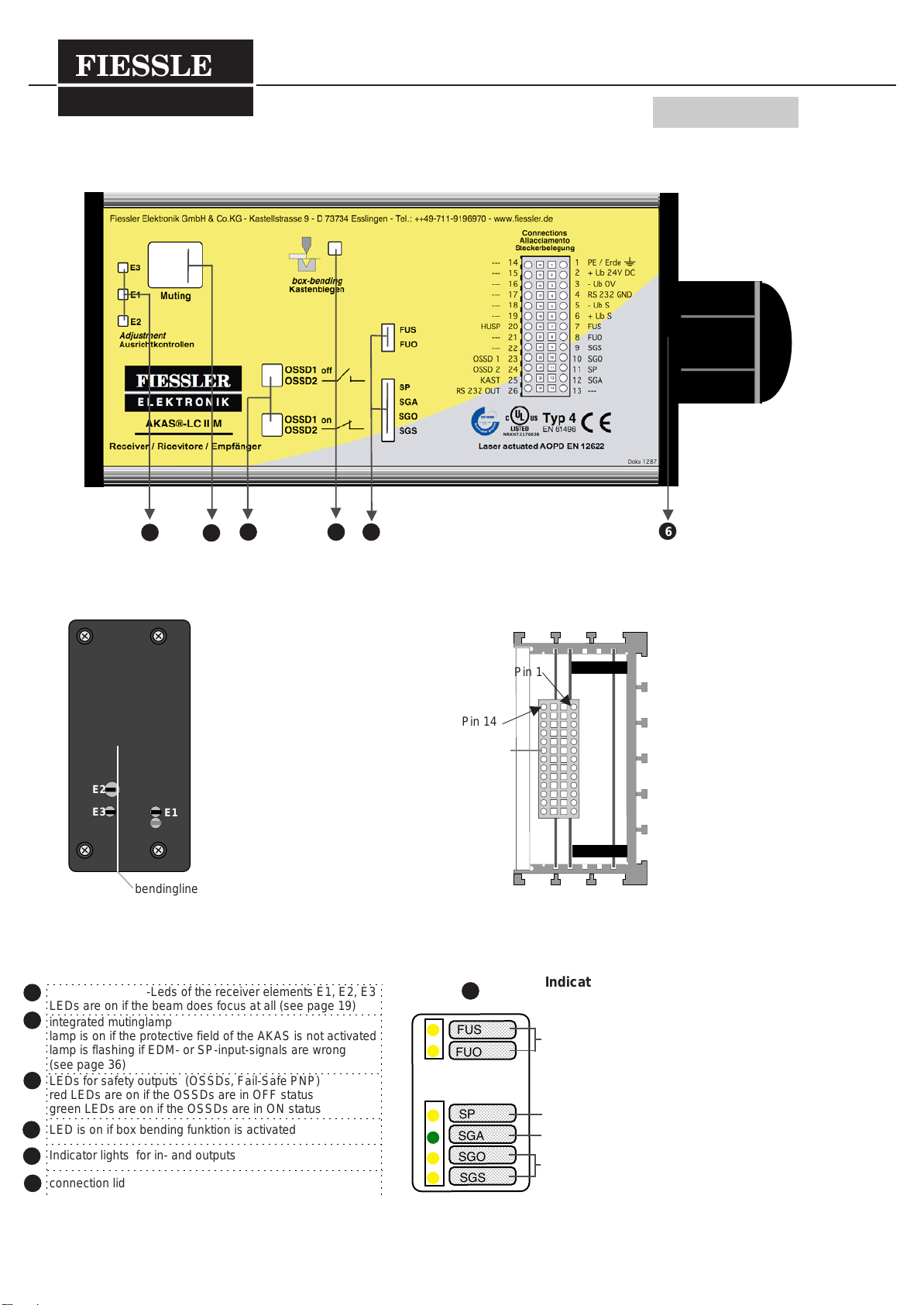

1Indicator lights on Frontpanel and switches for safe operation AKAS®-LC II F………………… 3

1.1 Indicator lights on Frontpanel and switches for safe operation AKAS®-LC II M ………………… 4

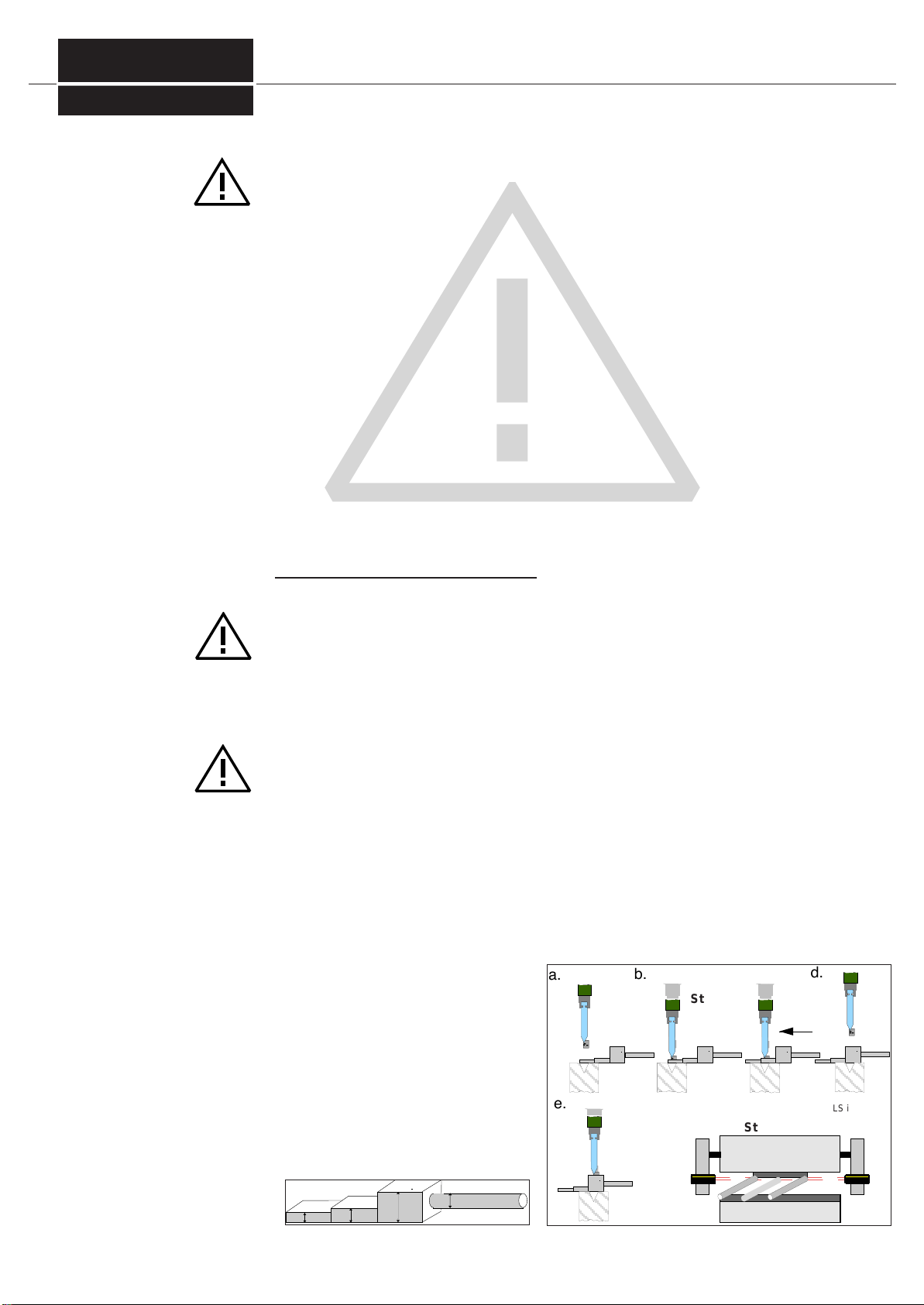

2General Safety Instructions …….……………………………………………………………………………………… 5

2.1 Prerequisites for using the press brake protection AKAS® ……………………………………………………………………………… 6

3 Description and fields of application for the equipment……..……………………………………………………………… 7

3.1 General Instructions ………………………………………………………………………………………………………………………… 7

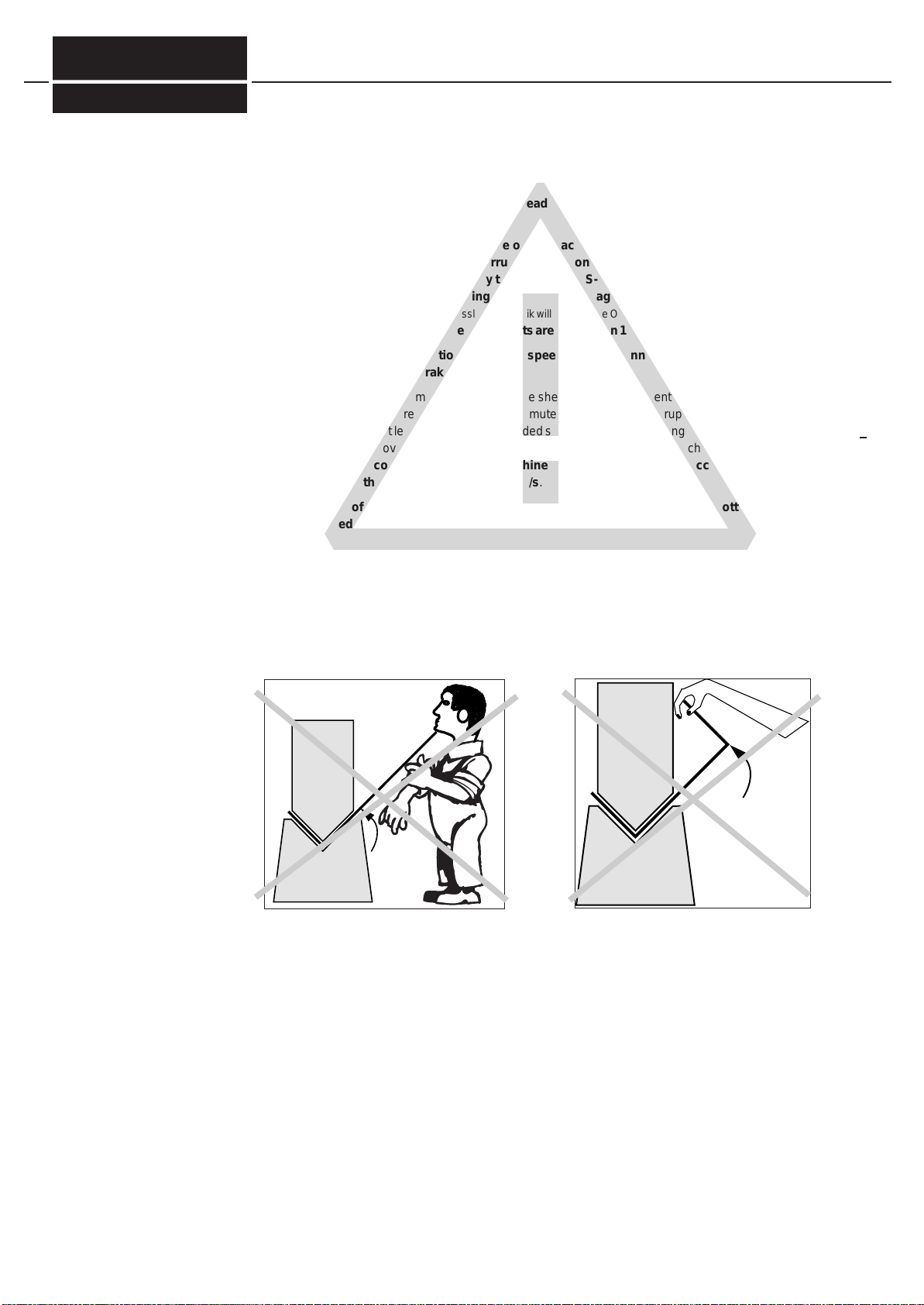

3.2 Function Description / Characteristics …………………………………………………………………………………………………… 8

3.3 Function description during bending of flat sheet metal / bending of wavy sheet metal …………………………………………… 9

3.4 Function description during Box bending / bending of small items …………………………………………………………………… 10

4 Mechanical data, dimension drawings ……………………………………………………………………………………… 11

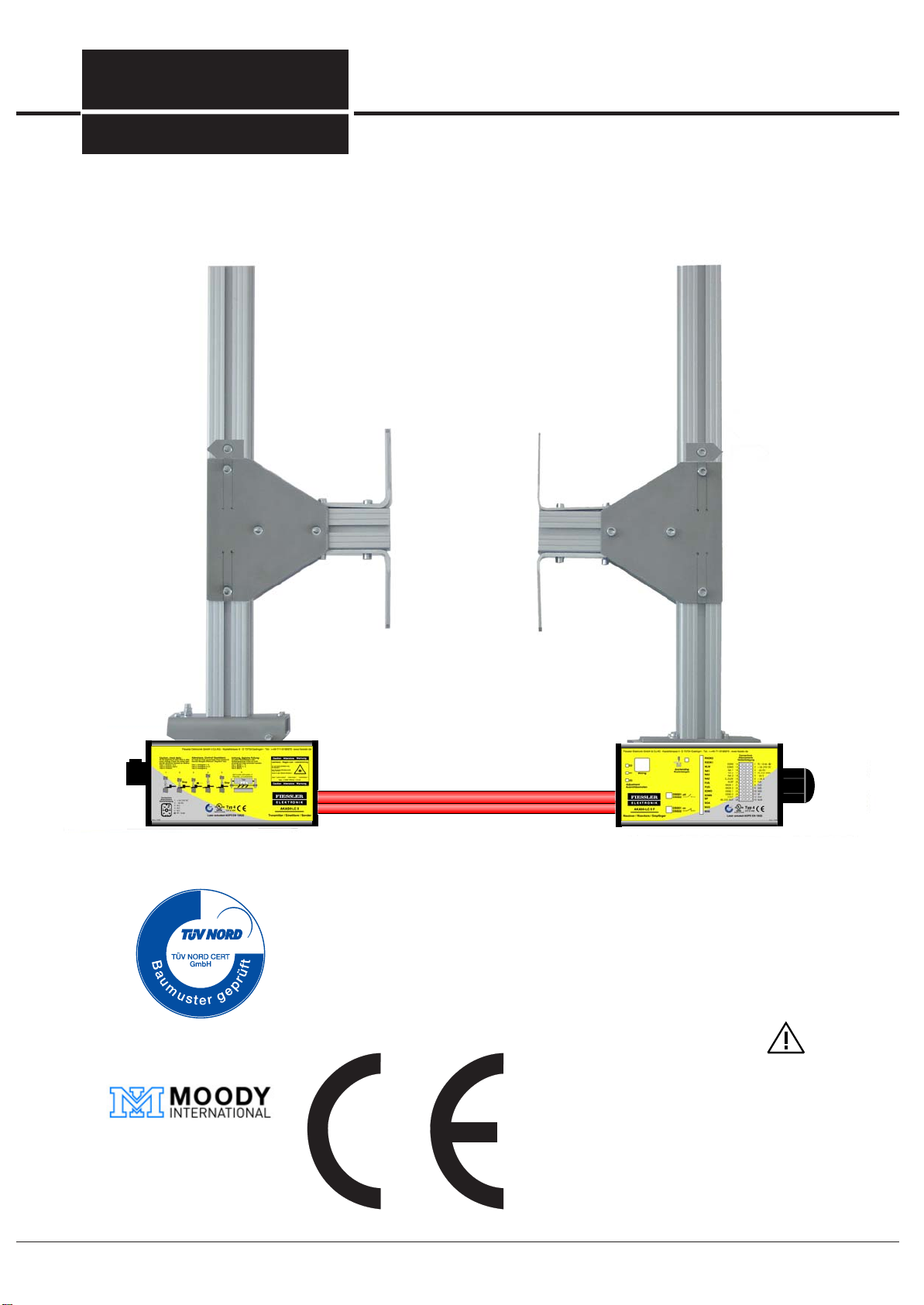

4.1 AKAS®-LC II M / -F ………………………………………………… ……………………………………………………………………… 11

5Mounting…………………………………………………………………………………………………………………… 12

5.1 How to proceed during the mounting of the AKAS® -system / Fiessler Suspension Devices …………………………………… 12

5.2 1. Overrun Traverse Measuring ……………………………………………………………………………………………… 13

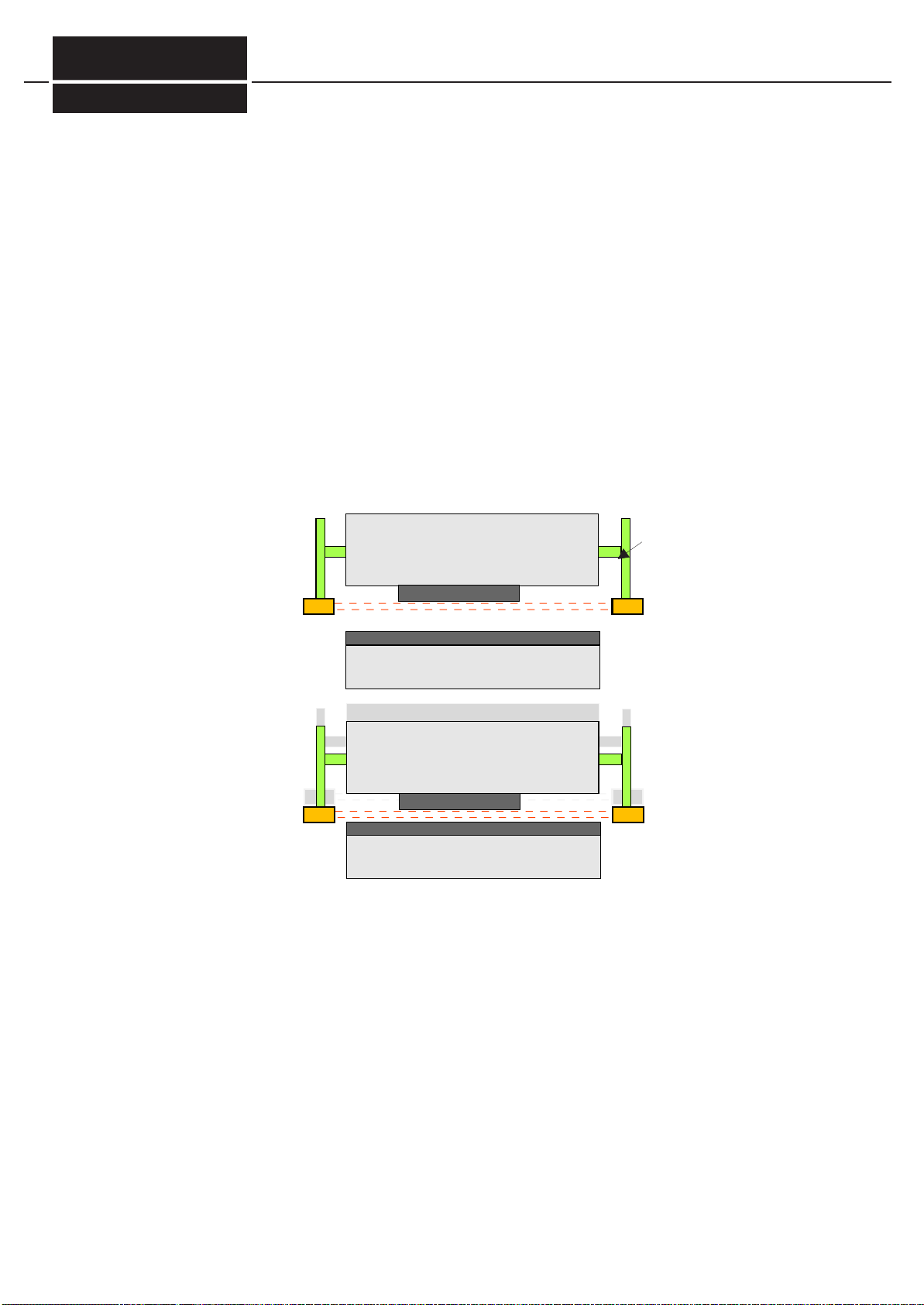

5.3 2. Design of a Mechanical Suspension Device - void if Fiessler Suspension Devices are used ……………………… 14

5.4 3. Mounting of the suspension devices at the ram ………………………………………………………………………… 14

5.5 4. Mounting of the AKAS® components at the suspension devices…………………………………………………… 15

5.6 5. Connection the AKAS® - wiring diagrams: see chapter 6 …………………………………………………………… 15

5.7 6. Adjustment of the AKAS® during first installationn …………………………………………………………………… 16

5.8 7. Adjustment of the distance of the AKAS® from the bending punch ………………………………………………… 20

5.9 8. Function Verification of all electrical connections in view of the safety classs 4 requirements………………… 21

5.10 9. Self-Acting Overrrun Traverse Test ………………………………………………………………………………………… 21

6Electrical connections -Descriptions / wiring diagrams ………………………………………………………… 22

6.1 Electrical Data ……………………………………………………………………………………………………………………………… 22

6.2 Instructions for Integrating the AKAS® inti the machine control system ……………………………………………………………… 23

6.4 AKAS®-LC II M …………………………………………………………………………………………………………………………… 24

Functions / Terminals …………………………………………………………………………………………………………………… 24

Connection ………………………………………………………………………………………………………………………………… 25

6.5 AKAS®-LC II F …………………………………………………………………………………………………………………………… 26

Functions / Terminals …………………………………………………………………………………………………………………… 26

Connection example: safety monitoring of the machine by AKAS®-...F ……………………………………………………… 28

6.5.1 AKAS®-...F selectable Safety functions …………………………………………………………………………………………… 29

1. Operation with additional safety control ………………………………………………………………………………………… 29

2. Monitoring of the Foot Pedal ………………………………………………………………………………………………………… 29

Connection: 2 Foot Pedals for 2 Operators …………………………………………………………………………………… 29

3. Easy-braking if the Foot Pedal is released (Delayed Foot Pedal Reaction) …………………………………………………… 29

4. Overrun Traverse Control ……………………………………………………………………………………………………………… 29

5. Monitoring of the Stop Valves (EDM) ………………………………………………………………………………………………… 30

6. Monitoring of the door- and the Emergency OFF-circuits, Emergency-OFF of the Motor-driven rear stoppers …………………30

Connection: Reset Button wiring for the rear protective grid if operated without EDM …………………………………… 30

Connection: Safety light Grid ( equivalent switching) as rear guard ………………………………………………………… 31

Connection: Safety light Grid ( antivalent switching) as rear guard ………………………………………………………… 31

7. Installation operation / protection by monitored slow speed wiithout activated protective field ……………………………………… 32

Connection: when equivalent switching door contacts are used …………………………………………………………… 32

Connection: when antivalent switching door contacts are used ……………………………………………………………… 32

8. Information about the traverse in slow speed -Connection of traverse measuriung device …………………………………… 33

9.Enhancement of Switching-over tolerances of the valve position monitors …………………………………………………… 33

6.5.2 Programming of the safety functions by Hex switches ……………………………………………………………………………… 34

6.6 Displaying outputs, Indicator-LEDs……………………………………………………………………………………………………… 36

-Muting lamp , adjustment control LEDs,Indicator-LEDs ……………………………………………………………………… 36

-Outputs via serial RS232-interface ……………………………………………………………………………………………… 37

7 Service / Maintenance / Warranty ……………………………………………………………………………………… 40

8 Order Codes ……………………………………………………………………………………………………………… 41

9 AKAS®-Inspection sheet………………………………………………………………………………………………… 42

10 Declaration of Conformity...…………………………………………………………………………………………… 43

11 Terms..................................................................................................................................................... 44

Doku Nr. 995 Stand 1.12.2011 / Aui

FIESSLER

E L E K T R O N I K