Table of contents

1. Manual r1. Manual reevision novision notteses.................................................................................................................................................................................................................................... 55

2. A2. Abbrbbreeviaviationstions ............................................................................................................................................................................................................................................................ 66

3. General3. General.............................................................................................................................................................................................................................................................................. 77

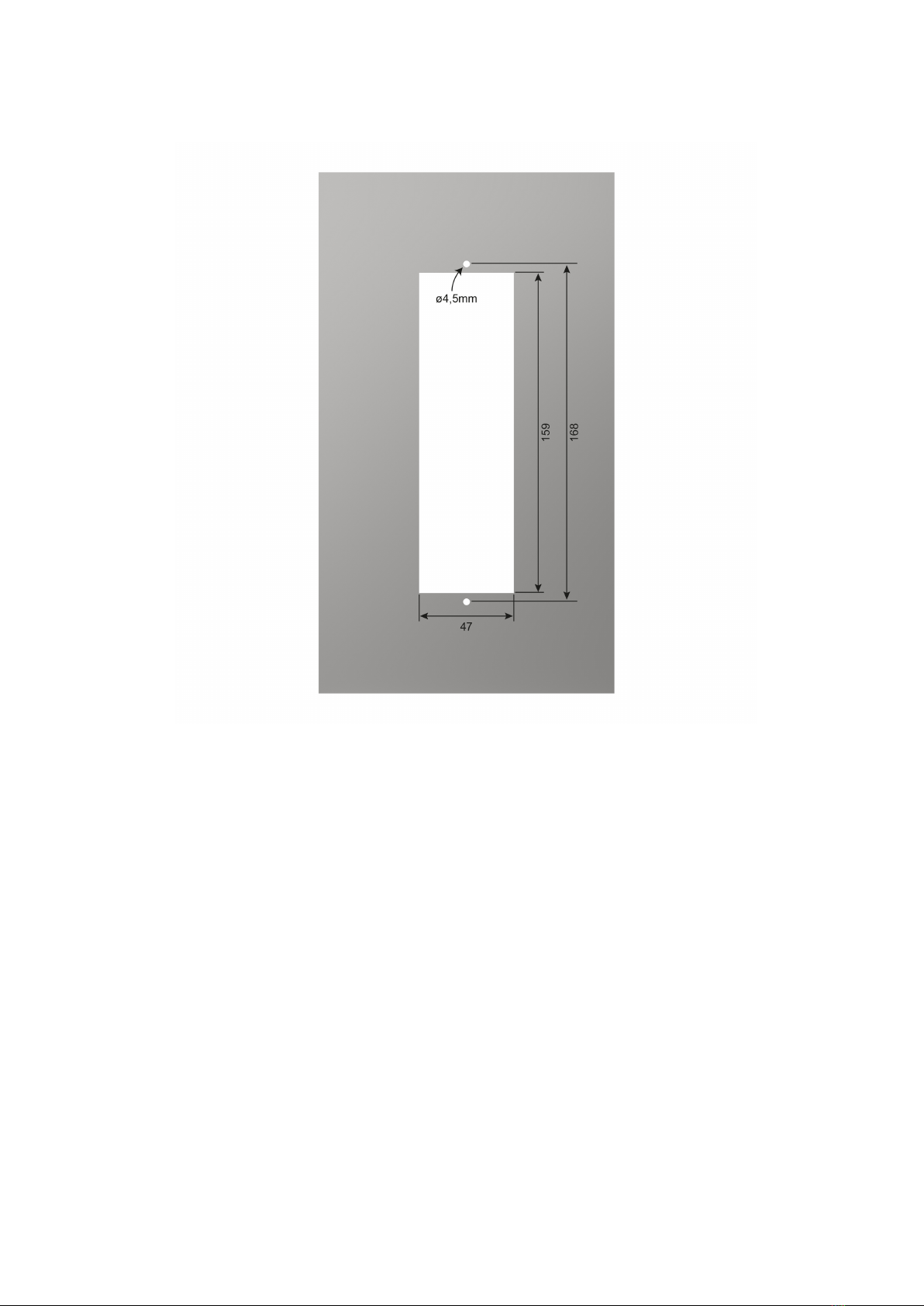

3.1. Dimensions and installation................................................................................................... 7

3.2. Wiring................................................................................................................................... 9

3.3. Unit features ....................................................................................................................... 10

3.4. SimpliZed block diagram ..................................................................................................... 11

4. Opera4. Operation and conZgtion and conZguraurationtion ............................................................................................................................................................................................................ 1313

4.1. LED indicator functions....................................................................................................... 13

4.2. LED operations guide ......................................................................................................... 13

4.3. Push-button (SET) .............................................................................................................. 14

4.3.1. System setup (auto-conZguration) ............................................................................ 14

4.3.2. Reset........................................................................................................................ 14

4.3.3. Input connection check ............................................................................................ 15

4.4. DIP switch settings ............................................................................................................. 15

4.4.1. Scheme selection ..................................................................................................... 16

4.4.2. Available logic schemes............................................................................................ 16

4.5. Non-volatile memory........................................................................................................... 18

5. Ar5. Arc sensorsc sensors.............................................................................................................................................................................................................................................................. 1919

5.1. Arc light Zber optic loop sensor AQ-06 ............................................................................... 19

5.2. Arc light Zber optic loop sensor AQ-07 ............................................................................... 19

5.3. Arc light Zber optic loop sensor AQ-08 ............................................................................... 20

5.4. Sensor—unit dependencies ................................................................................................ 21

5.5. Connecting sensors............................................................................................................ 21

6. S6. Syyststem self-superem self-supervisionvision.......................................................................................................................................................................................................................... 2222

7. Connections7. Connections............................................................................................................................................................................................................................................................ 2323

7.1. Outputs .............................................................................................................................. 26

7.1.1. Trip relays................................................................................................................. 26

7.1.2. inary outputs .......................................................................................................... 26

7.1.3. System failure relay................................................................................................... 27

7.2. Inputs ................................................................................................................................. 27

7.2.1. Arc sensor channels................................................................................................. 27

7.2.2. inary inputs ............................................................................................................ 27

7.3. Auxiliary voltage.................................................................................................................. 27

8. T8. Testingesting ............................................................................................................................................................................................................................................................................ 2828

8.1. Testing the light-only mode ................................................................................................. 28

8.2. Testing the light and current mode ...................................................................................... 28

8.3. Testing the C FP function................................................................................................... 29

8.4. Testing the unit operation time ............................................................................................ 29

8.5. Test plan example ............................................................................................................... 29

9. T9. Trroubleshoooubleshootingting.................................................................................................................................................................................................................................................. 3131

10. T10. Technicechnical daal datata.................................................................................................................................................................................................................................................. 3232

10.1. Protection......................................................................................................................... 32

10.2. Outputs ............................................................................................................................ 32

10.2.1. Trip relays............................................................................................................... 32

10.2.2. inary output(s) ...................................................................................................... 32

10.2.3. System failure relay................................................................................................. 32

10.3. inary inputs..................................................................................................................... 32

10.4. Auxiliary voltage................................................................................................................ 33

10.5. Sensors ............................................................................................................................ 33

10.6. Disturbance tests.............................................................................................................. 34

10.7. Voltage tests..................................................................................................................... 34

10.8. Mechanical tests............................................................................................................... 34

10.9. Environmental conditions .................................................................................................. 34

10.10. Casing and packaging .................................................................................................... 34

AAQQ-102L-102LVV

Version: 1.00

1 © Arcteq Relays Ltd