Figaro TGS2611 Supplement

Revised 08/03 1

APPLICATION NOTES FOR TGS2611

Application Notes for Methane Gas Detectors using TGS2611

The TGS2611 methane gas sensor

has been presorted into

groupings which will allow users

to simplify the manufacturing

process for methane gas

detectors. This brochure offers

example application circuits and

important technical advice for

designing and manufacturing gas

detectors which use classified

TGS2611 sensors.

Page

Introduction......................................................................................................2

Detector Circuit Design

BasicCircuitwithTemperatureCompensation............................................2

SelectingaLoadResistor.................................................................................2

CompensationforInternallyGeneratedHeat..............................................3

Heater Breakage Detection Circuit.........................................................3

SensorMalfunction DetectionCircuit.........................................................3

PreventionofIntermittentAlarming..............................................................4

AlarmPreventionduringWarmup................................................................4

Alarm Delay Circuit..........................................................................5

Application Circuit...................................................................................5

Manufacturing Process

Handling and Storage of Sensors..........................................................5

RLSelection...............................................................................................5

PCB Assembly....................................................................................5

Sensor Assembly..................................................................................5

FinalAssembly.................................................................................................6

Preheating of Final Assembly.....................................................................6

Gas Test..............................................................................................6

StorageofFinishedProducts..........................................................................6

AnticipatedPerformanceat10%LELofMethane...........................................................6

Pre-calibratedSensorModule...........................................................................................7

Appendix...............................................................................................................8

See also Technical Brochure ‘Technical Information on Usage of TGS

Sensors for Toxic and Explosive Gas Leak Detectors’.

an ISO9001 company

IMPORTANT NOTE: OPERATING CONDITIONS IN WHICH FIGARO SENSORS ARE USED

WILL VARY WITH EACH CUSTOMER’S SPECIFIC APPLICATIONS. FIGARO STRONGLY

RECOMMENDS CONSULTING OUR TECHNICAL STAFF BEFORE DEPLOYING FIGARO

SENSORS IN YOURAPPLICATION AND, IN PARTICULAR, WHEN CUSTOMER’S TARGET

GASES ARE NOT LISTED HEREIN. FIGARO CANNOT ASSUME ANY RESPONSIBILITY

FOR ANY USE OF ITS SENSORS IN A PRODUCT OR APPLICATION FOR WHICH SENSOR

HAS NOT BEEN SPECIFICALLY TESTED BY FIGARO.

TGS2611-J00 is a UL recognized component in accordance with the

requirements of UL2075. Please note that component recognition testing

has confirmed long term stability in 60ppm of methane; other characteristics

shown in this brochure have not been confirmed by UL as part of component

recognition.

Revised 08/03 2

APPLICATION NOTES FOR TGS2611

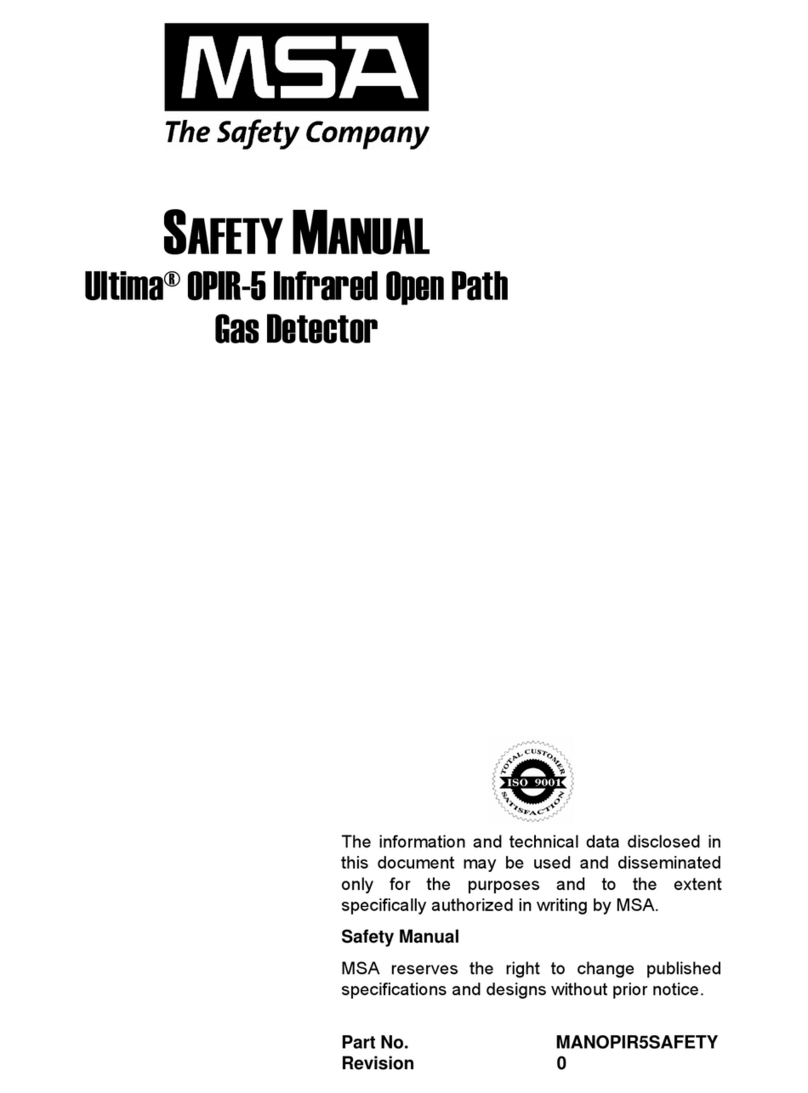

To facilitate ease in manufacturing gas detectors,

both Figaro TGS2611-J00 and TGS2611-B00

methane gas sensors are individually marked with

an ID number (see Figure 1) indicating a factory

presorted classification which corresponds to

narrow ranges of sensor resistance in methane.

When the sensor’s ID number is properly used,

the calibration process can be greatly simplified,

eliminating long preconditioning time and the

complicated handling of calibration gas.

1. Detector Circuit Design

1-1 Basic circuit with temperature compensation

Figure 2 shows an example of a basic circuit for

gas detection, including temperature compen-

sation for variations caused by ambient

temperature fluctuations. Typical values for the

circuit components are as follows:

RL: refer to Table 1

RTH : 4.7k

Ω

(

±

3%), B=3977 (

±

5%)

RA: 11.5k

Ω

(

±

1%)

RB: 4.32k

Ω

(

±

1%)

RC: 8.25k

Ω

(

±

1%)

The values for components related to

temperature compensation should be chosen so

that Vref is one-half of the Vc value at standard

temperature (20˚C). The Vref curve should

approximate the temperature dependency curve

of the VRL when compensation is properly done.

1-2 Selecting a load resistor (RL)

To optimize resolution of the output signal at

the desired alarming concentration, it is neces-

sary to adjust the resistance of the load resistor

(RL). It is recommended that RLbe selected at a

value which is equal to the sensor’s resistance

(Rs) at the alarming concentration (i.e. Rs/RL=

1.0). Please refer to the brochure “General

Information for TGS Sensors” for more details.

Since the ID number corresponding to sensor

resistance in methane gas is indicated on the

sensor cap, the load resistor value can be selected

according to Table 1. For example, for an alarm

setting at 10% LEL, when using a sensor having

an ID number of 7, the RLvalue should be set at

1.27kΩ. By using the recommended RL, the VRL

value at the alarming point typically will be 2.5V,

which is equal to half of the circuit voltage (Vc).

Fig. 1 - Sensor markings

Fig. 2 - Basic circuit with

temperature compensation

78M05

R

L

R

A

Alarm signal

(Active = 'L')

D.C. input +

-

V

REF

Vc = 5.0 ±0.2V

V

RL

R

B

R

C

R

TH

Comparator

GND

4

1

3

2

Voltage

regulator

TGS

2611

Table 1 - Recommended RLby sensor ID

Note: Lower explosion limit (LEL) of methane = 50,000ppm

rosneS #DI R

L

k( Ωhtiw) ±ecnarelot%1

LEL%5 LEL%01 LEL%51 LEL%02

10679.0517.0095.0115.0

2070.1787.0946.0265.0

3081.1668.0517.0916.0

4003.1359.0787.0186.0

5034.150.1668.0057.0

6085.151.1359.0528.0

7047.172.150.1909.0

8019.104.151.100.1

9001.245.172.101.1

0123.296.104.112.1

1155.278.145.133.1

2108.250.296.174.1

3190.362.278.126.1

4104.394.250.287.1

5147.347.262.269.1

6121.410.394.251.2

7135.423.347.273.2

8199.456.310.316.2

9194.520.423.378.2

0240.624.456.361.3

1256.678.420.484.3

2223.763.524.438.3

3260.809.578.422.4

4278.894.663.546.4

Sensor

code

Lot #

ID #

TGS2611

984AA #07

TGS2611

314AE #07

TGS2611-J00 TGS2611-B00

Revised 08/03 3

APPLICATION NOTES FOR TGS2611

Table 2 - Effect on selection of Rc by temperature

differential inside and outside of detector

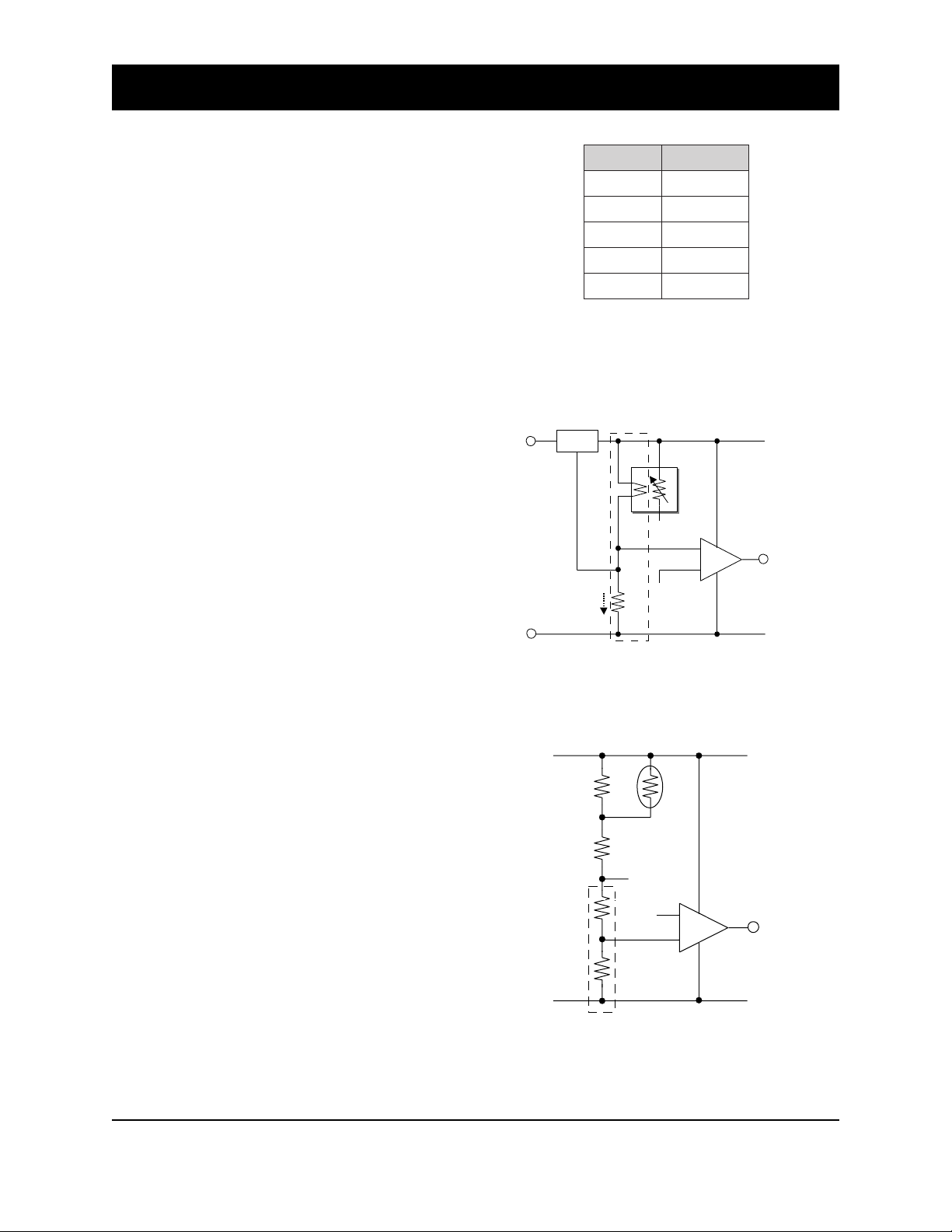

1-3 Compensation for internally generated heat

Depending on the design of the case and the

PCB, there is often a difference between the

temperature near the thermistor’s placement in

the detector and the ambient temperature.

Therefore it is recommended to measure the

actual temperature difference between the inside

and the outside of the detector and select the

value of RCaccording to Table 2. When RCis

selected in this manner and used in the basic

circuit (Figure 2), the result would be that

Vref=1/2 Vc.

1-4 Heater breakage detection circuit

Figure 3 shows an example of how breakage of

the sensor’s heater wire and/or heater element

can be detected. By adding RE(3.57Ω±1%) into

the circuit and monitoring VRE, a malfunction

can be considered to have occurred when VRE

(0.2V typ.) drops to near 0V. Please note that a

circuit voltage (Vc) of 5.2V should be applied to

a circuit which incorporates a heater malfunction

detection circuit.

1-5 Sensor malfunction detection circuit

Breakage of lead wires to the sensor’s electrodes

and/or sensor element can be detected by using

a circuit such as that shown in Figure 4. This

involves replacing RCwith RC1 and RC2, selecting

their values so that RC1/RC2≈35. Since VRL is

normally greater than 70mV in any atmospheric

conditions, by comparing VRL to a reference

voltage of 70mV, breakage of the lead wires and/

or sensor element can be considered to have

occurred if VRL drops below 70mV.

Figure 3 - Heater breakage detection circuit

(RE= 3.57Ω±1%)

78M05

+

-

Vc=5.2V

R

E

GND

0.2V

(

t

y

p.

)

56mA (typ.)

0.05~0.1V

Heater breakage

signal

(Active = 'L')

R

A

+

-

V

REF

V

RL

R

B

R

C1

R

TH

GND

R

C2

V

C

Sensor breakage

signal

(Active = 'L')

70mV (typ.)

Figure 4 - Sensor malfunction detection circuit

(RC1/RC2 ≈35)

∆∆

∆

∆∆ )C˚(T k(cR Ω)

052.8

586.7

0151.7

5156.6

0243.6

∆

T= (temp near themistor)-(temp outside detector)

Revised 08/03 4

APPLICATION NOTES FOR TGS2611

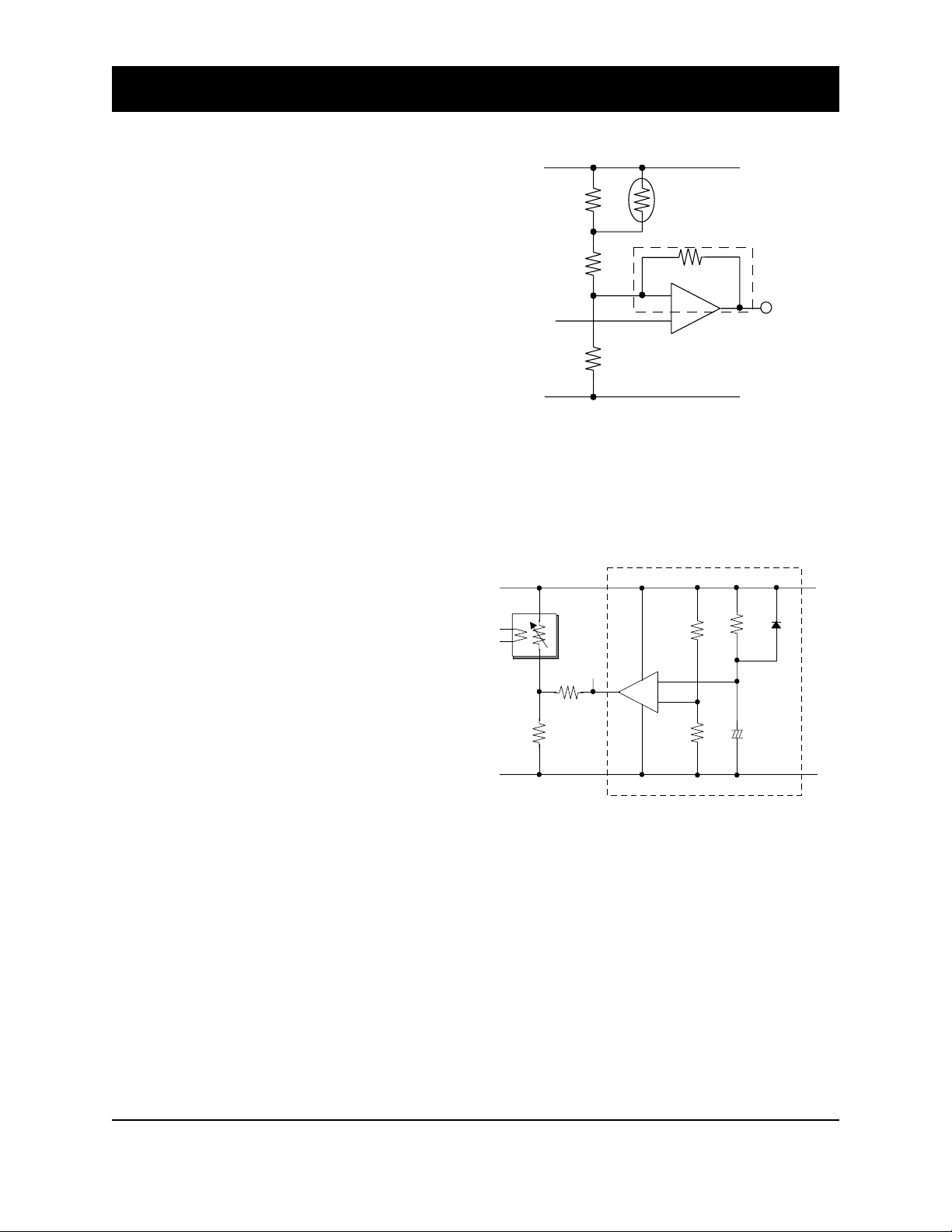

Figure 5 - Circuit for prevention of intermittent alarming

(RD/RC= 20~30)

Figure 6 - Circuit for alarm prevention during warmup

(RF> 5kΩ)

1-6 Prevention of intermittent alarming

When gas concentration fluctuates right at the

alarming threshold, dropping just below and

rising just above, the detector would

intermittently alarm in short bursts. In order to

prevent the nuisance of intermittent alarming,

a circuit such as that shown in Figure 5 can be

used. By adding RDto the original circuit, a

Schmidt trigger circuit which includes a

comparator can be created (the value of RD

should be set at 20-30 times that of Rc). As a

result, a range for the alarming threshold is

created. An alarm is then generated when the

upper range of the threshold is breached and

the alarm signal would cease after the signal

drops below the lower end of the threshold

range, thus eliminating frequent intermittent

alarming.

1-7 Alarm prevention during warm-up

As described in Sec. 2-6 of “Technical Information

for TGS2611”, when energizing the sensor after

an unpowered period, the sensor’s resistance

(Rs) drops sharply for the first few seconds after

energizing, regardless of the presence of gases,

before recovering to a stable level. This ‘initial

action’ may cause activation of an alarm during

the first few moments of energizing since VRL

would exceed Vref. To prevent this from

happening, a circuit modification such as that

shown in Figure 6 may be used. After powering

the detector, sensor output (VRL) should be set

to zero for a pre-determined period (2.5 minutes

is recommended--the timer function should be

created by selecting the proper combination of

C3and R11). In order to restrict current to the

sensor during this period, the recommended

value of RFshould exceed 5kΩ.

+

-

V

REF

V

RL

R

D

R

C

GND

V

C

R

A

R

B

Alarm signal

(Active = 'L')

R

TH

R

L

+

-

V

C

V

RL

GND

+

R

F

2.5 min. time delay circuit

R

10

C

3

R

9

R

11

D

5

Revised 08/03 5

APPLICATION NOTES FOR TGS2611

Figure 8 - Manufacturing process flowchart

1-8 Alarm delay circuit

To prevent false alarms caused by transient

interference gases such as alcohol in cooking

vapors, a delay circuit modification such as that

shown in Figure 7 can be used. The alarm signal

generated by this circuit should be connected to

the comparator in the basic circuit (see Figure

1). The recommended timer period for alarm

delay is 15 seconds--the timer function should

be created by selecting the proper combination

of C4and R15.

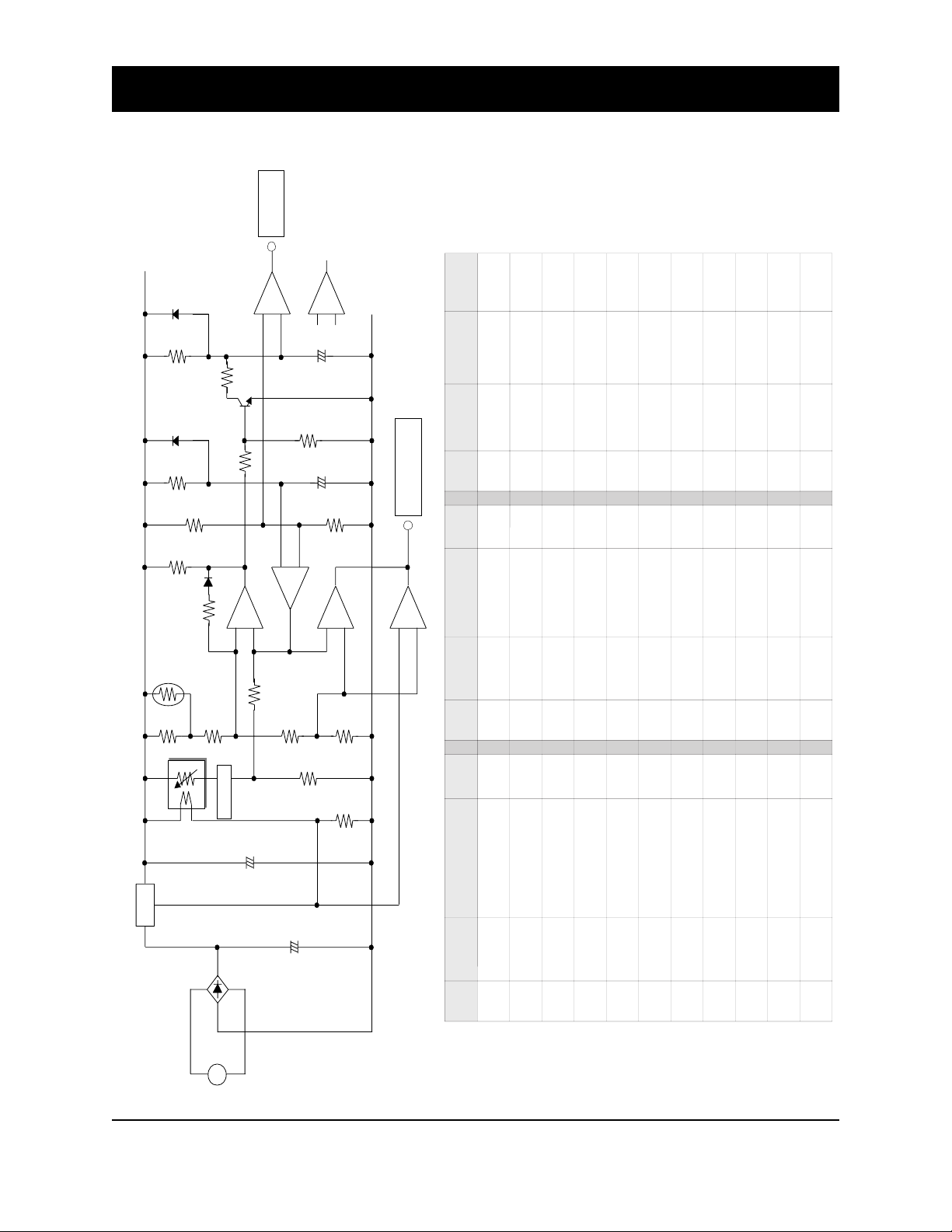

1-9 Application circuit

An application circuit which incorporates all of

the advice included in Secs. 1-1 through 1-8 can

be seen in Appendix 1.

2. Manufacturing Process (see Fig. 8)

2-1 Handling and storage of sensors

Prior to usage, sensors should be stored at room

temperature in a sealed bag containing normal

clean air. During manufacturing, sensors should

be handled in a clean air environment and at

room temperature. Clean air refers to air free of

contaminants, excessive dust, solvent vapors,

etc. Room temperature should be 20~25˚C.

2-2 RLselection

Choose the proper resistor for RLby referring to

the ID number of the sensor and Table 1.

2-3 PCB assembly

Flux should be sufficiently dried before sensors

are assembled onto the PCB to avoid any

contamination of the sensor by flux vapors.

2-4 Sensor assembly

Manual soldering of the sensor to the PCB is

strongly advised. Solders composed of

Sn63:Pb37 or Sn60:Pb40 with non-chloric resin

flux (MIL: RMA Grade; for example, Almit KR-

19) are recommended for usage.

2-5 Final assembly

Avoid any shock or vibration which may be

caused by air driven tools. This may cause

breakage of the sensor’s lead wires or other

physical damage to the sensor.

Figure 7 - Alarm delay circuit

+

-

V

C

GND

+

Alarm signal

(Active = 'L')

15 sec. time delay circuit

Delayed alarm

signal

(Active = 'L')

R

8

R

12

R

13

Tr

C

4

R

10

R

9

R

15

D

6

IC

3

R

14

OK

Acceptance of

classified sensor

*3

(PCB, casing etc.)

(≥48hours)

NG

OK

NG

PCB Assembly Repair

PCB Test

Sensor and RLAssembly

Final Assembly

Preheating

Packing

Storage

Shipping

Acceptance of components

Quality control sampling

*Alarm concentration

*Long term stability

RL selection

(manual soldering)

Investigation

Gas Test

Revised 08/03 6

APPLICATION NOTES FOR TGS2611

2-6 Preheating of final assembly

To stabilize the detector assembly before gas

testing, the minimum period for preheating final

assemblies should be 48 hours at room

temperature (20~25˚C). Be certain to maintain

clean atmospheric conditions for preheating.

2-7 Gas test

Test all finished products in the target gas under

normal operating conditions. Keep the

atmospheric conditions in the chamber stable,

utilizing a user-defined standard test condition

which is based on applicable performance

standards and on anticipated usage for

detectors. Remove any traces of smoke,

adhesives, gases, or solvents from the chamber.

NOTE: Without testing after final assembly,

detectors have no guarantee of accuracy or

reliability.

2-8 Storage of finished products

Detectors should be stored in a clean air environ-

ment at room temperature. Avoid storage in

dirty or contaminated environments. Cautions

listed in Sec. 6-1.3 of “General Information for

TGS Sensors” should also be observed.

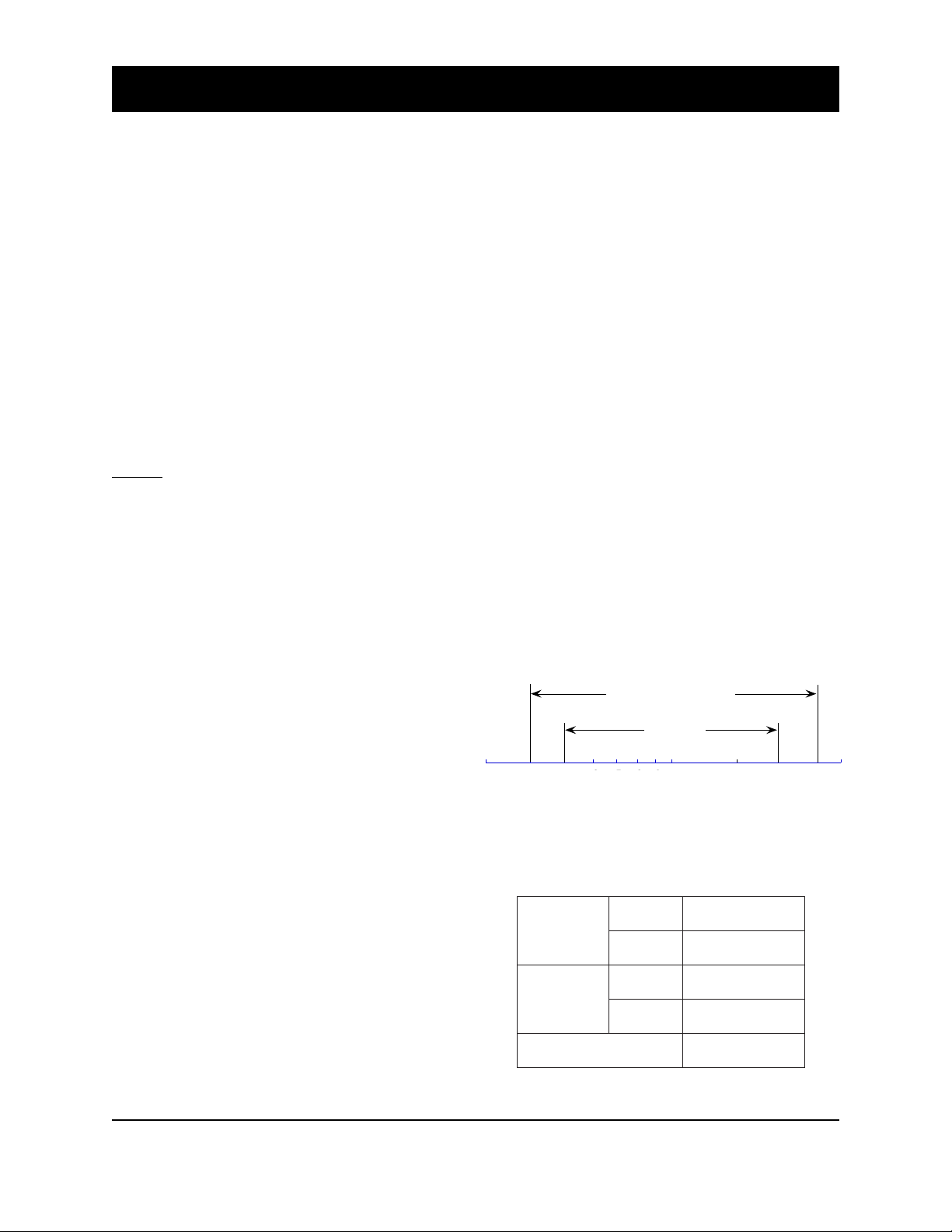

3. Anticipated Performance at 10%LEL of

Methane

When using the classified TGS2611 with Figaro’s

recommended RLfor 10%LEL (Table 1) and

temperature compensated circuit design (Figure

2), typical alarm tolerances for 10%LEL of

methane such as those shown in Figure 9 are

expected. Each RLclassification contains a range

of tolerance as exemplified by the alarming

range labelled as ‘standard conditions’ (i.e. these

conditions are well-controlled). When factoring

in the additional effects of environmental

extremes and the allowable variation in circuit

conditions, the resulting alarming range would

be typified by the range labelled as ‘operating

conditions’. However, in actual usage, alarm

thresholds may vary since the threshold is also

affected by factors such as the tolerances of the

thermistor and/or other components, load

resistor value, test conditions, and heat

generation inside the detector enclosure. As a

Figure 9 - Expected performance of methane detectors

with classified TGS2611 & recommended RLfor 10% LEL

(refer to Table 3 for test conditions)

dnaerutarepmeT ytidimuh

dradnatS snoitidnoc 02 ±56,C˚2 ±HR%5

gnitarepO snoitidnoc HR%59~03,C˚04~01-

tiucriC noitidnoc

dradnatS snoitidnoc 0.5=cV ±CDV10.0

0.5=HV ±CDV50.0

gnitarepO snoitidnoc 0.5=cV ±CDV2.0

0.5=HV ±CDV2.0

roirpgninoitidnoC tsetot ≥sruoh84

Table 3 - Test conditions for measuring

performance of methane detectors as shown in Figure 9

345678910 2015 30

under std

test conditions

under operating conditions

at recommended circuit condition

Alarming point (%LEL)

25

Revised 08/03 7

APPLICATION NOTES FOR TGS2611

Figure 10 - Pre-calibrated sensor module NGM2611

result, Figaro neither expressly nor impliedly

warrants the performance shown in Figure 9. If

a large difference between the expected and

actual performance of detectors is noticed, please

consult with Figaro.

Pre-calibrated sensor module

Figaro has available a pre-calibrated methane

sensor module NGM2611 (see Fig. 10). This

module includes the classified TGS2611 sensor,

a matched load resistor, and a factory preset

temperature compensation circuit, all on a small

PC board. The NGM2611 module is calibrated

for a typical set point at 10% LEL, achieving

performance as indicated in Figure 9 by simply

plugging it into a main PC board. Please refer

to the brochure “Product Information for

NGM2611” for detailed information.

Important Reminder

Without testing alarm threshold after final assembly,

detectors have no accuracy or reliability guarantee.

FIGARO GROUP

HEAD OFFICE

Figaro Engineering Inc.

1-5-11 Senba-nishi

Mino, Osaka 562-8505 JAPAN

Tel.: (81) 72-728-2561

Fax: (81) 72-728-0467

email: [email protected]

OVERSEAS

Figaro USA Inc.

3703 West Lake Ave. Suite 203

Glenview, IL 60025-1266 USA

Tel.: (1) 847-832-1701

Fax.: (1) 847-832-1705

email: figarousa@figarosensor.com

Figaro USA Inc. and the manufacturer, Figaro

Engineering Inc. (together referred to as Figaro)

reserve the right to make changes without notice to

any products herein to improve reliability,

functioning or design. Information contained in this

document is believed to be reliable. However, Figaro

does not assume any liability arising out of the

application or use of any product or circuit described

herein; neither does it convey any license under its

patent rights, nor the rights of others.

Figaro's products are not authorized for use as critical

components in life support applications wherein a

failure or malfunction of the products may result in

injury or threat to life.

Revised 08/03 8

APPLICATION NOTES FOR TGS2611

IC

1

R

L

R

1

SENSOR

Alarm signal

(Active "L")

Power Supply

(AC10V / 80mA)

+

+

-

-

+

-

+

C

3

D

6

Tr

IC

2

1/4

2/4

1/2

+

-

3/4

+

-

4/4

Malfunction signal

(Active "L")

+

+

+

R

2

R

3

R

9

R

5

R

6

R

8

R

7

R

4

R

10

R

11

R

12

R

15

R

TH

D

7

C

4

C

2

C

1

IC

3

+

-

2/2

~

D

1~4

R

13

R

14

1

4

3

2

(Note: "L" output also occurs during initial delay)

Initial delay: approx. 2.5 minutes

Alarm delay: approx. 15 seconds

D

5

traP .oN emantraP /.oNledoM noitacificepS rekaM traP .oN emantraP /.oNledoM noitacificepS rekaM traP .oN emantraP /.oNledoM noitacificepS rekaM

rosneSrosnessaG1162SGToragiF

R

9

rotsiseRk01ΩW8/1%5, D

1

noitacifitceR

edoid G6655SabihsoT

R

HT

CTN

rotsimrehtk7.4Ω7793=B,spillihP

R

01

rotsiseRk01ΩW8/1%5, D

2

noitacifitceR

edoid G6655SabihsoT

R

L

rotsiseRW8/1,%1,)1elbaTeeS( R

11

rotsiseRk074ΩW8/1%5, D

3

noitacifitceR

edoid G6655SabihsoT

R

1

rotsiseR75.3ΩW2/1,%1, R

21

rotsiseRk01ΩW8/1%5, D

4

noitacifitceR

edoid G6655SabihsoT

R

2

rotsiseRk5.11ΩW8/1,%1, R

31

rotsiseRk01ΩW8/1%5, D

5

langisllamS

edoid 8851S1abihsoT

R

3

rotsiseRk23.4ΩW8/1,%1, R

41

rotsiseRk1ΩW8/1%5, D

6

langisllamS

edoid 8851S1abihsoT

R

4

rotsiseRk78.7ΩW8/1%1, R

51

rotsiseRk074ΩW8/1%5, D

7

langisllamS

edoid 8851S1abihsoT

R

5

rotsiseR622ΩW8/1%1, C

1

citylortcelE

roticapac074µV52/F rT

NPN

rotsisnart 3062CS2ihsibustiM

R

6

rotsiseRk01ΩW8/1%5, C

2

citylortcelE

roticapac

01µV01/F CI

1

egatloV

rotaluger TC50M87CMalorotoM

R

7

rotsiseRk002ΩW8/1%5, C

3

citylortcelE

roticapac

074µ%01,V01/F CI

2

rotarapmoC933MLalorotoM

R

8

rotsiseRk01ΩW8/1%5, C

4

citylortcelE

roticapac

74µ%01,V01/F CI

3

rotarapmoC393MLalorotoM

Appendix 1 - Example application circuit for gas detector using classified TGS2611

Table of contents

Other Figaro Gas Detector manuals