SENKO SI-300 User manual

Explosion-proof pump type gas detector

(SI-300) OPERATING MANUAL

<< SI-300 Manual

`

1

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

WARNING

Please be fully aware of the manual before using the device. This device must be used and repaired in accordance

with the instructions, and failure to follow the instructions can cause device failure or risk user injury or life.

Warning

➢Please remove any debris on the surfaces of the sensor before use.

➢Please test the alarm to see if it's working regularly.

➢Use within the range of temperature, humidity, and pressure that meet the product specifications. Out of this

range, it may cause malfunction or failure of the device. The sensors inside the device may indicate the gas

concentration differently according to the environment such as temperature, pressure, and humidity. Please

make sure to calibrate the detector under the same or similar environment to the specification.

➢Extreme changes in temperature may cause drastic changes of the gas concentration. (e.g. using the detector

where there is a huge gap between the inside and outside temperature) Please use the device when the

concentration becomes stable.

➢The alarms are set according to the international standard and must be changed by an authorized expert.

➢The FLOW LIMITED DEVICE must be connected, and the material should not include a polymer or an elastic

material.

Caution

➢Use the device after reading this manual thoroughly.

➢This product is not a gas measuring meter. It's a gas detector.

➢Please stop using and consult the manufacturer if the calibration fails continuously.

Warranty

We, SENKO CO., LTD warrant replacement or repair for the products of SI series for 24 months from the shipment date of the

product(s). However, the parts, whose life can be shortened by use, such as sensors, batteries and lamps are not under the

warranty. Also, Free repair and replacement is not available in case of purchases of our products through unauthorized channels,

mechanical damage, and deformation by user’s misuse, and calibration and replacements of parts without following the

instruction in the manual. If any defect or quality problem occurs to the products during the warranty period, the user should

notify it to the manufacturer. In this case, all the expenses except freight cost are paid by SENKO. Repair, replacement and freight

cost for the products, whose warranty is already over, are paid by the user. SENKO CO., LTD does not have any responsibility for

indirect, or accidental loss which occurs while using our products, and the warranty is limited to the exchange of parts and

products. The warranty is subject to the users who have bought products from the authorized agency and office appointed by

SENKO CO., LTD, and warranty repairs must be made through the designated A/S center of SENKO CO., LTD with a skilled

technician.

<< SI-300 Manual

`

2

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

Contents

1. Product Overview ........................................................................................................................... 4

1.1. Specification..................................................................................................................................................4

1.2. Sensor List .....................................................................................................................................................5

1.3. Outline.............................................................................................................................................................6

2. Appearance and Description........................................................................................................ 7

2.1. Component ...................................................................................................................................................7

2.2. Front Display Configuration...................................................................................................................9

3. How to install................................................................................................................................ 10

3.1. Power, RS485, 4-20 mA Terminal configuration .................................................................................10

3.1.1. DC Terminal ....................................................................................................................................... 10

3.1.2. RS485 Terminal................................................................................................................................. 11

3.1.3. 4-20mA Terminal............................................................................................................................. 11

3.1.4 PoE Ethernet Terminal.................................................................................................................... 11

3.2. Alarm Terminal configuration............................................................................................................11

3.3.1. Fault Relay Output Configuration............................................................................................ 11

3.3.2. Low Relay output configuration.............................................................................................122

3.3.3. High Relay output configuration............................................................................................122

3.3 Ground connection configuration ..................................................................................................122

4. Usage ............................................................................................................................................133

4.1. Power On..................................................................................................................................................133

4.2. Measuring Mode ...................................................................................................................................133

4.3. Internal settings......................................................................................................................................144

5. System Mode...............................................................................................................................155

5.1. Mode configuration .............................................................................................................................155

5.2. Menu configuration..............................................................................................................................155

5.3. Setting/Configuration Menu ............................................................................................................166

5.4. Setting/Measurement Menu ..............................................................................................................20

<< SI-300 Manual

`

3

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

5.5. Setting/Calibration Menu ..................................................................................................................221

5.6. Setting/Alarm Menu............................................................................................................................... 22

6. Problem Solving............................................................................................................................ 24

6.1. Error code ...................................................................................................................................................24

7. Interface Configuration ............................................................................................................... 25

7.1 RS485 Interface setting..........................................................................................................................25

7.2 TCP Interface setting ..............................................................................................................................25

7.3 MODBUS RS485/TCP Register............................................................................................................25

⚫3000X Register Read.......................................................................................................................... 25

⚫4000X Register Read.......................................................................................................................... 26

⚫4000X Register Write......................................................................................................................... 28

8. Appearance and Dimensions................................................................................................ 29

9. Installation precautions......................................................................................................... 30

9.1 Selection of installation location.......................................................................................................30

9.2 Selection of installation position.......................................................................................................30

9.3 A/S Contact Information.......................................................................................................................30

10. Revised History ....................................................................................................................... 31

<< SI-300 Manual

`

4

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

1. Product Overview

1.1. Specification

◼Explosion-Proof structure.

◼Cartridge type sensor –Easy maintenance

◼Built-in flow control function.

◼4-Digit Digital Concentration Indication and Digital Flow

Indication

◼4-20mA / RS-485 / Ethernet

Model

SI-300

Size

194mm(W) X 152.4mm(D) X 136mm(H)

Weight

2Kg

Operating voltage

DC : 24V ± 10%

PoE : 36V~57V (Typical : 48V)

Flow rate

100 ~ 1,000 ml (Normal 300 ~ 500ml / min)

Power consumption

Approximately 5.0W

Measurement display

FND, gas concentration, flow rate, alarm, device faulty

Relay

Low Alarm, High Alarm, Fault Alarm

Analog Output signal

4-20mA

Digital communication

RS-485, TCP Ethernet

Sampling distance

Length of input gas tube: up to 30m (FEP tube)

Length of exhaust gas tube: up to 30m (FEP tube)

Input/Output tube

1/4” Teflon tube

Operating temperature

-40°C ~ 55°C

Certification

KCs: Ex db IIC T6 Gb

IP

IP 65 (KS C IEC60529:2013)

Control/Set

4 Button & RS485 & Ethernet & Bluetooth

Warranty period of the

device

2 years

Warranty period of sensor

cartridge

1year

Remote interface

Ethernet , RS-485, HART(Option)

Wiring

4 to 20mA / DC power / Relay : up to 14 AWG

Pressure range

90 to 110KPa

Maximum sample flow

Max. 1,000 ml

Maximum sample pressure

6KPa

<< SI-300 Manual

`

5

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

1.2. Sensor List

Gas

Sensor

Range

A1

A2

Resolution

Oxygen

O2

Electrochemical

0~30%Vol

19.0%vol

23.0%vol

0.1%vol

Carbon Monoxide

CO

Electrochemical

0~500ppm

30ppm

60ppm

1ppm

Sulfur Dioxide

SO2

Electrochemical

0~20ppm

2ppm

5ppm

0.1ppm

Hydrogen

H2

Catalytic

0~100%LEL

15%LEL

50%LEL

1%LEL

Hydrogen

H2

Electrochemical

0~1000ppm

100ppm

500ppm

within 5ppm

Hydrogen Sulfide

H2S

Electrochemical

0~500ppm

10ppm

15ppm

1ppm

Combustible

-

Catalytic

0~100%LEL

15%LEL

50%LEL

1%LEL

Combustible

-

IR

0~100%LEL

15%LEL

50%LEL

1%LEL

Ammonia

NH3

Electrochemical

0~100ppm

25ppm

35ppm

1ppm

Acetylene

C2H2

Catalytic

0~100%LEL

15%LEL

50%LEL

1%LEL

Ethanol

C2H6O

Catalytic

0~100%LEL

15%LEL

50%LEL

1%LEL

Toluene

C7H8

IR

0~100%LEL

15%LEL

50%LEL

1%LEL

Toluene

C7H8

Catalytic

0~100%LEL

15%LEL

50%LEL

1%LEL

Methane

CH4

IR

0~100%LEL

15%LEL

50%LEL

1%LEL

Methane

CH4

Catalytic

0~100%LEL

15%LEL

50%LEL

1%LEL

Chlorine

Cl2

Electrochemical

0~5ppm

0.5ppm

1.0ppm

0.1ppm

Chlorine

Cl2

Electrochemical

0~20ppm

0.5ppm

1.0ppm

0.1ppm

Carbon Dioxide

CO2

IR

0~2000ppm

1000ppm

1500ppm

3ppm

Carbon Dioxide

CO2

IR

0~5000ppm

3000ppm

5000ppm

8ppm

Carbon Dioxide

CO2

IR

0~5%Vol

0.5%vol

3%vol

0.1%vol

Hydrogen Chloride

HCl

Electrochemical

0~10ppm

1ppm

2ppm

0.1ppm

VOC

VOC

PID

0~1000ppm

50ppm

100ppm

within 3ppm

Xylene

C8H10

IR

0~100%LEL

15%LEL

50%LEL

1%LEL

Hydrogen peroxide

H2O2

Electrochemical

0~10ppm

1ppm

2ppm

0.1ppm

Nitrogen Dioxide

NO2

Electrochemical

0~20ppm

3ppm

5ppm

0.1ppm

Ethylene oxide

C2H4O

Electrochemical

0~30ppm

1ppm

2ppm

0.1ppm

Ethylene

C2H4

Catalytic

0~100%LEL

15%LEL

50%LEL

1%LEL

Nitrogen Monoxide

NO

Electrochemical

0~100ppm

25ppm

50ppm

1ppm

Hydrogen fluoride

HF

Electrochemical

0~5ppm

0.5ppm

1ppm

0.1ppm

<< SI-300 Manual

`

6

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

1.3. Outline

<< SI-300 Manual

`

7

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

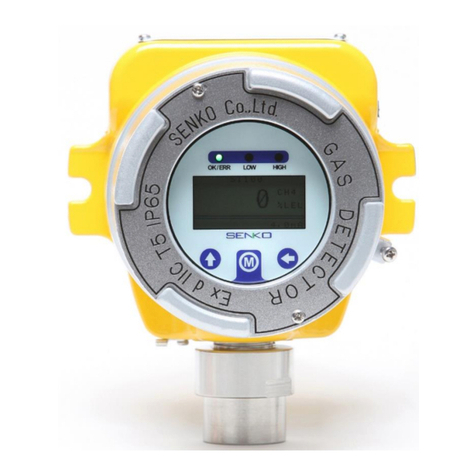

2. Appearance and Description

2.1. Component

<< SI-300 Manual

`

8

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

NO

NAME

DESCRIPTIONS

1

Case cover

It protects sensors and PCB boards built into the product from external

environmental changes and shocks.

2

Mount Holes

It is a Mounting Hole used to fix the product.

3

FND display

When setting the gas concentration value and parameter measured by the sensor,

the set mode is indicated by numbers and icons. (Refer to the "Front LED Display

Configuration" described in detail.)

4

Power LED

When the power supply DC 24V is normally supplied, the green LED is turned on.

5

Trouble LED

When sensors and flow rates are recognized as failures, the yellow LED is lit, and

when set, the Trouble Relay contact signal is output to the outside.

6

Alarm1 LED (Red)

When the measured gas concentration exceeds the Alarm1 setting, the LED is

turned on, and the Relay contact signal is output to the outside when setting.

(Alarm1 level setting can be arbitrarily set in Alarm setting mode.)

7

Alarm2 LED (Red)

When the measured gas concentration exceeds the Alarm2 setting, the LED is

turned on, and the Relay contact signal is output to the outside when setting.

(Alarm2 level setting can be arbitrarily set in Alarm setting mode.)

8

Menu key

Mode switching and setting key in function setting mode. If you press Menu for

more than 1 second in the measurement mode, it enters the function setting Menu.

(Configuration, Measurement, Calibration, Alarm, etc.)

9

Up key

It is a key that increases the setting value in the function setting mode.

10

Down key

It is a key that lowers the setting value in the function setting mode.

11

Select key

Select key is used when setting menu status in function setting mode. If you press

the Select key and Down key more than 3 sec at the same time in the measurement

mode, it enters the inspection mode, and the TEST LED flashes.

12

Window Glass

It is a tempered glass that allows you to see the display status that informs you of

the product status in Housing.

13

Cover fixed screw

It is a screw that fixes the main body case and the front cover case.

14

Gas inlet

Sample gas inlet port. (1/4” Tube)

15

Gas outlet

Sample gas output port. (1/4” Tube)

16

Cable gland

It's the entrance to the power and signal cable.

17

Breathing Device

Breather function of Flame arrester / Ex d IIC Air Breather (SAB)

Authentication number: 17-GA2BO-0697U

18

External earth

External earth to protect against external noise or ferroelectricity.

The earth wire is coupled and connected using a conductor of 4mm or more.

19

Internal earth

Internal earth to protect against external noise or ferroelectricity.

The earth wire is coupled and connected using a conductor of 4mm or more.

<< SI-300 Manual

`

9

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

2.2. Front Display Configuration

No

Name

Descriptions

1

Power LED(Green)

When the power (DC 24V) is supplied normally, the LED is lit..

2

Trouble LED

When self-diagnosis of Gas detector, display if fault is detected.

3

Alarm1 LED

Alarm1 is set or displayed when detected.

4

Alarm2 LED

Alarm2 is set or displayed when detected.

5

FND DISPLAY

When setting the gas concentration value and parameter by the sensor, the setting

mode is displayed as numbers and icons.

6

FLOW LED

Display the current flow rate in a graph bar.

7

CAL LED

Displayed during the calibration.

8

MAINT LED

Display when running Engineering mode.

9

COMM LED

Displayed during RS485/Ethernet communication.

10

TEST LED

Display when executing the test mode.

11

BT LED

Display when connecting to Bluetooth.

[Table 2. Description of Front LED Display Configuration]

<< SI-300 Manual

`

10

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

3. How to install

Installing a detector at a site, opening the cover of a detector, or operating it may cause fire or

explosion depending on the environment. Therefore, you should proceed with your work after turning

off the power and examining whether explosive residual gas is around you or not.

3.1. Power, RS485, 4-20 mA Terminal configuration

Loosen the case cover fixed screen on the side of the detector and separate the case

cover. Then Terminal appears.

3.1.1. DC Terminal

The DC terminal consists of a terminal for power supply of the detector.

Pin No.

Name

Description

1

GND

Ground

2

24V

Power

Shield cables above 1.5 sq should be used.

When the external power DC24V is used, connect to the "CON100" Terminal of the

terminal unit.

<< SI-300 Manual

`

11

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

3.1.2. RS485 Terminal

Connect the following MODBUS master terminals to RS-485A and RS-485B.

Pin No.

Name

Description

1

B

TR

XD-

’

or

‘

B

or

‘

N

’‘

2

A

TR

XD+

’

or

‘

A

or

‘

P

’

3.1.3. 4-20mA Terminal

The 4-20 mA terminal consists of terminals for 4-20 mA output.

Pin No.

Name

Description

1

GND

4~20mA Ground

2

OUTPUT

4~20mA Output Signal

3.1.4 PoE Ethernet Terminal

The PoE terminal connects the PSE and the detector through a LAN CABLE (CAT5

Cable or Equivalent RJ45).

Pin No.

Name

Description

CON400

RJ-45 JACK

PoE & Ethernet Connected

3.2. Alarm Terminal configuration

Connect the Alarm Relay connected to the terminal using the following configuration.

3.3.1. Fault Relay Output Configuration

Name

Fault Relay Contact

Jumper Setting

FAULT-OUT

Normal Close Mode

J7 Jumper NC on

Normal Open Mode

J7 Jumper NO on

FAULT-COM

Common

-

<< SI-300 Manual

`

12

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

3.3.2. Low Relay output configuration

Terminal

Fault Relay Contact

Jumper setup

AL1-OUT

Normal Close Mode

J6 Jumper NC on

Normal Open Mode

J6 Jumper NO on

AL1-COM

Common

-

3.3.3. High Relay output configuration

Terminal

Fault Relay Contact

Jumper setup

AL2-OUT

Normal Close Mode

J3 Jumper NC on

Normal Open Mode

J3 Jumper NO on

AL2-COM

Common

-

3.3 Ground connection configuration

⚫Internal grounding: You can ground the internal grounding through point 1 using the ring terminal.

⚫External grounding: Can ground the external grounding through point 2 using the ring terminal.

Internal

grounding

External

grounding

<< SI-300 Manual

`

13

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

4. Usage

4.1. Power On

Check the wiring and power voltage then turn on the power switch.

After the Power LED (Green) and Version information (ex V1.00) are displayed, it

followed to the Measuring mode.

It takes about 3 minutes to warm up. If the MENU key is pressed during the instrument warm

up operation, it immediately switches to the Measuring mode

.

4.2. Measuring Mode

Alarm LED

▶Power/Trouble/Alarm 1/Alarm2

Current gas concentration display

Gas concentration unit display

▶Changing a decimal point based on the range

Current Pump flow display

Pump flow

▶Current suction flow

Status LED

▶CAL: Calibration in progress

▶MAINT: Maintenance in progress

▶COMM: Communication status

▶TEST: Test in progress

▶BR: Bluetooth connection status

<< SI-300 Manual

`

14

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

Trouble(Fault) Status

▶Trouble LED lights up when a problem occurs

▶See Error Code 6.1.

4.3. Internal settings

▶In the measurement state, press the Menu Key

for more than 1 second to enter the password

request state.

1. [**] will be displayed at the PW state.

2. The initial value is [00] and can be changed from

[00] to [99] with the Up/Down Keys.

After entering the password, press the Select Key

to enter the internal setting.

1. In the internal setting mode, each setting can be

entered by using the Up/Down Keys.

2. CFG/MEAS/CAL/ALM are configurable.

<< SI-300 Manual

`

15

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

5. System Mode

5.1. Mode configuration

The device consists of the following menu configuration.

Division

Mark

Definition

Note

CONFIGURATION

CFG

Basic setting

MEASUREMENT

MEAS

Measurement setting

CALIBRATION

CAL

Calibration setting

ALARM

ALM

Alarm setting

TEST

TEST

Test

Engineering Mode

TIME

TIME

Time setting

Engineering Mode

FLOW

FLOW

Pump Flow setting

Engineering Mode

NETWORK

NET

Ethernet setting

Engineering Mode

ADJUST

ADJ

4-20mA output setting

Engineering Mode

FACTORY

FACT

Factory setting

Engineering Mode

[Table 4. Mode Configuration]

5.2. Menu configuration

The menu configuration of the equipment is as follows.

1 Depth

2 Depth

3 Depth

Default

CFG

(Configuration)

GAS

Gas sensor type

-

HART

HART Board availability

-

MODT

Modbus Type(RTU/TCP)

TCP

ADR(Address)

Modbus Address(0~64)

1

PWD(Password)

Password setting (00~99)

00

C-TM(Calibration Time)

Calibration cycle (1~12months)

12

HIDN(Hidden Area)

Hidden area (Full Range standard 0~20%)

03%

BRIT

FND Brightness

5

M1.00

Firmware version

-

S1.00

Sensor cartridge version

-

<< SI-300 Manual

`

16

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

1 Depth

2 Depth

3 Depth

Default

MEAS

(Measurement)

DECP (Decimal Point)

Decimal point (1000, 100.0, 10.00, 1.000)

100.0

F-RN (Full Range 1~9999)

Full measuring range (1~9999)

100

UNIT

Measuring unit (PPB, PPM, VOL%, %LEL)

PPM

1 Depth

2 Depth

3 Depth

Default

CAL

(Calibration)

ZERO (Zero Calibration)

Zero Calibration

Based on gas

S-CN (Span Concentration)

Span Gas Concentration setting

(1~9999)

Based on gas

SPAN (Span Calibration)

Span Calibration

Based on gas

1 Depth

2 Depth

3 Depth

Default

ALM

(Alarm)

LACH(Latch)

Alarm Latch(ON, OFF)

OFF

ENER(Energized)

Alarm Energized(EN, D-EN)

EN

DLY(Delay)

Alarm Delay(0~99sec)

0

ALM1(Alarm level 1)

Alarm 1 level (1~Full Range)

Based on gas

ALM2(Alarm level 2)

Alarm 2 level (1~Full Range)

Based on gas

5.3. Setting/Configuration Menu

Internal preferences are configurable by using

Up/Down Keys.

- GAS/HART/MODT/ADR/PWD/C-TM/HIDN

BRIT/M1.00/S1.00

<< SI-300 Manual

`

17

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

Gas type

▶Press the Select Key to display the current gas

type

HART availability

▶Press the Select Key to display the HART mode

availability

Changing to Modbus Type

▶Press the Select Key to enter the change

▶Select RTU/TCP by using Up/Down Key

▶Press the Select Key to save the change. The

mode applies after restarting the device

<< SI-300 Manual

`

18

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

Changing Modbus Address

▶Press the Select Key to enter the change

▶Select 1~64 by using Up/Down Key

▶Press the Select Key to save the change

Password settings

▶Press the Select Key to enter the change

▶Select 00~99 by using Up/Down Key

▶Press the Select Key to save the change

Calibration cycle setting

▶Press the Select Key to enter the change

▶Select 1~12months by using Up/Down Key

▶Press the Select Key to save the change

<< SI-300 Manual

`

19

©Senko 2021. All Rights Reserved Proprietary and Confidential to Senko

Hidden Area setting

▶Press the Select Key to enter the change

▶Select 0~20% by using Up/Down Key

▶Press the Select Key to save the change

Brightness setting

▶Press the Select Key to enter the change

▶Select 1~15 by using Up/Down Key

▶Press the Select Key to save the change

Firmware Version

Sensor cartridge version

This manual suits for next models

1

Table of contents

Other SENKO Gas Detector manuals

SENKO

SENKO SI-100 User manual

SENKO

SENKO iGas Detector CO2 User manual

SENKO

SENKO SI-H100 User manual

SENKO

SENKO SP secure User manual

SENKO

SENKO SP-MGTP User manual

SENKO

SENKO SI-100C User manual

SENKO

SENKO SI-100 User manual

SENKO

SENKO MGT User manual

SENKO

SENKO SGT User manual

SENKO

SENKO RAITEC SI-100D User manual

Popular Gas Detector manuals by other brands

New Cosmos Electric

New Cosmos Electric PS-7 instruction manual

SENSIT Technologies

SENSIT Technologies IRED instruction manual

Honeywell

Honeywell E3Point E3DA user manual

Sensitron

Sensitron SMART3G Short installation manual

Duran Electronica

Duran Electronica DURTOX-X Installation & user manual

Geca

Geca Beta 752CO quick start guide