Filamos CM Series User manual

Grouting and plastering pump –series CM

PRODUCER: FILAMOS, s.r.o.

Hatě 546, 261 01 Příbram, Czech Republic

Tel: + 420 318 637 763, Fax: + 420 318 624 181

www.filamos.cz

User Manual

Pump for transport, plastering, grouting and injecting

of fine- grained wet mixtures

CM 50 COM-V

Grouting and plastering pump CM 50 C0M-V

2

CONTENT Page

I. Terminology and marking...............................................................3

II. Machine use..................................................................................3

III. Machine description......................................................................3

IV. Technical data...............................................................................6

V. Instructions for operation and maintenance ..................................7

VI. Testing ........................................................................................13

VII. Acceptance, delivery, warranty ...................................................13

VIII. Packaging, transport, storage .....................................................14

IX. Service........................................................................................14

Grouting and plastering pump CM 50 C0M-V

3

I. Terminology and marking

The pump CM-50 COM-V

CM –basic marking of machine (pump + compulsory mixer)

50 –type series (max. output in l/min)

COM-V –machine drive equipped with a variator

Manufacturer

Name: FILAMOS, s.r.o.

Registered office and business address: Hatě 546, 261 01 Příbram

III, Czech Republic

Telephone: +420 318 637 763

Fax: +420 318 624 181

Internet: www.filamos.cz

II. Machine use

The machine is used for mixing, transporting and injecting of fine-grained

mixtures, e.g. fine plaster material, grout, coating putty, screed, insulating screed,

etc.

Suitability of conveyed mixture of spindle pump must be consulted with the

manufacturer or your own blend must be pre-tested.

In the case of use of the machine for plastering the separate pressurized air

supply must be used!

III. Machine description

The machine consists of the pump and compulsory mixer.

The pump:

- the drive (electric motor + gearbox with variator),

- frame with the trough,

- mixing (shoving) worm,

- transport spindle (rotor and stator),

- control manometer,

- tank cover with the sieve,

- travelling wheels of fixed frame,

- electric actuation (separate switchboard),

- accessories (material hose, injecting needle or nozzle)

Grouting and plastering pump CM 50 C0M-V

4

Mixer:

- tank

- drive (gearbox with electric motor)

- stirrer

- gear mechanism

- seal

- cover with filter and position switch

- electric actuation (separate switchboard)

Mixture (bagged or from silo) is fed to the mixer tank through a sieve of the

cover, which is provided with comb to rupture the packaging of bagged mixes.

Stirrer is composed from several stirring scoops of various designs for complete

mixing of the mixture with water. The stirrer is driven by chain wheels and chain.

The prepared mixture is emptied by opening segment in the bottom of the mixing

tank directly into the pump trough.

At the bottom of the pump trough there is horizontally stored mixing (shoving)

worm, which shoves the mixture to the transport spindle.

The drive of the pump is connected by the variator clutch to the mixing (shoving)

worm, which is hinge connected to the rotor part of the transport spindle.

The regulation of rpm of the variator is being done while machine is

operating (drive running) via regulation wheel of variator!

The whole machine is placed on metal wheels to allow movement at the place of

the machine use. Instead of metal wheels a rigid frame can be mounted for

hanging or tracked chassis. For this purpose serve the threaded holes in the frame

of the machine.

Behind the traffic spindle there is connected control manometer, transport hoses

and other accessories with couplings.

At the end of transport hoses the plaster nozzle or grout or injection needle

according to the kind of work is connected.

In the case of machine use for plastering it is necessary to inlet pressurized

air into plastering nozzle from separate source (external compressor) which

is not part of the pump!

Control of mixer and pump is done through separate valves mounted on the

machine frame.

Grouting and plastering pump CM 50 C0M-V

5

Mixer is controlled by the START button to start and by STOP button for ending

operation. When lifting the lid, the mixer automatically shuts down by limit

switch. In an emergency, you can stop the mixer by pressing TOTAL STOP.

The pump is controlled by the START button to start and by STOP button for

ending operation. Part of the operation is the reverse switch allowing reversing,

and thus relieving the pump (pressure drop in the transport hose). In an

emergency, you can stop the pump by pressing TOTAL STOP.

Inlet of electric current to the device is 5-PIN 32A / 400V.

Grouting and plastering pump CM 50 C0M-V

6

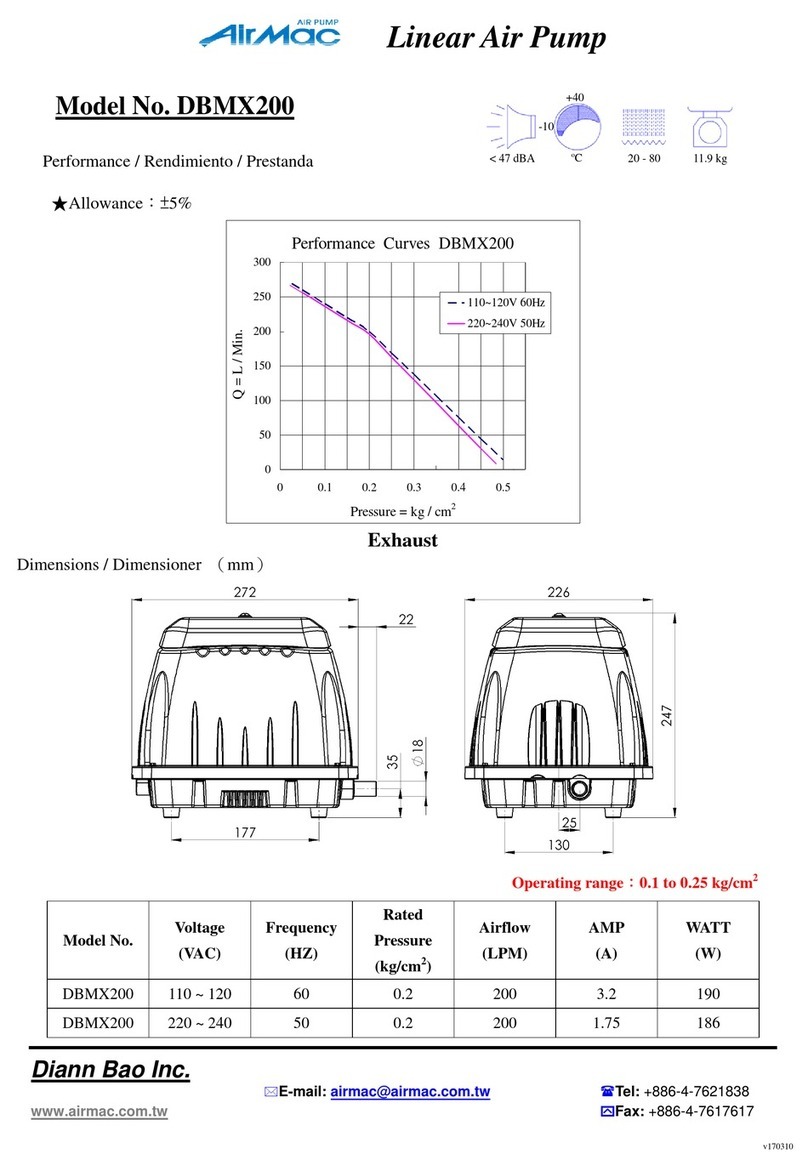

IV. Technical data

Mixer

Tank volume 150 dm3

Stirrer rate 65 rpm

Electric motor input 2,2 kW

Pump

Pump is fitted with various types of conveyors according to the customer request

for maximum capacity (l/min) and maximum pressure (MPa).

Technical parameters

Mixture granularity (mm)

0÷6

Max. transport distance - horizontal (m)

40

Inside diameter of transport hoses (mm)

25,35

RPM of variator (rpm)

39÷234

Electric motor input (kW)

5,5

Supply aggregate

3NPE~50Hz,400V/TN-S

Allowed variation of supply voltage

± 10%

Dimensions and weights

Length (mm)

2555

Width (mm)

700

Height (mm)

1280

Weight (without accessories) kg

375

Temperature of working environment: 5 ÷ 40 °C

Type of external influences by ČSN 33 2000-3:

Environment: AA5, AB5, AE6, AF2

Use: BA4, BE1

Note: Pump performance and output pressure are influenced by the density and

composition of the mixture. For thinner mixture flow rate is higher and traffic

pressure lower.

For a given mixture the performance must be individually verified.

Material, design, surface, treatment

The material used in the product corresponds to the composition and mechanical

properties of manufacturing documentation.

Type of conveyor

Max. Output

Max. Pressure

2L6

40 l/min

2,5 MPa

2L88

50 l/min

2 MPa

Grouting and plastering pump CM 50 C0M-V

7

All parts are made in accordance with this documentation, intolerable dimensions

conform to the relevant standard. Welds are made according to technical

documentation.

Coating, paint and colors correspond to documentation - coating thickness is

100μm. Unmetallized parts are prior to installation in the junction areas primed.

Marking

The device is provided with a type plate information:

- name of manufacturer

- specification of the machine

- serial No. of the machine

- total input of the drive

- weight of the machine

V. Instructions for operation and maintenance

Extent of Use

The equipment is designed for the mixing and transport of fine-grained wet

mixtures for the needs of construction, mining, metallurgy, etc.

Controls are mounted directly on the device.

The user must ensure that the machine is used in accordance with the law

No.258/2000 Coll. About the protection of public health.

Operating

Operation and maintenance may only be performed by staff familiar with the

instructions for use and safety and hygiene regulations.

Maintenance and repair of electrical wiring must be carried out by staff with

appropriate qualifications and skills.

Machine completion

If the rotor (screw) of the transport spindle is dismantled from the casing, it is

painted with silicone oil and screwed into the casing. Assembled spindle is

inserted into the carrier shoving screw and fixed flange and clamping bolts on the

front tank. Removal is carried out in reverse order. Worm input must always

overlap the front tires!

Quick connects on control spindle gauge and transport hose for him working with

the selected accessories (injection needle, needle pointing, and plastering nozzle).

The nozzle edger connects hose with compressed air.

Grouting and plastering pump CM 50 C0M-V

8

Machine preparation

Before putting the machine into operation, it is necessary first to examine the

connection of machine drive to the mains, which must comply with the applicable

safety regulations. The machine can be used only if the connection to the

power supply is in good condition.

Before starting the machine the machine must be established in a horizontal

position and secured against maneuvering and grounded through the grounding

screw.

Pour into pump trough a quantity of milk of lime, to shoving worm completely

sunk. By briefly turning of machine check the correct direction of rotation of the

screw for the transport of milk. If the direction of rotation is not correct and the

material does not pass to the hose, switch pump into reverse and wait until the

milk begins to flow out of hose. This ensures that the traffic is pruned in the

way the entire length.

After checking the bottom seal closure of mixer the tank is filled by mixture with

the necessary amount of mixing water. The filling is always made through the

closed lid with strainer!

Whisked mixture is put away from the mixer into the pump trough. The pump is

put on and at the end of the delivery hose we are watching, to be discharged

remains of lime milk. This is collected into a container. Then we can begin to

apply our own mix with the selected attachments.

New batch mixture may be prepared in the mixer simultaneously with the work of

the pump.

Principles of pump operation

-The pump must not operate on dry! This will damage or even destroy the rubber

cover (stator) of traffic spindle.

-The container can be filled by transported mixture after lubrication by the milk

of lime!

-Do not leave pumped mixture in the hose nor in the tank too long time, it could

cause the hardening. Therefore choose the shortest breaks, or rather drain the

mixture and clean the machine with a hose during a shift!

-If the traffic hose is clogged, release the pressure with reversing switch - switch to

the opposite direction and briefly turn on the drive. Check of hose depressurization

by drop of hand gauge to 0! Disconnect the hose and clean it by the tap, water, etc.

-During operation it is necessary to monitor the pressure on the control pressure

gauge!

-During operation covers with screens must be on tanks!

-Wear rubber casing (stator) or metal screw (rotor) traffic affects spindle loss of

pressure. In this case, it is necessary to replace damaged or worn out with a new

piece. In case of use of transport spindle with retractable spindle sleeve can be

traffic spindle drawn and thereby putting pressure recovery.

Grouting and plastering pump CM 50 C0M-V

9

-During operation the operator has a duty to continuously monitor the temperature of

the machine, especially the jacket temperature of the gearbox.

-When carrying the machine by crane, forklift, during transport or when moving to

another workplace machine must be disconnected from the mains or from an

external source of compressed air.

During the mixture transport the user must ensure:

-a place where it is stored mixture, connect by signaling device with the machine

operator,

-around machinery and transport hoses leave passages at least 1 m wide,

-couplers of transport hoses before starting operations must be cleaned and tightly

sealed,

-In the case of congestion of traffic hoses they must be underpressurized by the

reverse operation, then the parts must be disassembled and cleaned up

mechanically.

-Folding hoses, disassembly and repair of the machine shall not be performed

when the mixture in the tubes is under pressure. This also applies to the

tightening of flanges, moving of traffic hoses etc...

-Above the hoses laid in places of permanent pedestrian or another traffic must

be bridges or transitions where applicable.

-When connecting hoses only couplers supplied by the machine manufacturer

are allowed to use.

Stopping of the machine

After operation, the residue mixture from the tub pours by opening the seal

through opening in the bottom. Bathtub pours with water, close the drain and pour

lime milk. Disconnect transport hoses from the pump and put in cleaning ball.

Disconnect the injection needle (plaster or grout nozzle needle) and rinse it with

water. Connect the transport hose back and turn on the pump drive. We are

waiting for the cleaning ball pushes ahead pumped mixture and lime milk begins

to flow. Cleaning services of transport hoses by cleaning ball carry out at least 2x.

In the event that the next day we continue to work, we can let lime milk in the

tank and hoses. In case of prolonged disruption should be removed rotor from

stator of traffic spindle and both parts stored disassembled (both parts should be

coated by the silicone oil).

The mixer tank, control pressure gauge and all the accessories must be rinsed with

water.

Machine adjustment

Regulation of the output of machine is being done when machine is running by

means of regulation wheel of variator. The necessary amount of compressed air

for plastering is controlled at the nozzle valve.

Grouting and plastering pump CM 50 C0M-V

10

Security risks

-Repairs of el. installation must be performed only by a person with

professional training and electrical qualifications according to applicable

regulations. During repairs, cleaning and inspection machine, always

disconnect the machine from the power supply.

-When lifting covers (screens) do not reach into tanks, if the device is not

disconnected from the mains - the risk of injury from the rotating agitator

mixer or pump shoving screw

-During operation to perform mixture into the mixer and then into the tub

pumps only through a sieve - the risk of injury from the rotating agitator or

mixer shoving screw pumps.

-The mixing vessel and into the tub pump not put any objects - from becoming

trapped rotating agitator or auger and shoving of the damage to some parts.

-Mixtures filled into the mixing container or tub always pumps through a sieve

- a larger piece of falling and thereby blocking transport routes.

-When filling machines bagged blends attention to the possibility of injury

from bursting ridge - work in protective gloves.

-During operation or tamper with couplings on the hose and pressure gauge

(properly tightened before starting the pump) - risk of injury from pressurized

mixture.

-Operation of the pump must be equipped with protective equipment,

especially tools for eye protection - risk of injury due to a mixture of intrusion

into your eyes.

-During operation must be ensured or communication signaling between the

operator and the operator applying the mixture (operator nozzles, injection

needles) - danger of serving at the nozzle (injection needle).

-When clogged hose does not analyze the connections - stop the machine,

switch the reversing switch and release the pressure briefly switching on the

machine, the pressure drop is displayed on the gauge - the risk of injury from

pressurized mixture.

-Mixing (shoving) auger during operation must be completely sunk in the

mixture - this could damage or destroy the transport of rotor.

-When cleaning the transport hoses cleaning the nozzle to direct the ball into

an open space away from people - the risk of injury from pressurized cleaning

balls and mixtures.

-The machine must not be used under any circumstances, the engine cover

removed.

-The machine must not be used under any circumstances cover removed chain

transmission. The chain should be checked before each run and tension

tensioning mechanism.

-With the mixer can handle, fix it and clean only when the machine is

disconnected from the power supply. The machine must not be used under any

circumstances cover removed (sieve) mixer.

-The pump can handle, fix it and clean only when the machine is disconnected

from the power supply. The machine must not be used under any

circumstances cover removed (sieve) pump.

Grouting and plastering pump CM 50 C0M-V

11

-The machine must be the operator of the machine is grounded through the

grounding screw.

-For the transport of the mixture is necessary to use only antistatic hose with

the certificate.

-All conductive parts of machines, including transport hose, fittings of hose

and pressure gauge are the manufacturer of each other electrostatically bonded

and grounded copper conductor with a cross section of 10 mm2. At any

damage these jumpers must be a correction.

Maintenance

Maintenance, respectively replacement of parts must be performed by experienced

technician in accordance with currently applicable regulations for the operation of

production facilities and for environmental protection. In addition, this technician

must be trained by Filamos, s.r.o.

-Before starting any maintenance activities activate all appropriate safety

equipment and assess whether it will be necessary to warn personnel working

in the vicinity.

-Replace worn components with original spare parts only.

-After releasing of elements sealed by gasket check the seal wear.

-Check threads of mounting screws on covers and lids.

-Make sure that the fastening elements do not show deformation or cracks.

-The above principles will help to ensure the operability of the machine and the

desired level of security.

-The manufacturer accepts no liability for any injury or damage to property

caused by the use of non-original spare parts or improper implementation or

interventions non-approved by manufacturer that have an impact on safety.

-In the case of spare parts ordering process by list of spare parts, which is

delivered together with the machine.

-Do not release pollutants into the environment!

-When disposing of waste materials proceed in accordance with the relevant

regulations!

Proper maintenance achieves optimal performance, durability, and lasting

security.

During maintenance, cleaning and after work the machine must be disconnected

from the power supply.

Maintenance of the machine is carried out after each shift or stoppage of machine

operation.

Maintenance of the machine is formed by proper cleaning of tank, transport

spindles (stator + rotor), pressure gauge, hoses and nozzles (needles) always after

cessation of operations and by control of closing of outlet openings, check of the

proper connection of the pump, gauge and hose couplings always before

operation. It is necessary to control the overlap of the spindle from rubber stator

on the output side. In case of insufficient overlap (2-3 mm) extend it by the

weld to the front of shoving screw in the pump tub!

Grouting and plastering pump CM 50 C0M-V

12

Daily checking

-Rotor (worm) and stator (casing) state check,

-Transport hoses and pressure gauge state check

Weekly checking

-All screw connections check

-Electric wiring state and tightening check

Yearly checking

- Check of oil level in gearbox

In operation, the operator must monitor the correct operation of the device. In the

event of a reduction of function the device must be stopped and the fault

corrected. In the case of the wear of rotor and stator the quantity of transported

mixture is gradually reduced and the pressure is reduced. If the quantity of

transported mixture or the pressure falls below the level necessary for the type of

application, it is necessary to replace the rotor and the stator. Before replacing the

rotor and stator drain the pump tub, terminate operation of the machine and

disconnect it from the power supply.

Replacing the rotor and stator:

1. Release and remove the bolt M 12, which connects shoving worm with the

rotor in a pump tub.

2. Release two nuts M16 that tighten the output flange to the stator.

3. After sufficient releasing of nuts M16 screw M16 departs from the stator so that

it releases the output flange of the coupling on the hose.

4. After removing the output flange stator with the rotor are released.

5. By reverse procedure a new stator and rotor are connected to the machine.

After installing a new stator with the rotor it is necessary to evenly tighten nuts

M16 so as not to rotate the stator - the stator must not spin t after pump start - risk

of heat by friction of stator on pump front and output flange!

Installation of rotor into stator

1. Stator is ensured against rotating (e.g. by tightening into clamp).

2. Sufficient volume of the lubricating grease is applied on stator and rotor, too.

3. Rotor is inserted into stator.

4. Rotor is screwed into stator in such a way when rotor ends with stator at the

output side.

Lubrication

Into the bearing housing between gearbox and shoving worm 1x per week

supplement Grease T-A4, exchange 1x per year.

Check oil level in the transmissions on the mixer and the pump.

The factory filled them with mineral oil (e.g. KLUBER GEM 1-220,

MOBILGEAR 630 /XMP 220ú, SCHELL OMALA 220) for 10 000 operating

hours or for max. 2 years.

Grouting and plastering pump CM 50 C0M-V

13

You can mix different brands of oil, never synthetic and mineral oil each

other!

VI. Testing

Dimensional inspection done by the manufacturer according to the drawings.

Features of the machine are controlled functional test: directions, changes in

rotation speed, the maximum delivery rate and maximum pressure tested with

water.

Design tests indicate the manufacturer of the "Certificate of quality and

completeness."

Asking for customer design specific tests (e.g. own mixtures), it does so at his

expense!

VII. Acceptance, delivery, warranty

ACCEPTANCE

Acceptance by the manufacturer is provided only to customers requirement.

DELIVERY

The machine is supplied fully assembled with the accompanying documentation,

including:

-Instructions for use

-Certificate of Quality and Completeness

-Default electrical revision of the Equipment

-Declaration of Conformity el. motor end trigger and distributor with

requirements of the European Communities No. 94/9/ES - ATEX

100(95),

The basic kit is not part of the machine, to be ordered separately. It consists of:

-Transport hose DN 35 (alternatively DN 50) - 20 m

-Injection needle, needle pointing - alternatively - 1 pc

-Cleaning ball - 1 pc

WARRANTY

The warranty period is 12 months from the date of sale, the spare parts 3 months.

The manufacturer does not guarantee:

-If the machine is used for other purposes and in any other way than described

in the Instructions for use,

-If the machine is properly cared for (poor storage, installation, operation,

maintenance, etc.),

-If the machine is modified, modification or repair without the prior consent of

the manufacturer,

-There is the incorrect power. user involvement,

Grouting and plastering pump CM 50 C0M-V

14

-If damage to a third party or force majeure,

-During the warranty without warranty certificate (Certificate of Quality and

Completeness),

-Wear agitator in the mixing vessel, shoving screw, rotor and stator, pressure

gauge and transport hoses from the operation of the machine, because their

life depends on the abrasiveness transported mixture by the machine

manufacturer's control,

-If the used machinery manufacturers recommended blend mixture .

VIII. Packaging, transport, storage

PACKAGING

The machine is supplied in bulk or in pallet. The cost of packaging charge to

customer (it is non-refundable).

TRANSPORT

Transportation is normal means of transport. When transportation is responsible

for the proper attachment carrier.

STORAGE

The machine should be stored in areas that are protected against adverse effects

and excessive moisture.

For longer than one month, the machine stores the screw removed and a rubber

shell transport spindle. It is appropriate to be applied on both silicone oil.

IX. Service

WARRANTY REPAIRS

Warranty repairs are provided during the warranty period which is one year from

the receipt of customer machines.

Warranty repairs are free of charge in the event that the conditions referred to in

the relevant passages Operator's Manual.

Repairs under warranty for failure warranty will be charged according to the costs

incurred.

Grouting and plastering pump CM 50 C0M-V

15

AFTER-WARRANTY REPAIRS

Routine repairs done alone by the purchaser.

Medium and major repairs are always carried out by the manufacturer.

Preventive inspections are carried out by the customer for payment.

Machine supplier provides on demand information and advisory service.

Obligations of the machine operations:

-follow instructions in full text,

-not to make any changes on the machine or equipment without consultation

with the manufacturer,

-allow entry service workers to ensure their safety and to familiarize them with

the safety regulations applicable in the place of the machine,

-perform installation, repair and maintenance of electric motor according to

instructions issued by the manufacturer of the motor.

THE END

In Příbram –April, 2004

Made by: Ing. Jiří Labuda

Company: FILAMOS, s.r.o., Hatě 546, 261 01 Příbram, Czech Republic

Grouting and plastering pump CM 50 C0M-V

16

Appendix No. 1: Machine scheme CM 50 COM-V (main parts)

Grouting and plastering pump CM 50 C0M-V

17

Appendix No. 2: Electric wiring scheme CM-50 COM-V

-XC 01.01 supply IP 67

-RM 01.01 distributor

-F 03.01 engine switch

-M 01 asynchronous motor 2,2 kW

-F 03.03 engine switch

-M 02 asynchronous motor 5,5 kW

-F 01.01 circuit breaker

-S 01.01 emergency stop button

-S 02.01 central start button

-S 03.01 start button

-S 04.01 stop button

-Q 02.01 position switch

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Taco

Taco 1900e Series instructions

Pentair

Pentair JUNG PUMPEN MULTICUT 35/2 M Tan, EX instruction manual

baxter

baxter PCA II Operator's manual

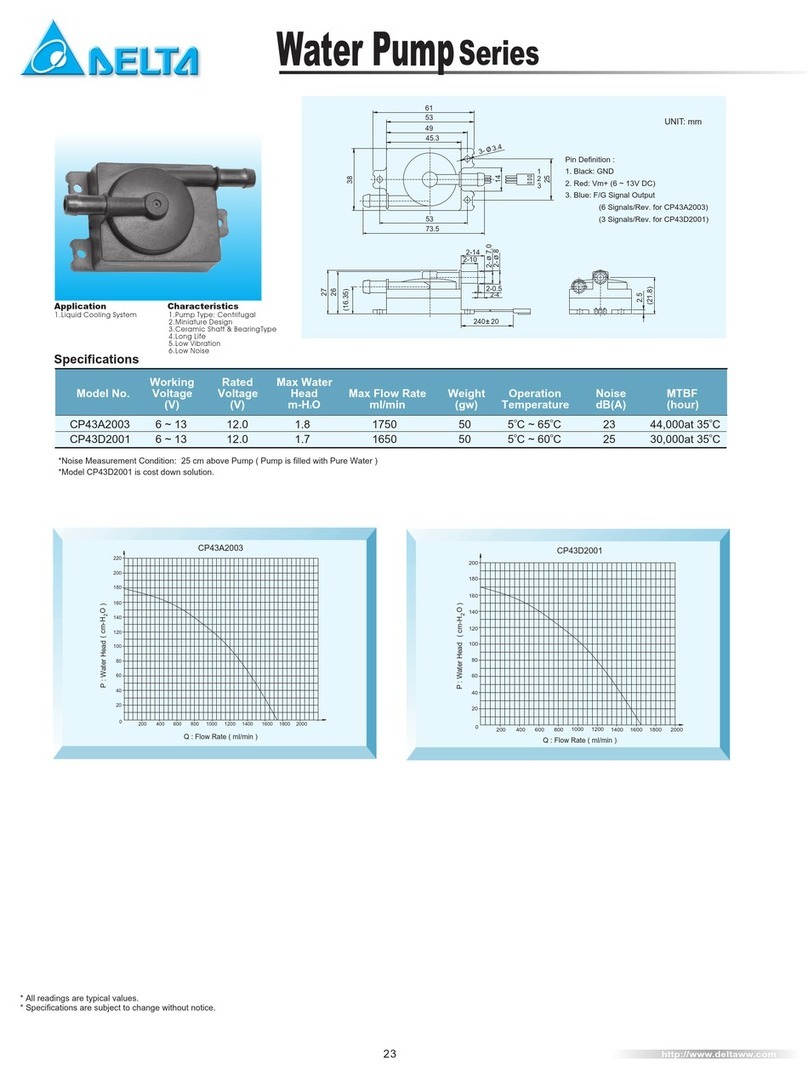

Delta Electronics

Delta Electronics Water Pump Series CP43A2003 Specifications

Performance Tool

Performance Tool W89727 owner's manual

Walrus

Walrus TPAK Series instruction manual

EINHELL

EINHELL RG-SP 750 LL operating instructions

Grundfos

Grundfos DME Installation and operating instructions

Whale

Whale BP0527 quick start guide

Delta Environmental Products

Delta Environmental Products D4E Series owner's manual

Pentair

Pentair HYDROMATIC HPUSP125 Installation, operation & parts

IKH

IKH XVP012 instruction manual