PRODUCT SPECIFICATIONS

Item Description

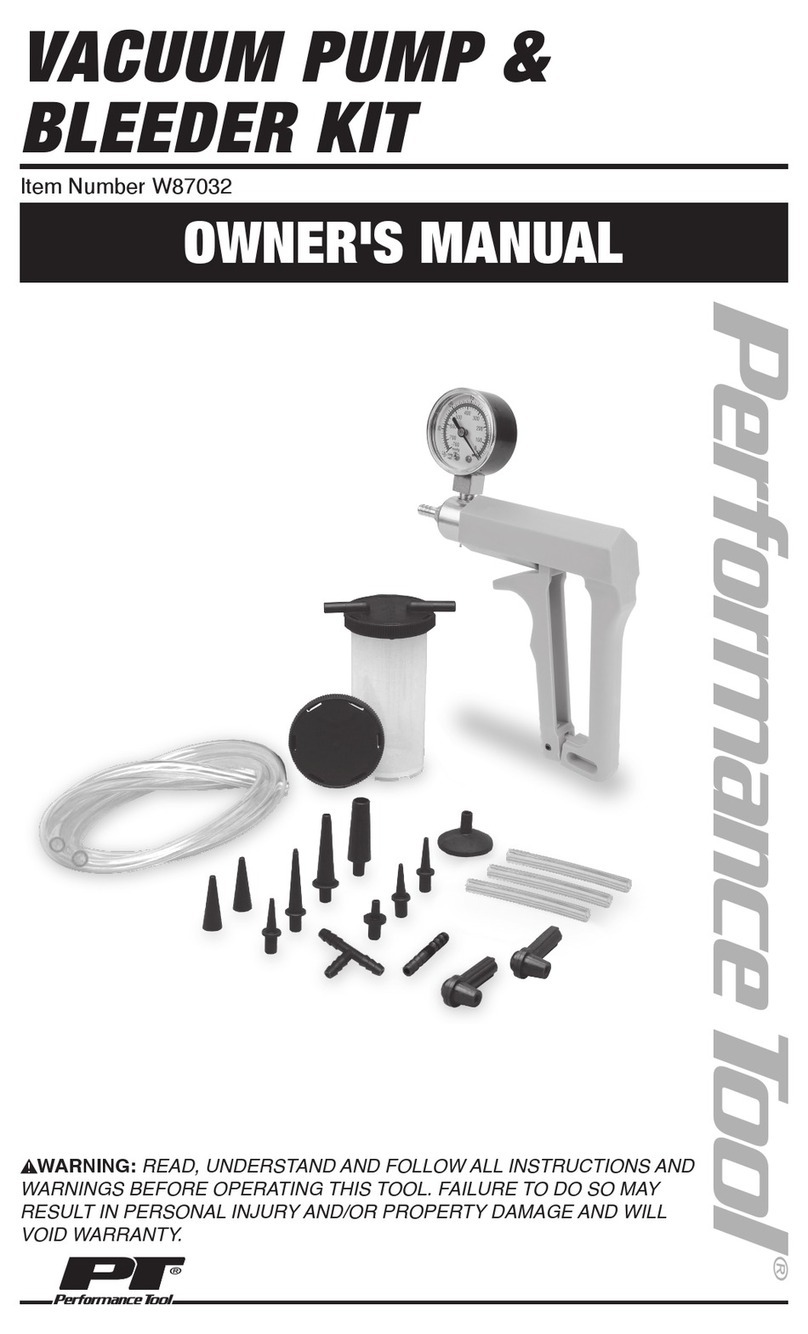

Gauge Size 2” Diameter

Gauge Scale 0,-.30 in/Hg (0<->76 cm/Hg) Vacuum

Accessories 1/4” I.D.X 23” LongVacuum Hoses (Qty.2)

1/4” I.D.X 3” LongVacuum Hoses (Qty.4)

Tapered Hose Adapters (Qty.4)

”T” Hose Connector

Straight Hose Connector

Brake BleederValve Adapters (Qty.2)

Universal Cup Adapter

4 oz. Reservoir Jar

Jar Lids (Qty.2)

Net Weight 1.8 Lbs

When unpacking, check to make sure all the parts shown on the parts list on pg. are in-

cluded.

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram. Keep

your invoice with this manual. Write the invoice number on the inside of the front cover.

Keep this manual and invoice in a safe and dry place for future reference.

Keep bystanders, children, and visitors away while operating the Brake Bleeder/Vacuum

Pump. Distractions can cause you to lose control. Protect others in the work area from

injury. Provide barriers or shields as needed.

PERSONAL SAFETY

1. Stay alert. Watch what you are doing, and use common sense when operating the Brake

Bleeder/Vacuum Pump. Do not use the tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating the tool may result in

serious personal injury.

2. Dress properly. Do not wear loose clothing or jewelry. Contain long hair.Keep your hair,

clothing, and jewelry away from moving parts.Loose clothes, jewelry, or long hair can be

caught in moving parts.

3. Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the power tool in unexpected situations.

4. Use safety equipment. Always wear ANSI approved safety glasses underneath a full

face safety shield. Nonskid safety shoes, hard hat, or hearing protection must be used for

appropriate conditions.

UNPACKING

SAVE THIS MANUAL

GENERAL SAFETY RULES

PERSONAL SAFETY

2

Item Description

1. Do not force the tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

2. Store idle tools out of reach of children and other untrained persons. Tools are dangerous

in the hands of untrained users.

3. Maintain tools with care. Keep tools dry and clean. Properly maintained tools are less

likely to bind and are easier to control. Do not use a damaged tool. Tag damaged tools “Do

not use” until repaired.

4. Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

5. Use only accessories that are recommended by the manufacturer for your model. Acces-

sories that may be suitable for one tool may become hazardous when used on another tool.

Tool service must be performed only by qualified repair personnel.Service or maintenance

performed by unqualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instructions in the

“Inspection, Maintenance, And Cleaning” section of this manual. Use of unauthorized parts

or failure to follow maintenance instructions may create a risk of injury.

SPECIFIC SAFETY RULES

1. Maintain a safe working environment. Keep the work area well lit. Make sure there is

adequate surrounding workspace. Always keep the work area free of obstructions, grease,

oil, trash, and other debris. Do not use the Brake Bleeder/Vacuum Pump in areas near

flammable chemicals, dusts, and vapors. Do not use this product in a damp or wet location.

2. Maintain labels and nameplates on this product.These carry important information. If

unreadable or missing, contact Harbor FreightTools for a replacement.

3. Keep the Handles of the Brake Bleeder dry, clean, and free from brake fluid, oil, and

grease.

4. Prior to using the Brake Bleeder/Vacuum Pump make sure to read and understand all

warnings, safety precautions, and instructions as outlined in the vehicle manufacturer’s

instruction manual. Every vehicle has specific measurement values for vacuum related

readings. It is beyond the scope of this manual to properly describe the correct procedure

and test data for each vehicle.

5.WARNING! Carbon monoxide is produced while a vehicle’s engine is operating and is

deadly in a closed environment. Early signs of carbon monoxide poisoning resemble the

flu, with headaches, dizziness, or nausea. If you have these signs, the work area may not

be vented properly. Get fresh air immediately.

6. Prior to using the Brake Bleeder/Vacuum Pump, make sure to place the vehicle’s trans-

mission in “PARK” (if automatic) or “NEUTRAL” (if manual).Then, block the tires with chocks.

TOOL USE AND CARE

SERVICE

SPECIFIC SAFETY RULES

3