Filtration Group SDG-100 User manual

Translation of the original instructions with installation instructions

Filter aid dosing device

SDG-100

Mat. No. of original instructions

79792383

Page 2

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

1 Contents

1Contents...................................................................... 2

2General safety instructions....................................... 2

2.1 Safety instructions for installation and

operating personnel .......................................... 2

2.2 Warning structure.............................................. 2

2.3 Warning symbols used...................................... 2

2.4 Other symbols used.......................................... 3

3Glossary...................................................................... 3

4General information ................................................... 3

4.1 Manufacturer..................................................... 3

4.2 Information about the original instructions ........ 3

4.3 Model code ....................................................... 4

5Intended use............................................................... 4

6Functional description............................................... 5

6.1 Principle of the process..................................... 5

6.2 Main components.............................................. 5

7Technical data ............................................................ 6

7.1 General data (excluding optional equipment) ... 6

7.2 Order-specific data............................................ 6

8Transport and storage ............................................... 6

9Installation .................................................................. 6

9.1 Installation......................................................... 7

9.2 Installing the piping / pump selection ................ 7

9.3 Compressed air supply ..................................... 7

9.4 Electrical connections ....................................... 8

9.4.1 Connection of the 2/2-way valves.......... 8

9.4.2 Calibrating the level sensor (optional).... 8

9.4.3 Dosing device controller (optional) ........ 8

10 Start-up ....................................................................... 8

10.1 Initial start-up or start-up after prolonged

shut-down ......................................................... 8

10.2 Starting up the dosing device............................ 8

11 Normal operation ....................................................... 8

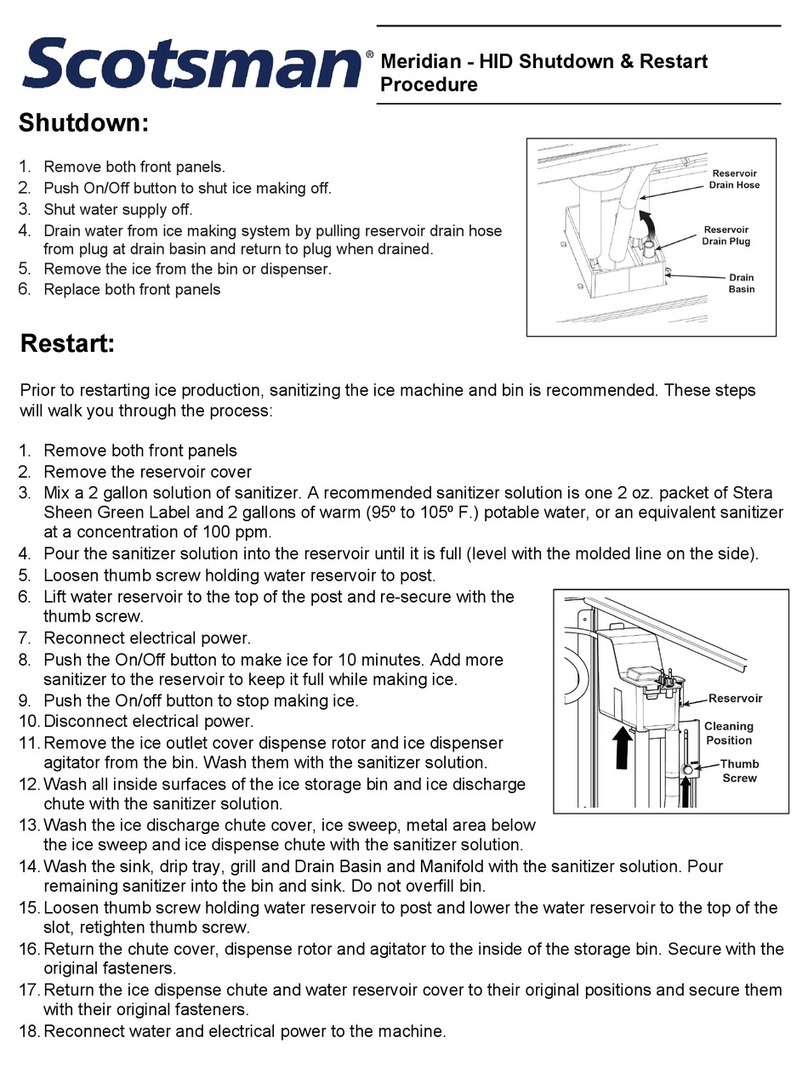

12 Shutting down the dust collector ............................. 9

12.1 Temporary shut-down....................................... 9

12.2 Prolonged shut-down (> 48 h)........................... 9

12.3 Emergency shut-down ...................................... 9

12.4 Transporting the dosing device......................... 9

13 Troubleshooting......................................................... 9

14 Maintenance ............................................................... 9

14.1 Inspection and maintenance schedule.............. 9

15 Appendix: Dosing device parameters .................... 10

16 Declaration of incorporation ................................... 11

17 Index.......................................................................... 15

2 General safety instructions

2.1 Safety instructions for installation and

operating personnel

This translation of the original instructions contains

important safety information which must be heeded at all

times during installation, normal operation and maintenance.

Non-observance can result in the following risks to persons

and the environment as well as in damage to the machine or

system:

Failure of critical functions of the machine or system or of

its component parts.

Danger to persons from electrical or mechanical effects

as well as from chemical reactions.

Danger to the environment owing to the leakage of

hazardous substances.

Before installation / start-up:

•Read this translation of the original instructions carefully.

•Make sure that installation and operating personnel are

adequately trained.

•Make sure the contents of the original instructions are

fully understood by the responsible persons.

•Define areas of responsibility and competence.

•Prepare a maintenance schedule.

During operation of the system:

•Keep this translation of the original instructions handy at

the place of use.

•Heed the safety instructions. Always operate the machine

or system in accordance with its ratings.

If in doubt:

•Consult the manufacturer.

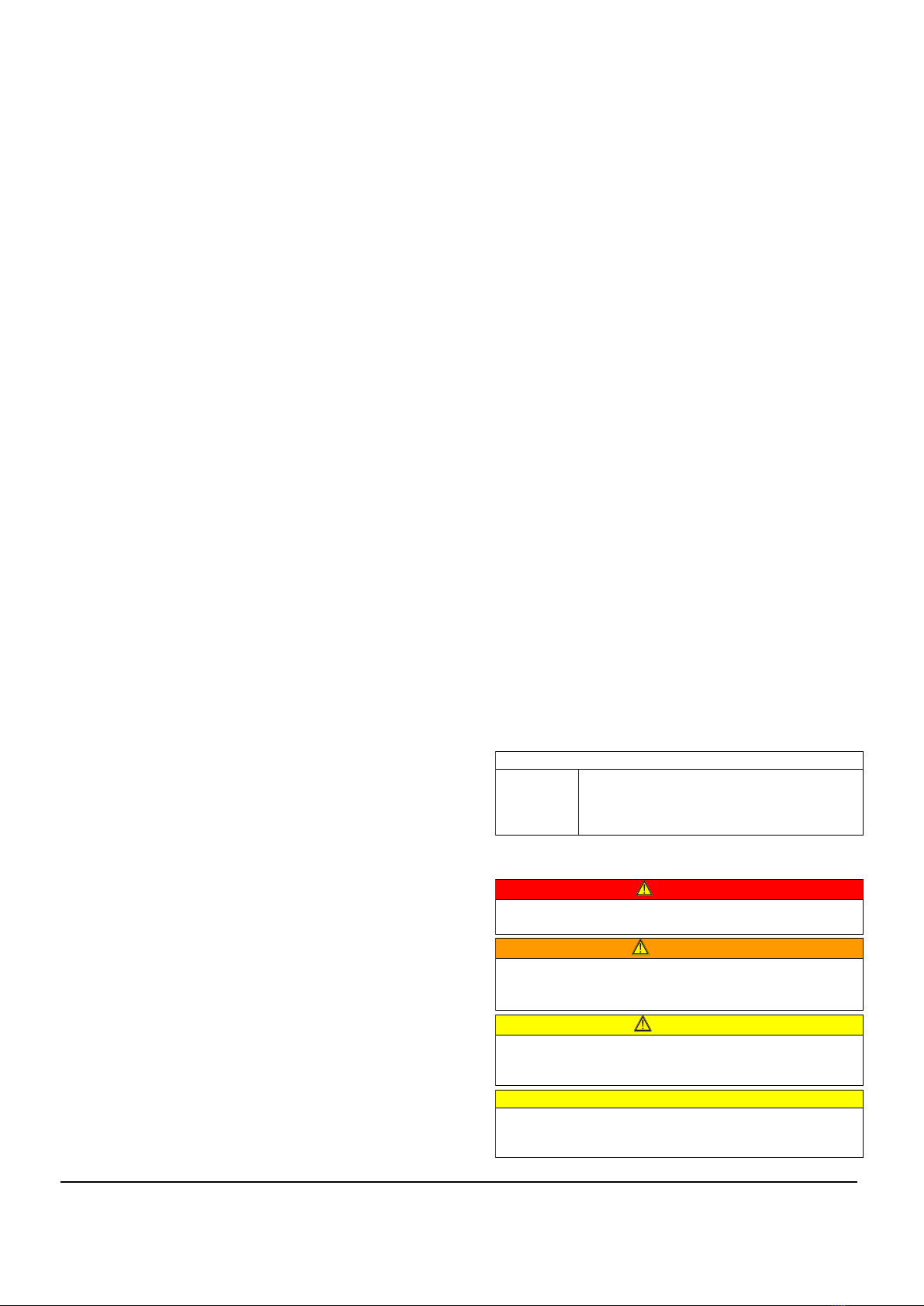

2.2 Warning structure

Where possible, warnings are structured according to the

following system:

Signal word

Possibly

with

symbol

Nature and source of the danger

Potential consequences of non-

observance

•Action to avert the danger.

2.3 Warning symbols used

DANGER!

Immediate danger!

Non-observance will result in serious or fatal injury.

WARNING!

Potentially dangerous situation!

Non-observance can result in serious or fatal injury.

CAUTION!

Potentially dangerous situation!

Non-observance can result in minor or moderate

injuries.

CAUTION! (without a symbol)

Potentially dangerous situation!

Non-observance can result in property damage.

Page 3

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

2.4 Other symbols used

Danger: High voltage!

Information about environmental

protection

Wear protective clothing!

Eye protection must be worn!

Respirator must be worn!

Hand symbol:

Indicates general information and

recommendations

•

Bullet:

Indicates the order in which

actions are to be carried out

Arrow:

Indicates responses to actions

3 Glossary

System:

Customer’s complete system in which the FG dosing device

is integrated.

Pressure difference / differential pressure:

Pressure difference between the dirty and clean air sides of

the filter in [mbar] or [Pa].

Velocity:

Flow rate through the filter surface. Calculated as the

volume flow divided by the filter area [m³/m² min].

Residual dust content:

Amount of particulate matter on the clean air side [mg/m³].

Dew point:

Temperature at which a gas is saturated with moisture. Mist

droplets form at temperatures below the dew point.

Filter aid:

Powdery aid to facilitate the separation of problem dusts.

Injector nozzle:

Used to add filter aid to the dust-laden air prior to filtration.

4 General information

4.1 Manufacturer

Filtration Group GmbH

Schleifbachweg 45

D-74613 Öhringen

Phone +49 7941 6466-0

Fax +49 7941 6466-429

fm.de.sales@filtrationgroup.com

www.industrial.filtrationgroup.com

4.2 Information about the original instructions

FG Mat. No. ........................................................ 79792383

Date: .................................................................... 16.01.19

Version: .......................................................................... 04

Page 4

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

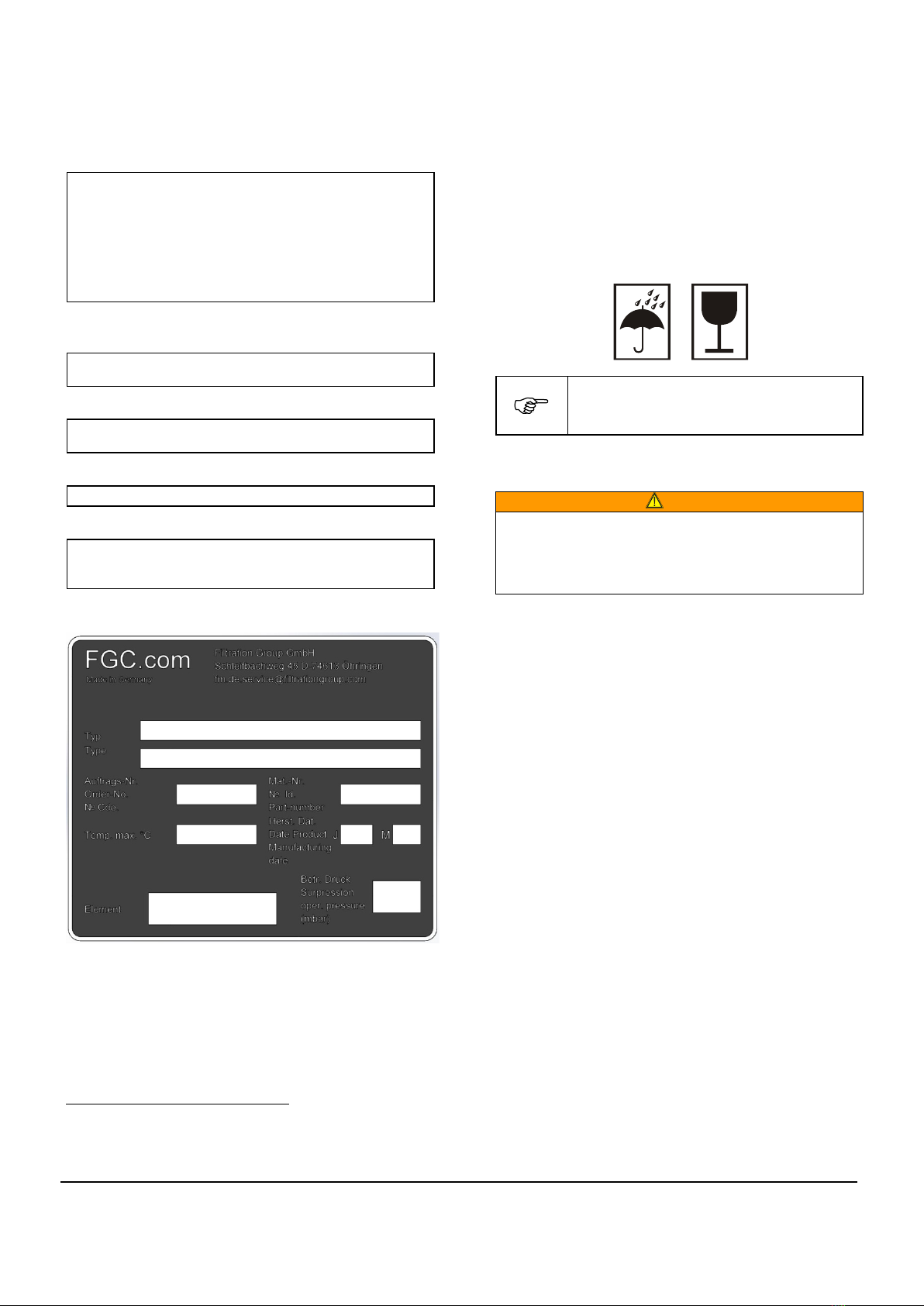

4.3 Model code

(Space for name-plate)

5 Intended use

DANGER!

PROHIBITED:

•Use for other purposes without prior consultation with

the manufacturer.

•Use with smouldering, burning or sticky particles.

•Use with highly explosive dusts (e.g. aluminium dust,

explosives, etc.).

CAUTION!

This FG dosing device is only allowed to be used in

accordance with the operating conditions specified in the

contract documentation and in the original instructions.

All forms of use which deviate from or exceed the limits of

use described above are considered to be contrary to the

intended purpose. The manufacturer is not liable for any

damage resulting from such use.

CAUTION!

Conditionally allowed:

•Use in connection with foodstuffs, provided this is

explicitly confirmed by the manufacturer in the contract

documentation (offer / order confirmation).

The FG dosing device is used in conjunction with an FG

dust collector to separate sticky or very fine dusts. A filter

aid is added to the dust-laden air. The filter aid surrounds

the problem dust and forms a layer on the cleaned filter

elements. The dust is not in direct contact with the filter

element and is thus no longer able to block it or clog it. The

element has a much longer service life as a result.

Problem dust Filter aid Filter element

Bound problem dust

Fig. 1: Principle of the filter aid

Page 5

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

6 Functional description

6.1 Principle of the process

CAUTION!

Abrasive filter aid must NOT be aimed at the wall when it

is added to the dirty air side.

1

The dust-laden air flows into the dirty air side.

2

The dust particles are separated on the filter

elements.

3

The cleaned air enters the clean air side.

4

Fig. 2: Filtration principle

4

Compressed air is applied to the injector nozzle.

A mixture of filter aid and air is fed into the air inlet

pipe. The filter aid forms a layer over the problem

dust and the filter elements.

The filtration process does not need to be interrupted for

cleaning (EXCEPTION: Dust collectors with only one

cleaning valve).

During intermittent operation, the filter aid is added as soon

as the fan is switched on.

6.2 Main components

Fig. 3: Main components

1

Housing

2

Ball valves for shutting off the compressed air

3

DRV 1: Pressure regulating valve for the injector

nozzle

4

Magnetic valve ¼”

5

Injector nozzle

6

Air breather / vent filter

7

DRV 2: Pressure regulating valve for the piston

vibrator

8

Magnetic valve ¼”

9

Piston vibrator (concealed)

Level sensor (optional):

Sensor for monitoring the minimum level in the filter aid

tank. An electrical signal is output if the level falls below this

minimum value.

Air injector loosening system

The air injector loosening system is used to

fluidise powdery products. Bridging is

prevented in this way and the powder is

discharged uniformly.

Fig. 4: Accessories for the dosing device

3

2

1

Air injector loosening

system

Air injector loosening

system

Page 6

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

7 Technical data

7.1 General data

(excluding optional equipment)

Dosing device housing (standard version):

Material: .......................................................... Sheet steel

Surface finish: .................................... EPS plastic coating

Colour: ............................................ RAL 7035 (light grey)

Seals:......................................................... Natural rubber

Max. operating temperature: ..................................... 40°C

Max. operating pressure: .......................................... 7 bar

Capacity: ................................................................... 100 l

Dosing rate:....................... Approx. 10 g/s (see Appendix)

Other materials available for special applications.

Pneumatic power consumption:

Compressed air:................................................. 6 bar, dry

Consumption per dosing cycle: .................. Approx. 2 m³N

*

Electrical power consumption:

Magnetic valves: ...................................... 24 VDC / 4.5 W

Cyclic duration factor:............................................... 100%

Noise emission (partially optional):

Continuous sound pressure level:.................. < 70 dB(A)

**

Ambient conditions:

Ambient temperature:......................................... 5 to 40°C

Floor:............................. Level surface, free from vibration

Atmosphere:................................................ Non-corrosive

7.2 Order-specific data

The order-specific data can be taken from the name-plate.

*N = Normal conditions (roughly equivalent to the “suction

capacity” of a compressor)

** Test set-up: Distance from the dust collector: 1 m,

height above floor: 1.60 m

8 Transport and storage

Transport

•The transport lock must not be removed until the system

has reached its place of use.

•Do not lift the dosing device by the handles.

Storage

•Always store in the original packaging.

•Always store in a dry, frost-free room.

Seaworthy packaging is specified in the

contract documentation as an option.

9 Installation

WARNING!

If the system is installed by unauthorised persons:

Risk of injury.

All warranty claims are rendered invalid.

•The system must be installed by a suitably trained

person!

Page 7

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

9.1 Installation

CAUTION!

•Do not install in the vicinity of devices which are

sensitive to vibration.

•Do not lift using the handles!

•Install the dosing device as close as

possible to the dust collector.

•Avoid long distances (> 5 m).

•Lift the dosing device off of the pallet and place it in

position.

•Align the dosing device so that it is exactly level.

•Bolt the dosing device tightly to a firm surface (use

dowels).

•Do not install the dosing device outdoors or in damp

areas.

Fig. 5: Installation

9.2 Installing the piping / pump selection

•All connections must be properly secured (e.g. with

clamps, clamp rings, flange joints, etc.).

•Check that all connections are tight.

9.3 Compressed air supply

CAUTION!

•Lay pipes WITHOUT STRESS!

•Lay hoses so that they CANNOT BE KINKED!

•Keep hoses clear of aisles!

Compressed air quality:

•Oil and water-free

•Free of debris

•Pressure p = 6 bar

•For quality grades, refer to PNEUROP 2001

Connection of the 2/2-way valves:

A: Piston vibrator, filter aid valve

P: Compressed air supply

Fig. 6: Pneumatic connections of the 2/2-way valves

•Install a separate air pressure reducer and

possibly a filter close to the dosing device.

•Install a suitable compressed air shut-off

valve in a readily accessible position (for

maintenance work, etc.).

•Connect the dosing hose to the air inlet pipe.

•All connections must be properly secured (e.g. with

clamps, clamp rings, flange joints, etc.).

•Check that all connections are tight.

•Supply compressed air (1/2”i) to the dosing device.

A

P

3.5 m

Page 8

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

9.4 Electrical connections

DANGER!

Danger of electric shock!

Risk of serious or fatal injury in case of

contact with electrical components.

All electrical installation work must be

carried out by a qualified electrician!

9.4.1 Connection of the 2/2-way valves

DC power supply:.................................24 VDC, 4.5 W

AC power supply (optional): .................... 230 VAC, 16 VA

Fig. 7: Electrical connections of the 2/2-way valves

9.4.2 Calibrating the level sensor (optional)

•Refer to the separate instructions.

9.4.3 Dosing device controller (optional)

The dosing device is controlled by means of an FG

controller.

•Refer to the separate instructions.

10 Start-up

DANGER!

This device must not be put into service until the relevant

machinery into which it is to be incorporated has been

declared in conformity with the applicable EC directives,

harmonised standards, European standards or equivalent

national standards.

10.1 Initial start-up or start-up after prolonged

shut-down

•Inspect all system components.

•Remove all parts that do not belong (e.g. tools,

installation waste, etc.).

•Check the pipe connections (e.g. clamps).

•Tighten all screws and bolts.

10.2 Starting up the dosing device

•Connect the compressed air supply.

•Switch on the controller.

•Check the level in the filter aid tank.

11 Normal operation

DANGER!

Danger due to high pressure in the dust collector!

Risk of injury to persons or damage to property.

Shut off the compressed air and vent the system prior to

working on devices with an air injector loosening system!

Always dispose of the concentrate in an

environmentally responsible way!

Consult the responsible authorities before

deciding upon the most suitable disposal

method.

The dosing device works largely automatically during normal

operation.

•Check the dosing device in accordance

with the inspection and maintenance

schedule (refer to section 14.1).

Topping up the filter aid

•Wear protective clothing and equipment appropriate to

the hazard potential of the medium (e.g. eye protection,

respirator, protective clothing, etc.).

•Shut off the compressed air and vent the system prior to

working on devices with an air injector loosening system!

24 VDC

230 VAC

*

A

P

Page 9

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

12 Shutting down the dust collector

12.1 Temporary shut-down

•Switch off the fan or shut down the dusty system.

•Switch off the dosing device controller.

•Switch off the compressed air supply.

12.2 Prolonged shut-down (> 48 h)

•Empty the filter aid tank.

•Blow the injector nozzle clean several times (either

manually or by means of the controller).

•Switch off the fan or shut down the dusty system.

•Switch off the dosing device controller.

•Switch off the compressed air supply.

•Disconnect any electrical connections.

•Carry out the maintenance work.

12.3 Emergency shut-down

•Activate the EMERGENCY STOP device (e.g. mushroom

button, to be provided by the customer).

12.4 Transporting the dosing device

•Shut down the dosing device as described in section

12.2.

•Disconnect the compressed air supply.

•Disconnect the electrical connections.

•Transport the dosing device as described in section 8.

13 Troubleshooting

Fault

Possible cause

Remedy

No filter aid

supplied

Tank empty

Top up the filter

aid (refer to

section 11)

Not enough

compressed air

Check the air

pressure

(6 bar)

Filter elements

clogged

Injector clogged

Blow out the

injector

Dosing rate too

low

Select a shorter

interval time

Select a longer

pulse time

•For all other faults, please contact FG Customer Service.

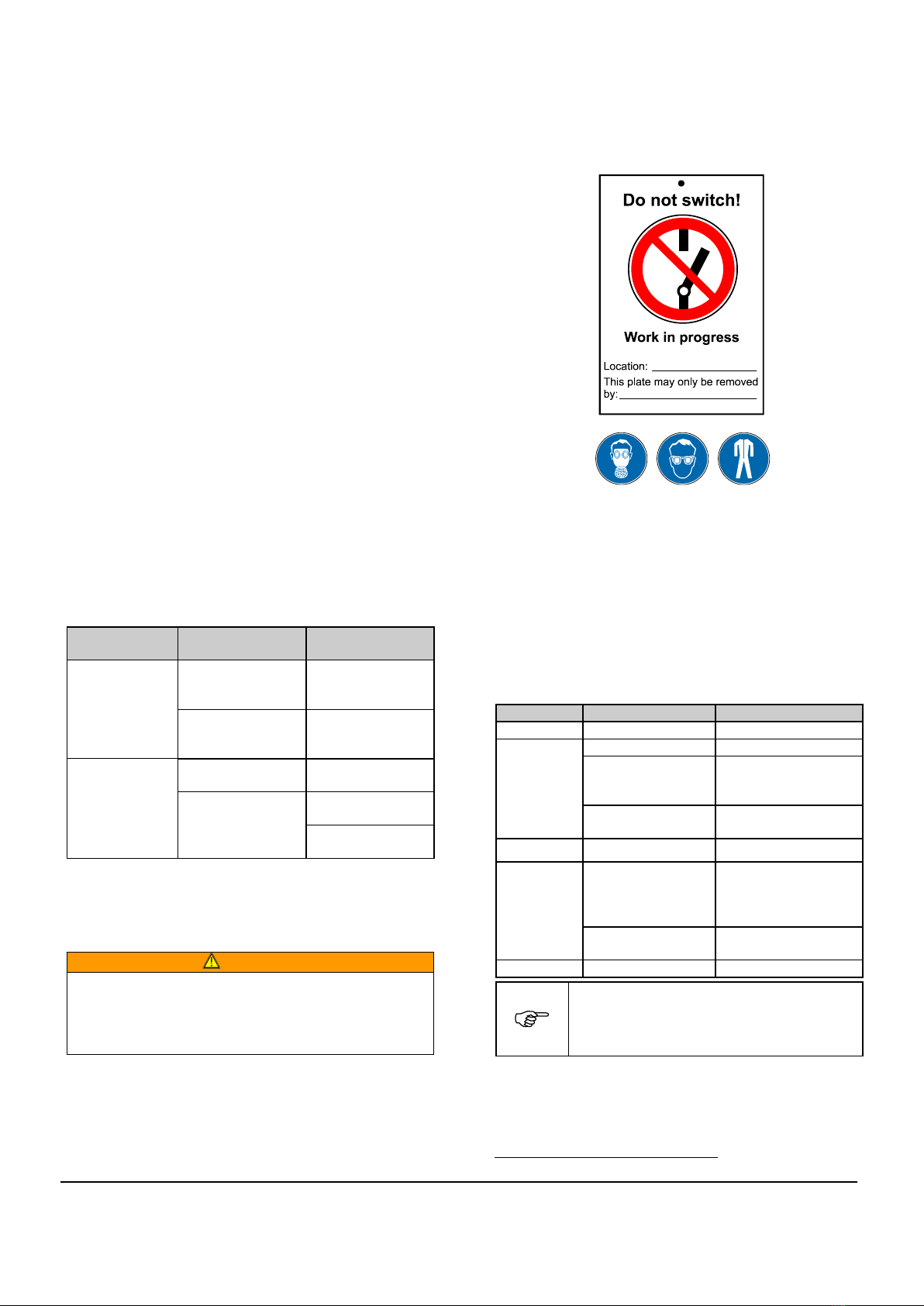

14 Maintenance

WARNING!

If the system is maintained by unauthorised persons:

Risk of injury.

All warranty claims are rendered invalid.

All maintenance work must be carried out by a suitably

trained person!

Before all maintenance work:

•Shut down the dust collector / system / dosing device.

•Switch off the compressed air supply.

•Take steps to prevent the machine / system from being

switched on again by unauthorised persons.

•Wear protective clothing and equipment appropriate to

the hazard potential of the medium (e.g. eye protection,

respirator, protective clothing, etc.).

•Carry out the maintenance work.

•Start up the dust collector / system / dosing device again.

•Observe the dust collector / system / dosing device.

•Does it operate normally?

14.1 Inspection and maintenance schedule

•See also contract documentation.

Interval

Component

Activity

Daily

Storage tank

Check the level

Weekly

Dosing device

Visual inspection

Compressed air

maintenance unit

Visual inspection

Empty the water

separator

Tank

Visual inspection, top

up if necessary

1

Monthly

Connections

Tighten

Yearly

(or

whenever

necessary)

Compressed air

connections

Check

Air breather

Replace the filter

element

Regularly

Filter mat in cover

Clean

The necessary inspection and maintenance

work is dependent on the particular

application.

Please consult the manufacturer if necessary.

1Check more often with short cleaning cycles.

Page 10

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

15 Appendix: Dosing device parameters

Date

Piston vibrator

Injector

Dosing rate

Remarks

Pressure

Duration

Interval

Pressure

Duration

Interval

HI 26

bar

s

s

s

s

s

kg/h

Example

6

1.5

120

5

1

10

3.3

Page 11

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

16 Declaration of incorporation

As defined by the EC Machinery Directive

Page 12

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

Page 13

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

Page 14

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

Page 15

Translation of the original instructions with installation instructions, Filter aid dosing device SDG-100, Filtration Group GmbH, 16.01.19, Mat. No.

79792383, Version 04

17 Index

C

Clean air side..................................................................... 5

Cleaning............................................................................. 5

Compressed air ......................................................... 6, 7, 9

Compressed air supply ...................................................... 7

Concentrate ....................................................................... 8

Continuous sound pressure level....................................... 6

Contract documentation..................................................... 4

D

Dew point........................................................................... 3

Dirty air side....................................................................... 5

Dosing cycle ...................................................................... 6

E

Environmental protection ................................................... 3

F

Fan .................................................................................... 9

Filter aid............................................................................. 3

Filter elements ................................................................... 9

I

Injector nozzle.................................................................... 3

L

Leakage............................................................................. 2

Level sensor.......................................................................8

M

Magnetic valve ...................................................................6

Manufacturer ..................................................................2, 4

P

Pilot control.........................................................................3

Pressure difference ............................................................3

Problem dust ......................................................................4

Protective clothing and equipment .................................8, 9

R

Residual dust content.........................................................3

Risks...................................................................................2

Rotating wing......................................................................7

S

Safety instructions ..............................................................2

Seaworthy packaging .........................................................6

V

Valves.................................................................................3

Velocity...............................................................................3

W

Warning ..............................................................................2

Filtration Group GmbH

Schleifbachweg 45

D-74613 Öhringen

Phone +49 7941 6466-0

Fax +49 7941 6466-429

fm.de.s[email protected]

www.industrial.filtrationgroup.com

77972383.I04.01/2019

Table of contents

Popular Dispenser manuals by other brands

Franke

Franke DVS SD99-009 Installation and operating instructions

Heinz

Heinz Keystone AF08 user manual

Lacava

Lacava EX26 owner's manual

Igloo

Igloo IGLWCRFTL353CRHWH instruction manual

Hilti

Hilti HIT-P 8000 D Original operating instructions

Lily Corporation

Lily Corporation CD65 Operation and service manual

GESAME

GESAME MH Super 114 instruction manual

Scotsman

Scotsman Meridian HID Series manual

Coastwide Professional

Coastwide Professional ExpressMix instruction manual

Fisherbrand

Fisherbrand 12867913 instruction manual

ViscoTec

ViscoTec preeflow eco-DUOMIX450 Operation & maintenance manual

Keurig

Keurig K10 Mini Plus owner's manual