DEMA Nitro Express User manual

I-974

Rev. J-43

Overv

i

The DEMA

and dish ma

c

p

otentiomet

e

Warni

n

816 3/

2

ew

Nitro Express

c

hines. The u

n

e

rs and dip sw

i

n

gs

Installat

i

b

y natio

n

regulati

o

For que

s

All inst

a

devices.

codes in

ALWA

Y

CHEM

I

2

3/18

D

Ware

is an analog

w

it is triggered

b

i

tches.

i

on of DEMA

p

n

al, city, coun

t

o

ns require tha

t

s

tions, contact

a

llations must

c

A pressure in

d

the state of W

Y

S WEAR P

R

I

CAL PROD

U

D

EMA

N

Wash

C

w

are wash disp

e

b

y a ware was

h

p

roducts must

t

y, parish, pro

v

t

a certified el

e

a

certified ele

c

c

onform to loc

a

d

icating tee is

t

isconsin and a

n

R

OTECTIVE

C

U

CTS.

N

itro E

x

C

hemica

l

e

nser designe

d

h

machine. Pr

o

meet all appli

c

v

incial or othe

r

e

ctrical contra

c

c

trician.

a

l plumbing c

o

t

o be installed

w

n

y other state

t

C

LOTHING A

N

x

press

l

Dispe

n

d

to dispense c

l

o

gramming is

a

c

able electrica

l

r

agencies. It i

s

c

tor or enginee

r

o

des and use a

p

w

ith existing

f

t

hat requires t

h

N

D EYEWE

A

Pa

g

n

se

r

l

eaning chemi

c

a

ccomplished

t

l

codes and re

g

s

possible that

e

r

perform the

e

p

proved backf

l

f

aucets accordi

h

e use of a pre

s

A

R WHEN W

O

g

e 1 of 8

c

als into ware

w

t

hrough the us

e

g

ulations estab

l

e

lectrical code

e

lectrical insta

l

l

ow preventio

n

ng to local pl

u

s

sure indicatin

g

O

RKING WIT

H

w

ash

e

of

l

ished

s and

l

lation.

n

u

mbing

g

tee.

H

I-974

Rev. J-43816 Page 2 of 8

3

/

23/18

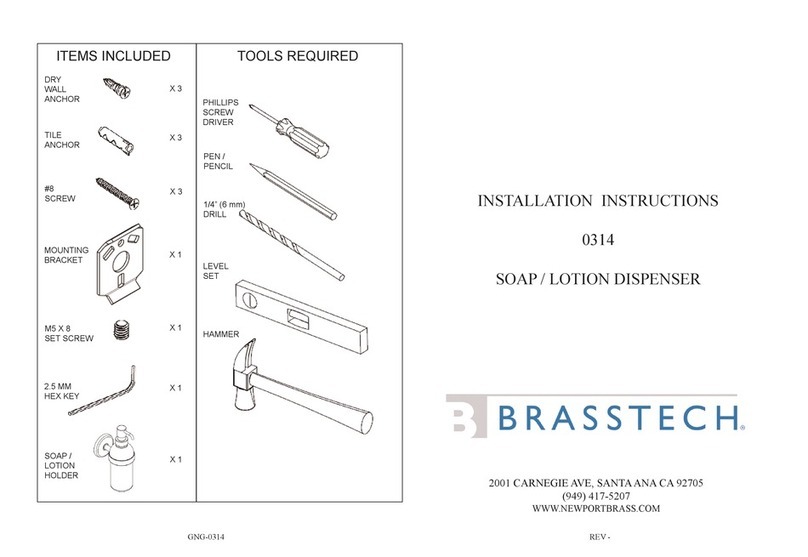

Packing List

X = included in kit

Part Number

Description

NE.DL.A

NE.LL.A

NE.DLL.A

NE.LLL.A

904.8T RINSE CHECK VALVE ¼” OD TEFLON BALL

X

X

X

X

80.55 LIQUID DETERGENT FEED INJECTION ELBOW

X

X

81.312.1 SPLIT PICK UP TUBE STIFFENER

1

2

2

3

25.68.20 20 FT ¼” OD LDPE TUBING

X

X

X

X

C.12B CONDUCTIVITY CELL

X

X

X

X

100.12.SV1 VINYL RINSE TUBING

X

X

X

X

58.5 OVERFLOW ELBOW KIT – DRY DETERGENT

X

X

904.8KY RINSE CHECK VALVE ¼” COMP X 1/8” NPT KYNAR

X

X

81.16.1 TIE WRAPS 8” LONG

5

5

8

8

I974 INSTRUCTION SHEET

X

X

X

X

Operational Requirements

For indoor use only

Trigger Signal Inputs 115/230VAC 50/60 Hz 1.5A

Motors/Solenoid Valves 24VDC

Detergent Pump Rate 6oz/min (180ml/min)

Rinse/Sanitizer Pump Rate 1.3oz/min (40ml/min)

Operating Temp 4-30°C 40-100°F

Case Material ABS

The integrity and operational characteristics of this unitare not guaranteedoutside the above

mentionedparameters.Useofthisunitoutsideoftheseparametersnullifieswarranty.

This unit will only accept up to 265 VAC. It cannot accept over this amount. If more than 265

VAC is supplied to this unit, critical damage will occur.

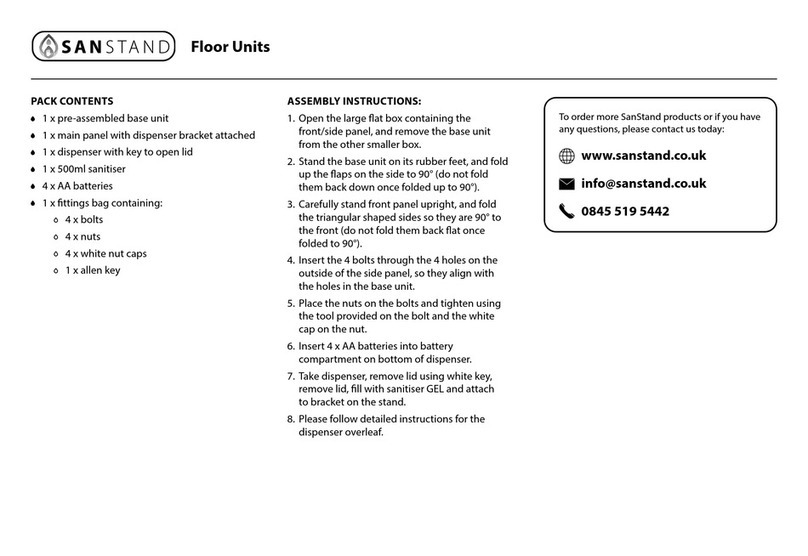

Overall Size

I-974

Rev. J-43816 Page 3 of 8

3

/

23/18

Replacement Parts List

81.316.6 NITRO/NITRO EXPRESS DETERGENT

VALVE CONV. AND REPLACEMENT KIT

58.104.2- J.G. ELBOW FITTING FOR VALVE

81.316.7 NITRO/NITRO EXPRESS

SANITIZER PUMP CONVERSION

KIT INCLUDING CONTROL BOARD

(NOT SHOWN)

O.A DC NITRO/NITRO EXPRESS

SANITIZER PUMP WITH TUBING

AND ACCESORIES

Model shown is of a NE.LL.A

NO. KIT NO. DESCRIPTION

1 81.316.1

NITRO/NITRO EXPRESS POWER SUPPLY REPLACEMENT KIT (TRIGGER OUTPUT

TRANSFORMER)

2 81.316.2 CONTROL BOARD NITRO EXPRESS FOR 2 PRODUCT (DETERGENT/RINSE)

81.316.3 CONTROL BOARD NITRO EXPRESS WITH SANITIZER (3 PRODUCT)

3 81.316.4 NITRO/EXP. DETERGENT PUMP HEAD AND MOTOR CONV. AND REPLACEMENT KIT

81.316.10 NITRO/NITRO EXPRESS DETERGENT MOTOR ONLY REPLACEMENT KIT

81.316.6 NITRO/NITRO EXPRESS DETERGENT

V

ALVE CONVERSION AND REPLACEMENT KIT

4 81.316.5 NITRO/NITRO EXPRESS RINSE PUMP HEAD AND MOTOR REPLACEMENT KIT

81.316.11 NITRO/NITRO EXPRESS RINSE MOTOR ONLY REPLACEMENT KIT

5

81.316.8 NITRO/NITRO EXPRESS DETERGENT PUMP HEAD ONLY REPLACEMENT KIT

81.316.9 NITRO/NITRO EXPRESS RINSE PUMP HEAD ONLY REPLACEMENT KIT

25.21.4 SINGLE SQUEEZE TUBE REPLACEMENT

25.21.5 BULK (5) SQUEEZE TUBE REPLACEMENT

6 L1115 MEMBRANE LABEL

7 81.275.1 MOUNTING BRACKET

I-974

Rev. J-43

Install

a

ALL ELE

C

MACHINE

UNIT MUS

Mountin

g

t

h

1. Re

m

2. M

o

3. Sli

d

Settin

g

up t

1. Lo

c

ma

n

2. Pr

o

3. If t

h

12

B

of

t

4. Ins

t

rea

d

5. Ins

t

ma

c

6. Ins

t

ma

n

thi

s

Connectin

g

1. Aft

e

co

n

an

d

2. Cu

t

ch

e

3. Me

4. Cu

t

Clasp Clos

e

The pum

p

help to ensu

r

When

p

ushi

n

clip is fully

c

p

icture. If t

h

p

ossibility o

the second

p

Wirin

g

the

N

The followi

n

816 3/

2

a

tion

WARN

I

ELECT

COUN

T

ELECT

ELECT

INSTA

L

C

TRICAL PO

W

PRIOR TO

B

T BE GROU

N

h

e Nitro Exp

r

m

ove mountin

g

unt the

b

racke

t

d

e the dispens

e

he Nitro Exp

r

c

ate the electri

c

n

ufacturer of t

h

perly ground t

h

h

e Nitro Expr

e

B

probe in the

w

t

he tank, and

m

t

all the deterg

e

d

ing of all che

m

t

all the rinse li

n

c

hine. If a tap

i

t

all the sanitiz

e

n

ufacturer of t

h

s

fitting.

the Chemica

l

e

r mounting t

h

n

tainers. The d

e

d

sanitizer tubi

n

t

the tubing to

t

e

mical contain

e

asure the leng

t

t

the tubing to

t

e

Pump Head

s

p

heads have

a

r

e the pump h

e

n

g the pump h

e

c

overing the n

o

h

e tab is not ful

f it popping o

f

p

icture.

N

itro Expres

s

n

g diagram is i

n

WARN

I

OVER

T

WARN

I

tri

gg

er

s

manufa

c

UNIT

M

2

3/18

I

NG: INSTA

L

R

ICAL COD

E

T

Y, PARISH,

R

ICAL COD

E

R

ICAL CON

T

L

LATION. F

O

W

ER MUST

B

B

EGINNING

N

DED (EAR

T

r

ess

g

bracket from

t

in an appropr

i

e

r onto the

b

ra

c

r

ess and the

D

c

al connection

h

e machine to

d

h

e dispenser t

o

e

ss will be ope

r

w

ash tank. Th

e

m

ust be kept a

w

e

nt injection b

u

m

icals enterin

g

n

e injection fit

t

i

s not provide

d

e

r injection fitt

i

h

e machine. If

l

Tubin

g

to th

h

e dispenser,

m

e

tergent tubin

g

n

g (100.12.SV

t

he length req

u

e

r.

t

h of tubing ne

e

t

he length req

u

s

a

n added featu

r

e

ad is installed

e

ad on be sure

o

tch as seen in

ly engaged, th

e

f

f the pump he

a

s

to the Dish

M

n

cluded to hel

p

I

NG: ONLY

U

T

HAT AMO

U

I

NG: For safe

t

s

i

g

nals to the

N

c

turer’s reco

m

M

UST BE GR

O

L

LATION O

F

E

S AND RE

G

P

ROVINCI

A

E

S AND RE

G

T

RACTOR

O

O

R QUESTI

O

B

E TURNED

INSTALLA

T

T

HED).

dispenser.

i

ate place on a

c

ket and attach

D

ish Machine

point. The in

p

d

etermine if t

h

o

earth ground.

r

ating in the c

o

e

probe must

be

w

ay from heati

n

u

lkhead fitting

g

the wash tan

k

t

ing (904-8T)

i

d

, follow the

m

i

ng (904-8KY

)

a tap is not pr

o

e

Nitro Expr

e

m

easure the len

g

g

(25.68.20) is

1) which is cle

a

u

ired and, if de

s

e

ded to go fro

m

u

ired to reach t

h

r

e which will

properly.

to see the

the first

e

re is a

a

d as seen in

M

achine

p

to install the

U

P TO 265 V

A

U

NT WILL C

A

ty

purposes d

i

N

itro Express

m

mendations.

O

UNDED (E

A

F

DEMA PRO

G

ULATIONS

A

L OR OTHE

R

G

ULATIONS

O

R ENGINE

E

O

NS, CONTA

C

OFF TO TH

E

T

ION

wall.

the secure scr

e

p

ut power may

h

ere are dedica

t

o

ncentration m

o

e

installed

b

elo

w

n

g elements, p

u

(80-55) above

k

.

i

nto the rinse l

i

m

anufacturer’s

r

)

(if sanitize

r

i

s

o

vided follow

t

e

ss

g

th of tubing n

e

opaque in col

o

a

r in color and

s

ired, place th

e

m

the dispense

r

h

e bulkhead fi

t

wires in the c

o

A

C SHOULD

A

USE CRITI

C

i

sconnect mai

. Connect po

w

A

RTHED).

O

DUCTS MU

S

ESTABLISH

R

AGENCIE

S

REQUIRE T

H

E

R PERFOR

M

C

T A CERTI

E

HEATING

e

w on the

b

ott

o

be 100V – 26

5

t

ed terminals a

o

de, locate the

w

the water le

v

u

mp intake, dr

a

the probe (if

a

ine tap provid

e

r

ecommendati

o

s

used) into th

e

t

he manufactu

r

e

eded to go fr

o

o

r and has a la

r

has a small in

s

e

pickup tube

o

r

to the chemic

t

ting or chemi

c

o

rrect places f

o

BE SUPPLI

E

C

AL DAMA

G

i

n power to th

w

er to the Nit

r

Pa

g

S

T MEET AL

H

ED BY NAT

I

S

. IT IS POS

S

H

AT A CER

T

M

THE ELE

C

FIED ELEC

T

ELEMENTS

o

m left corner

o

5

V 50/60 Hz.

C

a

vailable for in

s

proper

p

ositio

n

v

el, normally 1

a

ins and inco

m

a

probe is used

)

e

d by the man

u

o

ns for installi

n

e

rinse line tap

r

er’s recomme

o

m the dispens

r

ger inside dia

m

s

ide diameter.

o

n the tubing

be

al injection po

c

al injection p

o

o

r proper pow

e

E

D TO THIS

U

G

E TO THE

U

e dish machi

n

r

o Express pe

r

g

e 4 of 8

L APPLICA

B

I

ONAL, CIT

Y

S

IBLE THAT

T

IFIED

C

TRICAL

T

RICIAN.

AND DISH

o

f the dispens

e

C

heck with th

e

s

tallation.

n

for the DEM

A

-2” from the

bo

m

ing water sup

p

)

to obtain a ra

p

u

facturer ofth

e

n

g this fitting.

provided by t

h

e

ndations for i

n

er to the chem

i

m

eter than the

r

e

fore placing i

n

int on the ma

c

o

int on the ma

c

e

r for the unit.

U

NIT. ANYT

H

U

NIT.

n

e before wiri

n

r

the dish ma

c

B

LE

Y

,

e

r.

e

A C-

o

ttom

p

ly.

p

id

e

h

e

n

stalling

i

cal

rinse

n

the

c

hine.

c

hine.

H

ING

ng

c

hine

I-974

Rev. J-43816 Page 5 of 8

3

/

23/18

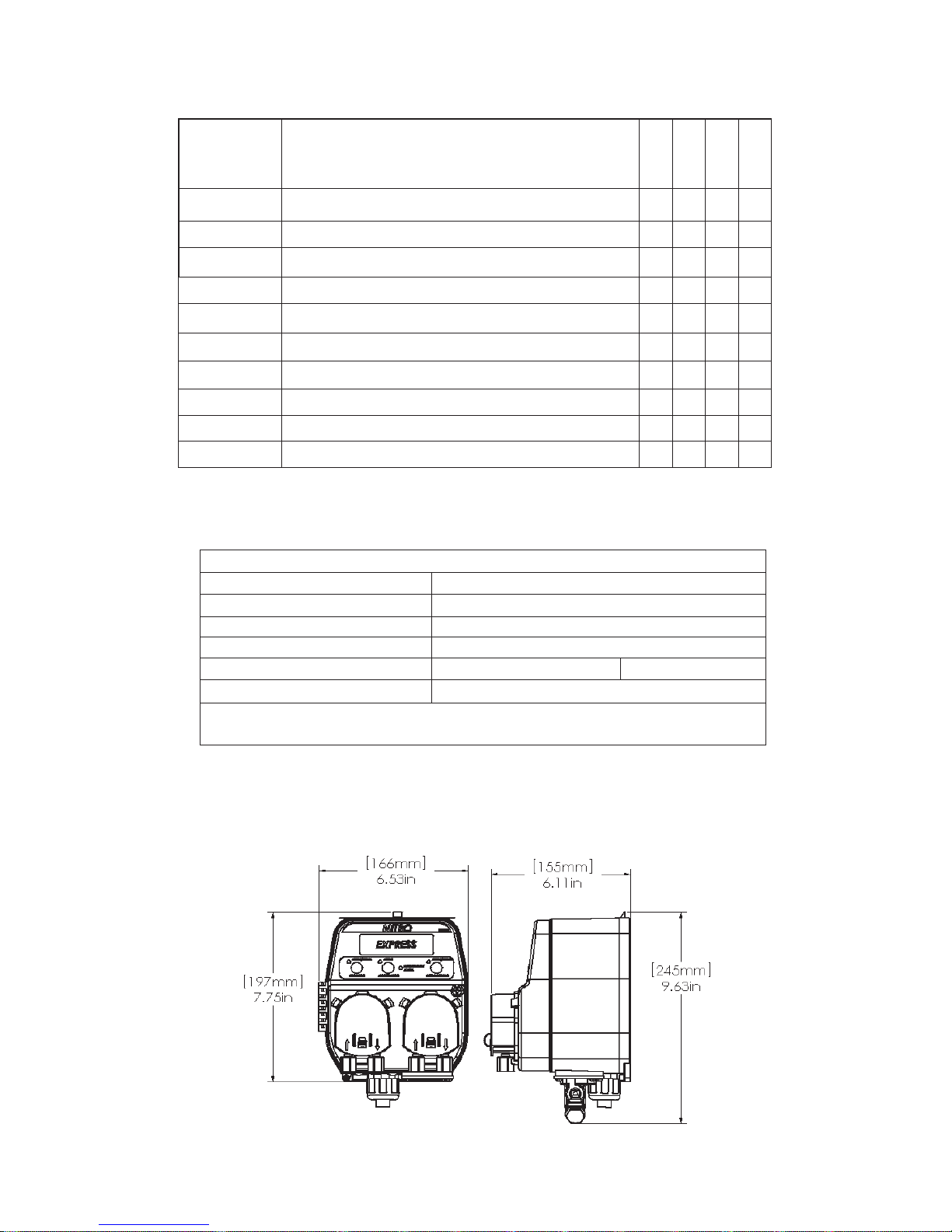

The following steps will help to insure the proper wiring of the unit. The unit should be triggered to power on from the

dish machine that it is being used in conjunction with. DEMA Engineering does not recommend powering the unit

separately from the dish machine. The following three steps will insure that the unit only receives power when it is

necessary to have power to run the setup that is programmed in the unit.

1. Connect the wash trigger (white and brown wires) to the appropriate wash trigger output (between 100 and 265

VAC 50/60Hz) as recommended by the dish machinemanufacturer.

2. Connect the rinse trigger (black and red wires) to the appropriate rinse trigger output (between 100 and 265

VAC 50/60 Hz) as recommended by the dish machine manufacturer.

3. Make sure to connect the earth ground (green wire) to the ground connection on the dish machine as

recommended by the dish machine manufacturer.

If there is ever any question about the connection to the dish machine, please check with the dish machine

manufacturer to see where the proper trigger connection points are located before installing the trigger

connection wires.

Below is a wiring diagram for the unit. This is the internal wiring of the unit.

Programming the Nitro Express

Programming is done through the setting of dip switches and potentiometers (knobs). The following states how to

program the Nitro Express.

Changing Settings

When switches are changed or pots are turned, the settings will take effect immediately. In the case that the unit is

processing the previous settings, it will finish the current cycle before the new setting is used. If the Probe/Probeless or

Door/ Conveyor Settings are changed, the unit will start the cycle over immediately.

BROWN – WASH TRIGGER (HOT)

WHITE – WASH TRIGGER (RETURN)

BLACK – RINSE TRIGGER (HOT)

RED – RINSE TRIGGER (RETURN)

GREEN – EARTH GROUND

DISH

MACHINE

ELECTRICAL

CONNECTION

POINT

I-974

Rev. J-43816 Page 6 of 8

3

/

23/18

F

Dip Switches

The following diagram illustrates what the different switches refer to so that the Nitro Express can be set up for the

proper situation.

The dip switches are set up so that the “up” position is “on” and the “down” position is “off”.

O ON

PRESS DOWN THIS

F WAY FOR ON

PRESS DOWN THIS

WAY FOR OFF

OFF

Potentiometers (Knobs)

The potentiometers can be set according to the following charts. Each of the next four figures will outline various

configurations that are possible. For more information on these configurations consult pages 5-6 to see how to set up the

dip switches for the configurations.

Rinse/Sanitizer Settings

4 5 6

3 7

2 8

1 9

0 10

Rinse

The Rinse and Sanitizer knobs control the same setting

whether in probe or probeless mode and in door or conveyor

mode. They control the speed of the rinse and sanitizer pump.

The table to the right has approximate values for the pump

rate at different settings of the knob.

Only the DLL and LLL models have a sanitizer

potentiometer.

Probeless and Door Configuration

4 5 6

3 7

2 8

1 9

0 10

Detergent

4 5 6

3 7

2 8

1 9

0 10

Initial Detergent Charge – The detergent knob sets the time the

detergent pump will run or detergent valve will remain open during an

initial charge. The time can be set from 0-60 sec.

The initial charge is activated in one of two ways.

1.It can be activated by 1 hour of elapsed time where no triggers have

activated the dispenser.

2.With the rinse limit turned on (switch 7) and a rinse trigger active for

more than 20 seconds, an initial charge will be dispensed.

Dead Cycles – The alarm knob sets the number of cycles no

detergent is dispensed before a recharge portion of detergent is added

to the machine.

The table to the right has the different settings for the Dead Cycle

count corresponding to the knob setting.

Alarm (Dead Cycles)

PROBELESS

MODE

CONCEN.

MODE

CONVEYOR

MODE

DOOR MODE

NORMAL

RANGE

HIGH RANGE

PULSE FEED

OFF PULSE FEED

ON

PLUS 0 SEC

RINSE

DELAY

PLUS 2 SEC

RINSE DELAY

PLUS 0 SEC

RINSE

DELAY

PLUS 4 SEC

RINSE DELAY

20 SECOND

RINSE LIMIT

ON

RINSE LIMIT

OFF

ALARM VOL

LOW ALARM VOL

HIGH

RINSE/

SANITIZER

SETTING

PUMP RATE

0

0 ml/min

2

8.5 ml/min

4

27 ml/min

6

33 ml/min

8

40 ml/min

10

43 ml/min

DETERGENT

INITIAL

CHARGE

SETTING

0-60 sec

0-170 ml

0-5.75 oz

ALARM

SETTING DEAD

CYCLES

2

0

4

1

6

2

8

3

I-974

Rev. J-43816 Page 7 of 8

3

/

23/18

4 5 6

3 7

2 8

1 9

0 10

Recharge

Detergent Recharge – The recharge knob sets the pump run time for

a recharge. The recharge takes place after the dead door cycles have

been reached.

The table to the right explains the differences in the Normal and High

range setting (switch 3).

Probeless and Conveyor Configuration

4 5 6

3 7

2 8

Initial Detergent Charge – Same as Probeless and Door above.

1 9

0 10

Detergent

4 5 6

3 7

2 8

1 9

0 10

Dwell Time – The alarm knob sets the amount of time before a detergent

recharge portion is dispensed.

The table to the right has the different settings for the dwell time

corresponding to the knob setting.

Alarm (Dwell Time)

4 5 6

3 7

2 8

1 9

0 10

Recharge

Detergent Recharge – The recharge knob sets the pump run time

for a recharge. A recharge will take place after the dwell time has

elapsed.

The recharge amount has two settings – normal and high (switch 3

sets the range).

Probe (Concentration) Configuration

The settings for the probe configuration are the same when the dispenser is being used in door or conveyor mode.

4 5 6

3 7

2 8

Detergent Concentration Level – The detergent knob sets the

concentration level or set point. DEMA Engineering recommends

starting in normal range (set using switch 3) and using a titration kit to

achieve the desired detergent concentration level.

1 9

0 10

Detergent

4 5 6

3 7

2 8

Alarm Time– The alarm knob sets the time that the dispenser will allow

itself to reach the detergent concentration level. An audible alarm will

sound if the concentration level is not reached in the set time.

1 9

0 10

Alarm

4 5 6

3 7

2 8

Recharge – The recharge knob has no function in probe or concentration mode.

1 9

0 10

Recharge

RECHARGE

Normal Range

0-30 sec 0-85 mL

High Range

0-60 sec 0-170

mL

DETERGENT

INITIAL

CHARGE

SETTING

0-60 sec

0-170 ml

0-5.75 oz

ALARM

DWELL

TIME

0-180 sec

RECHARGE

Normal Range

0-30 sec 0-85 mL

High Range

0-60 sec 0-170

mL

DETERGENT

Concentration

Normal Range

High Range

ALARM

TIME

0-180 sec

I-974

Rev. J-43816 Page 8 of 8

3

/

23/18

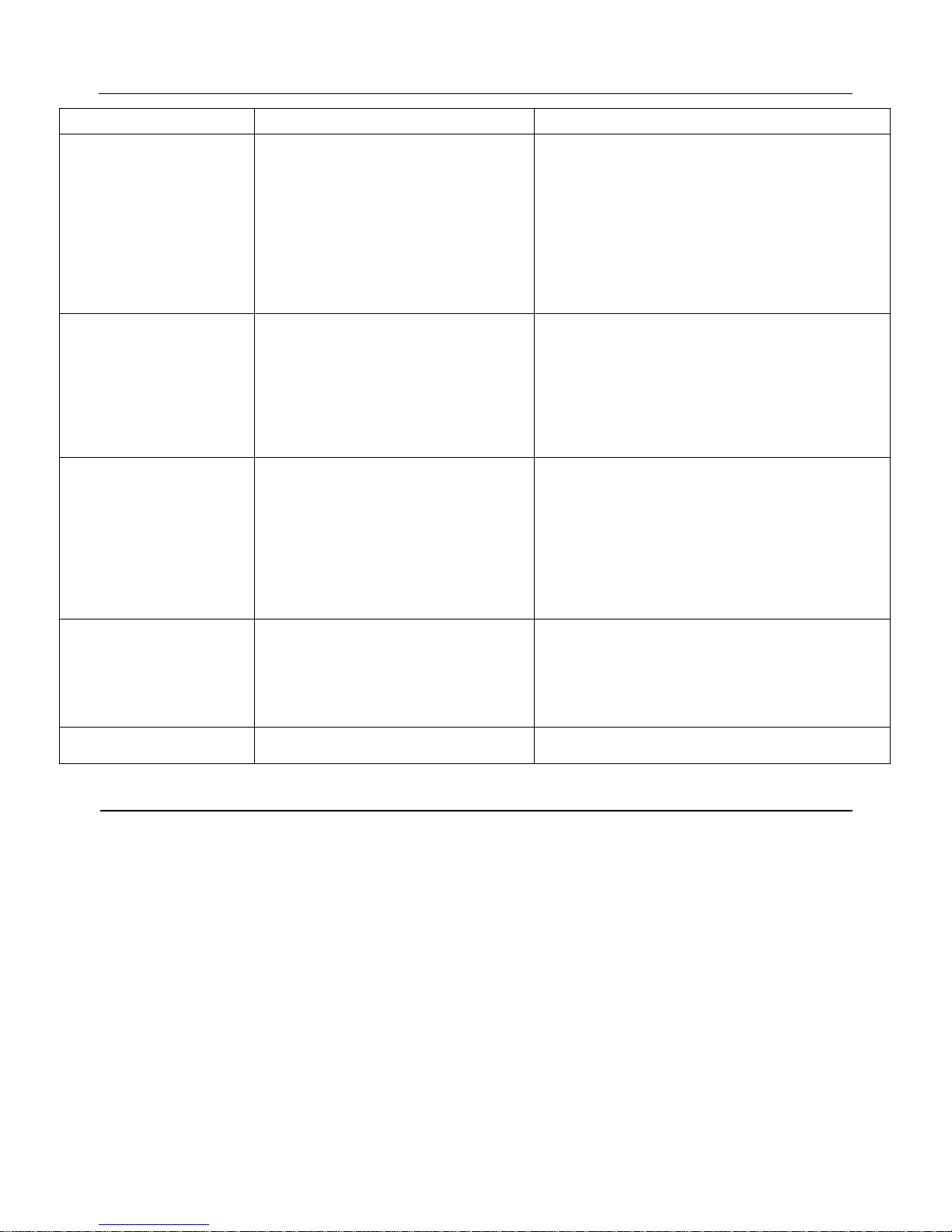

Troubleshooting

(Some models may not include all items listed below)

S

y

mptom Probable Cause Remed

y

No power is being supplied

to the unit 1. Trigger Cables connected to the wrong

place on the machine.

2. Switch on bottom of unit is turned off.

(Some units may not have aswitch)

3. Power is not cycling onthe machine

properly.

4. Trigger/Power cable is damaged from

installation.

1. Check wiring diagram for proper connection and

contact dish machine manufacturer for correct

trigger placement.

2. Make sure switch is turned on.

3. Check with the dish machine manufacturer if all

power should have been restored to the unit to see

if there is an issue with themachine.

4. Turn power to the dish machine off and inspect the

cable for any possible damage done.

Pumps are not priming like

they should be or not

holding a prime

1. Hole in the tubing from the chemical

container to the pump head.

2. Hole in the squeeze tube in the pump

head.

3. Fitting is not tight on the tubing

1. Check the tubing from the chemical container to

the pump head for leaks by feeling the tubing for

chemical that has leaked out. Replace the tube if

necessary.

2. Replace the squeeze tube after inspecting it for a

possible hole or leak.

3. Check both the inlet and outlet fitting and tighten if

necessary to create a good seal.

Pump over feeding 1. If in concentration or probe mode,

Pulse feed may be turned off.

2. If in concentration or probe mode,

probe cable may not be connected

properly.

3. If a probe is being used, scale could be

built up on the probe.

4. Dip switch is on High Range and pot

is set for low range.

1. Check the dip switches and turn the pulse fee

d

on.

2. Check the probe cable connection points and make

sure it is connected properly.

3. Clean Probe.

4. Switch dip switch to low range or set pot to needed

setting.

Pump under feeding 1. If in concentration or probe mode, the

probe cable may beshorted.

2. If a probe is being used, scale would

be build up on the probe.

3. Dip switch is on low range and pot is

set for high range.

1. Check the probe cable for any possible shorts and

correct the issue where necessary.

2. Clean Probe.

3. Check the dip switches and switch to high range if

necessary or set pot to needed setting.

Rinse/Sanitizer pump no

t

running 1. Speed turned off. 1. Check the pot to see the speed setting and make

sure it is turned to the proper setting.

Warranty

Merchandise Returns

No Merchandise will be Returned for Credit Without DEMA’S Written Permission. Returned Merchandise

Authorization Number is Required in Advance of Return.

Product Warranty

DEMA products are warranted against defective material and workmanship under normal use and service for

one year from the date of manufacture. This limited warranty does not apply to any products that have a

normal life shorter than one year or failure and damage caused by chemicals, corrosion, physical abuse, or

misapplication. Rubber and synthetic rubber parts such as “o”-rings, diaphragms, PVC tubing, and gaskets are

considered expendable and are not covered under warranty. This warranty is extended only to the original

buyer of DEMA products. If products are altered or repaired without prior approval of DEMA, this warranty is

void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection shows them

to be defective, they will be repaired or replaced without charge, F.O.B. factory. DEMA assumes no liability

for damages. Return merchandise authorization number must be granted in advance of returned units for repair

or replacement (See “Merchandise Returns”above).

Table of contents

Other DEMA Dispenser manuals

DEMA

DEMA 6300 User manual

DEMA

DEMA SQUIRT DRAIN UNIT User manual

DEMA

DEMA Master Nitro Express User manual

DEMA

DEMA 301B User manual

DEMA

DEMA Nitro Parts list manual

DEMA

DEMA PF651GAP User manual

DEMA

DEMA Nitro Installation guide

DEMA

DEMA One User manual

DEMA

DEMA Trapper User manual

DEMA

DEMA 607T-MC User manual