Filtration Group Air System Products Robo-Drain RD11-T User manual

Robo-Drain

Zero-Loss Condensate Drain

Model RD11-T

AIR SYSTEM PRODUCTS

51 Beach Ave.

Lancaster, NY 14086

716/683.0435

ASPSalesT[email protected]

www.airsyspro.com

Installation & Operation Manual

Making the World Safer, Healthier & More Productive

TABLE OF CONTENTS

GENERAL INFORMATION ............................................................................................................................ 3

SAFETY ....................................................................................................................................................... 3

WARRANTY .............................................................................................................................................. 3

INSTALLATION ....................................................................................................................................... 4

PRODUCT INFORMATION

INSTALLATION ................................................................................................................................. 4

POST-INSTALLATION CHECK ......................................................................................................... 4

TROUBLESHOOTING ....................................................................................................................... 4

OPTIONS ........................................................................................................................................... 4

INSTALLATION CONSIDERATIONS ................................................................................................... 5

RECEIVER ....................................................................................................................................... 5

FILTER AND AFTERCOOLER SEPARATOR ................................................................................. 5

REFRIGERATED DRYER ............................................................................................................... 5

INTERCOOLERS ............................................................................................................................. 5

BALANCE LINE ............................................................................................................................... 5

GENERAL SPECIFICATIONS ............................................................................................................. 6

DIMENSIONAL DRAWING .................................................................................................................. 7

EXPLODED PARTS DRAWING .......................................................................................................... 8

PARTS LIST ......................................................................................................................................... 9

MAINTENANCE ................................................................................................................................... 9

3

GENERAL INFORMATION

SAFETY

Locate, read, understand and follow all Danger, Warning, Caution, and Operating Instructions on the product

and in all Manuals. Failure to comply with safety precautions described in the manuals supplied with the product

this manual or any of the labels and tags attached to the product may result in death, serious injury or property

damage.

Check that all labels, tags and data (name) plates are in place and legible. It is your responsibility to ensure this

information available to others.

If you have any questions about safety or procedures not included in this manual, ask your distributor or contact

Air System Products, LLC.

GENERAL DESCRIPTION

For the condensate to properly enter the Robo-Drain reservoir, the condensate line to the Robo-Drain must

always be installed below the source to be drained. It is equally important to provide a means, such as a balance

line, for the air in the reservoir to be displaced as condensate enters the drain. If the air cannot be displaced, the

condensate will not enter the reservoir. Please review the following suggestions that might best fit your

installation. The use of unions and shut-off valves are recommended for both the condensate line and the balance

line.

WARRANTY

The Robo-Drain is warranted to be free from defects in workmanship and materials for a period of two years from

the date of shipment. The liability of the manufacturer is limited to repair or replacement of the drain at its option.

In no event shall the manufacturer be liable for special or consequential damages or for delay in performances

of this warranty.

4

The Robo-Drain is designed for trouble-free operation.

When installed and operated properly, the Robo-Drain will

provide years of reliable service collecting and discharging

condensate, along with pipe scale and other contaminants

typically found in a compressed air system.

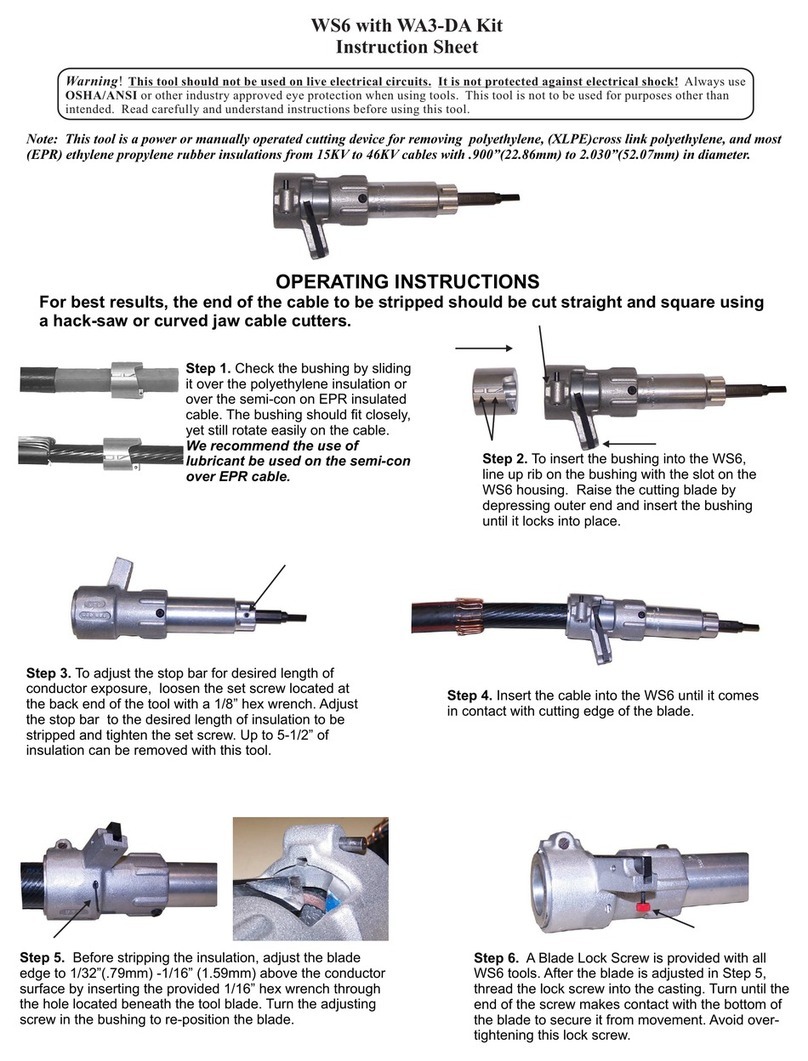

INSTALLATION

Before installing the drain, ensure the source vessel is

isolated from the interconnecting piping to the drain.

Confirm the air system pressure will not exceed the 250 PSI

(17 bar) rating of the drain and the inlet temperature should

not exceed 180 oF (82 oC).

Connecting drain should be done by using one of the

recommended installation diagrams shown on following

page. The installation of a pre-strainer is not required or

recommended.

Install the drain on a level surface and as close to the source

to be drained as possible. Since the Robo-Drain uses gravity

to fill the reservoir, the entire drain must be installed below

the source when using the top inlet. It isn’t recommended

that flexible tubing be used on the discharge to prevent it

from whipping casing damage or injury.

If the drain is to be installed where the temperatures can fall

below 32oF (0 oC), special precautions are needed, including

but not limited to heat tracing pipelines and the optional

immersion heater.

The Robo-Drain will accept condensate from either the

upper or the lower inlet connections. The upper inlet

connection is preferred. The inlet port not used must be

plugged by using a standard plug.

A balance line is highly recommended to avoid an air-lock

condition. The balance line should be connected to the

source device to prevent a flow path for system air or

condensate.

The drain has a 1/8” NPT vent connection to permit easy

installation of a balance line. Use a non-galling pipe sealant

on all joints.

The use of isolation valves and bypass piping will permit

quick and easy routine maintenance.

The Robo-Drain uses compressed air to drive (control) a

drain cycle. ONLY CLEAN DRY AIR MUST BE USED! The

required control air pressure for the standard models,

irrespective of system pressure is 60-130 PSIG (4.1-9.0

barg) Any of the Robo-Drain models can be supplied as an

LP variant and will model should be between 40 and 130

PSIG (2.8 and 9.0 barg).The Robo-Drain is supplied with a

filter for installation on the control head. The use of unfiltered

air can result in failure and can void the product warranty.

Once installed and control air supplied, the drain is ready to

be placed in service.

CHECKING THE OPERATION

After installation is complete and the drain is in service, a

check should be made that the drain is functioning properly.

1. Ensure that condensate is properly entering the

reservoir. This can be easily done looking through the

translucent reservoir

2. Press the test button to ensure the drain valve opens and

closes when the button is released.

3. Inspect for any air or condensate leaks. Correct as

necessary.

TROUBLESHOOTING

If condensation is not entering the reservoir, check for the

following:

1.

Check that any valves between the source and drain are

open.

2.

Check that the balance line is open and properly

installed. Alternatively, that the vent valve is cracked

open.

If the drain is not emptying:

1. Press the test button to force a manual drain cycle. If the

air actuator does not open the valve , check that the

control air supply is at least the minimum pressure

required.

2. If the valve opens, but the drain does not empty quickly,

no more than 20 seconds, ensure that there is system

pressure.

3. If still not emptying, check the downstream piping from

the drain valve to ensure there isn’t a closed valve or an

obstruction.

4. If the drain is still not draining, suggest contacting the

factory.

OPTIONS

High Level Alarm

Mechanical Cycle Counter

Digital Cycle Counter

5

INSTALLATION CONSIDERATIONS

For the condensate to properly enter the drain reservoir, the

condensate line to the drain must always be installed below the

bottom of the vessel to be drained. It is equally important to provide

a means for the air that is contained in the reservoir to escape (vent)

as the condensate enters the reservoir. If the air cannot escape, the

condensate will not enter the reservoir. Below are suggestions on

how to best install the drain on typical types of vessels that have to

drained of condensate. However, it is possible to install the drain

without a balance line (Dwg. not shown), providing the condensate

enters the top inlet and the flow rates are less than 9 GPH (750

SCFM for an aftercooler or 1,500 SCFM dryer) for a 1/2" drain line

and 19 GPH (1,500 cfm for an aftercooler or 3,000 SCFM dryer) for

a 3/4" line. The use of unions and shut-off valves are recommended

for both the condensate line and the balance line.

RECEIVER TANK

The preferred installation for this drain on a receiver tank is having

the condensate enter the top inlet port and having the balance line

go back to the tank at a position that is above the level of the

condensate. (See Dwg. 1).

FILTER and AFTERCOOLER MOISTURE SEPARATOR

If a cyclone separator or filter has pipe plugs located in the top of

the head, the plug closest to the discharge pipe should be removed

and the balance line should be installed (Dwg. 2). If there is no

provision on the cyclone separator or filter for a balance line, install

it in the discharge side of the pipeline and as close to the cyclone

separator as possible.

REFRIGERATED DRYER

If a balance line is required, it must be connected to the port located

on top of the separator that is closest to the discharge side (Dwg.

2), or between the separator and the air-to-air heat exchanger. If a

port is not available as described above, then venting to

atmosphere is recommended. When venting to atmosphere, the

condensate should enter through the bottom entry port on the drain.

The bleed or needle valve is installed on the 1/8" NPT vent port and

allows the air in the drain reservoir to escape to the atmosphere

(Dwg 3). The bleed valve (not included) should be adjusted so that

only 3 to 5 bubbles per second are visible. It is not recommended

to install a vent line downstream from the dryer. The vent line can

be a conduit for transferring moisture from the drain to the

previously dried air. This can result in unwanted moisture being sent

down stream.

INTERCOOLERS

Install the condensate drain line into the upper port only. This will

prevent the possibility of condensate being drawn back into the

intercooler on some systems. It is important that the vent line be

installed on the same stage that is being drained or to atmosphere.

BALANCE LINE

As mentioned above, both the use and the placement of a balance

line is very important. Most drain failures are the result of an

improper balance line installation. The balance line should be 1/4"

tubing or larger, and installed on top of a pipe or vessel, not the

bottom. A needle valve is recommended for controlling the air flow.

Avoid having any loops or low areas in the balance line that might

allow moisture to collect in the line and prevent the passage of air

from the drain’s reservoir.

DWG 1.

DWG 3.

DWG 2.

6

GENERAL SPECIFICATIONS

Inlets: Two (2) 3/4" NPT (BSPP Optional)

Outlet: 1/2" NPT (BSPP Optional)

Power: Clean, Dry Air: 60 - 130 PSI (Standard Design)

40 – 130 PSI (Low Control Pressure Design Option)

Operating Pressure: 0 to 250 PSI

Vacuum and High Pressure Designs Available

Operating Temperature: 32° to 180° F.

Optional Immersion Heater Available

Weight: 17 lbs. (Shipping)

26 lbs. Filled & Installed

Discharge: 24 ounces per cycle

Capacity: 6,600 SCFM at aftercooler*

*Capacity may be more or less depending on application

MATERIALS

Reservoir: Aluminum and Composite

Stainless Steel and Nickel-plated Optional

Drain Valve: Bronze w/SS Ball and Stem (Full SS Optional)

Trigger Float: Stainless Steel

Trigger Seat: Stainless Steel

Trigger Seal: Viton®

Control Tubing: Nylon 66

Stainless Steel Tubing and Fittings Optional

MODEL CONFIGURATION

RD11 -

LP T -

A

-

H

-

SSV

SSE

SS

NPT

BSPP

EXAMPLE: RD13-T-NPT

LEGEND:

LP - Low Control Pressure Design (40-130 PSIG)

T - Test Button (Standard)

A - High Level Alarm

H - Heater

SSV -

SSE -

Stainless-Steel Valve

Stainless-Steel Valve and Control Tubing and Fittings

SS - Complete Stainless-Steel Construction

NPT - NPT Process Connections

BSPP - BSPP Process Connections

7

8

9

SPARE PARTS

(Refer to RD11-T-NPT-EXP drawing on previous page.)

MAINTENANCE

The Robo-Drain has been designed and continuously improved to provide many years of trouble-free service.

Most Robo-Drains outlast the life of the compressor that it is serving.

Still, the Robo-Drain is a mechanical device and routine inspection and maintenance are important and

recommended.

Weekly/Monthly

1. Use the test button to ensure the drain valve opens and closes.

2. Inspect interconnecting piping and tubing to ensure there are no leaks or damage.

Annually

1. Use the test button to ensure the drain valve opens and closes.

2. Inspect interconnecting piping and tubing to ensure there are no leaks or damage.

3. Replace Control Air Inlet Filter.

4. Check the four body bolts to ensure tight.

5. On the standard Robo-Drain with the translucent vessel, if the condensate level isn’t visible due to

vessel coated with contamination, it is recommended to remove the drain from service and follow the

simple disassembly instructions to permit the vessel to be thoroughly cleaned.

6. With the drain disassembled, exercise the float assembly to ensure it moves freely.

7. Again, with the drain disassembled, ensure the float is securely attached to the float bracket.

Item No.

Qty.

Part No.

Description

1

1

RDP-H2-KIT

Control Head Assembly

2

1

RDP-H1-KIT

Inlet Head Assembly

3

1

SSP-COCYL

Translucent Cylinder

4a

2

Cylinder O-Rings

4b

2/2

RDP-SEAL KIT

Trigger Assembly O-Rings

4c

1

Control Air Inlet Filter

5a,b

4/16

RDP-BOLT-KIT

Bolt/Nut Kit

6

1

RD11-FA1

Float and Trigger Block Assembly

7

1

RDP-FIT-KIT

Control Tubing Assembly

8

1

RDP-AC-KIT

Air Actuator Assembly

9

1

RDP-BV-KIT

Ball Valve Assembly

All design specifications subject to change without notice

© 2020 ASP-S-RD-411-101320

AIR SYSTEM PRODUCTS

51 Beach Avenue

Lancaster NY USA

P: +1 716-683-0435

www.airsyspro.com

Table of contents

Other Filtration Group Industrial Equipment manuals

Filtration Group

Filtration Group Air System Products Robo-Drain RD11-VAC User manual

Filtration Group

Filtration Group PuraShield Smart 500 User manual

Filtration Group

Filtration Group Air System Products Robo-Drain RD750 User manual

Filtration Group

Filtration Group Air System Products Robo-Drain RD13 User manual