Filtration Group FG Fluid Solutions AF 73-76 S User manual

Translation of the original instructions with assembly instructions

Automatic metal-edge filters with radial scraper cleaning

AF 73 - 76 S

AF 93 - 96 S

Welded Type

Material No. of Instruction Manual

79301615

Page 2

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

1 Contents

1Contents...................................................................... 2

2General safety instructions....................................... 3

2.1 Safety instructions for installation and

operating personnel.......................................... 3

2.2 Warning structure.............................................. 3

2.3 Warning symbols used...................................... 3

2.4 Other symbols used.......................................... 3

3Glossary...................................................................... 4

4General information................................................... 4

4.1 Manufacturer..................................................... 4

4.2 Information about the Instruction Manual.......... 4

4.3 ATEX type key.................................................. 4

5Intended application .................................................. 5

6Functional description............................................... 5

6.1 Principle of the process..................................... 5

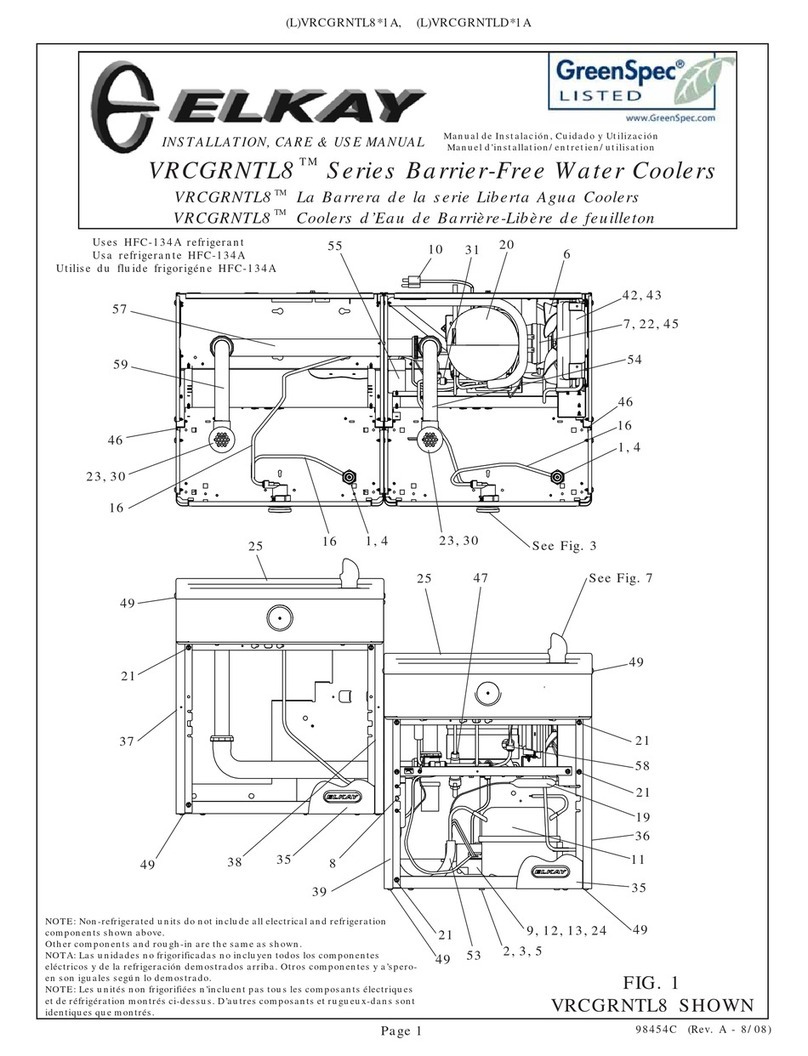

6.2 Main components of the metal-edge filter......... 6

6.3 Functional principle of a metal-edge filter ......... 6

7Technical data............................................................ 7

7.1 General data (without options).......................... 7

7.2 Order-specific data............................................ 7

8Transport and storage............................................... 7

9Assembly instructions............................................... 7

9.1 Mechanical installation...................................... 8

9.2 Special mounting instructions for the drain

pipe................................................................... 8

9.3 Electro-pneumatic connections......................... 8

9.3.1 Connection to customer's control........... 8

9.3.2 Connection to FG controller (optional)... 9

9.4 Control variants................................................. 9

9.4.1 Time-controlled cleaning, manual

draining.................................................. 9

9.4.2 Time-controlled cleaning and draining... 9

9.4.3 Time-controlled cleaning, counter-

controlled draining ................................. 9

9.4.4 Differential pressure/time-controlled

cleaning................................................. 9

10 Start-up ..................................................................... 10

10.1 Functional test ................................................ 10

10.2 Programming the operating settings............... 10

11 Normal operation ..................................................... 11

12 Shutting down the metal-edge filter ....................... 11

12.1 Temporary shut-down..................................... 11

12.2 Prolonged shut-down (> 48 h)......................... 11

12.3 Emergency shut-down.................................... 11

13 Troubleshooting....................................................... 12

14 Maintenance..............................................................12

14.1 Inspection and maintenance schedule............13

14.2 Removing the filter insert ................................13

14.3 Cleaning the filter............................................14

14.3.1 Cleaning the filter insert.......................14

14.3.2 Cleaning the filter housing ...................14

14.4 Replacing the filter element.............................14

14.4.1 To remove the filter element................14

14.4.2 To install the filter element...................14

14.5 Replacing the scraper.....................................15

14.6 Replacing the stuffing box...............................15

14.7 Replacing the bearing bush ............................16

14.7.1 Instructions for type AF 73...................16

14.7.2 Instructions for type AF 74 - 76............16

14.8 Replacing the approach disk...........................16

14.8.1 Instructions for type AF 73...................16

14.8.2 Instructions for type AF 74 - 76............16

15 Spare parts................................................................17

16 Declaration of incorporation ...................................18

17 Declaration of conformity........................................22

18 Index..........................................................................23

Page 3

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

2 General safety instructions

2.1 Safety instructions for installation and

operating personnel

This Instruction Manual contains important safety

instructions which must be heeded at all times during

installation, normal operation and maintenance.

Non-observance can result in the following risks to persons

and the environment as well as in damage to the machine or

system:

Failure of critical functions of the machine or system or of

its component parts.

Danger to persons from electrical or mechanical effects

as well as from chemical reactions.

Danger to the environment owing to the leakage of

hazardous substances.

Before installation/start-up:

Read the Instruction Manual carefully.

Make sure that installation and operating personnel are

adequately trained.

Make sure that the contents of the Instruction Manual are

fully understood by the responsible persons.

Define areas of responsibility and competence.

Prepare a maintenance schedule.

During operation of the system:

Keep the Instruction Manual handy at the place where

the system is used.

Heed the safety instructions. Always operate the

machine/system in accordance with its ratings.

If in doubt:

Consult the manufacturer.

2.2 Warning structure

Where possible, warnings are structured according to the

following system:

Signal word

Possibly

with

symbol

Nature and source of the danger

Potential consequences of non-

observance.

Action to avert the danger.

2.3 Warning symbols used

DANGER!

Immediate danger!

Non-observance will result in serious or fatal injury.

WARNING!

Potentially dangerous situation!

Non-observance can result in serious or fatal injury.

CAUTION!

Potentially dangerous situation!

Non-observance can result in minor or moderate

injuries.

CAUTION! (without a symbol)

Potentially dangerous situation!

Non-observance can result in property damage.

2.4 Other symbols used

Danger from high voltage

Danger information about explosion

protection

Information about environmental protection

Wear protective clothing!

Wear goggles!

Wear a respirator!

Hand symbol:

Indicates general information and

recommendations

Bullet:

Indicates the order in which actions are to be

carried out

Arrow:

Indicates responses to actions

Page 4

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

3 Glossary

Aerosol:

Distribution of minute liquid droplets (or solid particles) in a

gas.

Agglomerate:

Structure made up of several small particles which have

formed a ball (conglomerated) as a result of physical forces.

Cartridge (coiled):

Cylindrical structure consisting of a core element with

triangular wires wound or welded onto it. The suspension

that must be filtered flows inward. Solids are retained on the

outer surface of the cartridge.

Cleaning:

The coiled cartridge is turned and cleaned by a stationary

scraper.

Concentrate:

Quantity of residues enriched with solids. Is discharged from

the filter periodically. Further treatment may be necessary,

depending on the application.

Cooling lubricant:

Cooling lubricant acc. to DIN 51385.

Differential pressure (delta p):

Difference between the pressure on the dirty side and

the clean side.

Draining:

The drain valve is opened. The solids that have collected in

the collection cone are discharged.

Filter cake:

Layer that is built up by the solids retained on the surface of

the coiled cartridge.

Filtered fluid:

Substance that is filtered.

Filtration mode:

The metal-edge filter operates normally and the drain valve

is closed.

Homogenisation:

A system of substances is given a uniform composition.

Initial differential pressure:

Differential pressure at the start of the filtration process

(when the coiled cartridge is “clean”).

Precontrol:

5/2-way magnetic valves actuated by the controller, which

switch pneumatic control valves.

Siphon:

U-shaped pipe. A siphon cannot be discharged without a

valve.

Suspension (raw suspension):

System of substances that must be filtered, generally

consisting of solids in a liquid.

4 General information

4.1 Manufacturer

Filtration Group GmbH

Schleifbachweg 45

D-74613 Öhringen

Phone +49 7941 6466-0

Fax +49 7941 6466-429

www.fluid.filtrationgroup.com

4.2 Information about the Instruction Manual

FG Mat. No.: .......................................................79301615

Date: ....................................................................11.07.19

Version: ................................................................... 13

4.3 ATEX type key

II

2

G

c

T3

1.

2.

3.

4.

5.

1.

II

Valid for use above ground

2.

Use in:

Zone 1

2

Zone 2

3

3.

Atmosphere

G = Gas

D = Dust

G

G

4.

Types of protection

c= Constructional safety

5.

T3 = The maximum surface temperature on the

filtration device is 200°C.

(Field for rating plate)

(Space for ATEX name-plate)

The Ex type of protection is only valid in conjunction with the

declaration of conformity.

Page 5

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

5 Intended application

DANGER!

PROHIBITED:

Use for other purposes without prior consultation with

the manufacturer.

Use in potentially explosive atmospheres, unless

explicitly mentioned in the contract documentation.

Use with smouldering, burning or adhesive particles.

Use with highly explosive dusts (e.g. aluminium dust,

explosives, etc.).

CAUTION!

This FG metal-edge filter is only allowed to be used in

accordance with the operating conditions specified in the

contract documentation and in the Instruction Manual. All

forms of use which deviate from or exceed the limits of

use described above are considered to be contrary to the

intended purpose. The manufacturer shall not be liable

for any damage resulting from such use.

CAUTION!

Conditionally allowed:

Use of solvents in consultation with the manufacturer.

Reverse flow through the filter (pressure < 0.6 bar).

FG metal-edge filters are designed for filtering liquids or

pastes with a viscosity of up to 500,000 mPas. They can be

cleaned without interrupting operation. The cleaning process

can be either manual or automatic.

Types of application:

CLM filtration

Product filtration

Pre-separation within filter cascades

Protective filtration before or after certain process steps

Process filtration

Destruction of unwanted agglomerates

6 Functional description

6.1 Principle of the process

Filtration

A triangular-shaped wire is wound immovably on a

threaded, profiled support tube. The thread lead determines

the gap width and thus the fineness of the filter. The

suspension flows inwards through the filter element. The

particles settle on the outside of the element. The triangular

geometry results in a significant increase in the cross-

section after the narrowest gap. Clogging is thus practically

impossible.

Fig. 1: Principle of separation at the filter element

Cleaning

The particles that settle on the cartridge or on the split tube

cause the differential pressure between the muddy side and

the clean side of the filter element to increase.

If this pressure difference exceeds a (settable) limit value, a

cleaning process is started. The filter element begins to

rotate. The scraper scrapes the filter cake off of the filter

element.

Fig. 2: Cleaning

Filter element

Profiled support tube

Narrowest gap

Increase in cross-section

Triangular

wire winding

Filter cake

Scraper

Profiled

support

tube

Page 6

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

Start of cleaning process

The cleaning process can be started in the following ways:

manually,

with the differential pressure switch,

by means of a time switch,

by the control of a machine tool.

6.2 Main components of the metal-edge filter

Fig. 3: Diagram of the main components

1

Gear motor for driving the filter element

2

Gear (hidden)

3

Suspension inlet

4

Pneumatically or manually actuated drain valve

5

Filtrate outlet

6

Differential pressure measuring (optional)

7

Filter casing

8

Mounting connections

9

Vent plug

6.3 Functional principle of a metal-edge filter

1

The raw suspension flows into the metal-edge filter.

2

The suspension flows through the filter element . In case of

metal-edge filter with pre-separation (optional) the

suspension flows into the outer space downwards and is

reversed below the coils. A part of the solid matters is

already separated.

3

The (pre-cleaned) suspension flows through the filter

element.

The particles settle on this element.

Fig. 4: Functional principle of a metal-edge filter

4

The filtrate enters the clean room and leaves the filter.

5

The cleaning process is started either when the maximum

differential pressure is reached (optional) or after a preset

time.

6

The filter element is rotated by means of the gear motor or

the ratchet. The stationary scraper scrapes off the

separated particles.

The filtration process is not interrupted.

7

The enriched particles on the raw side can be emptied out

periodically.

1

2

3

5

9

5

6

7

8

1

2

3

6

4

5

7

Page 7

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

Pre-separation (optional)

The rough suspension flows first tangentially into an outer

space. A flow whirl moving downwards is created. Below the

pre-separation bushing the flow is reversed. The whirl al

well as the flow reverse cause centrifugal forces on the solid

matter particles. In particular in case of liquids of low

viscosity the pre-separation is improved by this procedure.

Fig. 5: Tangential supply of metal-edge filters with pre-

separation (optional)

7 Technical data

7.1 General data (without options)

Electrical power demand* .............250 VAC/400 V 3NPE

AF 73 S:..............................................................0,18 kW

AF 74 S, 75 S:.....................................................0,25 kW

AF 76 S:..............................................................0,55 kW

AF 93 S:..............................................................0,18 kW

AF 94 S, 95 S:.....................................................0,25 kW

AF 96 S: 0,55 kW

Noise emission (peaks):..................................< 70 dB(A)

Dimensions: .............................................See data sheet

Min. height for dismantling above filter:....See data sheet

Total dry weight without valves: ...............See data sheet

Max. permissible operating pressure: ......See data sheet

Max. permissible differential pressure

in the filter cartridge:............................................< 30 bar

Max. permissible differential pressure

in the split tube:...................................................< 10 bar

*See also name-plate on gear motor

7.2 Order-specific data

The name-plate is rendered invalid if the

coiled cartridge or the filter insert are

modified.

Please request a new name-plate from

the manufacturer.

This data is order-specific and can be taken from the

name-plate.

8 Transport and storage

Transport

Always transport horizontally in the original packaging

Avoid vibrations

Storage

Always store horizontally in the original packaging

Always store in a dry, frost-free room

Seaworthy packaging is specified in the

contract documentation as an option.

9 Assembly instructions

DANGER!

Explosion hazard!

Risk of injury to persons or damage to

property.

This FG metal-edge filter is only allowed to

be installed and operated in the category

specified in the contract documentation

(offer/order confirmation).

If no category is specified: Do not operate

the FG metal-edge filter in a hazardous

area!

The owner is responsible for zoning.

The owner of the plant is solely responsible

for implementing the appropriate explosion

protection measures!

If in doubt, please consult the responsible

authorities.

DANGER!

Explosion hazard!

Risk of injury to persons or damage to

property.

The system is only allowed to be installed,

accepted and tested by a suitably qualified

person (99/98/EC).

WARNING!

If the system is installed by unauthorised

persons

Risk of injury

All warranty claims are rendered invalid

The system must be installed by a suitably trained

person!

Preseparator bushing

tangential supply

Page 8

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

9.1 Mechanical installation

DANGER!

Explosion hazard!

Risk of injury to persons or damage to

property.

Check the conductivity between all

components!

Note the maximum permissible resistance:

R < 10 .

Make sure that earthing is provided by the

customer.

It must be possible to remove the filter insert

in order to carry out maintenance work.

Prepare a suitable seat on which to mount the filter

(e.g. supports).

Be sure to allow the required height for dismantling and

draining (see data sheet).

Replace two opposite screws at the flange cover of the

metal-edge filter by lifting screws.

Lift metal-edge filter at the lifting screws out of packaging.

Bolt the metal-edge filter to the prepared seat.

Remove the caps from the connections.

Connect the pipes.

Pressure relief

Design measures must be incorporated to prevent

inadmissible excess pressure on the dirty side.

Install a pressure relief device if necessary.

Fig. 6: Mechanical installation

9.2 Special mounting instructions for the drain

pipe

WARNING!

The full inlet pressure is present at the drain valve!

Make sure that the drain pipe is securely fastened.

Do not drain concentrate into the atmosphere.

Provide splash protection if necessary.

Lay the pipes without a syphon if possible.

Watch out for clogging as a result of sedimented

concentrate!

9.3 Electro-pneumatic connections

DANGER!

Danger of electric shock!

Risk of serious or fatal injury in case of

contact with electrical components.

All electrical installation work must be

carried out by a suitably qualified

electrician.

9.3.1 Connection to customer's control

Gear motor

See the rating plate or the contract documentation for the

connection data (please also refer to the connection

diagram for the terminal box).

Connect the gear motor .

Provide adequate protection for the motor.

Fig. 7: Connection of the standard gear motor

Differential pressure switch (optional)

Refer to the enclosed manufacturer’s documentation for

details of the connections.

Automatic drain valve (optional)

Provide a suitable compressed air supply.

Provide a suitable 5/2-way valve for pilot control.

Refer to the contract documentation for

special types.

Dismantling height

Draining height

(400 -600 mm)

Filtrate

Inlet

Drain

400V 3~ 230V 3~

Page 9

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

Fig. 8: Electro-pneumatic connections

Required on the switch box:

Manual release for cleaning

Manual release for drain valve

9.3.2 Connection to FG controller (optional)

Connect the incoming feeder, gear motor, differential

gauge/switch (optional) and precontrol valve (optional) in

accordance with the enclosed circuit diagram.

9.4 Control variants

The cleaning process is controlled differently according to

the application. The control variants described here are

examples and are simply intended to serve as a guide.

9.4.1 Time-controlled cleaning,

manual draining

Fig. 9: Time-controlled cleaning

Parameter

Description

Recommended

value

T0

Time interval

60 s - 24 h

9.4.2 Time-controlled cleaning and draining

Fig. 10: Time-controlled cleaning/draining

Parameter

Description

Recommended

value

T0

Time interval for cleaning

60 s - 24 h

T1

Time interval for drain

valve

60 s - 24 h

T2

Opening time of drain

valve

2 - 5 s

9.4.3 Time-controlled cleaning,

counter-controlled draining

Fig. 11: Time-controlled cleaning, counter-controlled

draining

Parameter

Description

Recommended

value

T0

Time interval for cleaning

60 s - 24 h

Z0

Cleaning counter

3 - 5

T2

Opening time of drain

valve

2 - 5 s

9.4.4 Differential pressure/time-controlled cleaning

Fig. 12: Differential pressure/time-controlled cleaning

Parameter

Description

Recommended

value

T0

Max. time interval

6 - 600 s

1 2 3 1 2 13

= Pneumatic

= Electrical

5/2-way valve

Compressed air

Cleaning

Drain valve

Cleaning

T0

T1

T2

p signal

Cleaning

T0

T0

Drain valve

Cleaning

T0

T2

Z0

Page 10

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

10 Start-up

DANGER!

This FG metal-edge filter is not allowed to be put into

operation until it has been established that the

machine/system in which it is to be installed complies

with the requirements of the applicable EC directives,

harmonised standards, European standards or equivalent

national standards.

DANGER!

Explosion hazard!

Risk of injury to persons or damage to

property.

The FG metal-edge filter must be

completely vented prior to start-up for

use with all media which are capable of

forming explosive gases.

The FG metal-edge filter must be

completely filled with liquid.

Take steps to prevent air pockets.

DANGER!

Danger due to high pressure in the filter!

Risk of injury to persons or damage to property

Do not allow concentrate to spatter into the

atmosphere.

Check that all the caps have been removed from the

connections.

Remove all foreign particles from the filter.

Check the pipe unions.

Tighten the bolts.

Rinse the pipes.

10.1 Functional test

Direction of rotation of the gear motor

Unscrew the cap of the gear motor.

Start up the gear motor briefly (<1 s).

Compare the direction of rotation of the shaft with that

shown by the arrow (clockwise direction).

Reverse the terminal connections of the gear motor if

necessary.

Screw the cap of the gear motor back on again.

Fig. 13: Direction of rotation of the gear motor

To check the differential gauge/switch (optional)

Refer to the enclosed manufacturer’s documentation.

Check the function of the drain valve (optional)

Supply compressed air to the pilot valve.

Actuate the manual release for the pilot valve.

The drain valve opens.

Set the manual release to the OFF position.

The drain valve closes.

10.2 Programming the operating settings

Switch on the control.

Carefully open the feed valve.

Vent the filter.

Note the initial differential pressure (optional).

Settings for time-controlled cleaning

Set the times according to the operating conditions and

correct them if necessary.

Settings for differential pressure-controlled cleaning

with a differential gauge/switch

Refer to the manufacturer’s documentation.

Adjust the set differential pressure to the setpoint

(see contract documentation).

Initial differential pressure

The initial differential pressure varies according to the

application.

General guide:

Installation on discharge side: delta p ≤0.3 bar

Installation on suction side: delta p ≤0.03 –0.1 bar

Gear motor cap

Drive shaft

(clockwise)

Page 11

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

Fig. 14: Initial differential pressure

After cleaning, the differential pressure

(delta p) must return almost to the original

initial differential pressure.

If it does not, the cleaning function is faulty

(in this case, please consult the

manufacturer).

11 Normal operation

DANGER!

Danger due to high pressure in the filter!

Risk of injury to persons or damage to property

Do not allow concentrate to spatter into the

atmosphere.

Always dispose of concentrate in a manner

which does not pollute the environment!

Consult the responsible authorities before

deciding upon the most suitable disposal

method.

The following must be monitored daily during normal

operation:

Differential pressure,

Concentrate tank level,

Control functions.

Rinsing the drain line

CAUTION!

A high proportion of fine dirt particles in a long

pipe can lead to clogging!

Risk of injury to persons or damage to property

Rinse the drain line daily/weekly, depending on the

application.

Open the drain valve manually for approx. 10 - 15 s.

The drain line is rinsed.

12 Shutting down the metal-edge filter

12.1 Temporary shut-down

On the installed metal-edge filter controller:

Switch OFF the main switch.

12.2 Prolonged shut-down (> 48 h)

Start a cleaning process manually.

Remove the filter insert (section 14.2).

Clean the filter insert (section 14.3.1).

Reinstall the filter insert.

Fill the metal-edge filter completely with liquid.

Switch OFF the main switch.

12.3 Emergency shut-down

Switch OFF the main switch.

The power supply is interrupted.

Filter on

discharge side

Filter on

suction side

Page 12

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

13 Troubleshooting

Fault

Possible cause

Remedy

Gear motor

does not turn

Motor fuse tripped

RESET motor fuse

Check gear motor

Filtrate solidified

Clean filter

Valve does not

open

Compressed air

pressure too low

Increase pressure

Pilot valve

defective

Check pilot valve

Pilot valve not

connected

correctly

Check electrical

and pneumatic

connections

Initial

differential

pressure no

longer obtained

Solids

concentration too

high

Improve

prefiltration

process

Gear motor

rotating in wrong

direction

Check direction of

rotation

Cleaning time too

short

Prolong cleaning

time (min. gear

motor speed: 1-2

revolutions)

Increased

concentration

of dirt on clean

side

Filter element

defective

Check filter

element and if

necessary renew

Seals brittle

Check seals and if

necessary renew

Leakage rate at

shaft seal too

high

Gear motor

does not turn

Tighten shaft seal

and if necessary

renew

14 Maintenance

DANGER!

Explosion hazard!

Risk of injury to persons or damage to

property.

Work is only allowed to be carried out in

hazardous areas if appropriate safety

precautions are implemented.

Safety precautions must be implemented

by the owner.

WARNING!

If the system is maintained by unauthorised

persons

Risk of injury

All warranty claims are rendered invalid

The system must be maintained by a suitably trained

person!

Before all maintenance work:

Shut down the metal-edge filter (section 12).

Take steps to prevent the machine/system from being

switched on again by unauthorised persons.

Wear protective clothing and equipment appropriate to

the hazard potential of the medium (e.g. goggles,

respirator, protective clothing, etc.).

Carry out the maintenance work.

Start up the metal-edge filter again (section 10).

Page 13

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

14.1 Inspection and maintenance schedule

Refer also to the contract documentation.

Interval

Component

Activity

Weekly

Metal-edge filter

Check for leakage

Check the differential

pressure

Pipes

Clean

Monthly

Coiled cartridge

Check for wear and if

necessary clean

Metal-edge filter

Check the

conductivity between

all components.

Note the maximum

permissible

resistance: R < 10 .

Yearly or

when

cooling

lubricant

replaced

Bearings

Check the clearance

Valves

Check correct

functioning

Metal-edge filter

Clean

Seal kit

Check for leakage

The necessary maintenance work is

dependent on the particular application.

Please consult the manufacturer if

necessary.

14.2 Removing the filter insert

DANGER!

The metal-edge filter is pressurised!

Risk of injury to persons or damage to property!

Make sure that the pipe is depressurised prior to

opening the metal-edge filter.

1

Close the filter inlet and drain.

Relieve the pressure in the pipe if necessary.

2

Open the vent valve.

Open the drain valve.

The filter is drained.

3

Close the compressed air supply.

4

Disconnect the gear motor.

Fig. 15: Disconnecting the filter

5

At the gear drive flange: loosen screws.

Take of gear drive from the stand.

6

Loosen screws at the filter cover.

Put in ring bolts.

7

Lift off filter insert vertically to the top.

Do not chock!

Fig. 16: Detaching the gear motor and levering off the cover

3

1 1

2

4

2

5

6

7

Page 14

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

8

Lay the filter insert down carefully on a level surface,

taking care not to damage the filter element.

Replace the cylindric bolt at the traverse by a ring bolt.

9

Place filter insert on motor stand.

10

Protect filter insert against falling.

Fig. 17: Turn and protect filter insert

To install

In reverse order.

Lower the filter insert into position without tilting it.

14.3 Cleaning the filter

Remove the filter insert (section 14.2).

14.3.1 Cleaning the filter insert

WARNING!

Danger of aerosol formation!

All work must be carried out in a room with a suitable

extraction system!

Wear protective clothing and equipment appropriate to

the hazard potential of the medium (e.g. goggles,

respirator, protective clothing, etc.).

Remove any coarse impurities by mechanical means.

Wash the filter insert in a suitable cleaning solution.

Carefully blow out the filter insert with a steam jet or

compressed air.

Clean (or if necessary renew) and oil the seals.

14.3.2 Cleaning the filter housing

Wear protective clothing and equipment appropriate to

the hazard potential of the medium (e.g. goggles,

respirator, protective clothing, etc.).

Remove any coarse impurities by mechanical means.

Wash the filter housing in a suitable cleaning solution.

14.4 Replacing the filter element

WARNING!

If the system is maintained by unauthorised

persons

Risk of injury

All warranty claims are rendered invalid

The system must be maintained by a suitably trained

person!

14.4.1 To remove the filter element

CAUTION!

Danger of injury to hands!

Scrapers are pre-tensioned by means of springs.

Never attempt to reach between the scraper and the

coil!

Dismount and clean filter insert (s.a.).

1

Lift off the scraper carefully.

Fix scraper with the screw.

2

Loosen screws of the cartridge cover.

Pull cartridge cover with end disc out of the cartridge

body.

3

Loosen safety nut.

4

Pull filter cartridge carefully out of the brackets.

Filter insert rotated 180°

Fig. 18: Removing the filter cartridge

14.4.2 To install the filter element

Oil the O-rings.

Check and clean the approach disk, and if necessary

renew.

Install in reverse order.

In case of multi-cartridge filters:

Put in properly the intermediate ring.

Fix safety nut with the required torque (see schedule).

Typ AF

72

73

74

75

76

Drehmoment [Nm]

20

20

20

20

25

8

10

9

2 1

3 4

Page 15

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

14.5 Replacing the scraper

Remove and clean the filter insert (chapter 14.4).

Lift off the scraper carefully.

Fix scraper with the screw (s.a.).

Unscrew the hexagon nuts on the scraper.

Replace the scraper.

Fig. 19: Replacing the scraper

Important when installing the scraper:

The leg springs must rest in the slots provided.

The scraper must rest cleanly against the filter element.

The scraper must not be tilted.

Check all screws and bolts, and tighten them if

necessary.

Tighten the cover bolts in accordance with

EN 286/ 6.4.5/ 6.

14.6 Replacing the stuffing box

DANGER!

Danger of electric shock!

Risk of serious or fatal injury in case of

contact with electrical components.

All electrical installation work must be

carried out by a suitably qualified

electrician.

1

De-energize the gear motor and disconnect it.

Unscrew the hexagon bolts on the motor stator.

Carefully lift the gear motor up and remove it from the

shaft.

2

Loosen and lift off motor stand.

3

Unscrew setscrew and lift off gear.

Fig. 20: Removing the gear motor

5

Loosen hexagon bolts.

6

Remove cover and cylinder.

7

Remove the Belleville springs and the gland.

8

The packing rings are now freely accessible and can be

replaced.

Hexagon

nuts

Scraper

1

2

3

Page 16

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

Fig. 21: Stuffing box accessible

To install the stuffing box

Fit the stuffing box elements one at a time with an offset

of 180°.

Fit the Belleville springs, the sleeve and the cover.

Tighten the hexagon bolts.

The stuffing box requires very little maintenance. Slight

leaking is perfectly normal and serves to lubricate the unit.

14.7 Replacing the bearing bush

The bearing bush must always be

replaced by a TRAINED MECHANICAL

FITTER.

Keep spare part drawing of the metal-

edge filter available.

(It. = Item numbers of the spare part

drawing)

14.7.1 Instructions for type AF 73

Dismount gland (see section 14.6).

Dismount and clean filter insert (see section 14.2).

Loosen hexagon nut (It.32) and pull off the complete

cartridge brackets.

Loosen cylinder bolts (It.41) and pull off flanged ring

(It.43).

Pull off bearing bush (It.40).

Remove bearing bush.

Press new bearing bush with pin uniformely into the seat.

Reinstallation in reverse order.

14.7.2 Instructions for type AF 74 - 76

Dismount and clean filter insert (chapter 14.2).

Loosen hexagon nut (It.58) and pull off the complete

cartridge brackets.

Remove bearing bush (It.56) and gearwheel (It.27).

Loosen hexagon bolt (It.15) and pull off bearing flange

(It.14).

Remove bearing bush (It.9).

Press new bearing bush with pin uniformely into the seat.

Mount bearing flange (It.14) and gearwheel (It.27).

Press new bearing bush (It.56) with pin uniformely into

the seat.

Mount cartridge brackets, take care of correct teeth

position.

Further reinstallation in reverse order.

14.8 Replacing the approach disk

The bearing bush must always be

replaced by a TRAINED MECHANICAL

FITTER.

Keep spare part drawing of the metal-

edge filter available.

(It. = Item numbers of the spare part

drawing)

14.8.1 Instructions for type AF 73

Dismount and clean filter insert (chapter 14.2).

Remove all filter cartridges (chapter 14.4).

Loosen cylinder bolts (It.10) and remove centering ring

(It.9).

Remove lower approach disk (It.8) and clean tight seat.

Loosen hexagon nut (It.32) and pull off sealing plate

(It.6).

Remove upper approach disk (It.8) and clean tight seat.

Reinstallation with new approach disks in reverse order.

14.8.2 Instructions for type AF 74 - 76

Dismount and clean filter insert (chapter 14.2).

Remove all filter cartridges (chapter 14.4).

Loosen cylinder bolts (It.55) and remove centering ring

(It.26).

Remove lower approach disk (It.24) and clean tight seat.

Lift segment (It.21).

Remove upper approach disk (It.24) and clean tight seat.

Reinstallation with new approach disks in reverse order.

5

6

7

8

Page 17

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

15 Spare parts

TYPE AF 73

Pcs.

Designation

Mat.-No.

Benennung

1

Set of gaskets VP FPM

Set of gaskets VP VMQ/FEP

77982143

77982150

Dichtungssatz VP FPM

Dichtungssatz VP VMQ/FEP

1

Set of bearing VP

78358947

Buchsensatz VP

1

scraper

71116805

Abstreifer

2

spring

79778846

Schenkelfeder

filter element → see name-plate

Filterelement →siehe Typenschild

TYPE AF 74

Pcs.

Designation

Mat.-No.

Benennung

1

Set of gaskets VP FPM

Set of gaskets VP VMQ

78319600

76191738

Dichtungssatz VP FPM

Dichtungssatz VP VMQ

1

Set of bearing VP

78318347

Buchsensatz VP

1

scraper

71116805

Abstreifer

2

spring

79778846

Schenkelfeder

filter element → see name-plate

Filterelement →siehe Typenschild

TYPE AF 75

Pcs.

Designation

Mat.-No.

Benennung

1

Set of gaskets VP FPM

Set of gaskets VP VMQ

79778135

79718206

Dichtungssatz VP FPM

Dichtungssatz VP VMQ

1

Set of bearing VP

78318354

Buchsensatz VP

1

scraper

71116805

Abstreifer

2

spring

79778846

Schenkelfeder

filter element → see name-plate

Filterelement →siehe Typenschild

TYPE AF 76

Pcs.

Designation

Mat.-No.

Benennung

1

Set of gaskets VP FPM

Set of gaskets VP VMQ

76198816

77982606

Dichtungssatz VP FPM

Dichtungssatz VP VMQ

1

Set of bearing VP

78321580

Buchsensatz VP

1

scraper

71116805

Abstreifer

2

spring

79778846

Schenkelfeder

filter element → see name-plate

Filterelement →siehe Typenschild

TYPE AF 93 - 96 S

Pcs.

Designation

Mat.-No.

Benennung

1

scraper

71116805

Abstreifer

2

spring

79778846

Schenkelfeder

filter element → see name-plate

Filterelement →siehe Typenschild

Please request a separate spare parts drawing and list of spare parts for special versions.

Page 18

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

16 Declaration of incorporation

As defined by the EC Machinery Directive

The filter is only allowed to be started if the complete machine is also started up!

Page 19

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

Page 20

Translation of the original instructions with assembly instructions AF 73 - 76 S/AF 93 - 96 S, Filtration Group GmbH, 11.07.19,

Mat. No. 79301615, Version 13

This manual suits for next models

1

Table of contents