Page 3

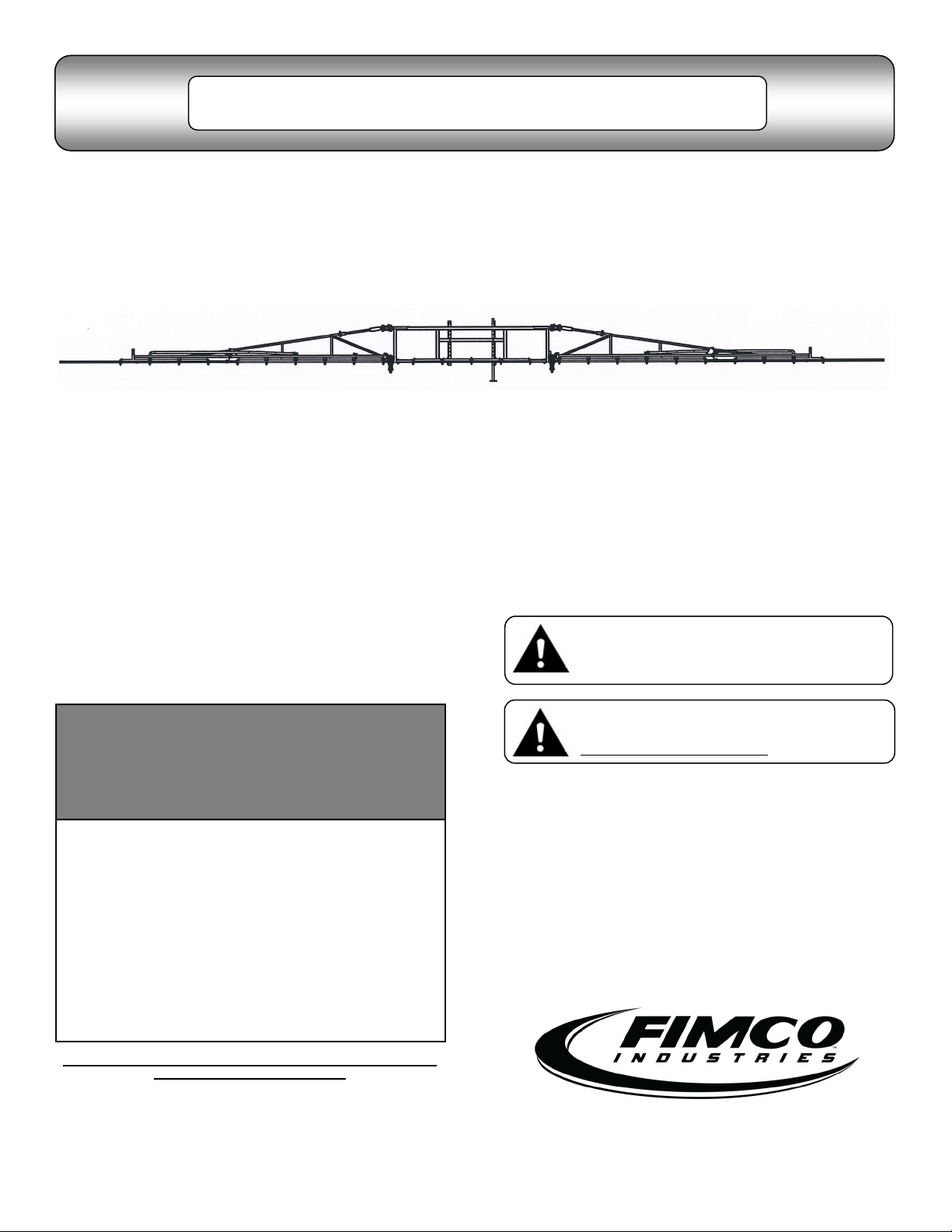

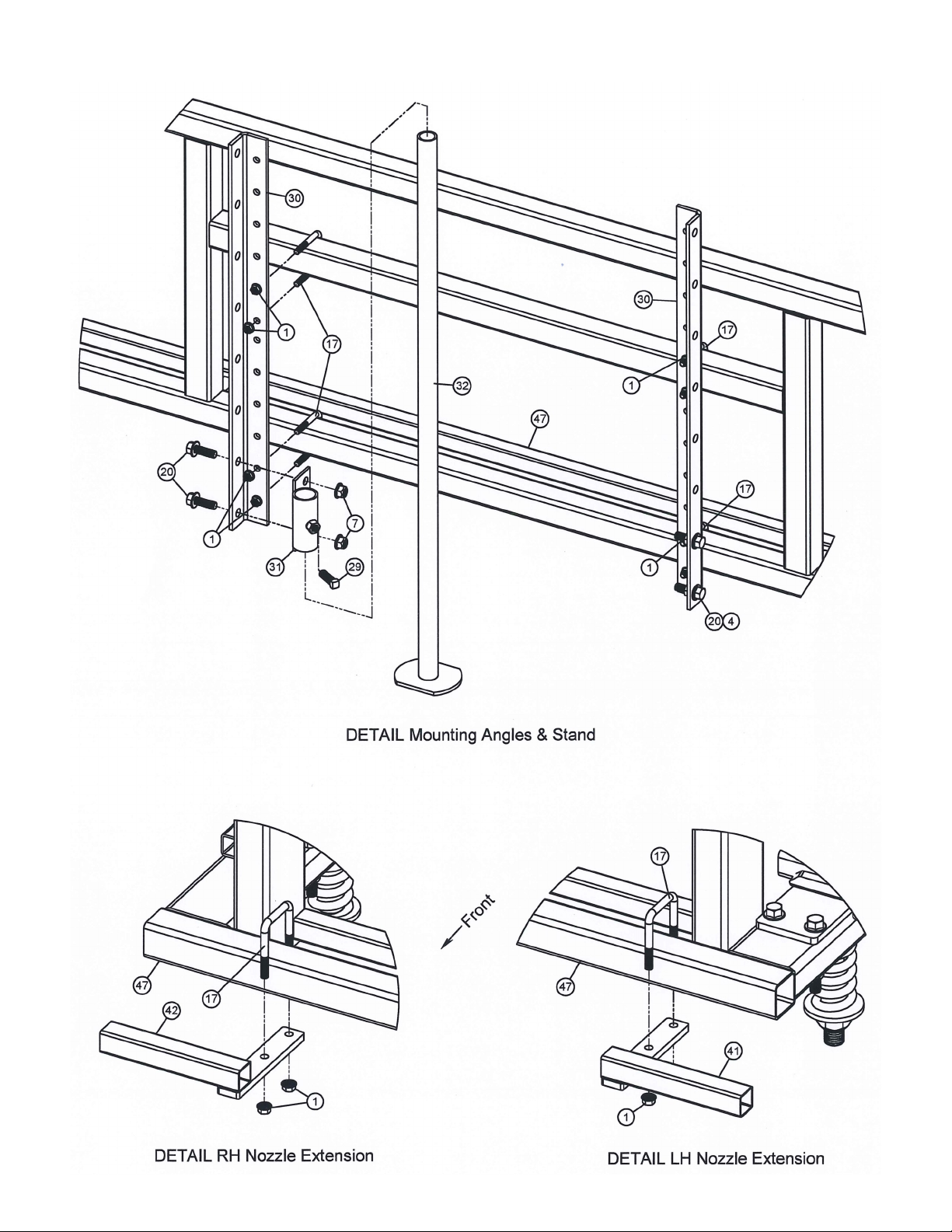

Assembly

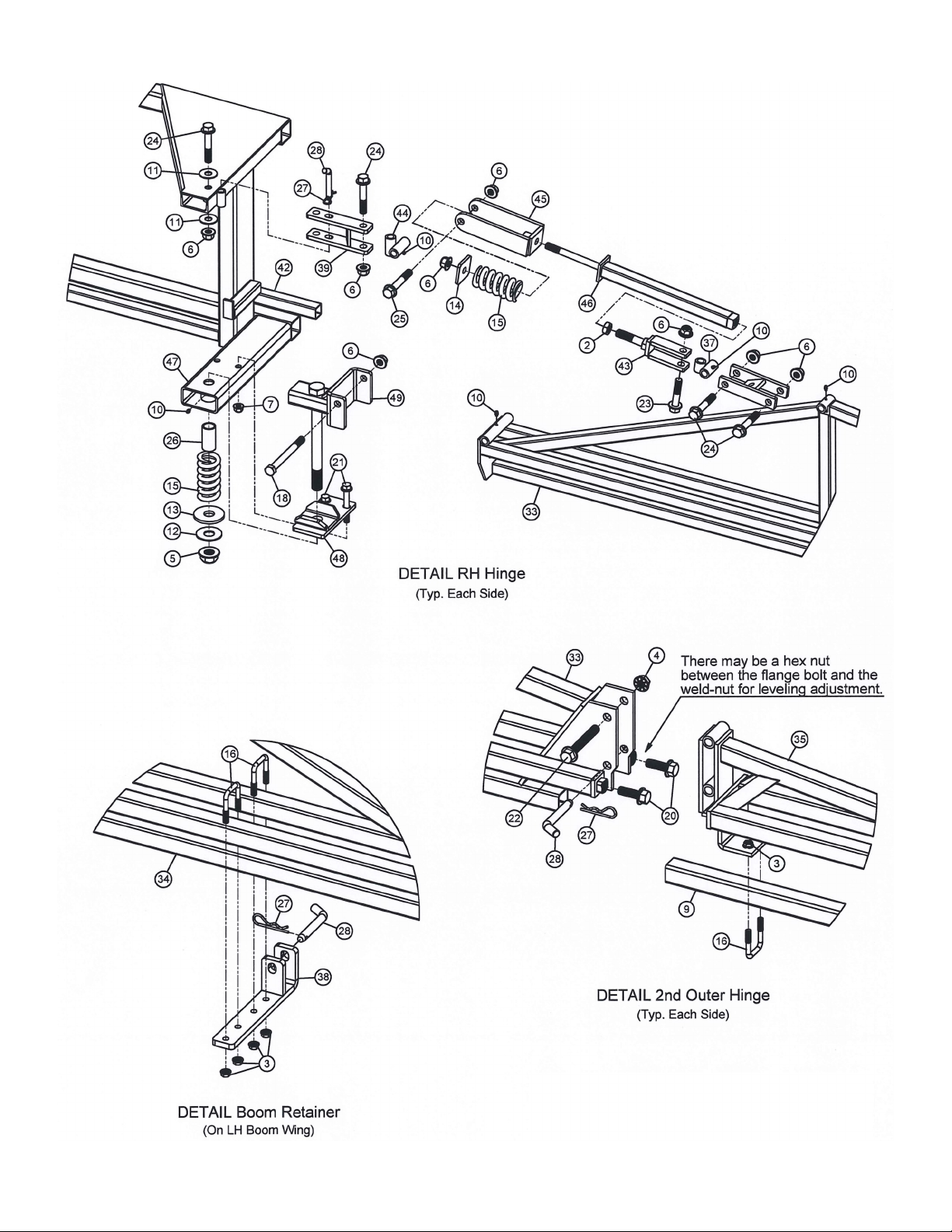

Refer to the exploded views and parts list to idenfy the parts.

1. Mount the center secon (back rack) of the boom to the carrier or to the spring suspension boom aachment if one is being

used. Use (4) bolts and hex nuts which are aached to the upright angles. It may be necessary to loosen the bolts which hold

the upright angles to the frame in order to adjust the upright angles to match aaching members of the carrier.

2. Aach the outer boom secons to the center frame assembly. The lower tube members of the outer booms will be oset to

the front to allow room for the hoses and nozzles, in the back. Join the outer boom secons to the center frame using (2) hex

bolts and hex ange lock nuts at the boom and use (2) hex ange bolts and hex ange lock nuts at the top of each outer sec-

on.

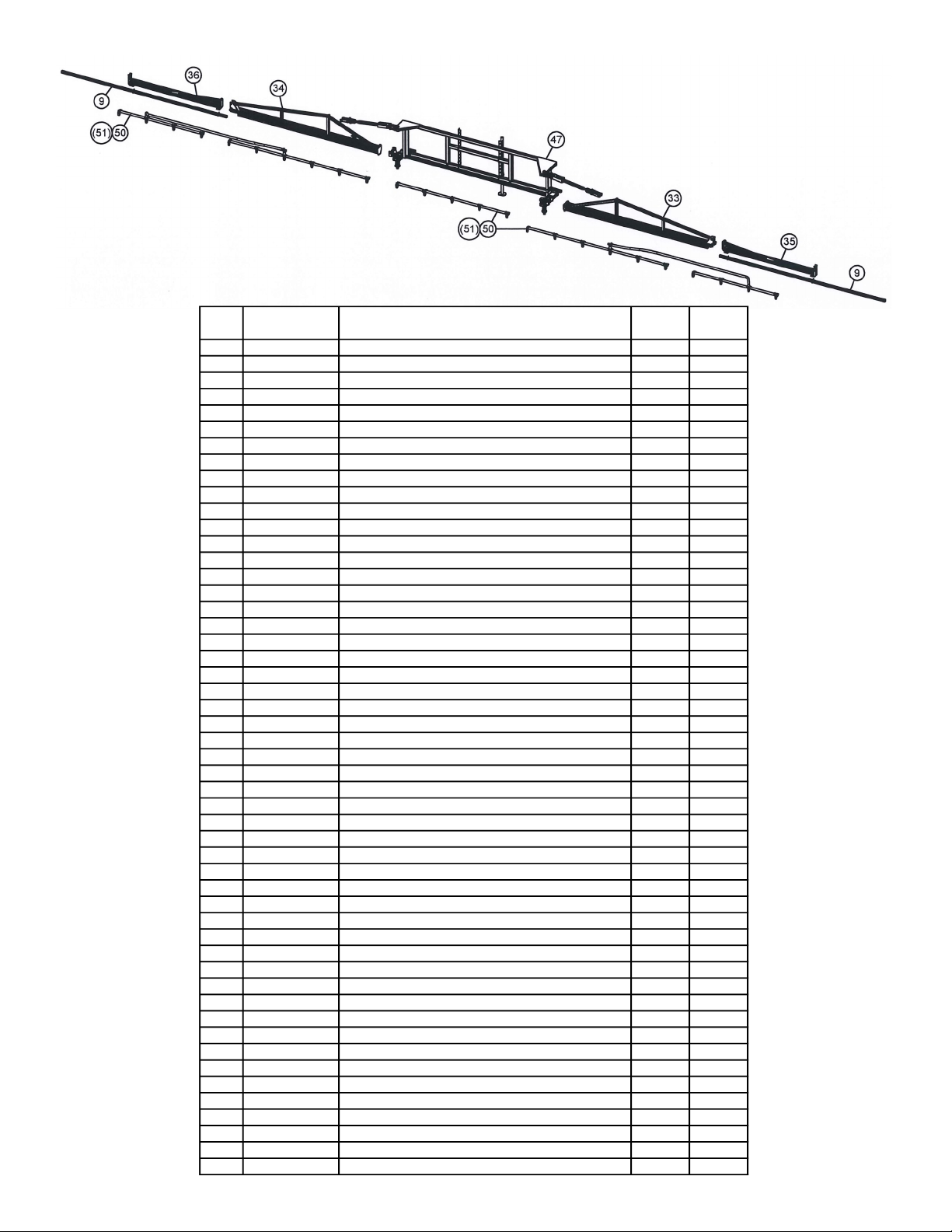

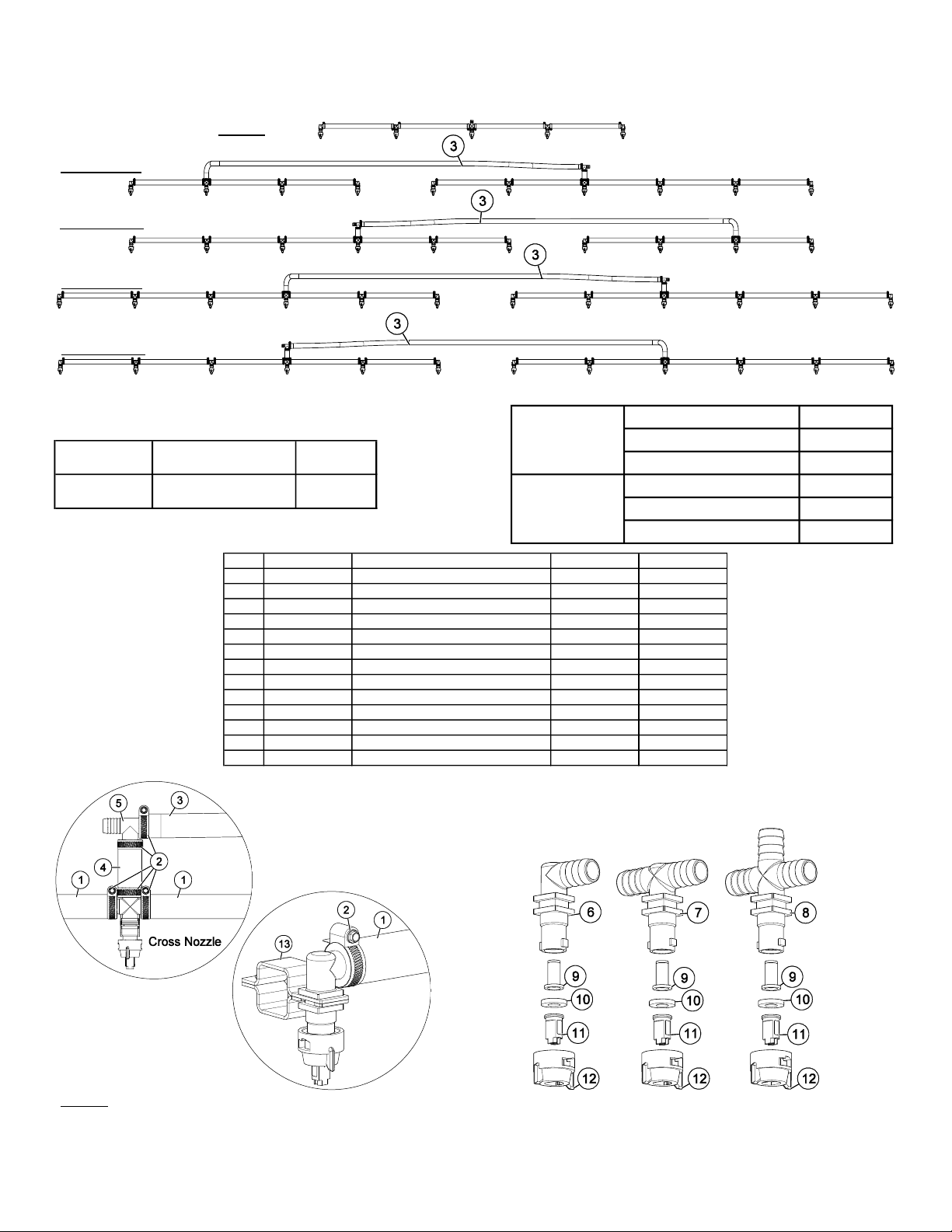

3. Aach the appropriate hose assemblies onto each of the three boom secons, the center secon has (5) nozzles with “ELL”

connectors on each end. Starng at the center, the nozzles should be placed about 20” apart. The outer boom harnesses are

made up for le and right sides when nozzles are on the back side of the outer boom tubing. Assemble the caps, ps and

strainers to each of the nozzle connectors, if not done so already.

4. Connect the feeder hoses (supply lines) from the pumping system and secure in place with hose clamps to each nozzle harness

assembly. Use nylon cable es to secure the feeder hoses to the boom so that the hoses will not snag on any object.

5. Make sure all hose clamps are ght before tesng or spraying for the rst me.

Aer assembling, sprayer will be ready to TEST w/plain water before actual use.

Fold Up Instrucons

Use cauon when folding up the booms. Do not force the pivot acon. Remember that the enre sprayer may move unless it is

anchored securely during the folding operaon.

Always begin with the le side outer boom. Remove the hairpin coer and the retainer lock pins. Fold the outer secon up and

over. Use the retainer pin and hairpin coer to secure the outer secon in place.

Remove the retainer lock pins which are located at the top ends of the center secon. These pins may be retained in the housing

aer the boom(s) have been folded back. This procedure will allow the booms to be folded without raising the ends.

Pivot the enre outer boom assembly to the rear of the sprayer and against the center frame. Use care when folding. The le outer

secon will rest on the boom carrier rack tube located on the right rear side of the center frame.

Use the same procedure to fold up the right outer boom assembly. This outer secon will rest on the boom retainer, located on the

le wing boom. Use the retainer lock pin to secure the right wing boom in place.

If it is necessary to ghten the spring tension, pivot the outer boom 90° before ghtening the tension. Do not ghten the tension

any more than can be done in this posion, otherwise the boom will not pivot out of the receiver.

Tesng the Sprayer

NOTE: It is VERY important to test your sprayer with plain water before actual spraying is aempted. This will enable you to

familiarize yourself with the sprayer and boom and to check for leaks, without the possibility of losing any expensive chemicals.

Follow the instrucons in your sprayer manual for tesng your sprayer.

Always have the pressure line open to the ps so that the air which may be trapped in the line will be forced (or purged) out. Start

the tractor PTO. Check the enre system for leaks. Once the pump is primed, the pressure may be increased by turning the handle

of the pressure relief valve. Keep the pressure line open to the ps when seng the pressure. Set the pressure and then lock the

relief valve handle in place. Pressure will increase when the pressure line valve is closed and then return to the preset pressure

when the valve is opened again.

The bypass valve is the “pressure control” for the enre plumbing system. The more the valve is open, the lower your line pres-

sure. Almost fully closed provides maximum pressure to your boom and/or handgun. NEVER run your system with this valve 100%

closed.

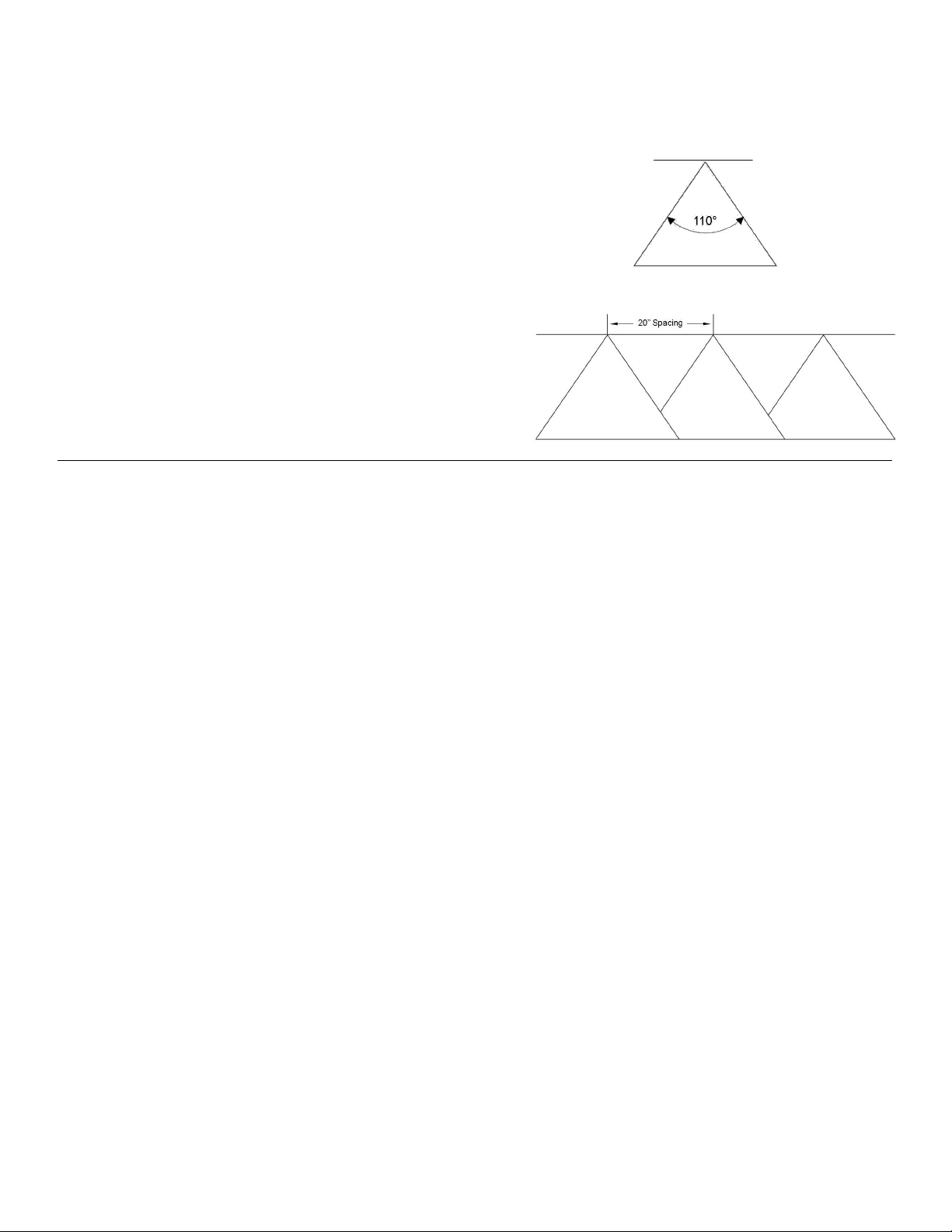

During the tesng period, be sure to observe the spray paern given by the spray nozzles. If there is any paern distoron, it will

be necessary to remove and clean the aected ps.

Cauon: Never use a metal object or other sharp item for cleaning a nozzle p. It is beer to use a nozzle brush (NOT wire brush)

or compressed air for p cleaning.

Condions of weather and terrain must be considered when seng the sprayer. Do not spray on windy days. Protecve clothing

must be worn in some cases

Be sure to read the chemical label(s) before applicaon!