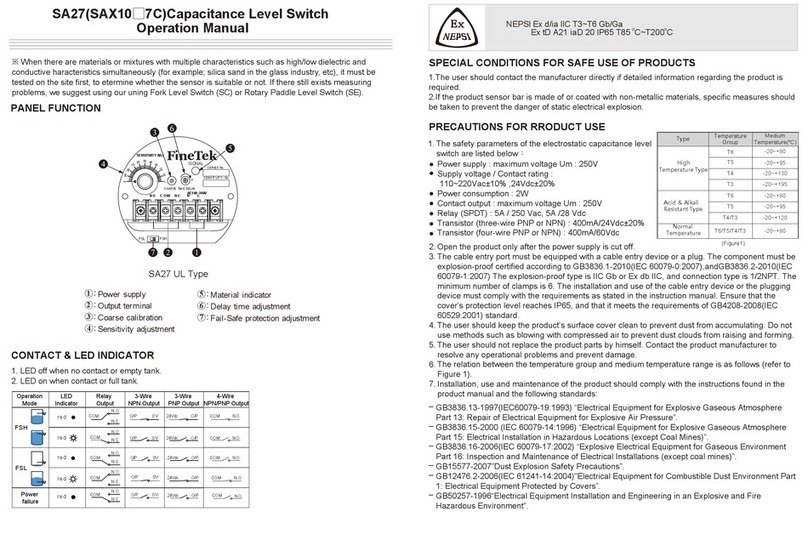

Material

OD8SUS SPST 50W300Vac/350Vdc

OD9.5 SUS SPST 50W300Vac/350Vdc

SPDT 20W150Vac/200Vdc

OD12.7 SUS SPST 50W220Vac/500Vdc

SPDT 50W400Vac/1000Vdc

0.5A

0.5A

1A

3A

1A

2.5A

2.5A

2A

4A

2A

Tube Type Switching

Contact from

Switching

Capacity Max.

Switching

Voltage Max.

Switching

Current Max.

Carry

Current Max.

FD7 Series Explosion Type Magnetic Float

Level Switch Operation Manual

PRINCIPLE

INDUCTIVE / CAPACITIVE LOADS

1) Open the cap of housing, connect the wire onto terminal through the conduit.

2) Check the terminal wire connection is correct for each float.

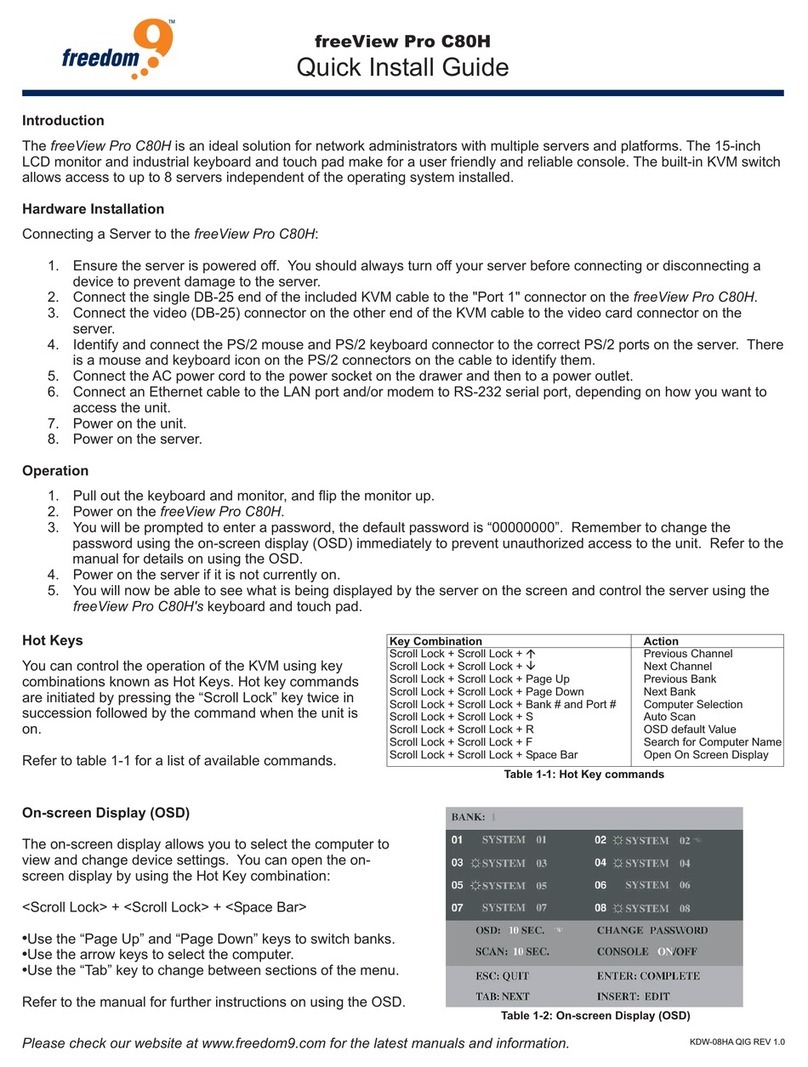

3) Connection Type : Please refer to Fig.1 below.

A) 1NO : Meaning that the NO-C circuit will be close while liquid level higher than the float

ball by mark of " ON".

B) 1NC : Meaning that the B-C circuit will be close while liquid level lower than the float ball

by mark of " ON".

C) 1C : Meaning that the NO-C circuit will be close while liquid level higher than

the float ball and NC-C circuit will be close while liquid level lower than

the float ball.

4) Please screw up the housing cap and fix the conduit outlet to prevent the moisture to

soak in.

CONNECTION INFORMATION

SPECIFICATION

WIRING

1NO 1C1NC 1NO 1C1NC 1NO 1C1NC

2NO 2C2NC 2NO 2C2NC 2NO 2C2NC

3NO 3C3NC

4NO 4C4NC

5NO 5C5NC

3NO 3C3NC 3NO 3C3NC

4NO 4C4NC 4NO 4C4NC

5NO 5C5NC 5NO 5C5NC

1

3

2

4

5

SPECIFICATION

(Fig.1)

1.Inductive : When using a reed switch with inductive loads such as motors,

relays,solenoids..etc, the contact will be subjected to a high induced voltage

during opening of the contact(load circuit). Such high induced

voltage(transients) may cause damages to the reed switch or significantly

reduce it life. Therefore,protective circuits such as : RC(snubber), varistors or

clamping diodes are recommended.

2.Capacitive : When using a reed switch with capacitive loads such as

capacitors,incandescent lamps or long cables, the contact will be subjected

to a high surge(inrush) current. Therefore, protective circuits such as:

surgesuppressors or current limiting resistors are recommended.

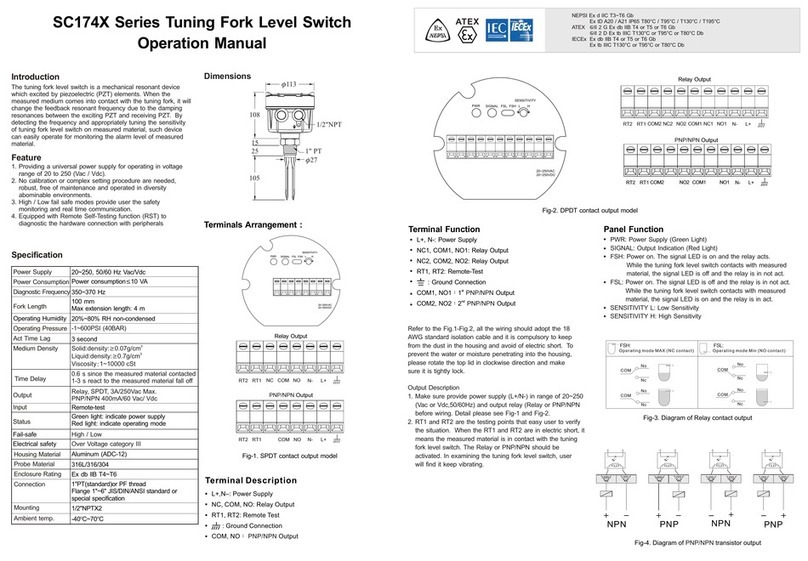

NEPSI Ex d IIC T3~T6 Gb

ATEX II 2 G Ex d IIB T3 or T4 or T5 or T6 Gb

II 2 D Ex tb IIIC T200BC or T135BC or T100BC or T85BC Db

IECEx Ex db IIB T3 or T4 or T5 or T6 Gb

Ex tb IIIC T200BC or T135BC or T100BC or T85BC Db

The single unit or multiple reed switch units are housed tightly in stainless steel stem and

tount the float ball to penetrate through the stem, then the liquid buoyancy will deliver the float

up and down at the specified position by graduating rings. When the reed switch is induction

the float internal magnet, then it will actuate the reed switch contact point to create an open or

close circuit. We can apply such on-off output signal to reach liquid level controlling and

monitoring purpose. The permanent magnet is interlined into the middle of the specified float

balls. You Can mhe figures below show the float orientations on N.O. (Normal Open) and N.C.

(Normal Close).

2 2

SUS floats is 35kg/cm (S10 floats can reach 50kg/cm )

2

1.Pressure Rating : Max. pressure of plastic floats is 5kg/cm and max. pressure of

2.Lead Wire : XLPE (UL3266, AWG22)

APPLICABLE MODEL:FD7 Series

ATEX