08-SA140-B6-EM,03/08/2023

Tel: 886-2-22696789 Fax: 886-2-22686682

No.16, Tzuchiang St., Tucheng Industrial Park, New Taipei City 23678, Taiwan.

FineTek Co. , Ltd.

Possibility Cause Inspection / Evidence Trouble Shooting

Water get into

housing

Unstable switch

signal.

Enclosure is not firmly

locked

Sensitivity Adjustment knob

is activated by mistake

Position of Sensitivity

Adjustment knob is abnormal Re-adjust sensitivity

False wiring of

power & signal cable

Re-wiring according

to wiring guide

False wiring of

power & signal cable

Dry powder or high

speed friction

Replace with

anti-static model

Dielectric constant of

medium is too small

Rough and fine adjustment

remain non-active

Please contact your

distributor or FineTek directly

Humidity inside tank

is over limit

Wiring terminals are loose

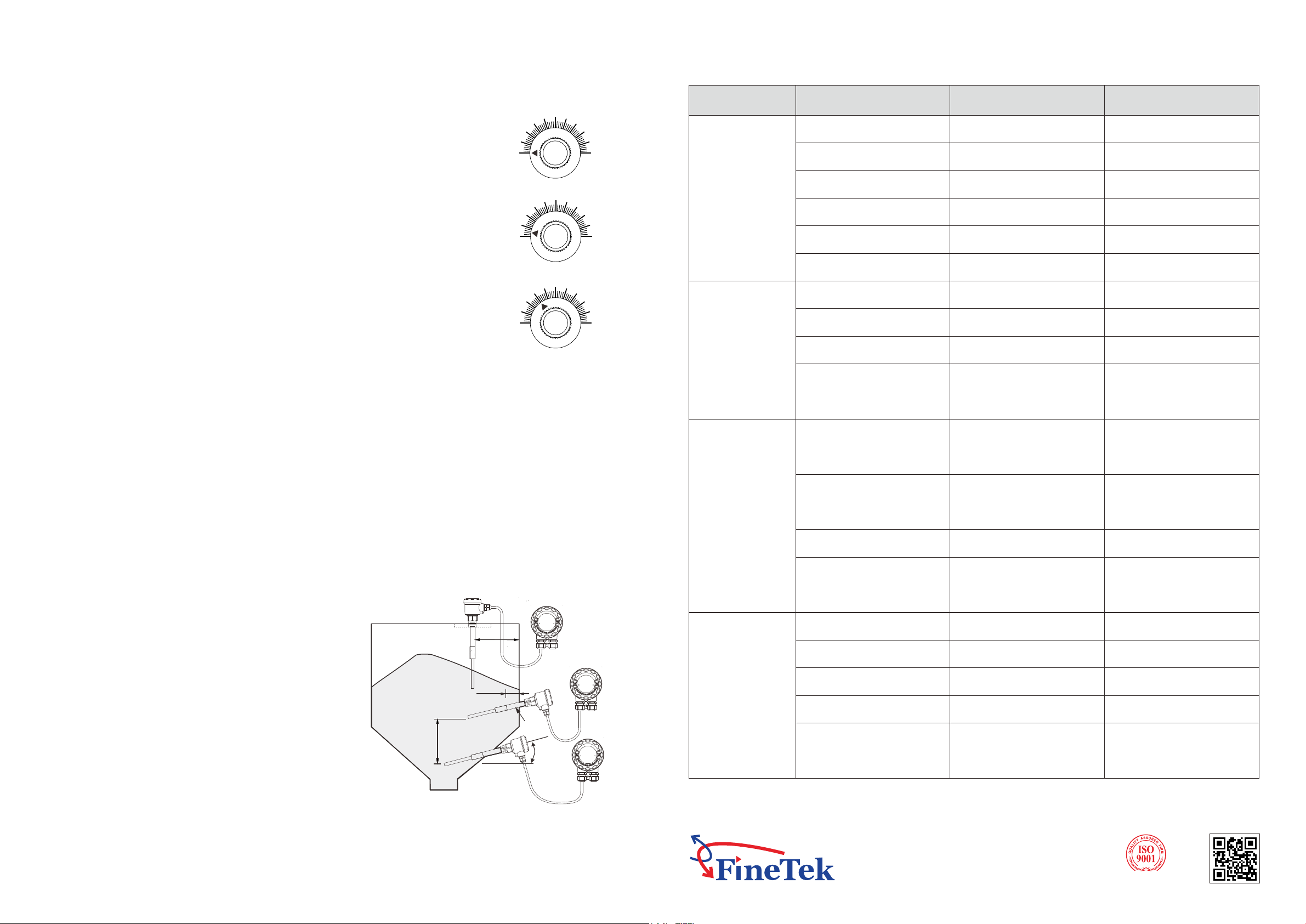

3. Side mounting angle: roughly 20 degrees.

1. Top mounted: Minimum distance should be 300mm

between the probe and wall.

2. The insulated probe should protrude at least 30mm

from the tank wall.

4. The conduit and wiring should face downward.

INSTALLATION (SEE THE SKETCH BELOW)

300mm

30mm

No induction body

20°

300mm

MAINTENANCE & TROUBLE SHOOTING

Circumstance

Level up & down

but switch / relay

no response

Level up & down

but switch on/off

continuously

non-stop or relay

can't be reset

Seal ring aged & failed

Cable entry is not

firmly locked

Cable entry does

not face down

Cable wire does not

connected downward

Diameter of cable wire

does not fit

Enclosure is loose

Seal ring aged

Cable entry is not

firmly locked

Cable entry faces up

Cable wire is connected

upward

Cable wire is loose

Lock the enclosure firmly

Replace seal ring

Lock the cable entry firmly

Turn the cable

entry & face down

Connect the cable

downward

Replace cable with

diameter 8mm~ 10mmf f

Circuit damaged by EMI

Probe contacts

with tank wall

Circuit damaged by EMI

Dielectric constant

is over limit

Probe contacts

with tank wall

Probe with water or dew

Dry powder or high

speed friction

Rough and fine adjustment

remain active

Replace probe with coating

Re-install and avoid

grounding

Replace with

anti-static model

Please contact your

distributor or FineTek directly

Process connection

is not firmly locked

Short-circuit due to aging

Abnormal of supply voltage

Loose structure due

to vibration

Loose screw bolt

Loose thread

Idle loop, resistance

abnormal

Supply voltage over limit

Obvious vibration

environment Replace with remote model

Restore power supply

Revise external layout

Lock thread or flange firmly

Lock screw bolt firmly

CALIBRATION (ROTARY KNOB)

H

90

80

70

30

60

50

40

20

10

L

H

90

80

70

30

60

50

40

20

10

L

H

90

80

70

30

60

50

40

20

10

L

Fig 2

Fig 3

Fig 4

(3) To increase the delay time, use a screwdriver to turn the "delay" trimmer clockwise. To decrease the delay time,

turn the "delay" trimmer counterclockwise.

(1) When delay time is "0" second, the LED and the relay signals will be activated simultaneously. The user can set

the delay according to his or her requirements.

(2) After delay set-up, the circuit functions as following: when LED of switch is on after time set-up, relay functions or

NPN signal outputs.

DELAY ADJUSTMENT

4. Turn the knob clockwise from H position to 90% position about 1/2 circle (95% position)

until LED indicator shut off (Figure 3). Then, Initial calibration is complete. After that,

please continue to next step "SENSITIVITY ADJUSTMENT".

1. After installation with power supply, make sure no material within 300 mm around the

probe.

3. Record the turning angle from "Indicator" sign lights up status to turn off status, then reset

"SENSITIVITY ADJ" by turning the knob counterclockwise back for half of the recorded

turning angle.

2. Turn the "SENSITIVITY" to the "H" position (Figure 2).

SENSITIVITY ADJUSTMENT

INITIAL CALIBRATION

1. Make sure the "Indicator" sign does not light up, when the medium does not contact with

the probe, and vice versa, when the medium contacts or covers the probe, then the

"Indicator" sign lights up.

3. Using flat-head screwdriver to turn "Coarse" clockwisely for adjustment until LED indicator

is on.

2. Gradually, adjust the capacitance value (turn the knob clockwise to the "L" direction) until

"Indicator" light turns off.

4. Based on the previous experience, 70% (Figure 4) adjustment position can be used to

most of mediums (Need to do INITIAL CALIBRATION first).